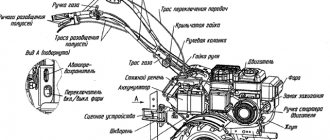

How the snow blower works

Snow removal attachment for walk-behind tractor - device

The market is oversaturated with offers of various snow blower models. But there is an easier way to create an automated snow removal assistant. A walk-behind tractor is used as the main device.

He does an excellent job of removing debris and cultivating the land. In combination with a snow removal attachment, a walk-behind tractor is capable of clearing a given area of snow drifts.

The snow blower on the walk-behind tractor is connected to the power take-off shaft. When moving, the auger crushes the snow into small pieces. The air flow, which is created by a powerful fan, throws the crushed snow mass to the side.

Depending on the thickness and volume of the snow cover, different types of snow removal attachments are used.

Helpful information

You need to be careful where the snow is thrown: there should be no fragile objects or windows nearby. Devices with powerful buckets allow you to get rid of even stale pieces of snow, and their reliable shafts will remain unharmed even if pebbles are accidentally hit.

Auger devices are in greatest demand due to their low cost. The following tips will help owners make their work safer:

- Before starting work, you need to make sure that all threaded connections are firmly fixed;

- check the chain tension level every 6 working hours, permissible deviations are up to 15 mm;

- during first operation, continuous operation should be up to half an hour, after which the engine is turned off and the fastenings are checked for tightness.

These simple recommendations will not only make the cleaning process safer, but will also extend the life of the devices.

Nozzle for "Salyut"

The device belongs to the category of mounted ones; it clears snow from flat areas and can operate in a temperature range from +5 to -20 degrees. There are several modifications that differ in the way they are connected to hand tractors. The design is prefabricated and welded.

Electric cultivator for the garden: electric cultivator and walk-behind tractor

The main functional component is a screw auger. During the movement, the snow moves from the edge to the center, and the mass is transferred to the nozzle through movable blades. The presence of support plates allows you to adjust the cleaning height. The device has the following characteristics:

- length - 60 cm;

- grip - 50 cm;

- height - 82 cm;

- width - 64 cm;

- weight - 60 kg;

- the ability to remove a snow globe up to 17 cm thick;

- screw speed - 2100 rpm.

Device for walk-behind tractor "Neva"

Welded housing with a screw rotating mechanism inside, a coupling device and drive elements to ensure connection with the shaft. A walk-behind tractor with such equipment can cover a path 60 cm wide in one pass and remove debris whose height is no more than half a meter.

It can be effectively used not only in personal plots, but also to clean large production areas.

The unit requires careful care and timely maintenance. Before each cleaning, be sure to check how well the belt and bolt connections are secured.

It is best to make a purchase through specialized stores that guarantee the quality and safety of the products offered. The snow blower attachment on the walk-behind tractor is an excellent assistant that allows you to quickly remove snow from your garden area.

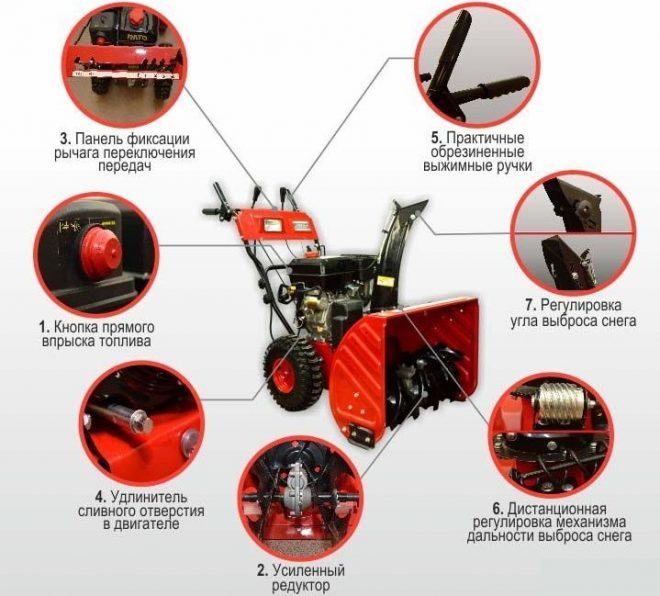

Factory snow blower for walk-behind tractor

The blade is the main component of the snow removal attachment for the walk-behind tractor. Its main function is to capture snow. Disks and bells help to spread it to the sides at a certain angle. You can adjust the direction of the angle and control the movement and speed.

Self-propelled snow blower design

Walk-behind snow blowers differ from each other in the following ways:

- working width;

- weight;

- disk revolutions;

- performance;

- dimensions.

The snow clearing attachment is installed in front of the walk-behind tractor and is selected depending on its type. This information is contained in the instructions.

Snow removal walk-behind tractors from various manufacturers

We invite you to familiarize yourself with various snow removal devices made by well-known and not so well-known brands.

Municipal brush “Tornado”

Characteristics:

| Operating speed, km/h: | 2-4 |

| Working width, mm: | 1000 |

| Diameter of brush disks, mm: | 350 |

| Weight, kg: | 45 |

Motoblock rotary auger snow blower Belarus 05-09N-MTZ SN-1M

Characteristics:

| Working speed | 2.5 - 5 km/h |

| Installation angle | ±20° |

| Diameter | 350 mm |

| Processing width | 1000 mm |

| Weight | 45 kg |

| Group | brushes |

Snow blower SM-1

Characteristics:

| Overall dimensions, mm no more |

length x width x height

Construction of snow blowers

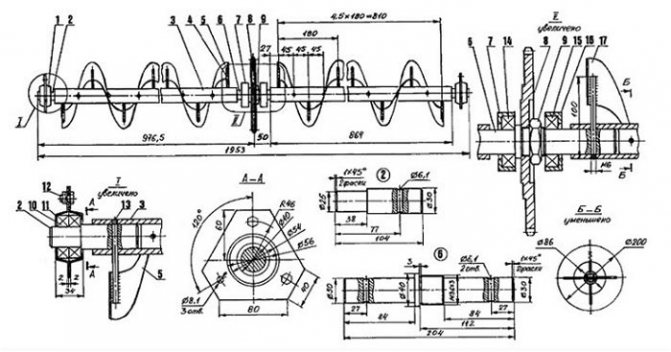

Assembly diagram for auger snow blower

A factory snow blower for a walk-behind tractor can be either auger or combined.

An auger or single-stage snow blower consists of a metal bucket with an auger inside. When moving, the snow cover is raked by screw knives and flies out through a special pipe.

A combined or two-stage cleaner, in addition to a screw, includes a rotor with an impeller. The snow crushed by the knives falls on the rotor, which grinds the snow mass with blades and throws it out through the sleeve.

Homemade snow blowers for walk-behind tractors are made according to the same scheme. Among them, the most common are rotary snow blowers, mechanisms with a bucket and a brush.

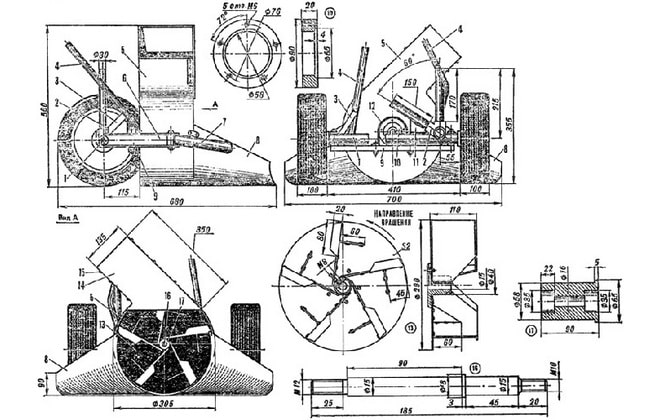

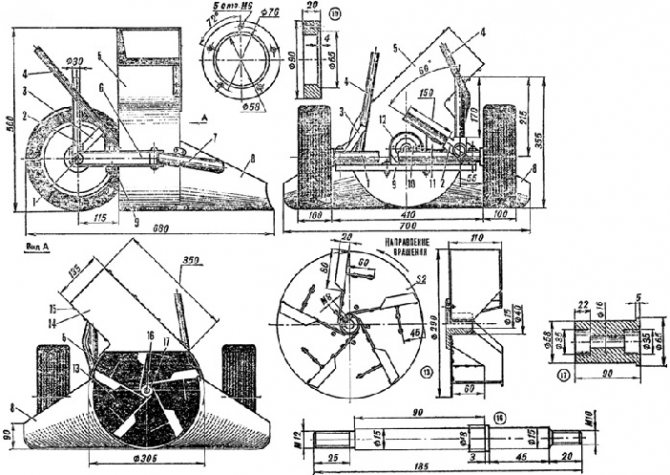

Rotary snow blowers

They consist of an auger that grabs snow with blades and throws it out through a folding pipe. The depth of snow collection is up to 50 cm. They are used when clearing the area of loose snow cover. The use of this device is not recommended for cleaning compacted and dense snow masses.

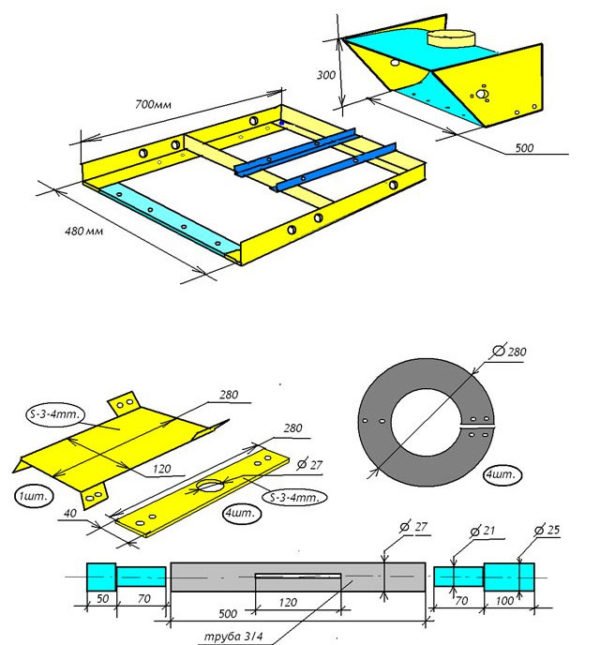

Do-it-yourself auger snow blower for walk-behind tractor - drawing

Attachments with shovel-bucket

These attachments are easy to use. They can be used not only in winter, but also when performing seasonal work: for leveling the soil or removing debris. A large metal iron sheet is used for production. The edges are protected from abrasion and damage by a rubber coating. When moving, you can change the angle of inclination and rotation. Depending on the type of work, the optimal mode is set. The length of the small-sized attachment is up to 1.5 m. The dimensions of the bucket must correspond to the type of walk-behind tractor. For ordinary ones - up to 1 m, for large and powerful walk-behind tractors - 1.5 m.

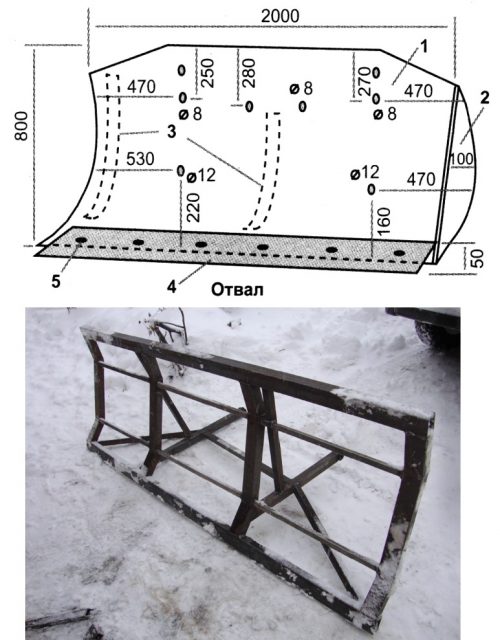

Snow shovel - dimensions

Snow blowers with brush

Used for cleaning decorative surfaces. The brush is attached to the rotation shaft. In one pass, an area more than 1 m wide is cleaned. The cleaning depth and direction of the structure are adjusted.

Step-by-step instruction

When starting the process of creating a snow blower from a motorized cultivator with your own hands, you need to draw up drawings and follow the step-by-step guide. This will make it possible to invent a reliable snow clearer that will perform its tasks without failure for many years. Step-by-step manufacturing instructions consist of the following steps:

- First you need to create a frame for the future purifier by welding pipes from any thick metal together. To make the structure reliable, it can be reinforced with steel corners. A separate pipe with a thickness of 20 mm is used to make the handle, and a pipe with a diameter of 5 cm is used for the shaft of the screw mechanism.

- Next, it is necessary to cut a through cut inside the auger pipe in order to install steel plates measuring 17x27 cm in it. The device is used as a blade, which rotates under the influence of the shaft and pushes snow masses in the auger mechanism.

- To ensure free passage of snow to the bucket, the device is equipped with a 2-way auger. It is made from a 1 cm thick conveyor belt or from the sidewall of a rubber tire of a car wheel. Requires 4 ring-shaped pieces with a diameter of 28 cm.

- A platform is welded to the supporting base of the snow clearer. It will be used to install and fasten the motor from a walk-behind tractor or cultivator. Installation is carried out by welding a steel plate with a thickness of at least 10 cm to the frame. Steel corners are used to strengthen the welding site.

- Next you will need to install sealed bearings into the internal cavity of the shaft. This is done by sawing the ends of the shaft being used with a file and tapping the bearings with a hammer. When performing such actions, you must be careful, otherwise you may damage the shaft and reduce its thickness. It is also important to provide space for mounting the key by making a small groove at the end of the shaft.

- To achieve smooth and uniform movements, the snow blower is equipped with a set of skis. This design is easy to make with your own hands from wooden blocks. A plastic panel is fixed to the bottom of each ski to ensure smooth movements.

- The role of a snow thrower in a snow blower is performed by a rotating mechanism made from a sewer pipe with a thickness of 160 mm. The part must be connected to the screw mechanism.

- Next, a piece of pipe is welded to the rotating chute to change the direction where the snow will be thrown.

- At the stage of installing the working units on the frame, it is necessary to ensure that the blade is slightly thinner than the rotary chute. This will ensure that snow is thrown freely without delay inside the mechanism.

- At the end, it is necessary to complete the decorative part of the work, paint the metal parts with an anti-corrosion paint composition.

Read also Recipe for delicious pancakes with milk and water

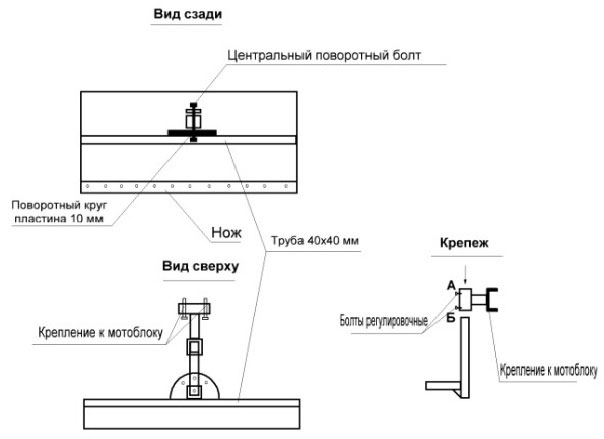

Shovel blade

The simplest version of a cultivator-snow blower is a blade. And although it is more expedient to use this design for walk-behind tractors with a more powerful motor, in the case of a walk-behind cultivator, you can invent a simplified model with reduced weight.

Working with such attachments is characterized by simplicity and accessibility. The blade is fixed on a bracket to the cultivator frame, and during operation of the equipment it accumulates snow masses.

To throw snow to the sides, the shovel is fixed at an angle.

In the manufacture of the blade, a steel sheet with a thickness of 3 mm or more is used. To give it the desired shape, you will need special equipment. If possible, it is better to find a piece of steel pipe with a diameter of 2-3 cm, cut it in half, and then divide it into 3 parts.

The lower element will act as a knife and cut layers of snow.

Rotary linkage

To make a rotary snow blower, you will need to show some skills in turning and welding. This type of hitch is also called an auger hitch, because a screw is placed on its internal bearings.

Spiral knives capture snow masses and push them towards the central part. They quickly pick up the snow and then push it out through the nozzle.

A visor is used to adjust the direction of snow emission.

Fan snow blower

Using ready-made drawings and diagrams, you can make a multifunctional fan snow blower. Sheet steel is used as the basis of the future device; it is welded into an oval body. This shape is necessary for the fan to effectively suck up snow.

A bushing for 4 bearings is fixed on the rear side of the housing: 2 for the shaft attachment and 2 for the brackets. After assembling the rotating mechanism, fan blades are placed on the protruding shaft. The impeller is protected by a special mesh, and a pulley is installed on the outer end of the shaft. A transmission belt from the working shaft of the power plant will be connected to it.

Next, it remains to equip the snow throwing mechanism. It is created as follows: a hole is made in the upper part of the oval body, a pipe is welded into it, and a tin sleeve with a visor is put on top. Rotating mechanisms will draw snow into the body and then throw it out along the sleeve.

Combined snow blower

Some craftsmen who own walk-behind tractors or walk-behind cultivators invent functional prototypes of snow blowers from improvised means. Some people combine rotary and fan models into one unit, which makes it an effective tool for removing thick layers of snow.

This manufacturing option is characterized by a sharp screw mechanism that cuts off compacted and wet snow. The effectiveness of using the combined model is due to the increased distance where the snow is thrown. Another such invention is characterized by an improved height of fresh snow removed.

When creating such attachments, the first step is to install the rotor part. The diameter of the outlet nozzle increases. A sleeve with a rotating visor is fixed over the nozzle, and a belt drive is used to rotate the fan.

Snow removal attachment for walk-behind tractor "Neva"

You can make a snow blower for the Neva walk-behind tractor yourself or buy a ready-made one. The first method is the most common (due to the high cost of the factory nozzle).

There are 3 types of homemade snow blower for the Neva brand walk-behind tractor.

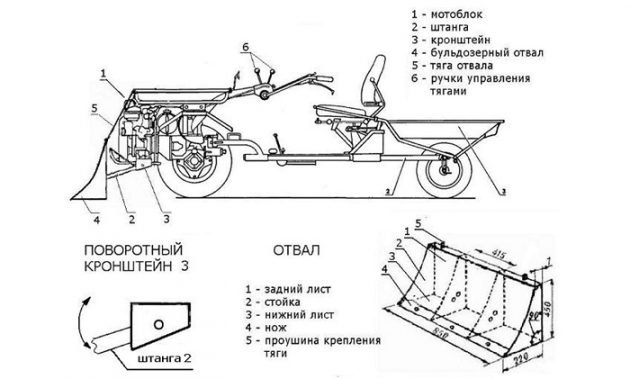

Bulldozer - through a special adapter, an attachment similar to a tractor is attached to the walk-behind tractor. To crush the snow mass, a metal sheet with pointed ends is used. It functions as a knife that cuts snow and throws it to the side.

Do-it-yourself bulldozer snow blower for walk-behind tractor

Two-stage - a blade is used on a walk-behind tractor. To make such a nozzle you will need a welding machine and detailed drawings. The principle of operation is similar to the factory version and has an auger, a rotor with blades and a pipe for throwing snow.

Motoblock Neva with two-stage snow blower

Fan - for cleaning, a fan is used that captures snow with blades and scatters them over short distances through the sleeve. Despite the simplicity of the mechanism of action, this version of the nozzle is very difficult to implement.

To independently manufacture a snow blower for the Neva walk-behind tractor, you need to have special knowledge. Therefore, before making a suspension with your own hands, you need to make sure of your own engineering competence.

For long-term operation of both finished and home-made devices, it is recommended to systematically inspect fasteners, screw bands and bolts.

Do-it-yourself fan snow blower for walk-behind tractor - drawing

How to do it yourself

The walk-behind tractor includes an adapter where a snowblower attachment is attached, which represents a homemade blade, thanks to which snowdrifts are cleared. A sharpened metal sheet is used as a knife to cut layers of snow, which are transported and then thrown to the sides.

And the parts of the blade itself are cut out of a sheet of steel, then welded. The knife is welded to the bottom. The blade is attached using rods and brackets to the main block. The rods are attached to the eyes of the blade and are connected to the handles for control through rollers or metal pipes.

Using the mechanism is not effective without an adapter.

The process of installing the attachment on the Neva walk-behind tractor

When independently attaching the hitch to the Neva walk-behind tractor, you need to:

Attaching a snow blower to the Neva and Oka walk-behind tractor

- Place both devices on a flat surface.

- Remove the pin used for load weights and attachments from the walk-behind tractor.

- Using a hitch, attach the suspension to the walk-behind tractor and tighten with two bolts.

- Remove the protection from the walk-behind tractor pulley and tighten the V-belt of the snow removal attachment.

- Using a special adjustment mechanism, adjust the belt to the correct tension. Correct installation will ensure that the belt does not slip on the pulley.

- Reinstall the protective cover on the pulley and tighten with bolts.

- Avoid friction of rotating parts against each other. To do this, the entire mechanism is turned by hand.

- Turn on the engine and start driving.

After using a homemade snow blower for the first time, you need to check the tension of the belts and tighten them if necessary.

Attaching a snow blower to the Salyut walk-behind tractor

How to make a snow blower from a walk-behind tractor

Users are mainly interested in the following questions:

- Is it possible to build a snowblower from a ready-made walk-behind tractor?

- How to make a walk-behind snow shovel with your own hands.

- Is it possible to make a rotary screw device for snow removal yourself?

On the Internet you can find many options for solving these issues, for example, we suggest that you familiarize yourself with the drawings of a walk-behind snow scraper with your own hands:

For work, prepare:

- sheet steel;

- welder.

Now study the drawing of a rotary snow clearing attachment; there are videos on the Internet showing and telling all the stages of creating such a canopy:

- pipe (shaft);

- Sheet steel;

- lathe;

- welding machine.

Safety precautions when working with a snow blower

When operating a snow blower, it is important to follow basic safety rules:

Working with a snow blower

- Before starting, all parts of the device are checked. There should be no loose parts. The auger is turned by hand. If there are no difficulties in operation, you can turn on the motor.

- The starting speed is no more than 2 km/h. Increased speed is possible on long and flat surfaces. Clearing the area of snow is not recommended on steep slopes.

- The canopy of the folding pipe is adjusted so that snow flying out with great force does not hit others.

- If a foreign object gets into the auger, turn off the engine and clean the mechanism.

- When clearing wet snow, it is necessary to periodically check all parts of the snow blower for the presence of snow and remove it in a timely manner. Hard lumps of snow may damage the unit.

Depending on the type of walk-behind tractor, you can make or buy the appropriate version of the attachment yourself. For long-term operation, it is recommended to regularly inspect the snow blower and troubleshoot problems in a timely manner.

With proper care, a snow blower can become a faithful assistant for a long time in clearing the area of snow mass.

Video on the topic: Removing snow with a walk-behind tractor with a mounted snow blower

Publications on the topic

Features and principle of operation of snow blowers for Neva walk-behind tractors

Operation of the Neva MB-2 walk-behind tractor, according to the instructions

Advantages of Chinese engines for a walk-behind tractor

How to choose a walk-behind tractor for snow removal

If you are planning to purchase a walk-behind tractor for clearing snow in your garden in winter, pay attention to the following points:

- Engine type: four-stroke petrol. Motoblocks with such a motor have good performance and are light in weight. They also emit less exhaust gases and are cheaper than similar models with a diesel engine.

- A snow plow walk-behind tractor must be equipped with a power take-off shaft. Such models work perfectly with active attachments for cleaning large and small amounts of precipitation: a shovel blade, a brush, a rotary snow blower (snow rotor).

- Choose a medium (semi-professional) technology class. The weight (80-120 kg) and engine power (6-8 hp) of such walk-behind tractors will be enough to clear large amounts of snow.