Today it is difficult to imagine a construction site without special equipment that quickly and accurately moves a wide variety of construction loads in the vertical and horizontal direction over short distances. Anyone who has ever been to a construction site has probably noticed that something is constantly rising there, only to perhaps fall in another place within a minute. Without the use of crane manipulators and hook loaders, it is impossible today to maintain the achieved level of construction productivity. This is fully confirmed by the recently held STT-2015 exhibition.

Almost all participants demonstrating wheeled cargo vehicles presented options for equipping trucks with CMUs or hook loaders of various lifting capacities. Today, the choice of these lifting devices on the Russian market is very wide, and the buyer has the opportunity to choose the best option for himself, corresponding to the operating conditions and price level.

PALFINGER INMAN in the spotlight

The stand of the Austrian concern PALFINGER, located in the center of one of the exhibition halls, was constantly full of visitors, and they had something to pay attention to. A poster board with the slogan “Together we are stronger” was installed next to the presented equipment. By this, the company wanted to say that the presented products are the fruit of the labor of all enterprises included in PALFINGER CIS.

It should be noted that at the present stage, when imported products have become significantly more expensive due to changes in exchange rates, the PALFINGER concern, having organized local production in Russia, can offer its products at more favorable prices than its closest competitors.

The first new product brought from Velikiye Luki is a hook loader with a telescopic mechanism with a lifting capacity of 20 tons on a KamAZ-6520 chassis. The loader was assembled on and received the name PALFINGER PHT20Pi. The novelty of the product lies in the fact that the hook loader of a very well-known brand is manufactured entirely in domestic production, according to PALFINGER drawings and technologies. The manufactured “multilift” systems of the MPR series have a slightly different design. But now “Lifting Machines” plans to create a series of PALFINGER hook lifts, so, apparently, next year we will see new models in this direction.

INMAN's products are mainly aimed at the Russian market, although they are quite successfully sold in neighboring countries. It must be said that before cooperation with PALFINGER, the production of crane manipulators was focused mainly on the oil and gas industry, and in a certain sense, INMAN is a monopolist in its field. Therefore, the previous model range will apparently continue to be produced in the future. As if to prove this, the INMAN IM-100 manipulator was presented at the stand. But as a result of cooperation with PALFINGER, models of manipulators that are in demand in the retail market are not being created.

The Austrian concern is characterized by a careful selection of partners in countries recognized by the company's management as promising for PALFINGER's business. After acquiring production facilities, as the experience of other countries shows, PALFINGER brings production at these enterprises to European levels. Therefore, the acquisition of PALFINGER by the concern should only have a positive impact on the development of these enterprises.

The second new product at the stand was the PALFINGER INMAN IM-150N CMU, produced at . The manipulator, in fact, is the “equivalent” of the PALFINGER PK 15500A Performance model, popular in Europe. At the same time, the production of parts and assemblies on the IM-150N is carried out partially at facilities.

Visitors were also shown a model of the PALFINGER INMAN IT-150 cable-mounted crane, which can be operated at air temperatures from +40 to –40 °C. With a total weight of 2.9 tons, the maximum lifting capacity of the cable crane is 6.6 tons, and with a maximum reach of 19 meters - 0.3 tons, while providing a load moment of up to 15 tm. A rotation angle of 420° and a maximum lowering depth of up to 18.3 m allow the CMU IT 150 to deliver cargo to the most inaccessible places. The CMU is controlled from a seat on a column. The 5.63 m legs supplied with the crane have a hydraulic extension and manual rotation. The PALFINGER INMAN IT 150 cable-mounted crane is an effective tool for operating companies to achieve their tasks, without unnecessary downtime and costly maintenance.

Modern products and “Lifting machines” look European not only because of design requirements. To reduce costs, PALFINGER unifies its models as much as possible, so not only body parts, but also the internal “filling” of models produced in Russia must be interchangeable with PALFINGER models produced in other countries.

PALFINGER continues to import original PK crane models to Russia. Sales fell slightly due to currency fluctuations, however, in the segment with a capacity of over 30 tons, the company’s competitors are also importers who suffered from rising prices.

Today, the situation on the CMU market gives Russian enterprises a chance to increase their market share, and local production organized by PALFINGER in Russia allows the concern to feel comfortable. On July 23, 2020, the grand opening of the new INMAN plant will take place, on 10,000 m2 of which the latest turning and milling equipment will be used, as well as modern control and logistics systems.

"Kominvest-AKMT": the prospect of using CMU is growing

Following its own principle of integrated supplies, the company offers various options for mounting chassis with CMU. At its stand this year, Kominvest-AKMT presented one of the latest developments of its engineers - the Atlas 105.2A3 loader crane with a rotation angle of 410°, mounted on a Hyundai HD120 chassis. The installation parameters are selected in accordance with the current demand for the use of CMUs of this class. The load moment is 10.6 tm with a boom reach of up to 9.0 m. The hydraulic pump creates a pressure in the system of up to 270 bar. At a minimum outreach of 1.98 m, essentially “under a crane,” the installation is capable of moving and lifting loads weighing up to 4.92 tons. At a maximum outreach of 8.91 m, the lifting capacity at the end of the boom is 1.11 tons The outrigger extension width is 4.8 m, the outrigger cylinder stroke is 0.68 m for an installation height of up to 1.35 m.

Structurally, the installation is made very competently - the column bearing and rotation mechanism are centrally lubricated, eliminating the human factor. The linkage system increases the efficiency of the CMU. The secondary boom is attached to the side of the main boom. A model with a CMU installed behind the cab was presented at the stand, but Kominvest also offers the option of installing the manipulator on the rear overhang in a folded position across the direction of movement of the machine.

The unique safety system Atlas Crane Management (ACM) combines many useful functions that allow us to talk about a high degree of safe performance of work. ACM includes a m/h meter, light and sound devices that warn when the permissible load is exceeded, emergency shutdown buttons and bubble inclinometers installed on the installation control units.

One of the priority areas of activity of Kominvest-AKMT is to provide domestic enterprises working in the field of waste collection and transportation with modern vehicles and technologies. At the exhibition, unfortunately, the company did not show tractors with hook loaders, but it constantly sells cargo chassis equipped with multi-lifts from the Dutch company VDL, and customers are also offered VDL loaders with cable drive and a winch.

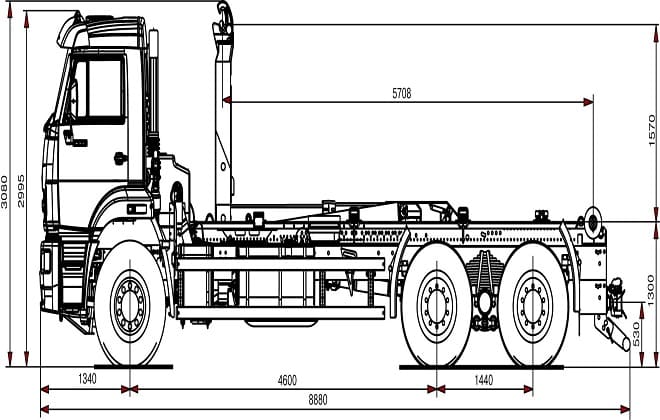

Characteristics of a hook lift based on KamAZ

The main disadvantage of specialized transport is its downtime in the absence of specialized work. KamAZ with a multi-lift turns a truck into a universal, wide-range vehicle suitable for work in a wide variety of fields.

Device

The multi-lift hook system consists of an L-shaped frame that is mounted on a truck chassis. A hook is attached to the short end of the frame. This hook hooks onto the swap body standing on the ground and drags it onto the truck.

The multilift frame can be fixed, telescopic or folding. The fixed frame is designed for installation on a car or on several brands of cars that are similar in length to the cargo platform.

The telescopic frame of the multilift allows the same equipment to be mounted on trucks of different lengths and with different numbers of axles, and to use longer interchangeable bodies.

The cable multi-lift system, instead of an L-shaped frame, is equipped with a platform that is raised and lowered using hydraulic cylinders, as well as a winch with a cable and a hook at the end. When loading a container, the platform lowers, the cable grabs the cargo and pulls it onto the vehicle frame. It is considered an outdated design due to the unreliable attachment of the body to the car.

There is another type of multilift - a frame one. Despite the fact that it provides the tightest load fixation and the highest speed of changing bodies, it is practically not used. The reasons are high cost, difficulty in operation, and the requirement for high precision in approaching the body or container.

Multilifts were widely used in the military sphere, from where they came into civilian life. Thanks to the multi-lift system, a KAMAZ vehicle can transport various types of cargo:

- bins for agricultural products, feed or bulk materials;

- garbage containers for household, food, construction and industrial waste;

- sea and rail containers;

- cabins, modular living quarters and houses;

- tanks and tanks;

- press containers and compactors;

- various wheeled and tracked vehicles, equipment on special platforms.

In addition, a truck with a multi-lift system can tow trailers.

Specifications

Models of multi-lift systems are manufactured, differing in their characteristics:

- The load capacity of the system is from 5 to 42 tons (the most common are 16-ton and 20-ton options).

- The frame lifting angle (body tipping angle) is from 48 to 53 degrees.

- Container volume is from 8 to 40 cubic meters (8-12 cubic meters and 20 cubic meters are more often used).

- Container length - from 4.5 to 9.48 m.

- The width of the replacement body is 2500 mm.

- Body height - from 3050 mm to 3850 mm.

- The technological time for performing an unloading or loading operation is no more than 3 minutes.

- The control system is electro-pneumatic type.

- System weight - 2000 kg.

- KAMAZ engine power is from 210 to 428 hp. With. depending on the model and modification.

All hook lift systems are reliable, simple to operate and easy to maintain. The technology for loading and unloading containers does not require the driver to leave the cab. The interchangeable body is rigidly fixed on the vehicle at least at three points throughout the entire loading/unloading operation, which ensures high rigidity of cargo fastening and the ability to transport it at a higher speed.

Price and analogues

Prices for a hook lift installed on the basis of a 2-axle KAMAZ-53605 chassis start at 4 million 700 thousand rubles. (2-axle chassis) up to 6 million 170 thousand rubles (3-axle chassis) and up to 7 million 300 thousand rubles (4-axle chassis).

The cost of renting a car with a multi-lift ranges from 780 to 1000 rubles per hour (with driver).

It is possible to rent a KAMAZ truck with a multi-lift loading and unloading system for a month. In this case, the rental price will start from 60 thousand rubles per month without a driver and from 140 thousand rubles per month with a driver. The duration of a work shift for a monthly rental is 7 hours plus 1 hour of car delivery.

The cost of one-time removal of a garbage container in Moscow is:

- 8 cubic meters - from 4300 to 5500 rubles;

- 15 cubic meters - from 9900 to 11000 rubles;

- 20 cubic meters - from 10,300 to 11,500 rubles;

- 27 cubic meters - from 10,600 to 12,500 rubles.

A more exact price depends on the location from which the dumpster needs to be removed.

"Tradition-K" does not stand aside

The attention of visitors at the stand is drawn to the wide capabilities of the CMU. The Moscow company demonstrated mounted hydraulic drills that can be equipped with CMUs of various brands. A hole drill is purchased mainly for drilling wells for supports of traffic signs, for lighting masts, and for screwing in screw piles. The combination of the capabilities of the drilling rig, CMU and wheeled chassis allows drilling to be carried out in inconvenient, hard-to-reach places. The work will not be interfered with by trenches, barriers and fences. Unlike hole drills mounted on excavators, installing them on a CMU has obvious advantages. Due to the reach of the boom, it is possible to obtain wells of considerable depth without wasting time on installing extensions, and to work with long-length screw piles. Another advantage is that a truck with a CMU and a drill can move on public roads, and an excavator, as a rule, is transported on a trailer.

Tradition-K specialists have developed a technology by which engineers design and install additional hydraulic lines on the customer’s car if it is missing. The vehicle is equipped with a drum for winding the hydraulic hose, additional sections of the hydraulic distributor, couplings for quick-release connections of hoses, etc. After wiring to ensure the supply of hydraulic fluid to the hydraulic rotator, a hydraulic drill is installed at the end of the CMU boom.

Choosing a hydraulic drill is not an easy question. The power of the drilling rig is limited by the resistance of the manipulator boom to lateral loads. KMU booms have different strengths and torsional resistance, which should also be taken into account when choosing a hydraulic drill.

But Tradition-K specialists will give answers to all questions. Thus, for manipulators with a hydraulic unit of low capacity, but creating high pressure in the hydraulic system, the company’s stand presented hydraulic rotators Delta CD3, Delta CD6, Delta CD7, specially designed for such situations.

Multilift KAMAZ 53228 and KAMAZ 65115 model MSK-10-04

Technical characteristics of the multilift KAMAZ-65115 or KAMAZ-53228 model MSK-10-04:

| Overall dimensions of the car, mm | length | 7660 |

| width | 2500 | |

| height | 2850 | |

| Vehicle curb weight, kg | 9380 | |

| Total weight, kg | 22400 | |

| Axle load, kg | front | 5550 |

| rear | 16850 | |

| Vehicle wheelbase, mm | 3690 | |

| Maximum speed, km/h | 80 | |

| Load capacity of the chassis with a mechanism for changing platforms, kg | 12870 | |

| Volume of replaceable containers, m3 | 12-40 | |

| Container lifting height, m | 2,7 | |

| Angle of dump truck unloading, degrees | 50 | |

| Pressure in the hydraulic system, MPa | 16 | |

Technical characteristics of the Kamaz 53228 chassis:

| Model | KAMAZ 53228 (6*6) | |||

| Overall dimensions, mm | length | 7415 / 8300 / 8900 | ||

| width | 2500 | |||

| height | 3310 | |||

| Front overhang, mm | 1420 | |||

| Rear overhang, mm | 1335 / 1870 / 2060 | |||

| Wheelbase, mm | 3340 / 3690 / 4100 | |||

| Base between 2nd and 3rd wheel | 1320 | |||

| Internal platform length, mm | 5215 / 5015 / 4680 | |||

| Loading height, mm | 1115 | |||

| Wheel formula | 6*6 | |||

| Total weight, kg | 24500 | |||

| Axle load, kg | front | 6000 | ||

| rear trolley | 18500 | |||

| Curb weight, kg | 8320 / 8280 / 8700 | |||

| Axle load, kg | front | 4185 / 4160 / 4370 | ||

| rear trolley | 4135 / 4120 / 4330 | |||

| Load capacity, kg | 16070 | |||

| Permissible weight of the superstructure with cargo, kg | 16030 / 16070 / 15650 | |||

| Engine | 740.31-240 (Euro-3) diesel | |||

| engine's type | 8 V-shaped cylinders. With turbocharging and intercooling of charge air | |||

| Working volume, l | 10,85 | |||

| Maximum net power, kW (hp) | 165 (225) | |||

| Rated gross power, kW, (hp) / rpm. | 176 (240) at 2200 rpm | |||

| Maximum torque, Nm (kg*cm) / rpm. | 912 (93) at 1100 - 1500 | |||

| Cylinder diameter and piston stroke, mm | 120 / 120 | |||

| Compression ratio | 16,5 | |||

| Fuel | diesel | |||

| Environmental class | Euro-3 | |||

| Fuel tank capacity, l | 210 or 350 + 210 or 170+125 or 170 | |||

| Electrical equipment | Voltage, V | 24 | ||

| Batteries, V/Ah | 2?12/190 | |||

| Generator, V/W | 28/2000 | |||

| Clutch | type | friction, dry, double-disc | ||

| drive unit | hydraulic with pneumatic booster | |||

| Transmission | Mechanical, 10-speed | |||

| Control | Mechanical, remote | |||

| Final drive ratio | 6,53 / 5,94 / 7,22 | |||

| Gear ratios | 1 – 7,82; 6,38 2 – 4,03; 3,29 3 – 2,5; 2,04 4 – 1,53; 1,25 5 – 1,0; 0,815 ZH – 7.38; 6.02 | |||

| Transfer case | type | mechanical, two-stage with lockable center differential | ||

| control | pneumatic | |||

| Transfer case ratios | first gear (low) | 1,692 | ||

| second gear (highest) | 0,917 | |||

| Brakes | front | disk | ||

| rear | disk | |||

| Brake drive | pneumatic | |||

| Dimensions: drum diameter, mm | 400 | |||

| Brake lining width, mm | 140 | |||

| Total area of brake linings, cm2 | 6300 | |||

| Wheel type | disk | |||

| Tire type | pneumatic, chamber | |||

| Rim size | 7,5-20 (190-508) | |||

| Tires, size | 11.00 R20 (300 R508) | |||

| Cabin | type | located above the engine, with a high or low roof | ||

| execution | K (short without sleeping place) / D (long with sleeping place) | |||

| Characteristics of a vehicle with a gross weight of 24500 kg | Maximum speed, not less, km/h | 80 | ||

| Climbing angle, not less, % | 31 | |||

| External overall turning radius, m | 11,3 | |||

| Optional equipment | PTO power take-off | |||

Technical characteristics of the Kamaz 65115 chassis:

| Model | KAMAZ 65115 (6*4) | ||||

| Overall dimensions, mm | length | 6700 — 10120 | |||

| width | 2500 | ||||

| height | 2825 | ||||

| Front overhang, mm | 1320 | ||||

| Rear overhang, mm | 870 / 3010 | ||||

| Wheelbase, mm | 3190 / 3690 / 4470 | ||||

| Base between 2 and 3 wheels | 1320 | ||||

| Internal platform length, mm | 4300 — 6900 | ||||

| Loading height, mm | 1010 | ||||

| Wheel formula | 6*4 | ||||

| Total weight, kg | 22400 — 25200 | ||||

| Axle load, kg | front | 5500 — 6200 | |||

| rear trolley | 16900 — 19000 | ||||

| Curb weight, kg | 7500 — 8050 | ||||

| Axle load, kg | front | 3800 — 4050 | |||

| rear trolley | 3700 — 4000 | ||||

| Load capacity, kg | 17350 | ||||

| Permissible weight of the superstructure with cargo, kg | 14650 — 17350 | ||||

| Engine | 740.62-280 (Euro-3) diesel | 740.65-240 (Euro-3) diesel | |||

| engine's type | 8 V-shaped cylinders. With turbocharging and intercooling of charge air | 8 V-shaped cylinders. With turbocharging and intercooling of charge air | |||

| Working volume, l | 11,76 | 11,76 | |||

| Maximum net power, kW (hp) rpm. | 206 (280) at 1900 | 176 (240) at 1900 | |||

| Maximum torque, Nm (kg*cm) / rpm. | 1177 (120) at 1250 - 1350 | 980 (100) at 1250 - 1350 | |||

| Cylinder diameter and piston stroke, mm | 120 / 130 | 120 / 130 | |||

| Compression ratio | 16,8 | 16,8 | |||

| Fuel | diesel | ||||

| Environmental class | Euro-3 | ||||

| Fuel tank capacity, l | 210 or 350 or 500 | ||||

| Electrical equipment | Voltage, V | 24 | |||

| Batteries, V/Ah | 2?12/190 | ||||

| Generator, V/W | 28/2000 | ||||

| Clutch | type | diaphragm, single disk | |||

| drive unit | hydraulic with pneumatic booster | ||||

| Transmission | Mechanical, 10 or 9-speed | ||||

| Control | Mechanical, remote | ||||

| Final drive ratio | 4.98 or 5.43 | ||||

| Gear ratios | Maud. KAMAZ-154 or KAMAZ-152 | 1 – 7,82; 6,38 2 – 4,03; 3,29 3 – 2,5; 2,04 4 – 1,53; 1,25 5 – 1,0; 0,815 ZH – 7.38; 6.02 | |||

| Maud. ZF 9S1310 | 1 – 9.48; 2 – 6.58; 3 – 4.68; 4 – 3.48; 5 – 2.62; 6 – 1.89; 7 – 1.35; 8 – 1.00; 9 – 0.75; ZH – 8.97 | ||||

| Brakes | front | disk | |||

| rear | disk | ||||

| Brake drive | pneumatic | ||||

| Dimensions: drum diameter, mm | 400 | ||||

| Brake lining width, mm | 140 | ||||

| Total area of brake linings, cm2 | 6300 | ||||

| Wheel type | disk | ||||

| Tire type | pneumatic, chamber | ||||

| Rim size | 7,5-20 (190-508) | ||||

| Tires, size | 11.00 R20 (300 R508) or 10.00 R20 (280 R508) | ||||

| Cabin | type | located above the engine, with a high or low roof | |||

| execution | K (short without sleeping place) / D (long with sleeping place) | ||||

| Characteristics of a vehicle with a gross weight of 25200 kg | Maximum speed, not less, km/h | 90 | |||

| Climbing angle, not less, % | 25 | ||||

| External overall turning radius, m | 10 | ||||

| Optional equipment | PTO power take-off | ||||

View more KAMAZ multilift

| Multilift KAMAZ-6520 | Multilift KAMAZ 65115, KAMAZ 53228 and KAMAZ 65111 model 6888 | Multilift KAMAZ 65201 model 684901 |

| Multilift KAMAZ 6520, KAMAZ 6540, KAMAZ 65115, KAMAZ 65201 model MSK-22 | Multilift KAMAZ 65115 model MSK-16-01 | Multilift KAMAZ 65115 model MPR-6851 |

View multilift from other manufacturers

| multilift tata | multilift hyundai | isuzu multilift |

Hyva Cranes – it doesn’t get any cheaper

The Hyva Cranes stand attracted visitors with a “live” model of the HV147 manipulator. The HV series combines Z-shaped CMUs in the transport position. Mostly, the guests of the stand were surprised by the price tag attached directly to the CMU. It was reported that this model of the famous European company costs less than 1 million rubles. The price is really low, since a similar crane from Palfinger costs almost twice as much.

Maud. HV147E1 with a vertical boom reach of almost 10 m, with a dead weight of 1.375 t, provides a load moment of 13.9 tm. The installation makes a full revolution in just 15 seconds, the hydraulic pump creates a working pressure of 285 bar in the system.

According to a company representative, the price was reduced due to successful logistics solutions. Hyva CMU deliveries today are carried out to Russia from Italy. The Hyva company, corresponding to its transnational status, acquired the Amco Veba plant in Poviglio, owned by the Ferrfri group, in 2006, and today the company operates three technological lines, producing CMUs of such brands as Ferrari, Amco Veba, but mainly the Hyva brand - the owner of everything production complex.

In addition, Hyva takes into account the specifics of Russian operation, in mod. The HV147 has virtually no expensive electronics, and uses only hydraulics. This approach significantly reduces the cost of the product, as well as the fact that the HV series cranes have a lightweight design. Such a CMU is easier to mount on a chassis, and its price, of course, is lower.

Interest in CMU is growing

As noted above, the majority of exhibitors involved in equipping truck chassis with various superstructures brought to the exhibition trucks with different brands of hydraulic power units installed on them. At the stand of the Moscow LLC KB Spetsavtotekhnika, a Shacman tractor unit with a Kromann multilift mod. 30/6200 g/p 30 t.

Spetsavtotekhnika specialists have been dealers of the Kromann company for several years now and install Kromann multi-lifts with hydraulic gripping capacity of 24 and 30 tons. The Polish manufacturer offers the widest selection of hook loaders with capacity from 5 to 32 tons, 2- and 3-axle trailers - multilifts with lifting capacity of 14.7 and 22.65 tons, respectively.

To transport bunkers weighing up to 40 tons, KB "Spetsavtotekhnika" offers Hyva 40-65 multi-lifts with a capacity of 40 tons for installation. Installers install Kromann and Hyva equipment on Shacman chassis and offer customers ready-made multi-lift bunker trucks. In KB "Spetsavtotekhnika" on Shacman and FAW chassis they also mount XCMG cable-type cranes with a maximum capacity of 5–7 tons, Hyva HB 170-E2 cranes with a maximum capacity of 5–7 tons. payload 7,215 tons. “Spetsavtotekhnika” is an official dealer of companies from South Korea DongYang, Kanglim, so the company has the opportunity to install the model range offered by these at competitive prices. They also install manipulators from Daehan, another South Korean company producing manipulators.

The Nizhny Novgorod stand was decorated with a Fuso FE85DJ flatbed truck with a 4x2 wheel arrangement, equipped with a Unic 374 max. lift capacity 3.03 t at a radius of 1.6 m, while the maximum boom radius is 9.81 m.

It should not give preference to any one or two CMU manufacturers. If the client has not decided in advance to purchase a car with a certain model of the CMU, then the company manager will select the option the client needs. In addition to the already mentioned Unic company, Automechanical Plant has been cooperating for a long time with the Italian manufacturer of CMUs, FASSI, and installs Palfinger manipulators and other participants in the CMU market. In this exhibit, the emphasis was placed on reducing the weight of the superstructure through the use of open-type profiles in the base structure and increasing corrosion resistance, which was achieved thanks to hot-dip galvanizing of the platform base and subframe.

Most recently, the plant presented a 7-ton KamAZ-43118 flatbed truck, on which the domestic KMU INMAN 250-04 was mounted. A special feature of this configuration is that the design provides for the installation of a basket on the boom of the CMU for lifting people. The basket is fully certified, and the CMU is equipped with all the safety devices necessary for normal work at height. Thus, the buyer, purchasing this assembly, can use the CMU both for its intended purpose, to perform crane work, and as a hydraulic lift, lift workers and tools to a height of up to 14 m. The lifting capacity of the basket is 0.25 tons, and the maximum horizontal the boom reach reaches 11.7 m.

What drew attention when visiting the exhibition was that many companies represented at STT-2015, engaged in the installation of CMUs on truck chassis, such as GosSpetsAvto, SPM, Auto-Alliance, etc., choose Horyong manipulator installations. even received the status of an official Horyong dealer.

The products of the Korean company Horyong Co., Ltd are well known to Europeans, and this is not an accident. The company is known for its powerful design and research center, which continuously introduces innovations into the production process. The company's plant is equipped with the most modern equipment, most of the technological operations are performed automatically. The company's specialists have defended about a dozen patents for inventions.

The safety systems of Horyong aerial platforms and cranes are certified in South Korea and some foreign countries. They fully meet Russian requirements for hazardous production equipment. Most companies choose Horyong CMU primarily due to the compactness of the units. The manipulators fold when the base vehicle moves and have a low mass due to the use of high-strength metal, which makes it possible to reduce the thickness of the metal sheet. Horyong installations have an increased service life, since the design development is carried out using computer analytical programs that identify the weak points of the models.

The advantages of using the Horyong CMU include the additional possibilities for using the manipulator provided by the manufacturer. You can install a basket on the boom and use the manipulator as an AGP; if you install a hydraulic rotator, the CMU will effectively perform the functions of a drilling rig.

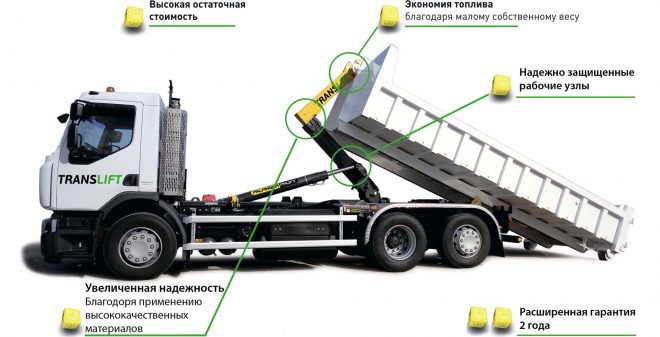

Advantages of using the design

The multi-lift system is made of high-strength alloys, and therefore is reliable. It reduces financial and time costs during vehicle operation. Loading and unloading cargo is easier and faster.

Thanks to the multi-lift trailer:

Advantages of a lift trailer

- Transport downtime is reduced. While one cargo container is on the ground, the vehicle can be transporting another.

- You can move loads for various purposes. The system is one of the universal ones.

- The safety of the process of loading and transporting containers increases.

- It is possible to double the volume of special cargo transported by road trains.

The multifunctional and reliable system is easy to operate and maintain. It does not require regular expensive procedures. Replacement containers can be supplied with the vehicle, expanding the list of possible transport tasks.