Segment mower KSF 2.1

Segment mowers of the KSF-2.1 type were manufactured in (Russia, Moscow). This enterprise is the legal successor of the Ukhtomsky plant and a continuation of its many years of work. Production of haymaking equipment of various types and designs.

Business date, meeting

KSF-2.1 copes well with haymaking mainly in flat areas. They mow various grass crops, laying down the vegetative mass during mowing:

- Naturally growing herbs.

- Seeds of cereals and other crops.

The mower is used for routine mowing in areas of almost any climate zone. Ensures uninterrupted operation, except in semi-desert and desert areas. Photo mower KSF-2.1

Advantages and disadvantages

In addition to the ability to be used in all weather conditions, KSF-2.1 segment mowers have a number of other advantages for which they are valued by many business leaders:

- High productivity is achieved due to the relatively high operating speed and large simultaneous grip width. More than 2 meters.

- The light weight of this attachment allows it to be used even on small types of transport devices.

- The low power consumption of the device will help save money and will not increase the cost of hay as the harvest decreases.

- Simple control without hydraulics is required without the need for additional maintenance personnel other than the tractor operator.

- Economical purchase of the device and its spare parts, available everywhere.

- High-quality work at high speed and long service life. At the end of the operating period, it will be enough to replace the cutting disc, and the mower will be ready for the mowing season again.

AllTransportation

Information » Machine and tractor units for applying fertilizers » Classification of mowers and agrotechnical requirements for them

Page 1

The classification of mowers is as follows. Mowers are divided according to the number of cutting devices and purpose.

According to the number of cutting devices, mowers are single-bar, double-bar, triple-bar and five-bar.

According to their purpose, mowers are divided into grass mowers, mower-conditioners and chopper mowers.

The agrotechnical requirements are as follows. Mowers must ensure that feed is obtained without loss and of high quality. They must: cut natural grasses no higher than 6 cm and seeded grasses no higher than 8 cm, lay the mown mass in straight windrows, turn the windrows half a turn to dry the lower layers, create conditions for the complete collection of the mown mass of standard moisture.

Types of mowers:

The mounted rotary mower KRN-2.1A is used for mowing high-yielding natural and seeded grasses. The mower is combined with tractors MTZ-80 and MTZ-82.

The mower includes a hitch frame 8, a rotary cutting device 3, a balancing mechanism 4, a subframe 5, hydraulic equipment 7, a traction fuse 9, a drive mechanism 10 and a field divider 1.

The workflow is as follows. Plant stems are cut with blade knives hinged on rotors. The knives rotate towards each other at a speed of 65 m/s. Plant knives are cut according to the principle of an unsupported cut, they are grabbed and taken out of the cutting zone, then moved over the cutting apparatus. This cut mass, meeting the field divider shield, changes the trajectory of movement, falls into the swath, freeing up space for the tractor wheels to pass during the second drive.

The hitch frame provides connection of the mower to the tractor hitch. It consists of a main frame and suspension.

The main frame is welded and has axles for connecting it to the lower links of the tractor hitch. The right side of this frame is equipped with an axle for the traction fuse. After installation, this fuse is fixed to the axis with a pin and a cotter pin. The suspension is hinged to the frame, the lower part of which is equipped with a bracket for installing a subframe. The suspension has a chain for connecting the transport rod. A rotary cutter is used to cut grass. The device has a timber panel and a bottom, fastened with bolts. Shoes are placed under the bottom for support on the ground.

The cutting device rotates in the axles of the brackets, which allows you to follow uneven soil. The cutting device is equipped with four identical rotors. Each rotor is equipped with two knives, which are hingedly mounted on special bolts. The middle rotors are equipped with elongated blades.

The right side of the cutting device is equipped with a bracket for attaching a field divider. The balancing mechanism ensures: limiting the pressure of the cutting device on the soil, copying field unevenness with this device, and moving the mower to the transport position.

The balancing mechanism includes a hydraulic cylinder articulated with a lever. This lever is connected to the cutting device using a freewheel.

In the transport position, the balancing mechanism is fixed with a transport rod thrown onto the bracket pin 2 (Fig. 1) and a telescopic locking device installed in the transport position. Hydraulic equipment ensures the operation of the balancing mechanism.

The hydraulic equipment includes: a hydraulic cylinder, a delayed valve, a breather, high-pressure hoses and a device that prevents oil from leaking out of the hydraulic system when it is separated from the tractor.

Rice. 1 — Mounted rotary mower KRN-2.1A: 1 — field divider; 2 — bracket; 3 — cutting apparatus; 4 - balancing mechanism; 5 — subframe; 6 - stand; 7 — hydraulic equipment; 8 — hinge frame; 9 — traction fuse; 10 — drive mechanism; 11 - sock.

The traction fuse serves to protect against damage to the cutting device when encountering an obstacle. It has two rods with wedge clamps. In the fixed state, the latches are held using the force provided by a cylindrical spring. The force for triggering the fuse is adjusted with a nut.

The field divider separates the mown mass from the unmown grass. The field divider includes a bracket, a divider shield, a spring with a cup-washer and a bolt. The divider shield is mounted so that it forms an angle with the direction of movement of the unit. In the working position, this shield is held by a spring, which allows it to move back during overloads and return to its original position when overloading them.

The KPRN-ZA rotary mower-conditioner is used for mowing high-yielding seeded grasses with simultaneous flattening of the stems and laying the mass in a windrow or spread. The machine can work in fields with tangled and laid down grass in conjunction with MTZ-80, MTZ-82, YuMZ-6AL tractors. Drive of the mower's working parts from the tractor's PTO.

The mower consists of a frame assembly, a driveshaft with a cardan drive, a cutting device, conditioning rollers, a transmission and a protective device. The grass is mowed using a rotary cutting device. The rotors, having counter rotation and having a high peripheral speed of rotation of the knives, carry out unsupported cutting of plants. Knives and rotor discs feed the cut grass into the area of the flattening rollers. Further flattening of the plant mass is carried out by ribbed flattening rollers across the entire working width. Then this mass is placed into the windrow by the guides of the swath-forming device. It is not recommended to flatten grass in wet weather, because... Flattened stems rot faster than unflattened stems.

Pages: 1

Current on the website:

Parallel control systems Parallel control systems, or multi-channel control systems, consist of parallel (simultaneous) operating control channels (Figure 4.1). Each control channel in such systems operates independently of other channels and...

Determination of standards for the frequency of track repair work Track maintenance work is divided into the following main types: enhanced overhaul of the track; complete replacement of rails (in certain sections - with the permission of JSC Russian Railways), accompanied by work in the amount of...

Costs of maintenance and technical repairs Costs of repair materials and spare parts Costs of spare parts for repair of rolling stock are determined by the formula [2, p. 165]: Ззч=nзч*Ltotal*к1*к2*к3/1000 Where nзч – standard cost for spare parts per 1000 km, rub.; k1 – coe...

Device

The KSF-2.1 mower consists of the following main structural elements and parts:

- The frame on which the rest of the working tools are based and has a mount for attaching to the tractor hitch.

- The traction rod is designed to connect the working cutting tool to the frame of the device.

- Cutting the blade with sharp segments (fingers).

READ How much oil to add to gasoline for brush cutters

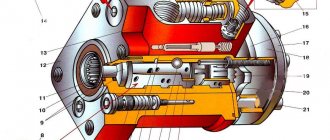

During operation of the mower, the blade with knives is driven in a reciprocating motion parallel to the surface of the ground. In this case, the stems that get in the way fall onto the stationary segments of the canvas and are immediately pressed tightly against them, moving the blades. Cutting the grass is similar to the work of regular scissors, leaving a strip of finished mowing. Scheme of the KSF-2.1 mower 1. Cutter head; 2. Guide knife heads; 3. Knife head cover; 4. House shoes; 5. Rod tap; 6. Outdoor shoes; 7. Field board; 8. Finger; 9. Insertion finger; 10. A piece of knife; 11. Clip knife; 12. Knife back; 13. Friction plate.

Mower device Kzn 2 1

Content

Nav view search

Navigation

Search

Main Menu

Operation of the T-25 tractor with a mounted mower

The KZN-2.1 mower (Fig. 29) is mounted on the rear suspension device of the T-25 tractor

Rice. 29. Mounted mower KZN-2.1.

The drive of the working parts of the suspended mower is carried out from the power take-off shaft of the T-25 tractor. Before hanging the mower, you need to prepare the tractor, which consists of the following: 1. Rebuild the T-25 tractor to the highest setting; 2. The track of the front and rear wheels is set within 1400-1500 mm; if this requirement is not met, the wheels will crush the mown grass and it will be difficult to control the tractor; 3. Adjust the central rod of the suspension device so that its length is 590 mm; 4. Adjust the braces so that their length is 490 mm; 5. Move the longitudinal rods to the middle holes of the brackets; 6. Raise the rear suspension and , by moving the lifting arms on the splines of the lift shaft, set the suspension axis at a height of 600 mm. Hanging the mower is done in the usual manner, described in the general instructions for hanging and working with mounted machines. After hanging, lift the mower so that the cutting device does not touch the ground, and by adjusting the length of the braces, level the mower in the transverse plane (the mower frame should be placed horizontally). By adjusting the locking devices, remove the lateral displacement of the mower frame relative to the longitudinal axis of the T-25 tractor. Lower the mower until its legs touch the ground, which corresponds to the location of the mower's suspension axes at a height of 350 mm from the ground. During operation of the mower, its suspension axles should not fall below 350 mm, which is achieved by installing the limiting clamp on the cylinder rod in the appropriate position. When moving, you need to raise the mower to the transport position, loosen the bolt securing the front stand, set it in a horizontal position and tighten the bolt tightly. Remove the lower bolts securing the rear strut to the frame and loosen the upper ones, set the strut in a horizontal position and secure firmly with the previously removed and loosened bolts.

READ How to Remove a Reel From a Mower

We mow the grass with a segment mower KS-2.1

In this video I talk about modifying the mower

segmented KS-2.1 and show it in action when mowing grass.

Modernization of the KSF-2.1 mower. Pulley replacement

First, a video of a piece of haymaking in 2020. Before replacing the drive pulley, our mowing proceeded approximately like this.

Before operating the mower, you need to carefully check the correctness of assembly, adjust the mechanisms and turn them manually using the eccentric.

cutting device blade parts must lie on the finger pads.

If there are gaps between the liners and the ends of the parts or between the clamps and sectors, then during operation the cutting apparatus will become clogged with weed, and great effort will be required to cut, which can lead to the knife breaking. Operation mower on various types of land

If the ground is uneven, the cutter may dig into the ground. To avoid this, tilt the cutting unit backwards. When the grass is laid down, the cutting device must be tilted forward so that the fingers do not crush the grass, but, going deeper into the laid down mass, lift it. When working on lumpy or rocky soil, in order to avoid breaking the fingers of the cutting device and parts of the knife, it is necessary to increase the height of the finger bar relative to the ground. To do this, it is necessary to move the soles of the inner and outer shoes to the overlying holes, as a result of which the height of the grass cut will increase. When moving the soles to the underlying hole, the cutting height of the grass will decrease. To reduce damage to plants when moving the mower, and to reduce clogging, the cutting device should put as little pressure on the ground as possible. To reduce this pressure, you need to increase the tension of the lift spring, but so that when the mower is operating, the cutting device does not jump and does not come off the ground, but adapts to the unevenness of the ground. When operating the mower on sandy soils or flooded meadows, where there is sediment of silt and sand, the blade clamps should not be lubricated, because the sand, mixing with oil, will linger on the parts and, getting between the rubbing parts of these parts, will increase their wear. The mower's cutting device must operate across the entire working width. To do this, you need to drive the tractor so that the inner boot goes as close as possible to the edge of the unmown grass. To avoid running into an obstacle with the cutting device, it must be lifted using the attachment of the T-25 tractor. To avoid accidents when working with the mower, you must follow the following rules: 1. Before starting the mower , make sure that no one is in front of the machine; 2. When stopping the unit, be sure to turn off the tractor power take-off shaft; 3. Make corrections to the mower when the tractor engine is not running; 4. When cleaning the cutting apparatus from grass at stops, do not touch the cutting parts with your hands; 5. When installing the mower into the transport position, do not touch the fingers of the cutting device .

READ What Oil to Pour into a Lawn Mower Engine

Operational Features

The mower is attached to the tractor using the longitudinal connection of the tractor support, establishing a distance from the ground to their rear ends of approx. 40 cm and a rise of no more than 65 cm. This is done so that the lawn mower frame is not sideways.

When working with the device, you must follow the rules that promote long-term and safe operation:

- The cutting unit of the mower must be covered with a protective cover.

- The tractor must be stopped while the power take-off shaft is moving.

- All adjustment and cleaning operations with the mower itself and especially with the cutting tool are carried out with the tractor completely stopped and turned off.

- The device is transported with a protective shield attached to the teeth.

Characteristics

Technical characteristics of the KSF-2.1 mower:

| Characteristics | Unit | indicators |

| Total weight of the device | kg | 190 |

| Overall dimensions during transportation, length / width / height | mm | 500/1800/2555 |

| Drive power | kW | 7,5 |

| Speed of progress in work, up to | km/year | nine |

| Grabbing the beveled strip | mm | 2100 |

| Cutting height | mm | 40-60 |

| Maximum performance | ha/year | 1,7 |

| A tractor is needed for traction | — | 0,6-1,4 |

| Required PTO frequency | rpm | 540 |

Changes

Mowers of this brand are now the most popular and widespread in the Russian Federation; they work successfully on the fields of collective farms and private farms. This high demand is also achieved due to the variability of equipment characteristics. The KSF-2.1 mower can be presented in different versions:

- Fingerless.

- Equipped with the German Schumacher cutting system.

- With hydraulic cylinder in lifting mechanism, etc.

READ How to Repair a Petrol Mower

Its “sister” KSF-2.1V requires more tractor power, but at the same time has light weight and mechanical lifting using a hydraulic cylinder.

Technical characteristics of the mower modification:

| Characteristics | Unit | KSF-2.1 b4 | KSF-2.1 V |

| Total weight of the device | kg | 230 | 180 |

| Overall dimensions during transportation, LxWxH | mm | 500/1800/2555 | 500/1800/2555 |

| Drive power min | kW | 7,5 | 18 |

| Speed of progress in work, up to | km/year | 12 | nine |

| Grabbing the beveled strip | mm | 2100 | 2100 |

| Cutting height | mm | 40-60 | 60 |

| Maximum performance | ha/year | 2,3 | 1,7 |

| A tractor is needed for traction | — | 0,6-1,4 | 0,6-1,4 |

| Required PTO frequency | rpm | 540 | 1000 |

Mower KSF-2.1 B works in video:

Source

Video: How to Choose a Mower Trimmer

The lightweight electric mower is designed to care for lawns up to 300 square meters. A special feature of the model is its compactness and maneuverability, which, together with the articulated handle, make it easier for even women and teenagers to work with the tool.

To change the cutting height (20-60 mm), the manufacturer has provided a central three-level adjustment mechanism. The herbs are collected in a solid grass catcher. The price of this equipment is only 4 thousand.

Advantages:

- A light weight;

- Ease of Management;

- Good performance;

- Thoughtful design.

Flaws

- Small grass catcher.

DDE LME. This is a convenient and inexpensive model for processing small areas, even if there is no strong person in your family.

Makita ELM 3311. Reliable and inexpensive mower

Reliable and comfortable wheeled lawnmower with easy movement is designed to care for areas up to 400 sq.m.

READ Refilling Line In Huter Trimmer

Its main feature is maximum simplicity of design. The absence of a belt drive ensures high reliability and good knife speeds.

The cutting height is three-level and can be adjusted between 20-55 mm. The foldable height-adjustable handle allows the tool to be adjusted directly under the operator. There is also a soft grass catcher with a capacity of 27 liters.

Advantages:

- Powerful power supply;

- Maneuverability;

- Convenient control;

- Protection against unintentional activation;

- Low cost. Just over 6 thousand.

Flaws:

- Small container for catching grass;

- The plastic inner protective cover is too soft.

The Makita is suitable for minor maintenance of a small front lawn.

Bosch ARM 37. Reliable model for large areas

This durable lawn mower can easily cover areas of up to 500 square meters thanks to its strong engine power and good cutting width. The main feature of the model is the competent design of the guides to the cutting module.

The cutting height adjustment is central and ranges from 20 to 70 mm. The grass is thrown back directly into the 40 liter coarse grass catch. The folding handle and relatively light weight (12 kg) make it easy to transport the device to the workplace.

Advantages:

- Compact size;

- Ergonomic handles

- Motor overload protection;

- Ability to work near curbs.

Flaws:

- Poor location of the tunnel for supplying grass to the storage;

- High cost of components.

Bosch ARM 37 is suitable for caring for large and not yet forgotten areas.

Drawings of the layout and location of the main components and parts of the mower segment

The drawings of a segmented mower for a walk-behind tractor The design and general arrangement of the main components and parts of a lawn mower based on cutting segments (knives) show: 1 - metal protection (partially shown); 2- clamping bracket for cutting segments; 3- back part of the upper blade of the mower; 4-segment lower knife segment; 5-segment of the upper blade of the mower; 6. Drive lever; 7- bracket for attaching the segmented mower to the drive; 8-segment mower bar for walk-behind tractor; 9. Drive the segment mower; 10. Two support sliders (with which you can adjust the height of grass mowing); 11. Engine of a homemade walk-behind tractor; 12. Engine air filter cylinder block; 13. Control cable suspension clamps; 14- gas tank; 15. Bracket for fastening the fuel tank; 16, 17. Handles with handles for controlling the walk-behind tractor; 18, 19. Lever and throttle control cable; 20, 21. Control lever and clutch cable; 22. Fuel line; 23. Self-propelled carburetor tractor; 24 wheel walking tractor; 25-drive box of a segment mower for a walk-behind tractor. The operating principle of a segment mower is based on the reciprocating movement of the cutting segments of the upper and lower knives. To do this, the torque from the power take-off shaft of the walk-behind tractor engine is transmitted through a bevel gear to the drive box, where it is converted using an eccentric mechanism into a reciprocating movement of the mowing section drive lever. The mower device for a walk-behind tractor segment is a bar on which the lower knives are mounted on the bottom, and the upper knives on top with cutting segments attached to them. The blades of the segment mower are installed in the grooves of the clamping arms: from below without adjustment, and from above the clamp should allow adjustment of the gap between the upper and lower cutting segments of the mower for a walk-behind tractor (based on the use of metal spacers). To ensure a high-quality, grass-free mow, the gap between the knives should be 0.5 mm, and the knives. Well sharpened.

READ Petrol Mower Malfunctions

The best riding lawn mowers

Self-propelled lawn mowers can vary greatly in their drive type. Front-wheel drive models are more maneuverable, but can only be used on flat areas.

The rear wheels are easier to overcome small obstacles, and the all-wheel drive technology can be freely used on slopes and rough terrain.

AL-KO 119387 Silver 46 BR Comfort. Ideal in terms of price and quality

The self-propelled mower with rear wheel drive has good performance, as it is equipped with a powerful four-stroke engine and produces high cutting speeds. The thoughtful design of the manual start system ensures that the device starts “half a turn”.

Advantages:

- Excellent build quality;

- Durable design;

- Simple and easy start;

- Electronic engine power control.

Flaws:

- It stands on an uneven surface in “self-propelled” mode.

AL-KO is suitable for large and relatively flat areas.

Daewoo Power DLM 5100 SR products are the most popular

A reliable and fairly large mower with an increased cutting width has a powerful engine and a well-thought-out design of the blade system.

This model has an almost zero turning radius. Due to the peculiarities of the wheelbase. Side and rear discharge of grass into a 70-liter soft grass catcher. The unit price is about 30 thousand rubles.

Advantages:

- Amazing maneuverability;

- 7 levels of cutting height adjustment from 25 to 75 mm;

- Ease of Management;

- There is a mulching function.

Flaws:

- Manual adjustment of the front wheel height is required.

Daewoo Power. An excellent choice for maintaining large and challenging terrain.

Huter GLM-5.0S. Powerful and convenient model

Another rear-wheel mower, equipped with a 4-stroke powerplant that starts with a “half-start”.

A special feature of the model is the high quality of work, which is not inferior to the results of divisions of more well-known brands.

The performance features are standard for lawnmowers in this class: central cutting height adjustment from 25 to 75mm and a 50-litre lawnmower capacity with reverse gear. The price of self-propelled equipment reaches 19 thousand rubles.

READ Which Gasoline Is Better To Pour Into The Huter Trimmer

Advantages:

- Powerful engine

- 5 levels to adjust cutting height;

- Affordable price;

- High quality build.

Flaws:

- Incorrect location of the oil drain hole;

- The grass catcher is periodically killed.

Huter offers a good selection for large areas, although it's still quite affordable.

Hyundai L 4300S. With movable knives

Reliable and comfortable rear-wheel drive model with excellent mowing quality. The 4-stroke engine has enough power to handle tough maintenance jobs on even the most neglected lawn.

The cutting height (25-75 mm) is adjusted by a central mechanism. But the main “trick” of this mower is the automatic folding of the blades when colliding with an obstacle. And as soon as the lawnmower passes the dangerous place, they themselves will immediately fall into place.

Advantages:

- Quality work;

- Maneuverability;

- Good performance

- Presence of a catalytic converter;

- Protecting knives from breakage.

Flaws:

- As in the previous model, the entrance for collecting grass is clogged.

Hyundai. An excellent lawnmower for difficult terrain with many obstacles (such as tree stumps, stones and just large burrs).

Champion LM 5345 BS. Really powerful

A powerful, really large 6-litre lawnmower designed to handle large and neglected areas.

Despite the Chinese assembly, inside it is a purebred American Briggs&Stratton engine, which, thanks to the Ready&Start function, starts without pre-pumping the carburetor.

The cutting height in this model is adjustable within the range of 19-76 mm. Self-propelled guns cost 25–26 thousand rubles.

Advantages:

- Increased cutting width;

- Powerful engine

- Excellent balance of power unit and knife mechanism;

- Adequate cost.

Flaws:

- Big sizes;

- Small fuel tank capacity for such a voracious engine.

In fact, Champion LM. This is not just a lawn mower, but a low-performance mini-tractor that can work even in the most difficult conditions.