Mineral fertilizer spreaders

The mineral fertilizer spreader is presented in the form of additional equipment, through the use of which the process of soil fertilization or direct sowing of seeds is significantly accelerated. Such equipment can be mounted or trailed. In some cases, mineral fertilizer spreaders are used to add sand to the soil. In any case, we can talk about the high efficiency of the equipment used.

Some models are distinguished by high weight indicators and multifunctionality. Such spreaders are simply irreplaceable in agriculture.

Thanks to the spreaders, all mineral fertilizers are accurately dosed. Uniform distribution over the soil surface allows you to achieve a positive result when growing crops. The use of this type of equipment allows you to minimize the cost of purchasing the necessary mineral fertilizers.

Some spreaders are attached to the main agricultural transport using additional attachments. This technique helps enrich the soil with minerals in a scattered manner.

Advantages and disadvantages

Each type of agricultural machinery is designed to facilitate agricultural work, mine spreader. fertilizers are no exception. Before you start using it, you need to familiarize yourself with all the advantages and disadvantages.

Do-it-yourself auger snow blower for walk-behind tractor

The positive characteristics of the unit include:

Possibility of applying nutritional compositions over large areas.- Regardless of the spreader model used, fertilizer is supplied only while the vehicle is moving.

- Rapid movement of complementary feed substances to the main destination.

- There are universal units on sale that provide a function for controlling the amount of fertilizer. The user can always increase the concentration of nutrients where needed. This function is in demand among large landowners, as it saves money.

- The unit ensures quick and uniform distribution of nutritional components over the entire treated area.

Many farmers have discovered another possibility for using this technique - seed dispersal. The only drawback is that it is not cheap. If the farm is just developing, purchasing such a unit will be problematic. Because of this, the owner has to do everything manually.

Design and principle of operation

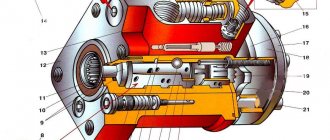

The mineral fertilizer spreader consists of a drive of working parts, a chassis system, a body part, a hydraulic system, a conveyor and a scattering device. The latter is presented in the form of two disks with blades that rotate in the same direction. These blades are additionally equipped with extensions. The option to change their overall length ensures a uniform supply of fertilizer to the discs.

Mounted

Mounted spreaders can be mounted on tractors of any power. Most often these are models equipped with an 80-horsepower or 100-horsepower engine. This spreader consists of a frame and an attachment. A hopper with two funnels is attached to the top. There are also two loading grids that prevent large particles from getting into the device. At the bottom there are two funnels necessary for distributing fertilizers.

Mounted units are distinguished by the presence of distribution discs, which can be replaced if necessary. During operation, fertilizer is uniformly supplied from the hopper to the distribution discs under the influence of the agitator shaft. The latter rotate in opposite directions. Subsequently, mineral fertilizers move along the grooved blades and are discharged outward due to the centrifugal force of inertia. Ultimately, they are evenly scattered on both sides of the machine and cover the strip being processed.

Photo of a mounted mineral fertilizer spreader

Trailed

Trailed type spreaders are shaped like a trailer. They are equipped with a hydraulic drive of the working parts. The body part of such a unit can accommodate up to 3.5 tons of fertilizers.

The conveyor here is a kind of chain of wavy-shaped rods. These elements are driven by the left running wheel of the unit through a rubber-coated pressure roller.

The dosing device is presented in the form of a sectional valve. A special grille is installed in its rear part, which allows the fertilizer to be distributed as evenly as possible. The amount of fertilizer applied is regulated thanks to the possibility of changing the position of the metering valve. This can also be influenced by the speed of movement of the feeding conveyor.

Photo of a trailed mineral fertilizer spreader

Types of spreaders

Experts are accustomed to classifying modern fertilizer spreaders according to several criteria. First of all, by the type of components added to the soil. The technique can be used for organic or mineral formulations. Even if a farmer decides to make a fertilizer spreader with his own hands, such a unit must be able to work with the following forms of materials:

- Granules.

- Dust-like fertilizers.

- Liquid solutions.

- Manure compositions.

All units differ in functionality. With their help you can grind, mix, and transport. Depending on the final method of fastening, such units are :

- Trailed. Attached to the tractor.

- Self-propelled. Fully automated, do not require connection to other installations.

- Manual. Suitable for small areas.

- Semi-trailer. They are universal, can work either independently or in combination with other machines.

- Mounted. Installed on powerful agricultural implements.

Garden vacuum cleaner with wind blower for cleaning leaves

Recently, more and more farmers have decided to make a mounted mineral fertilizer spreader with their own hands. Thanks to this, you can get a high-quality and durable unit, spending much less money.

Don’t forget about homemade manual spreaders, which are based on wheelbarrows or carts. Such a unit operates on a pneumatic, pendulum or centrifugal principle.

Pendulum units

The production of such systems occurs exclusively in foreign companies. Because of this, their popularity is at a rather low level. The main working unit is not represented by disks, but by a special swinging tube. To ensure that this part is of high quality and durable, it is made of the best quality plastic. The swinging of the tube is provided by reciprocating movements that come from the shaft.

Pendulum spreaders are inferior to disk models in terms of productivity. They produce a lot of noise and distribute fertilizer unevenly across the land.

Trailed systems

This category of units distributes fertilizers and seeds well even with minimal pressure. The equipment consists of a conveyor, a body, a drive mechanism and a dispenser. To control seeding, the user must change the speed of the conveyor and the width of the gap. Statistics show that trailed mineral fertilizer spreaders are considered the most common. Their appearance resembles a trailer. However, the accuracy of the distribution of introduced materials leaves much to be desired.

Mounted installations

Manufacturers claim that the power of such units is in no way inferior to a conventional tractor. The design is a special attachment with a frame and a spacious hopper. The spreaders are equipped with discharge grates that prevent large particles from entering the internal compartment of the unit. The lower part consists of special funnels that ensure uniform application of fertilizers.

Many landowners choose this model because it contains spreading discs. When they fail, they can be easily replaced. When the unit is actively used, previously loaded fertilizers fall onto the discs moving in the opposite direction. Thanks to this, the applied materials are distributed as evenly as possible.

Choosing electric snow blowers: electric snow blowers

Disc mechanisms

Such units have universal stainless steel blades, disks, and a driveshaft. The advantage is that the user can independently control the intensity of work from the tractor cabin using special dampers. Changing their position regulates the concentration of mineral or organic components. The presence of special mixers and safety nets eliminates the possibility of large particles getting into the inside of the installation.

Popular manufacturers

The modern market offers products from various manufacturers, including not only foreign companies, but also domestic companies. Equipment from Germany is very popular. Manufacturers there devote a lot of time to the quality of the product they offer, so the products can be used for a long period of time.

Models RUM-5, RUM-8 and RUM-16 are positioned as semi-trailer equipment for applying mineral fertilizers. RUM-8 is equipped with a towing device. The spreader has two axles with pneumatic wheels. The latter are distinguished by the presence of shoe brakes with pneumatic drive.

At the bottom of the body there is a chain-slat conveyor that supplies fertilizer through a metering valve. The RUM-16 model has a longer body length. In addition, in its front part there is a special saddle device.

| Characteristics | RUM-5 | RUM-8 | RUM-16 |

| Dimensions, mm: | |||

| - length | 5350 | 6000 | 1160 |

| - width | 2152 | 2465 | 2465 |

| - height | 2000 | 2300 | 2300 |

| Weight, kg | 2060 | 3220 | 3860 |

| Body volume, m3 | 5 | 8 | 16 |

| Load capacity, t | 5 | 11 | 20 |

| Operating speed, km/h | 14,8 | 15 | 15 |

| Productivity, t/h | 5,6 | 7,1 | 13 |

Photo of fertilizer spreader RUM-5

Amazon

Amazon fertilizer spreaders are a high quality German product. Characteristic features of such models include a double funnel-shaped hopper, as well as a special device for accurately setting the required amount of fertilizer. The output dampers are controlled by two double-acting hydraulic cylinders.

The presence of a special loading grid prevents foreign bodies from entering the mechanism. Such attachments allow you to speed up the work process and achieve a positive result in the shortest possible time.

| Characteristics | ZG-B 5500 | ZG-B 8200 | ZA-M 900 |

| Weight, kg | 2709 | 2809 | 275 |

| Hopper capacity, l | 5500 | 8200 | 900 |

| Application rate, kg/ha | 20-5000 | 200-8000 | 10-4000 |

| Working width, m | 18-24 | 18-24 | 10-36 |

| Productivity, ha/h | 45 | 45 | 20 |

| Required tractor power, hp | 80-100 | 100-120 | 50 |

Photo of Amazone mounted fertilizer spreader

Biardzki

Another mounted mineral fertilizer spreader. Such equipment is manufactured in Poland. At the same time, the products meet all necessary quality standards. In most cases, spreaders of this brand are used for surface application of mineral fertilizers in granular form. Sometimes this technique is used during sowing of grain crops. If necessary, the machine can be loaded even in the field.

| Characteristics | MVU-5 | RNZ-500 |

| Dimensions, mm | ||

| - length | 2350 | 1250 |

| - width | 2125 | 1250 |

| - height | 2000 | 1200 |

| Weight, kg | 2060 | 1100 |

| Operating speed, km/h | 15 | 15 |

| Fertilizer dose range, kg/ha | 100-10000 | 20-1000 |

| Load capacity, t | 5 | 0,5 |

This product comes from Germany. The built-in innovative spreading system not only ensures precise dosing of fertilizers, but also ensures uniform nutrition of crops. Depending on the characteristics of a particular model, the working width of sowing may vary.

Considering that all mineral elements have a rather aggressive effect on the metal elements of equipment, the manufacturers decided to use high-quality stainless steel when creating the unit.

| Characteristics | MDS-935 | MDS-19.1 K |

| Dimensions, mm: | ||

| - length | 5000 | 2350 |

| - width | 2100 | 2152 |

| - height | 2000 | 2000 |

| Weight, kg | 240 | 230 |

| Operating speed, km/h | 18,3 | 15 |

| Load capacity, t | 800 | 500 |

| Productivity, h/ha | 32,96 | 27,64 |

Trailed mineral fertilizer spreader Rauch

Bobruiskagromash

Bobruiskagromash products are intended for transportation and surface application of solid mineral fertilizers and chemical ameliorants. Some models are equipped with a feed conveyor drive. This design feature ensures synchronization of the supply of the working product.

Of the entire existing model line, the RU-7000 spreader is very popular. Such a unit has manual adjustment for a specific type of work product. In addition, the operator is given the opportunity to dose the selected fertilizer as easily as possible.

| Characteristics | MZHT-10 | Ru-7000 | MVU-1200 |

| Dimensions, mm: | |||

| - length | 2350 | 6300 | 2600 |

| - width | 2152 | 2800 | 2465 |

| - height | 1100 | 2700 | 1300 |

| Weight, kg | 260 | 5 | 230 |

| Body volume, m3 | 5 | 8 | 5 |

| Load capacity, t | 0,7 | 8 | 1,2 |

| Operating speed, km/h | 15 | 12 | 15 |

Mineral fertilizer spreader RU-7000

Belarus

Such spreaders are also manufactured in Belarus. The L-116 model, which has a mounted design, deserves special attention. Such equipment can be used with tractors of any power. Many models are equipped with wide-profile wheels with a large radius. As a result, the pressure on the ground is significantly reduced. Mineral fertilizer spreaders have special blades that prevent granules from crumbling.

| Characteristics | RMU-8000 | L-116 | RU-3000 |

| Dimensions, mm: | |||

| - length | 6800 | 2320 | 2600 |

| - width | 2400 | 1665 | 2465 |

| - height | 3000 | 1300 | 2300 |

| Weight, kg | 3470 | 3220 | 3860 |

| Load capacity, t | 5 | 10 | 12 |

| Operating speed, km/h | 8-20 | 15 | 15 |

| Productivity, t/h | 5,6 | 8-16 | 25 |

Functionality

Most often, the spreader is filled with those mineral fertilizers that belong to the salts of chemical elements - sodium, potassium, phosphorus. They penetrate the soil as deeply as possible over the entire treated surface. Before starting work, you need to pay attention to the external condition of the equipment. If necessary, you need to replace faulty parts, tighten fasteners, and treat all rubbing mechanisms with special oil.

The operating principle of the spreader is as follows:

- The necessary nutrient materials with a high level of humidity, with the size of individual fractions not exceeding 7 mm, are poured into the bunker. If the agronomist decides to use larger fractions, this is fraught with arching. Important mechanisms of the unit may stick, which will disrupt the entire work process. Loading is done using a tractor or truck loader.

- Sieve. This is a durable mesh that is installed in the bunker itself. Its main task is to prevent the entry of large particles of fertilizer and foreign objects.

- Fertilizers. All mineral and organic components reach the diffuser thanks to the shutters. It is he who is responsible for ensuring that nutrients enter the soil in a fan-shaped manner.

- Multifunctional drive of working parts. The operation of this system depends on the power take-off shaft. The frame houses the fasteners for all assembly elements of the spreader. The frame itself is represented by a powerful tubular structure. A special attachment, which is fixed with bolts, helps to increase the volume of the bunker.

How to choose a good variety of cucumbers for a polycarbonate greenhouse

The drive of the unit is presented in the form of a single-stage bevel gearbox and a telescopic cardan shaft. The presence of universal dampers helps the farmer control the intensity of work. The main control mechanism for the mounted spreader is located under the bottom of the hopper. The main emphasis is on the movable damper, the rod and the lever attached to it. Using this technique, you can fertilize not only fields, but also gardens and pastures. Thanks to this, farmers have an excellent opportunity to feed row crops and winter crops.

When the inspection of the equipment is completed, you can set the fertilizer supply rate. To do this, fill the hopper with the necessary mineral or organic components in the required dosage. It all depends on the established standards of concentration and path length.