Peculiarities

When choosing this element, the soil to be cultivated plays an important role. Thus, a chain gearbox, like a worm gearbox, performs well on light soil - black soil and sandstone.

If the site is composed of heavy loams, especially full-fledged clay, it is recommended to choose between chain and gear devices.

The worm version is suitable only for lightweight and especially light cultivators that will cultivate well-groomed plots of up to 6-8 acres. This method of energy transfer occurs due to the coupling of the screw with a wheel covered with teeth of a special profile. When the worm (as the screw is called) rotates, the thread moves along its axis. The teeth are pushed in the same direction at the same time. The main part of the wheel spins, and the cutters also receive an impulse from it.

The main properties of this design are:

- smooth movement of the cultivator;

- faint noise;

- cost savings;

- low efficiency;

- excessive heating and powerful waste of oil;

- small resource;

- inability to use reverse mode and add attachments.

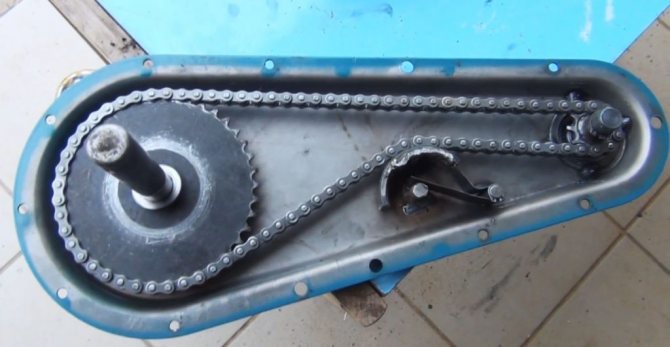

Most of the latest model cultivators use chain gearboxes. Simplicity is considered their important advantage. There is only a chain and a pair of sprockets: one at the bottom (mounted on the shaft), and the other at the top.

It is worth remembering that chain gear units can be non-separable; they are used if areas of no more than 15 acres are to be processed. In this case, the device’s lifespan may exceed 10 years.

Even experts cannot name the obvious disadvantages of a chain gearbox. But its advantages are obvious:

- minimal energy loss between the motor and cutters;

- affordable price;

- relatively narrow body;

- simple maintenance;

- the ability to reverse.

If reliability comes first, you should give preference to a gear design.

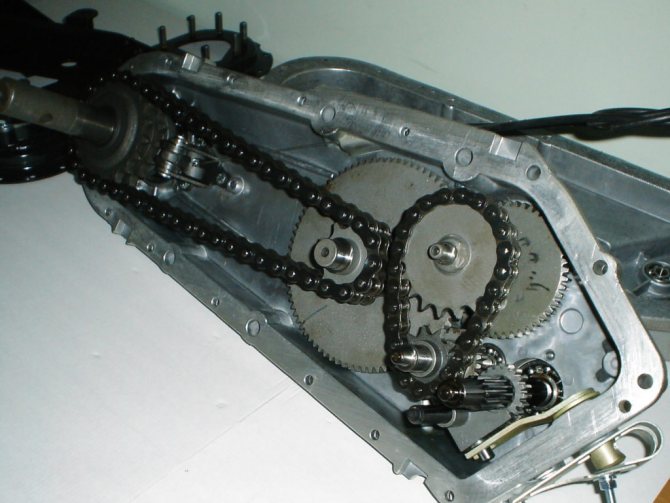

In most cases, it contains 3 to 5 gears in a closed but disassemblable housing. Such devices perform very well in heavy-duty cultivators. They are even used in walk-behind tractors designed to cultivate land with an area of over 25 acres. But it is important to understand that the cost of gear reducers is very high.

How to disassemble?

The gearbox must be lubricated as thoroughly as possible. Even noise can be eliminated if the deficiency of lubricants is replenished. But you should be as careful as possible when choosing a suitable brand of lubricant; the use of contaminated compounds is unacceptable.

It is worth considering that extraneous sounds are often associated with poor tightening of fasteners, wear of bearings and gears. To disassemble the gearbox, you need to:

- remove it;

- unscrew the screws;

- remove the protective caps;

- pull out the output shaft bushing;

- disconnect the lever and then the plug;

- remove the input shaft (in close connection with the gears);

- remove the shaft and chain bushings;

- dismantle the shaft and sprocket block;

- remove the intermediate shaft and gears;

- remove the coupling and axle shafts (assembly is carried out in the reverse order).

Gearbox lubricant.

I purchased a Pubert ELITE 55 HC 2 cultivator, the instructions do not say anything about lubrication of the chain and reverse gearbox. Good people, tell me what type (brand) of lubricant is used for these components.

Shihan wrote: I purchased a Pubert ELITE 55 HC 2 cultivator, the instructions do not say anything about lubrication of the chain and reverse gearbox. Good people, tell me what type (brand) of lubricant is used for these components.

On the website » > it is written that you need to use a special engine for the Pubert transmission, apparently any GL5 class will do.

2Misha_30, in my case (motor cultivator), grease is used to lubricate the gearbox. That's what interests me about its name.

Shihan wrote: 2Misha_30, in my case (motor cultivator), grease is used to lubricate the gearbox. That's the name that interests me

Are you sure? From the picture, it seemed to me that the gearbox is a chain gear, not a worm. If it’s grease, then you can look at Mantis, Husqvarna for brush cutters, the price is up to 250 rubles for 100-150g.

Yes, definitely a chain one, it says on the page.

Misha_30 wrote: Yes, definitely a chain one, it’s written on the page.

But why is it lubricated with grease? Here it is" >

Misha_30 wrote: But why is it lubricated with grease?

This is to the manufacturer. But some gearboxes (chain) are powered by a transmission.

Do you have shovels or vertical motorized equipment? And you don't serve her. Does everyone really pay 250 rubles for a hundred grams of I don’t know what, but branded? Which is probably packaged around the nearest corner from a barrel of Litol.

Shihan wrote: Do you have shovels or vertical motorized equipment? And you don't serve her. Does everyone really pay 250 rubles for a hundred grams of I don’t know what, but branded? Which is probably packaged around the nearest corner from a barrel of Litol.

I have living, working motorcycle equipment

, I didn’t buy lubricant for 250 rubles, although sellers everywhere not only advise, but simply push branded lubricant. When I opened the gearbox of the Mantis cultivator and looked at what was there, I decided not to add anything - it was not required. But the lubricant is completely different from Litol, it is “greasy” in color and quite thick. But I constantly add Litol to my lawn mower. Nothing, the flight is normal, according to those. documentation, branded lubricant up to 200 C supposedly.

2Misha_30, I looked at a substitute for branded lubricant from a similar motor cultivator, and so it turned out to be Litol-24. In general, I will smear it with it. The topic can probably be closed.

Lubricant for angle grinder gearbox

Almost all of the world's tool manufacturers require a recommended "proprietary" oil, sold under its brand name. In principle this is correct. The oil used for grinding grinding machines is in this case tested at the factory, it guarantees long-term and correct operation of angle grinders. However, there are also disadvantages, which include the high price of oil of these brands.

Lubricant for open gearbox angle grinders

In addition to original oils, there are many lubricants on the market that are produced by third-party manufacturers, so the question of what exactly to lubricate a grinder on a grinder is not an acute one.

Russian manufacturers also keep up with foreign ones and offer their products. Thus, the lubrication of a bevel gear angle grinder from Nanotech is very popular. Of course, this gear oil is not original and is not recommended by the manufacturer, so if used in subsequent warranty repairs, you can simply refuse.

READ Stihl Lawnmower Gear Lubricant

Changing the oil in a walk-behind tractor: what and how much to fill in the gearbox

by the presence of a walk-behind tractor in a private household, because this technical device has been known since Soviet times. Thanks to him, it became possible to quickly and efficiently cultivate the soil , which previously took quite a long time and also took a lot of effort.

However, in order for your walk-behind tractor, as they say, to serve you faithfully, regularly plowing the ground and performing its other functions, you need to operate it correctly.

In particular, you need to know how much oil to pour into the gearbox of a walk-behind tractor so that it works in optimal mode, and its parts do not wear out due to the lack of necessary lubrication.

In principle, all the necessary information, as a rule, is indicated in the operating instructions for a specific walk-behind tractor model, where the brands and grades of recommended oils are directly indicated.

However, there are cases when a walk-behind tractor is purchased by hand or in another way, but the point is that such walk-behind tractors are supplied, basically, without any instructions.

A person may be at a loss, not knowing what kind of oil is poured into the gearbox of a walk-behind tractor, so it will be useful for him to know about its main types, as well as how to fill it into a walk-behind tractor.

Changing the Oil in the Gearbox of the Plowman Motoblock

Many new owners of walk-behind tractors are interested in issues related to the use of oils for agricultural machinery. It is necessary to consider which compositions are suitable for lubricating certain devices of the walk-behind tractor, and how to use them for smooth operation and extending the life of the unit.

The working life of the engine of an agricultural implement depends not only on the properties of its devices and assembly, but also how accurately and how often you will have to change the engine oil. By following the manufacturer's advice, you can easily extend the life of the unit and protect it from normal breakdowns.

To change the lubricant in the walk-behind tractor, you must first warm up the unit’s motor. To change the oil in a walk-behind tractor engine, you must proceed in the following order:

- First install the unit in a horizontal position. The holes for filling and draining oil are always located on the left side of the walk-behind tractor engine. The remaining oil inside the engine must be drained through the drain hole, which is closed with a conical threaded plug. If the plug is very tightly screwed in, you can unscrew it with a long screwdriver;

- Place a wide container with a volume of more than two 2 liters under the drain hole and slowly unscrew the plug. Having completely removed it, wait 10 minutes until the lubricant is completely combined with the motor of the walk-behind tractor;

- Then tighten the drain plug and start filling in new engine oil. It is best if you choose 10W40 oil on a synthetic or mineral base as a new composition. Its volume is equal to the amount of previously drained oil.

The lubricant in the walk-behind tractor engine should be changed at least once every 25–30 hours of operation. If you rarely use the unit, and the full range of work takes you approximately the same amount of time, then there is an option to change the oil once a year. In this case, remember that if you do not have time to work 30 hours per season, then the oil must be changed in any case, because during the entire time the walk-behind tractor is idle, the characteristics of the composition deteriorate noticeably.

If you have just received a walk-behind tractor, then you need to change the lubricant in its motor within the first 5 hours of operation of the unit. It exists that after assembling new walk-behind tractors, small debris remaining inside the motor gets into the oil, which leads to jamming of the motor and minor breakdowns. In order for the engine of the new unit to be one hundred percent clean, the oil here will need to be changed three more times - Twice after 5 hours of operation, and the third time after 10 hours.

READ Centrifugal Clutch For Motoblock Engine

myth is a very pressing issue, especially among beginning farmers. Most people use motor oil, believing that there is absolutely no difference between it and the composition for pouring into a walk-behind tractor engine.

Really using car oil is a big mistake. What exists, that such a tool does not have the features that are necessary for the proper operation of a walk-behind tractor. The result of this is accelerated wear of the cylinders and piston group of the engine, which leads to breakdown of the walk-behind tractor and the need to replace its engine.

To prevent this, you should use special motor oil for a walk-behind tractor, the composition of which fully meets the requirements of an agricultural machine. To fill the engine, of course, use 2-stroke or 4-stroke oil - it all depends on the type of motor of the walk-behind tractor.

The manufacturer of the lubricant is also of great importance - formulations from the favorite brands have proven themselves to be the most ideal: Shell, Mobile, Castrol and Liqui Moly - they work equally well in engines manufactured by Briggs & Stratton, Subaru and other recognizable companies. The third important factor is the seasonality of the motor oil - this property determines at what temperatures the composition loses its most important characteristics. In order not to make a mistake, we recommend choosing an all-season type of oil for a walk-behind tractor - it does not lose its features at temperatures in the range from 25 to 40 °C.

Oils are poured into the walk-behind tractor. Changing the oil in the walk-behind tractor.

To find out whether it is necessary to dilute gasoline for a walk-behind tractor, you need to study the instructions for its operation. It indicates what type of engine the unit is equipped with - 2-stroke or 4-stroke.

If the walk-behind tractor is equipped with a 2-stroke engine, then its fuel mixture certainly consists of gasoline and oil. During the production of the consistency, observe the exact proportion indicated by the manufacturer in the instruction manual. Moreover, the fuel for a walk-behind tractor with a 4-stroke engine does not need to be mixed with oil, because what remains for our client to do is that 4 strokes of such engines run on pure fuel.

It should be kept in mind that walk-behind tractors on which diesel is poured also do not need to produce a fuel mixture. There is something that remains to be done for our client: diesel engines are 4-stroke engines and run on clean fuel.

When choosing engine oil for a diesel walk-behind tractor, you should follow the instructions in the instruction manual. But if the application control has been lost, then you will have to study the compositions available in the current market segment more closely.

READ What kind of oil to pour into Tarpan walk-behind tractor

Motor oils for diesel engines are classified into the following categories. The special markings indicated on the container with lubricant will help you find the type and compliance of the composition for a particular walk-behind tractor:

- API CJ-4 - compositions with this marking are designed specifically for walk-behind tractors with a capacity of 10 hp or more. With. and not easy. The composition of these lubricants has an increased viscosity, which guarantees the proper operation of all parts of the unit’s motor;

- API CI-4 - these oils should be used for engines equipped with various types of injection and supercharging. Such oils have good dispersing properties and the highest resistance to thermal oxidation;

- API CH-4 - lubricants with this marking fully comply with all modern requirements and performance standards. Among the advantages of these compositions, one should highlight the ability to fill them into diesel engines running on fuel, where the sulfur percentage exceeds 0.5%;

- API CA - compositions of this type are normally suitable if the diesel fuel contains a small amount of sulfur. Oils with this marking protect the walk-behind tractor engine from the formation of harmful deposits on its walls;

- API CB - the use of oils of this oil reduces the risk of corrosion of walk-behind tractor bearings;

- API CC - such oils will be a good option for an engine equipped with a turbocharger, but without a supercharger. These compounds help walk-behind tractors withstand long loads and work properly in difficult conditions;

- API CF-2 - oils of this group demonstrate excellent performance when used in walk-behind tractors that are subject to heavy loads.

Changing the gearbox seal of the weima 1050 walk-behind tractor (clone of the Russian winner).

After purchasing a suitable motor oil, of course proceed to pouring it into the motor of the walk-behind tractor. The procedure for all this is quite simple:

- Install the unit horizontally at first;

- Place a wide container under the drain hole in the engine and remove the plug by carefully prying it off with a screwdriver;

- Wait until the old oil drains from the engine and screw the plug back into the hole;

- Fill more than 4 liters inside the engine. new lubricant composition.

Remember that the oil in new walk-behind tractors should be changed three times at intervals of 5 hours of moderate use. After which it is necessary to create a shift no more than once per 25 hours of operation of the walk-behind tractor.

A gearbox is a fundamental element of a walk-behind tractor, the function of which is to transmit torque from the motor to the wheels of the unit using a V-belt drive. Gearbox parts are subject to increased wear, which is why they require constant lubrication. Let us immediately make a reservation that not many of the means available in the field are suitable for this purpose.

READ Supplying Oil to a Chainsaw Chain

The best option for lubricating the gearbox is gear oil. This type of composition is beneficial for lubricating moving parts. The second fundamental question is how much lubricant needs to be poured into the gearbox. To find out, you will need to perform a number of specific actions:

- Carefully place the walk-behind tractor so that its wings are parallel to the surface;

- Take a wire two or more than 70 cm long and bend one of its sides into an arc;

- Insert the wire through the filler hole completely, then pull it back.

Next, look at the wire. If its wet side is 30 cm, it means there is no need to add oil to the gearbox. If the lubricant level is lower, it means that you will need to add as much oil as required to reach the 30 cm mark on the wire. It is necessary to fill the lubricating fluid into the gearbox in the following order:

Changing the cultivator oil

- Place the walk-behind tractor on stands;

- Under the walk-behind tractor at the bottom of the gearbox you will find a drain plug. Place a wide container under it and slowly begin to unscrew the lid;

- Wait 10 minutes, during which the oil will flow out of the gearbox; our client will be left with oil;

- Screw the drain cap all the way, unscrew the filler plug and place a funnel there;

- Fill the gearbox with approximately 2.4 liters of transmission oil;

- Check the level of the composition if there is a wire - if there is less than 30 cm of wire in the oil, then add a little more material.

As a rule, it is necessary to change the lubricant in the gearbox of a walk-behind tractor no less than once every 100 hours of operation of the unit. With all this, the frequency of changes may differ based on the advice of the walk-behind tractor manufacturer. If you use your agricultural machine for more than 4 hours during the day, this means that you need to change the composition once every 50 hours of operation of the walk-behind tractor.

When choosing gear oil for yourself, the first thing to find out is the advice of the walk-behind tractor manufacturer. Any of the brands involved in the creation of agricultural machinery uses mechanisms of different designs. Accordingly, the latter require oils of different composition. To avoid mistakes when choosing gear oil, we recommend studying the table, which contains advice from more global brands of walk-behind tractors.

Source

Device

The gearbox is a special device included in the design of any walk-behind tractor. It is this part that is responsible for converting and transmitting torque that is generated from mechanical transmissions. In fact, the gearbox powers the walk-behind tractor, making it work.

The service life of the entire walk-behind tractor, as well as its normal functioning, will depend on its quality, as well as on the correct lubrication of its components.

For more details about the gearbox, watch the video:

Depending on the model of the walk-behind tractor, be it Cayman, Patriot Ural, Patriot, Texas, Foreman or some other, the gearboxes may differ from each other in some design features. Conventionally, gearboxes can be divided into several types:

- Angular reducers. Such units are quite effective and allow you to couple the engine and transmission.

- Gear reducers. In this case, the gearbox transmission acts as a kind of intermediary between the engine and the wheelbase of the walk-behind tractor.

- Reduction gearboxes. These units achieve an increase in power indicators by reducing the total number of revolutions. Such gearboxes are most preferable because their design includes an air cooling system, which allows them to operate at maximum loads.

- Reverse gearboxes. The main advantage of such gearboxes is the ability to reverse the walk-behind tractor. However, units equipped with this type of gearbox do not show high performance indicators and speeds.

Regardless of which gearbox is used in the design of the walk-behind tractor, they all consist of almost the same components:

- shaft;

- gear housing;

- flange and its fastening;

- pulley with V-belt drive (or chain);

- ball bearing;

- stars;

- drain plug;

- steel washer and nut;

- input shaft

These components traditionally form the gearbox itself. and service life will depend on how well they are

Checking the correct application of lubricant to the angle grinder gearbox

The last step when servicing angle grinders. Checking the correct application and distribution of oil inside the gearbox. To do this, after assembling the gearbox, turn on the power tool without load for a few minutes, making sure that there are no extraneous sounds, smells or other things. If they occur, immediately unplug the coffee grinder. The gearbox heating is also checked. The oil should distribute heat evenly and the gearbox temperature should not be too high.

READ What kind of oil is poured into the gearbox of a walk-behind tractor?

After a short operation, unscrew the 4 screws, then remove the gearbox cover. Visually inspect the helical gears for lubrication. If it is missing, it means too little oil was added and should be reported. If during the work it is squeezed out of the cracks, then too much of it is laid, and the excess must be removed. After making changes, they check the mill again without load.

What kind of oil is poured?

Many people are interested in what kind of oil to pour into the gearbox of a walk-behind tractor? To answer this question, you need to take into account several factors, the main one of which is the manufacturer's recommendation regarding the type of oil.

You also need to be guided by price, without buying very cheap liquids, because they are unlikely to be of adequate quality.

No matter how reliable the original tracks of a snowmobile are, sooner or later during active use of the machine there is a need to replace them. Here is everything about snowmobile tracks from the Composite company.

A garden sprayer is an indispensable assistant in pest control. By clicking on the link you can get acquainted with the gasoline backpack garden sprayer.

MAZ-5337 appeared in the second half of the eighties of the last century. MAZ-5337 is a versatile, powerful and very reliable truck.

In the store you should also pay attention to the degree of viscosity of the oil, which is indicated on the packaging. In addition, there are special additives - substances that increase the beneficial properties of the lubricant.

In general, oils can be of various types:

- SAE. These types of oils cope very well with sudden temperature changes, so they can be used all year round.

- The selection process is as follows: you need to look at the number in front of the letter W - a lower value will indicate that the oil is very well adapted to low temperatures (the smallest is 0W). If the letter W is not on the label, then this oil is suitable for the summer period.

- API. In this case, the letters in the marking will indicate the type of engine - gasoline or diesel. Accordingly, a certain letter will indicate that the oil is suitable for gasoline units, and another – for diesel units.

- The numbers will indicate the type of engine , i.e. number 4 means the oil should be used for a 4-stroke engine, etc. The EC value is the degree of energy conservation, i.e. The higher the value, the better the quality of the oil.

- ASEA. The highest number in the labeling will indicate that the oil can function in very difficult conditions.

- GOST 17479, 1-85 . These indicators characterize the degree of viscosity of the oil. As a rule, alphabetic and numerical values are written after this parameter, and their absence indicates that the oil is universal.

Transmission oils for filling into gasoline and diesel walk-behind tractors

As for the gearbox, transmission oils must be used to fill it. For example, a good choice would be semi-synthetic oil ZIC 10W40, intended for gasoline and diesel walk-behind tractors. API indicator – SM/CF, ACEA – A3/B3, A3/B4, C3.

It is usually sold in 4-liter containers, the cost of which is in the range of 890-950 rubles.

Another decent oil is Super T-3 85W-90 from Gazpromneft. Its technical data will be as follows:

- API indicator – GL-5;

- viscosity degree – 85W90;

- temperature indicator of loss of fluidity – -280C;

- flash point – 2170C;

- package length – 270 mm;

- packaging width – 130 mm;

- packaging height – 240 mm.

This gear oil is also supplied in 4-liter containers, the cost of which is approximately 600 rubles.

This is not the entire list of oils that can be poured into the gearbox of a walk-behind tractor. In principle, anyone who has become familiar with the basic parameters of the oil can independently determine what is needed for their walk-behind tractor.

What kind of oil to pour into a worm gearbox

When choosing the oils that best suit your gearbox, at least 2 factors are taken into account:

- Ambient temperature where the drive is operated;

Operating mode of the unit.

Considering the temperature regime, in the coldest climates, preference should be given to synthetic materials. Among these, the website “site” sells products of the following type: CA 2-100 and CA 2-100 Spray, which are resistant to sudden drops in temperature and aging; having universal application in gearboxes CA 2 series and others, manufactured by Kluberbio. At higher temperatures, oils based on mineral bases, such as the GEM line with modifications 1-46...680 N, which are resistant to any load, including wear and exposure to a humid environment, are better suited. All lubricants we offer have passed the necessary tests and meet special requirements for a number of properties and safety levels. Also, the choice according to operating conditions is important, where you should pay attention to the load criterion before scuffing appears (at least 10-12, etc.).

How much to fill?

Another important point is the amount of oil needed. Before answering the question - how much oil should be poured into the gearbox of a walk-behind tractor, for example Crosser, Viking, Forza, Sadko, Don, Huter, Profi, Plowman, Champion, Carver, you must first check the oil level in the gearbox. To do this, you need to perform certain actions:

- It is necessary to place the walk-behind tractor on a flat surface so that its wings are strictly parallel to this surface.

- We take a wire or rod about 70 cm long, which will act as an oil dipstick.

- We bend the improvised probe into an arc.

- We insert the resulting dipstick into the filler hole to the very end, i.e. all the way. After that we pull it back out.

If the wire is 30 cm deep in oil, then this is the optimal indicator, i.e. no need to add oil. If it is a little less, then it is necessary to top up within these values.

If the gearbox is completely dry, then you will need at least two liters of gear oil.

How to check the oil in the gearbox of a walk-behind tractor?

Monitor the amount of oil constantly. Otherwise, careless attitude to technology will lead to fatal consequences. Fresh oil is added every 50 hours. Along with this, excessive loads should be avoided, which ultimately lead to the rapid deterioration of mechanisms and components. Let's move on directly to changing the oil:

- We install the equipment on a flat area. We find a probe 70 cm long.

- The dipstick is bent and pushed into the oil fill hole until it stops, after which we remove the rod.

- We observe the oil level, which should be at least 25 cm. Add 2 liters of oil to the dry gearbox, at least 1.5 liters.

How to fill oil into a walk-behind tractor gearbox

Before pouring new oil into the gearbox, you need to drain the old fluid . This is exactly how the oil is changed in the gearbox of the Salyut walk-behind tractor, a video of which can be found on the Internet, as well as other models of walk-behind tractors.

The algorithm of actions will be as follows:

- The walk-behind tractor needs to be installed on some hill so that the oil can be easily drained from the gearbox.

- There are two plugs on the gearbox - a drain plug, which is located at the bottom of the gearbox, and a plug that closes the oil filling hole. First, unscrew the filler plug, which is located on top of the walk-behind tractor body (at the gearbox).

- We take a sufficiently capacious container (an old bottle of transmission oil will do), and then place it under the gearbox drain plug.

- Carefully unscrew the drain plug , after which the oil will begin to flow into our container. After waiting until the oil has completely drained, screw the drain plug back in. Then tighten it with a spanner of a suitable diameter until it stops.

- Insert the funnel into the filling hole. Then we take the appropriate gear oil to fill the gearbox.

- Having filled the reducer to the optimal level, screw the plug back. This plug is equipped with a special dipstick, and its length is approximately 10 cm. After we have filled in the oil, we need to check its level. To do this, we tighten this plug-dipstick, after which we unscrew it again and check it.

- If the oil is at the tip of this dipstick, then there is no need to add any more .

As a rule, the oil change procedure must be performed every 100 hours of operation of the walk-behind tractor. In some cases, this procedure must be performed every 50 hours.

Frequency of oil change in gearbox

A fairly common question is how often and why to change the oil in the gearbox. Most experts recommend replacement in accordance with the spent resource. For automatic transmissions this figure is 30 thousand kilometers, for manual transmissions the figure is 50 thousand kilometers.

Replacement is carried out for the following reasons:

- Over time, due to overheating and other influences, the basic properties of the oil deteriorate. An example is a decrease in lubricating properties and many other points. This is why the device will not last for a long time.

- Natural wear and tear of metal products causes the composition to contain a large amount of metal shavings. It causes intense heat due to the resulting friction.

- Deterioration of the basic properties of the worm gear lubrication causes overheating and increased wear of the main elements.

- Over time, the amount of lubricant decreases naturally. At the same time, manufacturers do not recommend mixing waste with new, as this will only reduce the main performance characteristics.

The use of worm gearboxes is typical for machines that have special requirements for the parameters of sudden changes in speed and noiselessness of the drive. But in order to significantly prevent the decrease in efficiency that is typical for such gears, the use of special lubricants is recommended. High-quality oil for worm gearboxes allows you to protect the gearbox from such losses, which can sometimes amount to up to 42% (more relevant for systems with a high gear ratio). The need to choose such an oil is also justified by the following needs:

- Reducing the heat received from a large amount of kinetic energy at the moment of conversion;

Preventing wear of parts during self-braking;

Improved power transmission;

Increasing the service life of the worm gearbox;

Wear protection from frequent load changes.

To achieve all the parameters, there is a need to select the most suitable lubricant composition, which will reduce the level of wear, especially at high operating rates typical for modern equipment produced in 2014-2016.

Chain gear: device and principle of operation

The chain gearbox is one of the most popular types for use in walk-behind tractors. How to make it yourself, and what criteria are used to calculate it.

The gearbox is an integral part of walk-behind tractors, cultivators and other garden equipment. This is a complex mechanism that is a transmission link that is located between the rotation devices of an electric motor or internal combustion engine to the final operating unit. Among the main indicators that a chain gearbox has are:

- Transmitted power;

- Efficiency;

- Number of driving and driven rotation shafts.

Gear drives are attached to the rotating devices, which transmit, lower and regulate the movement of the chain conveyor drive.

Peculiarities

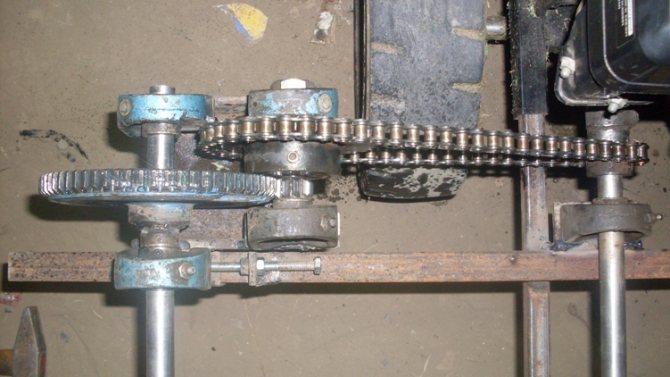

Chain gearboxes can be different, but mostly they are dismountable, that is, they have a bolted connection. This makes it possible to carry out easy visual diagnostics, identify any deviations in gears and chains in a timely manner, and the lubricant will be conveniently applied to the mechanism.

The main advantages of chain gearboxes include:

- Availability of reverse function;

- Simple operation;

- High level of conveyor reliability.

The most common failures of chain gearboxes are associated with chain rupture or stretching. These faults are very easy to fix even by people who do not have special technical skills. This is a big plus, since repairing a chain gearbox does not require contacting a specialist.

The gearbox has a fairly simple structure. Among its components, we can note a chain and two sprockets, upper and lower. The lower sprocket is located on the working shaft, due to which the mechanism operates, in which lubricant is used to reduce its wear. A manual chain reducer works on the same principle. The existing gear ratio on the stars allows you to increase the force on the cutters. This version has a thin body, as this ensures maximum penetration of the cutters. The housing is equipped with holes with bearings, and the shafts are located on them. Below we will describe the process of how to assemble a chain gear yourself and carry out calculations.

Preparatory work

To make a homemade gear-chain reducer, the following tools and materials are required, and in particular the presence of:

- Sprockets, with a thoughtful number of teeth, in order to provide the desired gear ratio;

- driven shaft;

- Bearings of the required size to install the drive and driven shafts;

- Chains of the right size;

- Metal corners to secure the crankcase;

- Carter.

Before starting the manufacturing process, you need to make a certain calculation, which will indicate the assessment:

- Gear ratio;

- Gearbox type;

- The magnitude of the load on the shafts;

- Overall dimensions of transmission mechanisms, which will depend on the selected type of gearbox.

When the calculation is completed, you can begin assembly.

Build process

It will be better to start making a homemade gearbox by installing the drive sprocket of the first stage of the gearbox on the output shaft. The star can be attached in different ways, in each design individually. Can be fixed with a key, flange, or spot welding. The driven shaft is assembled using 2 axle shafts. Their ends require counter flanges. Between the flanges, you need to install the 2nd stage driven sprocket in its place, after which you can assemble the axle shafts into a whole structure using a bolt connection.

To organize the protection of the chain transmission, the 2nd stage gear unit is protected with a protective housing. In addition to its protective function, it serves as a reservoir in which the liquid is located. It is capable of ensuring smooth operation and helping to reduce wear of parts due to friction.

The housing must have coaxial mounting slots where bearings are installed, which serve as shaft support. To install the driven shaft, conventional ball bearings having a cylindrical housing are required.

Due to the design feature, the eccentric is able to change its location by an angle in the socket, up to 15°. Along with it, the location of the drive gear shaft also changes, which allows you to adjust the amount of chain tension.

When the mechanism operates, the calculation is that the teeth of the 2nd stage driven sprocket are immersed in the oil in the container to form a lubricant. Due to rotation, the lubricant is evenly distributed over all chain transmission units.

You can create a seal around the casing. To do this, it is necessary to install standard sealing gaskets and seals on the bearing seats and on the housing split line. They can be selected without much difficulty, because all sizes in the design have standards.

In order for a self-made gearbox to have a sealed housing, you will have to put in more effort. When non-standard products or outdated types of shells are used, it will be more difficult to find seals on them. For these purposes, you can use special oil-resistant sealants.