Common parameters

Galich truck cranes in the mentioned lifting capacity category are mounted on the basic three-axle chassis of KamAZ, MAZ and URAL vehicles.

Most of the types of equipment described are equipped with all-wheel drive, which allows this special equipment to operate confidently in difficult conditions.

Also improving the quality of cross-country ability is the option of automatic tire inflation, which ensures the required pressure in the wheel chambers when moving from one type of road surface to another.

The “Galichanin” truck cranes under consideration are equipped with YaMZ or KamAZ diesel turbo engines, the power of which ranges from 230 to 300 hp. With.

The crane installation on the described machines is controlled using a dual-circuit hydraulic system, the main elements of which are axial piston type pumps.

Their advantages include ease of maintenance, smaller radial dimensions and the ability to carry out the work process at high speeds. The crane unit operates from the power take-off and gearbox.

What are the owner reviews of the Baw Fenix 33462 car? You can find out in the article prepared for you. And from the video posted here you will get more information about the installation of Liebherr tower cranes.

Load-lifting 25-ton Galichanin trucks are equipped with a 3- or 4-section retractable boom, the length of which varies from 9.7 to 28 m for different models.

The special specifications of the equipment in question include the ability to extend the boom with a load located on the hook.

A lattice-type jib 9 m long can also be additionally mounted, which guarantees an increase in the working space and the area under the boom.

The designers paid special attention to the safety of the work process carried out by “Galichanin” truck cranes.

The unprecedented reliability of equipment of this class is ensured by the data collection unit, which records the main parameters of the current process.

In the event of a dangerous situation, the operator will be notified of the need for an emergency stop of work by an audible signal and will be able to interrupt the process in a timely manner.

The mentioned block processes data received from the tilt and lift angle sensors, boom radius, piston pressure converter, activating the crane load limiter and anti-tip system.

Important! In the case of work carried out in close proximity to power lines, the machines are equipped with a special module that prevents the occurrence of emergency situations.

Thus, we have before us an example of durable equipment, indispensable both within the city on narrow streets and off-road in large-scale industrial projects.

The described equipment continues to be improved and successfully proves its worth in the most difficult road and weather conditions.

KS-55713-1 and 1B

In order to more thoroughly study the design features of this class of machines, it would be advisable to dwell on a comparison of the Galician truck crane models KC-55713-1 and KC-55713-1B of the declared load capacity class.

The first of these units is the model with which the production of 25-ton trucks started, the second is a modernized machine, shown in the photo on the left. KC-55713-1B has been produced since 2009.

A number of technical characteristics common to these vehicles include the following specifications:

- the chassis with a 6x4 wheel arrangement based on KamAZ-65115 is made using heavy-duty steel welding technology, which guarantees the special reliability of this important structural unit;

- Cummins ISB6.7e4 300 diesel engine with a power of 219 kW allows you to effectively cope with long-term intensive loads;

- maximum load moment of 80 t.m is responsible for excellent traction characteristics;

- travel speed 60 km/h;

- equipped with an additional 9-meter jib, which is controlled manually and does not require the participation of special equipment;

- microprocessor load limiter, monitor in the operator's cabin with a display of the main operating parameters, protection against tipping over and exceeding the permissible weight of the load, a coordinate mechanism for protecting the crane.

The set of technical characteristics that differ between the described units consists of the parameters listed below.

First of all, attention should be paid to the length of the boom and its design. In the first model, this element is three-sectional with a rectangular profile, adjustable in the range of 9.7-21.7 m, in the second, it is a four-sectional boom with a hexagonal cross-section, its dimensions are 9.7-28 m.

Hence the rather significant difference in the parameters of the maximum hook lifting height. For the KC-55713-1 truck crane, these figures are 21.9 m with the main boom, which are inferior to the height of 28.3 m for the KC-55713-1B.

The lift coupled with the jib for the first machine is only 30 m, while for the second it is 37.3 m. The depth of lowering of the hook at the outreach is also different: 5 m: for a crane with a shorter length of 12 m, for a longer one - 25 m .

The 2009 model has improved load-bearing characteristics. Here, the sections are pulled out not sequentially, but synchronously, which significantly reduces the time spent on the entire work process.

The load lowering speed for KC-55713-1 is 0.3 m/min, for KC-55713-1B it is no more than 0.2 m/min.

The compared truck cranes also differ in their weight in the transport position. The unit mentioned first weighs 20.5 tons, the second - 23.41 tons.

The compact size of the described truck cranes characterizes the equipment as perfectly adapted to functioning in a small space, as well as to trouble-free movement in dense city traffic conditions.

Truck crane "Galichanin" KS-74713 80 t. based on a special chassis MZKT-790200 (10×10)

Description of the model The KS-74713 jib crane with a lifting capacity of 80 tons is mounted on a special all-wheel drive chassis of the MZKT-790200 type with a wheel formula of 10 x 10 and is intended for loading and unloading and construction and installation work at dispersed sites. Having the first, second, fourth and fifth steered axles, the chassis has excellent maneuverability and ease of control, which allows the crane to be used on sites with various types of access roads. The total weight of the crane in transport position is 60 tons (12 tons for each axle). The chassis is equipped with a power crane frame, which has a support ring for fastening the support support, transverse beams with sockets for placing outrigger beams. The mechanisms of the fixed part are driven by the chassis engine.

The crane mechanisms of the turning part have a separate diesel-hydraulic drive, consisting of a liquid-cooled Deutz BF4M1013EC engine, with systems: starting with batteries; exhaust gas removal with a muffler; air purifiers with filters; fuel supply, including control and monitoring system and pump unit.

To control working operations on the crane, an electro-hydraulic proportional control system is used, which provides more precise and smooth control of working operations, which ensures smooth control of all mechanisms with a wide range of speed control for working operations, as well as the ability to simultaneously combine several crane operations.

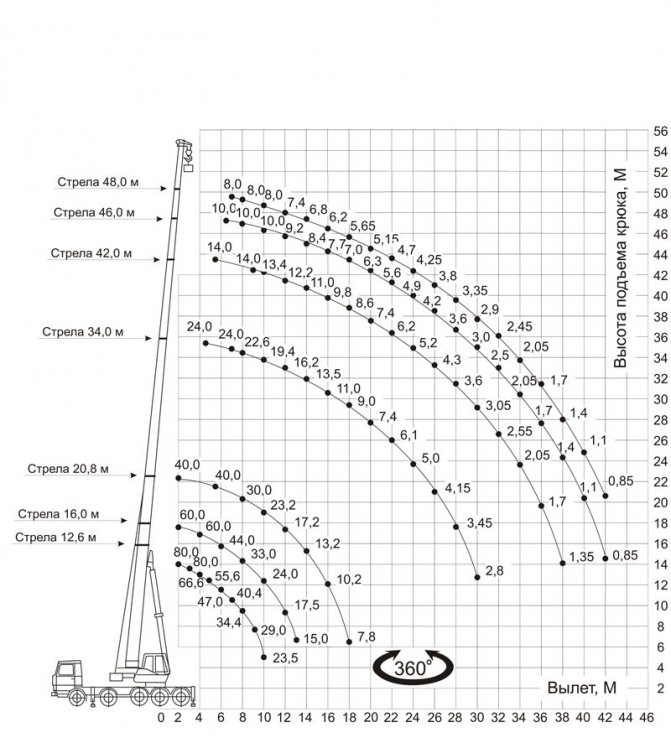

In the manufacture of load-bearing metal structures of the crane installation and the five-section telescopic boom, imported high-strength WELDOX steel is used. The boom sections are made of two bent all-metal profiles and, in accordance with modern trends in global crane construction, have a non-rectangular cross-section with a lower chord in the form of an ellipse. The length of the boom in the retracted position is 12.6 m, which ensures the crane's compactness and maneuverability when moving. When all five sections are fully extended, the length of the boom is 48 m, which ensures a wide area and the greatest height of load movement during operation. The ability to telescope a boom with a load on a hook allows the crane to perform special tasks: installing loads in hard-to-reach places, carrying them among mounted structures. For the convenience of working in cramped conditions, a mode for working with loads with the outrigger beams not fully extended is provided. The maximum size of the support contour (8.47 x 7.6) is achieved through the use of 2-section outriggers, thanks to which the crane is able to work with loads in a 360-degree circular zone without loss of lifting characteristics in the front working area “above the cabin” . The ability to carry out work in a 360-degree zone minimizes the number of changes when working on site and increases operational efficiency.

A single block can be installed on the boom head to operate as an auxiliary winch with a single reeving of the cargo rope.

The use of additional removable counterweights during operation can significantly increase the load characteristics of the crane at medium and long ranges, which provides the best performance among similar cranes of this size group.

Installation of additional counterweights into the working position is carried out without the use of additional lifting equipment and human resources.

The crane is equipped with two main and auxiliary lifting winches, which eliminates the need to re-pass the rope and allows independent work on the main boom and a single block (beak). The gearbox of the mechanisms for lifting loads and turning the crane is of a planetary type with disc brakes, which meets modern requirements for load-lifting machines. Many crane components use imported components that do not require replacement or repair over the entire service life of the crane. An autonomous WEBASTO diesel heater is used to heat the crane operator's cabin. The crane operator's cabin has a panoramic front glass and can be tilted during operation, which increases the viewing angle in the vertical plane, thereby providing excellent visibility of the working area at any boom length and any boom angle.

Safe operation of the crane is ensured by a complex of instruments and devices, including a microprocessor load limiter with digital indication of operating parameters on the display in the driver’s cabin. The device automatically protects the crane from overload and capsizing, is equipped with a crane coordinate protection system necessary for working in cramped conditions, has a built-in telemetric memory unit (“black box”) and a crane protection module from dangerous voltage (MZON) for working near power lines.

Specifications

Maximum load moment, t.m - 282.8 Maximum load capacity, t/reach, m - 80/3.0 Boom length, m - 12.6 - 48.0 Maximum hook lifting height, m - with main boom 48.0 m — 49.0 Max. depth of lowering of the hook by the boom, m - 4 Weight of the load at which extension of the boom sections is allowed, t - 12.0 Speed of lifting and lowering the load, m/min - nominal (with a load weighing up to 80.0 t) - 3.2 - increased (with a load weighing up to 10.5 tons) - 6.4 - maximum (pulley multiplicity 1) - 45.0 Load landing speed, m/min no more than - 0.1 Rotation speed of the turning part, rpm - up to 1, 2 Travel speed of the crane under its own power, km/h - up to 70 Size of the support contour along x across the chassis axis, m - with outrigger beams extended 8.47 x 7.6 - with outrigger beams retracted 8.47 x 5.3 Weight crane in transport position, t 60.00 Wheel arrangement of the base vehicle 10 x 10 Engine of the base vehicle: diesel - model TMZ-8431.10 Dimensions of the crane in transport position, m (length x width x height) 15.08 x 3.0 x 4, 0 Operating temperature, degrees. From -40 to +40