Ways to increase speed on a walk-behind tractor

Many farmers are interested in how to increase the speed of a walk-behind tractor. The most common agricultural machinery is a walk-behind tractor. With its help, work on land and personal plots is greatly simplified. Let's look at how you can increase the speed of this technique. With increased speed, the performance and maneuverability of the mini-machine will increase, which can be used in any season and weather.

How to increase the speed of a walk-behind tractor

You can increase the speed of the walk-behind tractor in two ways:

- installation of large wheels;

- replacing a gear pair.

Let's first look at how changing wheels helps increase the speed of a motor cultivator. The standard wheel size of almost all mini-unit models is 57 cm. When replacing, you can install tires 1.2 times larger in diameter. Typically, wheels of 70.4 cm are used. Despite the small difference, the speed of the walk-behind tractor increases noticeably. If the arches into which the tires are inserted allow you to insert wheels with a larger diameter, then you can try adding centimeters.

When using a walk-behind tractor for cultivating land, lugs are used. These are wheels with iron plates that freely grip the ground or snow. They can be purchased in specialized stores, or you can make them yourself. Their size also affects the speed of movement of the unit.

Let's look at how to increase the speed on a walk-behind tractor using the second method. Like any equipment, the cultivator has several speeds, which are controlled using gears. Typically, cultivators move at a speed of 2 to 15 km/h, with the large gear having 61 teeth and the small gear having 12. To increase the speed, the gear pairs of the gearbox are replaced. We increase the number of teeth, thus achieving the maximum speed of the walk-behind tractor.

It is recommended that replacement be carried out by professionals and preferably in specialized centers, since parts machined with minimal error will affect the operation of the motor. It is important not only to replace the gear, but also to select the correct pulley.

How to make reverse gear on a walk-behind tractor

Let's look at how to make reverse gear on a walk-behind tractor. The presence of reverse depends on the model and dimensions of the mini-equipment. You can cultivate the land with a motor-cultivator, a light walk-behind tractor and a heavy unit. It all depends on your goals and objectives. Typically, when using models weighing up to 30 kg, there is no need for reverse speed, and it also complicates the design of the unit. On a heavy unit without this function it will be more difficult to perform work.

Without a gearbox, agricultural machinery will not move. It happens:

The purpose of the bevel gearbox is to ensure that the transmission collides with the engine, which affects the power of the gearbox. The gear is the transmitter between the motor and the wheels. A reduction gearbox is used to reduce the speed to increase power.

The reverse mechanism has a clutch located between the gears. They are located on the main roller. The main task of this system is to ensure the reverse movement of the vehicle. To make this mechanism yourself, the first step is to prepare the body, for which many people use a two-inch fitting square.

You can use a generator shaft from a Ural motorcycle. The gears will fit from the Druzhba chainsaw. You just need to drill a hole of the appropriate diameter in the shaft. On the opposite side, mount another gear shaft with bearings. And already on the weekend, install a pulley to ensure rotation.

You can purchase a ready-made gearbox, but when purchasing, it is better to give preference to more expensive mechanisms, since they are more reliable and last longer.

Among the malfunctions of gearboxes, users highlight the rapid wear of gears and the fact that the gear falls out.

If you increase the speed of the cultivator, you need to take into account that wear will occur much faster. When performing earthworks, you want to quickly complete the task. To increase or decrease the speed of movement, you can try the throttle. If the work ahead is hard, then when the gas is reduced the engine will stall.

The first speed is used when plowing the land, when more power of the unit is required. Accelerated work reduces the depth of cultivation.

What are the minimum and maximum speeds of the walk-behind tractor and how to regulate them?

Today, walk-behind tractors are perhaps the most common type of mini-equipment for agricultural purposes. It happens that users of some models are no longer satisfied with the speed and performance of the unit. Purchasing a new model is quite expensive. In this case, you can try to upgrade your device.

A walk-behind tractor is a kind of mini-tractor, designed for carrying out various agricultural operations on relatively small areas of soil.

Its purpose is to perform arable work on small and medium-sized plots of land, cultivating the land using a harrow, cultivator, and milling cutter. Also, walk-behind tractors can process potato and beet plantings, mow grass, and transport cargo (when using a trailer).

It is also possible to use additional attachments to expand the list of tasks performed by this powerful unit, which is indispensable in many cases: a trailer-trolley for transporting cargo weighing up to half a ton, cutters, harrows, etc.

There are gasoline and diesel varieties of walk-behind tractors. For the most part, diesel units are more powerful than their gasoline counterparts. Gasoline-powered devices win in the price category - they are cheaper. But the choice largely depends on the size of the land plot and the frequency of use of this equipment, because diesel fuel is more affordable than gasoline.

Motoblock devices come in two- and four-wheel configurations. Not all devices have a reverse function.

Motoblock Tselina MB-600

The Tselina MB-600 walk-behind tractor is a universal unit for performing various excavation work; it can be used in combination with attachments such as a plow, hillers, harrow, or with cutters to perform cultivator tasks. The recommended area of land on which this walk-behind tractor can be used is from 30 to 60 acres or more, subject to compliance with the operating rules.

Tselina MB-600 is equipped with a Lifan engine (China) with a power of 6.5 horsepower. Some models are produced with the Vympel DBG engine, the power of which is similar to the Chinese engine. The brand of engine depends on the year of manufacture and batch; new models are produced mainly with Chinese engines.

Purpose of the Tselina MB-600 walk-behind tractor:

- gardening work;

- auxiliary work in greenhouses;

- agricultural operations with attachments - plowing, cultivating, watering, hilling, mowing grass, planting potatoes and digging up potatoes;

- communal function - cleaning the territory;

- throwing snow;

- transportation of goods weighing up to 400 kg.

Walk-behind tractor equipment

The fastest models

First, let's find out which walk-behind tractors are considered the fastest? Do domestic manufacturers have advantages or does the palm unconditionally belong to foreign competitors?

By the way, it is quite difficult to determine the undisputed winner in terms of maximum speed, because not only are there a great many models of walk-behind tractors from various manufacturers today, but it is also possible to independently modernize this multifunctional agricultural unit.

The number and speed indicators of a walk-behind tractor depend on the engine and gearbox installed in the unit.

Motoblocks MTZ-05, MTZ-12 have 4 speeds when moving forward and 2 in reverse. The minimum speeds correspond to the first gear; when switching to the next gear, it increases. For the above models, the minimum speed when moving forward is 2.15 km/h, when moving in reverse – 2.5 km/h; the maximum when driving forward is 9.6 km/h, when driving backwards – 4.46 km/h.

repair of the gearbox of the Cascade walk-behind tractor

The assembly of walk-behind tractors is carried out at the Perm enterprise "Academy of Instruments". At the same time, most of the equipment parts are made in China, but they are of good quality.

The delivery set for this model includes:

- walk-behind tractor (engine, gearbox, controls, clutch, two wheels);

- cultivators (mills);

- additional accessories;

- two extension cords;

- two additional protective wings;

- two stoppers;

- operation management.

Related Posts

Tselina MB-601 is suitable for various types of work in small areas with an area of 10-80 acres.

The equipment has a two-by-two wheel arrangement. The weight of the model is 100 kg.

- length – 1470 mm;

- width – 580 mm;

- height – 1000 mm;

- transport gauge – 350 mm;

- small turning radius – 1100 mm;

- ground clearance - 140 mm.

The equipment is capable of moving at a speed of 1-9 km/h.

Performance characteristics of the Tselina MB-601 model:

- processing width – 720-1130 mm;

- permissible tilt angle – 20 degrees;

- lateral angle – 10 degrees.

The equipment remains operational at temperatures from 5 to 35 degrees.

The fuel consumption of the Tselina MB-601 model is 395 g/kW per hour. The fuel tank holds up to 3.6 liters of fuel.

The walk-behind tractor is equipped with a high-quality Chinese LIFAN 168F engine. The 4-stroke gasoline engine starts manually and has the lowest possible noise level, which makes working with it pleasant and easy. The power plant is characterized by an overhead valve arrangement and forced air cooling. The LIFAN 168F motor is characterized by increased durability and strength even with constant operation. The unit is not afraid of Russian frosts either. Another advantage of the power plant is its low fuel consumption (Ai-92, Ai-95 gasoline).

The design of walk-behind tractors is almost the same, regardless of the brand of walk-behind tractor. The walk-behind tractor consists of such components as: engine, chassis, transmission and controls. Below is a diagram of the MTZ-05 walk-behind tractor

How to adjust the speed?

Sometimes it turns out that you want to change the speed of movement of your walk-behind tractor: increase it or, which happens quite rarely, decrease it.

To increase the speed of movement of walk-behind tractors, one of the two methods below is usually used:

- replacing wheels with larger diameter ones;

- replacing a pair of gears in the gearbox.

The usual wheel diameter of almost all walk-behind tractors is 570 mm. Most often, when replacing, tires are selected with a diameter that is approximately 1.25 times larger than this - 704 mm. Although the difference in size is relatively small (only 13.4 cm), the speed of movement increases significantly. Of course, if the design allows for larger tires, you can try to increase the speed gain.

A gear pair installed in a wheel reducer usually consists of two gears with the number of teeth 12 for the small one and 61 for the large one. You can change this indicator to 18 and 55, respectively (only from specialists at agricultural machinery service centers), then the gain in speed will be approximately 1.7 times. Do not try to carry out the operation of replacing gears yourself: it is very important to select not only high-quality parts with minimal errors, but also the appropriate pulley. The gearbox shaft locking plate also plays an important role.

Logically speaking, reducing the speed of movement of a walk-behind tractor can be achieved by performing diametrically opposite actions - reducing the diameter of the tires or the number of teeth on a gear pair.

A possible solution to increasing the speed is to adjust the gas switch: when the device turns on, move it from the first position to the second. To reduce the speed of movement, return to the starting position. Of course, to change the speed down, you don’t need special reducers - it’s enough not to switch to high gears.

Also possible solutions to the problem of increasing the speed of a walk-behind tractor are replacing the motor with a more powerful one and upgrading or installing a clutch system (in some outdated models it is not provided).

It can help to increase speed (especially on uneven terrain or heavy soils, where equipment often slips due to insufficient weight of the unit) and installing weights. They can also be made with your own hands from metal parts. Weighting structures are installed on the walk-behind tractor frame and wheels. For the frame you will need metal corners, from which a homemade removable structure is formed, that is, you can easily remove it if not needed. Additional ballast weights are attached to this removable additional frame. The wheels require steel discs and solid iron blanks with a hexagonal cross section. These parts are welded and inserted into the hubs. For reliable fixation, cotter pins are used, which are installed in specially prepared holes.

Of course, if you don’t have round steel elements at hand, you can replace them with almost any available material: reinforced concrete products or even flattened round plastic flasks with sand poured inside.

Don’t forget to maintain balance: the loads on the wheels must be equal in weight and evenly distributed across the frame, otherwise there will be a misalignment, which could cause your unit to fall on its side when performing turning maneuvers.

To speed up a walk-behind tractor with a trolley in bad weather conditions - snow, slush, soil soggy from heavy rains - you can install tracks (if the design allows). This method requires the installation of an additional wheel pair and the purchase of rubber tracks of a fairly large width. Limiters are attached to the inside of the track to securely fix the rubber and prevent it from jumping off the wheelset.

Also for this purpose, you can replace the original gearbox with a similar device with a lower gear - to make it easier to overcome obstacles.

And don’t forget about prevention: change the oil more often, regularly lubricate all the components of your mechanical friend, monitor the condition of the spark plugs, replace worn parts with new ones.

If you take good care of the unit, follow all recommendations for operating the device, and carry out regular preventative maintenance, then the walk-behind tractor will produce the maximum of its capabilities in terms of speed and performance.

To learn how to adjust the speed of a tiller on a walk-behind tractor, watch the video below.

Technical characteristics of the walk-behind tractor

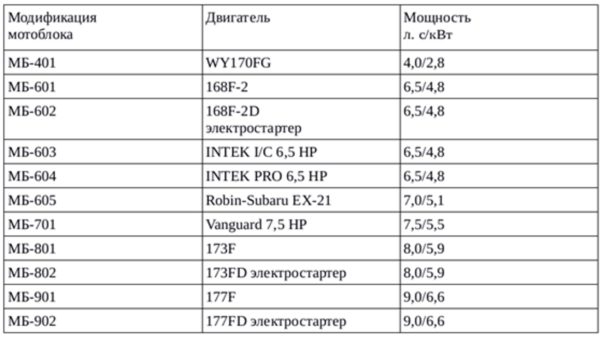

Under the Tsilina trademark, a number of models are produced that differ in both design and appearance. Therefore, it is more clear to present data on models in the form of tables.

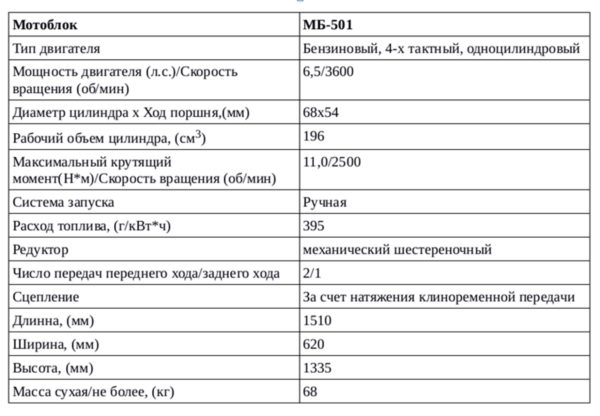

Technical characteristics of Tselina MB-501 walk-behind tractors

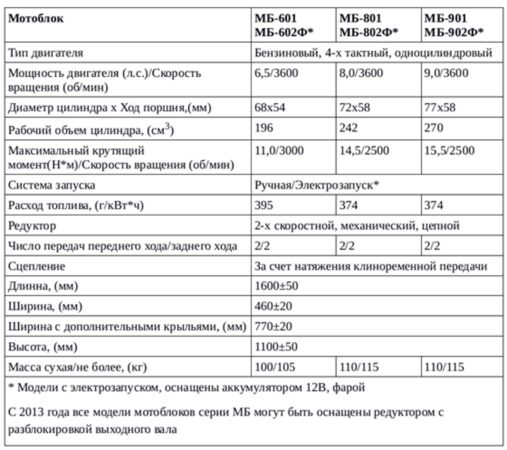

Technical characteristics of Tselina MB walk-behind tractors

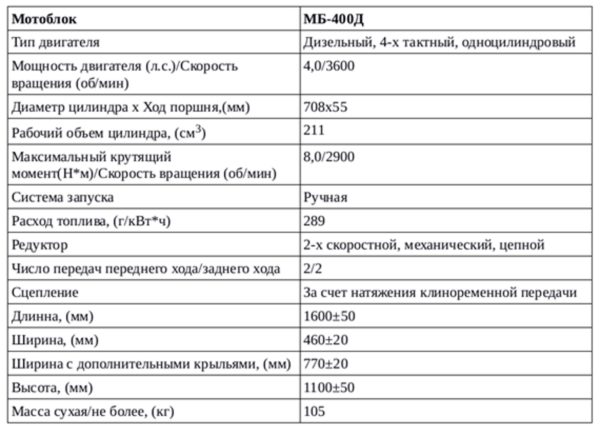

Technical characteristics of diesel walk-behind tractor Tselina MB - 400D

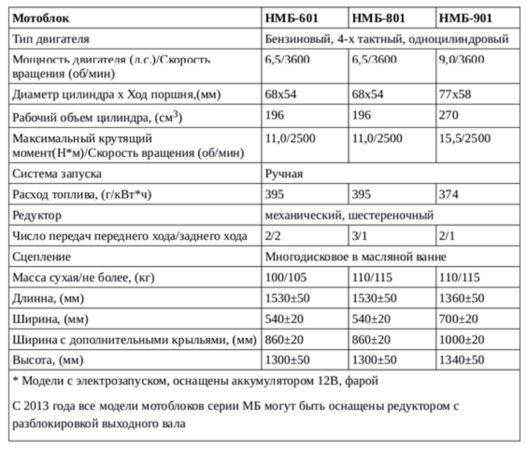

Technical characteristics of Tselina walk-behind tractors NMB-601, 603.901

In their total mass, Tselina walk-behind tractors, according to the technical characteristics stated in advertising brochures, are analogues of well-known domestic manufacturers. But it is worth noting that the dry mass is heavier in comparison with the originals, on average about 10-20 kg. The center of gravity is high, which can lead to a fall on the side with such a mass, which is what happened in one of the videos.

We recommend reading: Tractor Kamaz CX 105

Some models add an electric starter, with battery and headlight. The model range is marked by the presence of a model with a diesel engine. It is worth noting that these walk-behind tractors are compatible with a number of attachments produced by domestic manufacturers.

Walk-behind tractors are designed to perform various agricultural functions: caring for a personal plot, for preparing feed and firewood, for transporting building materials and various cargo weighing up to 300 kg.

Motoblock engines

The main part of the engines used to assemble Tselina walk-behind tractors operates on a four-stroke circuit and has one cylinder. They are characterized by efficiency, reliability, and low weight. Almost all of the engines listed in the table are used by others, including domestic manufacturers of small-scale agricultural machinery.

It is worth noting that it actively cooperates with the Lifan company, being its main distributor in Russia. Thus, it is not surprising that the powerful nine-horsepower Lifan engine is present in the lineup.

Regarding engines, on the Tool Academy website you can find a special offer for replacing an old engine with a new one from Lifan. Details of the promotion can be found on the website.

Motoblock engines

The engines presented above operate on fuel not lower than AI-92. Do not forget that any engine on new equipment must go through a grinding-in period. During this period, try not to overheat the engine and monitor the oil level. After the first oil change, you can operate at full throttle. One of the frequent tips for caring for a walk-behind engine is the need to monitor the cleanliness of the air filter.

The model range includes the Vympel 170 OHV diesel engine. This engine is equipped with the MB-400D walk-behind tractor. The engine is made according to a four-stroke single-cylinder design. By the way, the stated service life for this engine is 3000 hours.

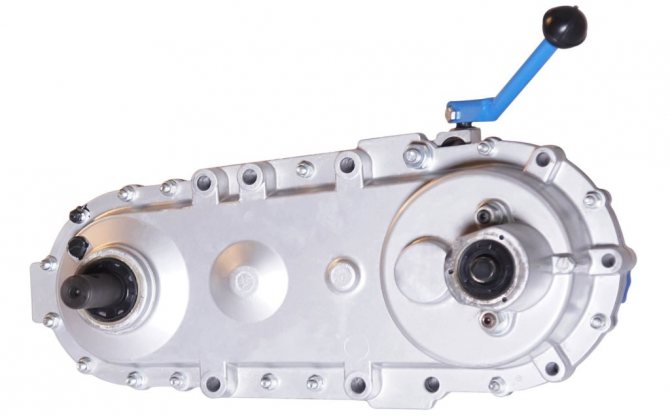

Walk-behind tractor gearbox

The Tselina trademark uses two types of gearboxes for its products: chain and gear. Above in the technical characteristics of walk-behind tractors section, the tables provide explanations of which gearboxes are installed in which models.

Chain reducer

Unfortunately, there is no factual data on the gearbox from the Tselina trademark, except that the improved chain gearbox (MB.01.000.1-01) is taken as a basis; specifications have been issued for it, according to which it is produced in China. Therefore, the description of the gearbox is taken from the “Operating Manual” 005.45.0100 RE1 for the OKA KADVI walk-behind tractor. This gearbox has two forward speeds and two reverse gears. The design used was used in walk-behind tractors developed in the eighties of the last century, having undergone a number of modifications, it is also suitable for use in modern devices.

Gear reducer

The gear reducer is made according to the specifications from the original one, which is installed on SALYUT-5 (650300000-01). The original gearbox is stronger than the above-mentioned housing, since it is made of casting. During the casting process, a number of stiffening ribs are added to its structure, which give the assembled structure strength. Thus, increased wear resistance of gearboxes of this design is achieved. Typically, the service life of such a gearbox is over 3000 operating hours. Thanks to the tight fit of the internal elements and the rigidity of the housing, the gearbox is able to operate under peak load without collapsing.

We recommend reading: Motoblock Pubert: reviews

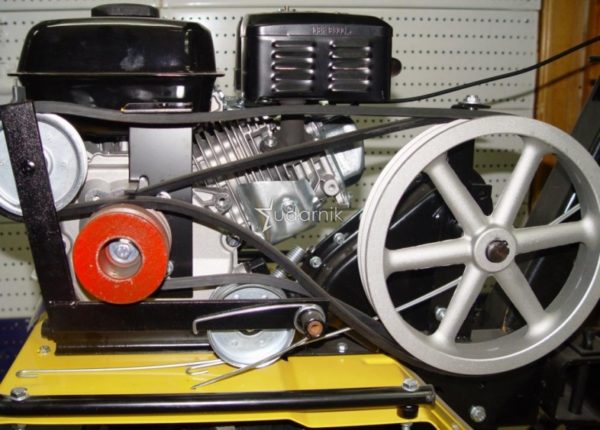

Walk-behind tractor transmission

Tselina uses two types of gearbox coupling with the engine pulley. V-belt transmission has proven itself to be a reliable and relatively cheap system. This type of clutch can be easily repaired in the field; this is important considering that the walk-behind tractor itself weighs 110 kg without body kit. In addition, belt-driven devices visually “jump” less during operation.

A multi-disc oil bath clutch is used on a number of models for Tselina walk-behind tractors. This kind of clutch is considered reliable and more responsive compared to a belt clutch. True, it is practically impossible to repair this transmission in the field if it fails.

Increasing the power of the walk-behind tractor

You can increase the speed of the walk-behind tractor in the following ways:

- replacing a gear pair;

- installation of wheels with a large diameter.

Increasing speed in the first way is a rather complicated process. Therefore, without knowledge and skills in this area, it is better not to do this yourself and contact a special service center. If you have the necessary skills, you can make the replacement yourself. Just like any other equipment, the walk-behind tractor has several speed modes controlled using gears. The walk-behind tractor moves at a speed of 2 to 15 km/h. The larger gear usually has 61 teeth, and the small one – 12. To increase the power of the walk-behind tractor, the gear pairs of the gearbox are replaced. Maximum speed can be achieved by increasing the number of teeth on the gear.

When replacing a gear, be sure to select the correct pulley. If the pulley is selected incorrectly, the walk-behind tractor may stop working.

How to make a walk-behind tractor go faster by changing wheels? Motor cultivators have a standard wheel size of 57 centimeters.

Specifications

The engine of the Tselina MB-600 walk-behind tractor is gasoline, four-stroke, air-cooled, forced. Due to this function, the walk-behind tractor operates longer without interruptions for engine cooling. The total duration of continuous operation is 4-5 hours. The cultivation track is adjustable from 72 cm to 113 cm.

Characteristics of the Tselina MB-600 walk-behind tractor:

- The engine capacity is 196 cc, manual starting system, fuel consumption is 395 g/l/hour.

- As in previous models, the gearbox is mechanical, reinforced; Ravenol SAE 80W-90 API GL-5 oils are used to fill it. For the engine - oils SAE 30, API SF/CD.

- The wheels of the walk-behind tractor are stable and wide, wheel size is 4.0-10.

- Number of speeds: 4.

- Dimensions: length 1600 mm, height 1100 mm, width 460 mm.

- The total weight of MB-600 is 95 kg.

- When working with dense soil, use weights.

Increasing cross-country ability and improving the walk-behind tractor

So, how to improve a motor cultivator with the help of weights. You can buy them or make and install them yourself. Weights are installed on the frame and wheels. Wheel weights are made of solid profiles and steel wheels. The body is weighted using special removable frames and a corner. Loads with different weights and configurations are attached to the frame.

So, sometimes you need to make a motor cultivator quite heavy, you can use reinforced concrete products.

Such loads can load the walk-behind tractor quite well. With the help of such simple devices, the range of application of technology is significantly expanded.

You can increase the capabilities of a walk-behind tractor and turn it into a snowmobile using tracks. To do this, you just need to install an additional axle with wheels and buy wide rubber tracks. Stoppers are attached to the inside of the tracks to prevent them from sliding off the wheels. Such a snowmobile will be useful on the farm in winter, when it is difficult to drive a car through huge snowdrifts, and in spring, when the ground is still too wet and the terrain is impassable for other equipment.

A homemade snowmobile can be equipped with a sled to transport property or feed for animals, or go fishing or hunting.

How to increase the power of a walk-behind tractor using reverse speed

The presence of reverse depends on the sizes and models. It can work on any type of equipment, it all depends on the tasks assigned to the equipment, be it a light or heavy walk-behind tractor, or a motor-cultivator. For equipment weighing up to 30 kg, there is no need for reverse speed, but on a heavier unit it is more difficult to weed without it. A gear reducer is a transmitter that operates between the wheels and the motor. The reverse gearbox consists of a clutch located between the gears and located on the main shaft. The corner is responsible for the operation of the transmission with the engine, which affects power. The reduction gearbox is responsible for reducing the speed, which helps increase power. The main task of this system is to provide reverse gear. To make this mechanism at home, you first need to make the case. Then select the necessary parts. But it’s better to buy a ready-made gearbox.

Assembly diagram of the Gearbox of the Tselina Motoblock MB 601r

The Tselina MB-601 walk-behind tractor with a Chinese LIFAN engine is a good assistant in forestry, farming, park management and gardening. The machine is suitable for operation in areas, towns and other places where the most stringent requirements for the level of vibration, noise and emissions of harmful parts into the atmosphere have been established. Using this walk-behind tractor, starting from selected suspended and trailed equipment, various operations are performed.

- inter-row hilling;

- plowing;

- cultivation;

- cleaning snow, leaves and dirt;

- cargo transportation;

- harvest;

- mowing the grass;

- pumping water;

- feed crushing;

- other agricultural work.

Tselina MB-601 works with different types of modern additional equipment created for other Russian-made walk-behind tractors. Mud flaps and additional fender liners installed on this model protect against dirt and increase its strength. With all this, the durability and reliability of the walk-behind tractor is determined by timely maintenance and correct running-in, which is not advisable for at least 30 hours.

The equipment has a rotating control column, and the operator can adjust the steering in the vertical and horizontal plane. The driver has two speed modes: forward and reverse. Special wheels installed on the Tselina MB-601 model guarantee the highest stability of the equipment and the highest maneuverability even in areas with loose and cultivated soil.

Among the advantages of this walk-behind tractor are:

- comparatively enormous power;

- reliable gearbox;

- upper placement of the cylinder;

- cast iron cylinder liner, which improves reliability characteristics;

- wide pneumatic wheels;

- huge protective wings;

- PTO;

- ability to work with a cart weighing up to 400 kg;

- good grip on the road thanks to a special type of wheels;

- mass sufficient for processing virgin soil;

- adjustable steering wheel;

- small dimensions making the model very maneuverable.

READ How to Install a Lifan Engine on an Oka Motoblock

repair of the gearbox of the Cascade walk-behind tractor

The assembly of walk-behind tractors is carried out at the Perm enterprise "Academy of Instruments". At the same time, most of the equipment parts are made in China, but they are of good quality.

The delivery set for this model includes:

- walk-behind tractor (engine, gearbox, controls, clutch, two wheels);

- cultivators (mills);

- additional accessories;

- two extension cords;

- two additional protective wings;

- two stoppers;

- operation management.

Tselina MB-601 is suitable for various types of work in small areas with an area of 10-80 acres.

The equipment has a two-by-two wheel arrangement. The weight of the model is 100 kg.

- length – 1470 mm;

- width – 580 mm;

- height – 1000 mm;

- transport gauge – 350 mm;

- small turning radius – 1100 mm;

- ground clearance - 140 mm.

The equipment is capable of moving at a speed of 1-9 km/h.

Performance characteristics of the Tselina MB-601 model:

- processing width – 720-1130 mm;

- permissible tilt angle – 20 degrees;

- lateral angle – 10 degrees.

The equipment remains operational at temperatures from 5 to 35 degrees.

The fuel consumption of the Tselina MB-601 model is 395 g/kW per hour. The fuel tank holds up to 3.6 liters of fuel.

READ What is the Power of a 12 Volt Screwdriver

The walk-behind tractor is equipped with a high-quality Chinese LIFAN 168F engine. The 4-stroke gasoline engine starts manually and has the lowest possible noise level, which makes working with it pleasant and easy. The power plant is characterized by an overhead valve arrangement and forced air cooling. The LIFAN 168F motor is characterized by increased durability and strength even with constant operation. The unit is not afraid of Russian frosts either. Another advantage of the power plant is its low fuel consumption (Ai-92, Ai-95 gasoline).

MB1 gearbox repair and why they don’t trust me

The Tselina MB-601 walk-behind tractor is quite widespread on the Russian market. With all this, equipment owners highlight both the good and bad sides of this model.

Most owners, when choosing this walk-behind tractor, are guided by two components: low price and high power. In terms of numerical characteristics, the model is noticeably superior to its rivals. The LIFAN 168F engine does not cause any complaints and is characterized only on the positive side (highest reliability, efficiency, vibrations like in a movie theater).

With all the advantages of a walk-behind tractor, there are many difficulties that come with it. Thus, the annotation for the Tselina MB-601 model is very unclear, and when it comes to purchasing unassembled equipment, severe assembly problems occur.

READ How to Start a Neva Motoblock With a Subaru Engine

Among other disadvantages, the owners highlight the following:

- low operating speed (the Mole walk-behind tractor is almost twice as productive);

- the processing depth does not correspond to the declared characteristics (less than 150-200 mm);

- the equipment is not adapted to light work, which affects the operator, who gets tired quite quickly;

- insufficient weight for plowing heavy soil;

- to change gear you need to approach the engine;

- To change the oil in the gearbox, you will have to drain the oil and gasoline from the crankcase and turn the walk-behind tractor on its side.

The price of the new Tselina MB-601 walk-behind tractor starts at 30,000 rubles, which is much less than its competitors. In this case, the attachment and additional equipment will increase the cost by 6,000-10,000 rubles.

There are few used versions of this equipment in market conditions. Their price varies from 10,000 to 25,000 rubles, depending on the condition and configuration.

The Tselina MB-601 walk-behind tractor has many analogues. Among them are the Krot-2, Ugra NMB-1N7, Patriot T7.0/1150 2FB PG, CROSSER CR-M5 and CARVER MT-650 models.

Source

Additional accessories

Walk-behind tractors are sold with a minimum number of components. However, a milling cutter and a standard plow are not enough to perform all agricultural work. How to improve a motor cultivator using scrap materials? With the help of tools that are found in every home, you can expand the capabilities of the walk-behind tractor. Equipment that you can make yourself:

- Installation of a rake on a walk-behind tractor for collecting debris, leaves, and hay. Such a simple device will speed up autumn field work and allow you to clear large areas of debris in a matter of minutes. To make a rake you will need: several meters of reinforcement with a cross section of 8-12 mm and a strip of sheet metal. The reinforcement is cut into pieces 10 cm long and welded to the plate in several rows with an interval of 3-5 cm. To increase maneuverability, the rake can be equipped with roller wheels.

- A trailer and cart will help transport large loads. The cart can be made from scrap materials - channel and old car wheels, metal profiles and boards. The clutch is made standard for both tractors and cars.

- If desired, you can make a potato digger, hiller and harrows, which will not be inferior in quality to purchased ones.

Plows for walk-behind tractors

The following types of plows are distinguished:

- The easiest to use is the single-hull one, also known as the Zykov plow.

- Reversible plow for walk-behind tractor: rotary or reversible. The upper part has a curved feather, which turns the soil over during plowing. A universal device that easily copes with plowing heavy soils. Quickly copes with the treatment of areas with clay and marshy soil.

- The rotary plow for a walk-behind tractor has a complex design. Depending on the number of ploughshares, there are two-body and three-body models. Active plowshares dump soil in one direction only, while passive plowshares level the beds and lift them. Tilling the soil with such a plow has a number of advantages: the soil is maximally saturated with oxygen; tire wear and fuel consumption are reduced; after processing there are no large clods of earth left.

- A rotary plow for a walk-behind tractor provides unlimited possibilities. During operation, the axis rotates, and with it the soil layers. It easily plows even very hard soil at a depth of about 30 centimeters. There are paddle, drum, shovel and auger plows. Devices of the first type are equipped with a rigid pusher and can consist of a spring plate or be combined. Units of the second type are equipped with a disk with blades that rotate during operation. A plow with a disc blade for a walk-behind tractor is suitable for work in early spring; it copes well with wet soil.

Any of the above plows can be made independently, taking into account the design features and following the instructions and diagrams. You can also improve an already purchased plow.

A rotary reversible plow for a walk-behind tractor copes with the processing of plots most efficiently, thanks to the optimization of the plowing process. And it is most in demand among agricultural workers.

Thanks to the expansion of capabilities, the walk-behind tractor becomes universal. It can be used to solve a variety of tasks from field work to snow removal in winter.