Engine

The KamAZ 4911 engine is characterized by the following indicators:

- model - 7E846;

- four-stroke, eight-cylinder with a camber angle of 90°;

- cylinder diameter, piston stroke - 14 by 14 cm;

- working volume - 17.24 l;

- engine weight - 1.38 tons;

- rated power - 538/730 kW/hp. at rev. (min.): 2500;

- torque Nm/Kgcm - 2700/275 (maximum), at rev. (min.) – 1300 – 1400;

- specific fuel consumption (minimum), g/kW per hour - 211;

- valves in the cylinder - 4.

Air supply system: 1 dry type air cleaner, 2 filters each. Exhaust system: two straight-through type mufflers with a metal sleeve. Combined lubrication system, with a wet sump.

Reducing the oil temperature in a water-oil heat exchanger. The cooling system is liquid, closed, with forced movement. The radiator is double, tubular-band, equipped with a fan casing and an expansion tank.

The thermal operating mode of the engine is regulated by a thermostat and a viscous fan clutch. The diameter of the fan is 7.3 cm. The intermediate cooling of the air-to-air charge air has 2 blocks located in the side parts of the vehicle behind the cabin. Thermoregulation - through air ducts, four electric fans.

Table: technical characteristics of KamAZ 4911

| Wheel formula | 4x4 |

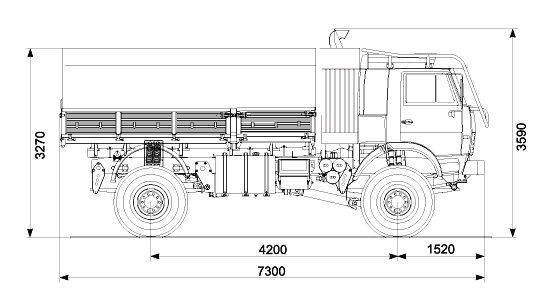

| Overall length | 7300 (mm) |

| Overall height | 3590 (mm) |

| Overall width | 2550 (mm) |

| Wheelbase | 4200 (mm) |

| Track | 2155 (mm) |

| Fuel tank capacity | 1000 (l) |

| Engine model | YaMZ-7E846 |

| engine's type | diesel with turbocharging and intercooling |

| Location and number of cylinders | V-shaped, 8 |

| Curb weight of the vehicle without fuel | 10300 (kg) |

| Gross vehicle weight | 11500 (kg) |

| Clutch | ZF-SACHS MFZ430 |

| Clutch type | friction, dry, single-disc |

| Transmission | ZF 16S-251 |

| Gearbox type | mechanical, sixteen-speed |

| Wheel type | disk |

| Tire type | pneumatic, with pressure regulation |

| Tire size | 425/85 R21 (1260×425-533P) |

| Brake system drive | pneumatic |

| Maximum climb angle | no less than 36% |

| Maximum speed | 165 (km/h) |

| Fuel consumption per 100 km |

|

KAMAZ constantly wins the Dakar. Why?

Yes, and it may stop soon.

Reports on the successes of the KAMAZ-master team at the Dakar rally have long been a January tradition, like tangerines and the 69th repeat of the Blue Light. Even those who do not follow motorsports and cannot name the name of the Russian Formula 1 pilot have probably heard about Russian trucks that win. The victories really look grandiose: out of 16 Dakars held in the 21st century, 12 were won by KAMAZ. We have not been surprised for a long time that the South American deserts are dominated by cars of the same brand that bring sand to our dacha and force us to close the damper when they are standing in front of you in a traffic jam. What is the secret to the success of the most unexpected combination of Russian motorsport - KAMAZ trucks and deserts?

State support

The minimum budget for maintaining a team is approximately $10 million per year, and every year it becomes more and more difficult to maintain it. After the problems that arose with Vnesheconombank, VTB Bank remained the only general sponsor, but their injections were not enough. The issue of preserving the team was resolved at the highest level: as a result, the state corporation Rostec became another sponsor, and VTB increased the amount of investment to $2.5 million.

Although, according to KAMAZ director Sergei Kogogin, “the good life is over,” Chelny residents still have much more opportunities than their Dakar competitors. They can afford to simultaneously participate in the Africa Eco Race and Dakar raids, even though training for multi-day races now takes place not in Morocco, but in Karelia and the Astrakhan region.

Limited Opponent Opportunities

If the last time you looked at the Dakar reviews was seven years ago, then you didn’t miss anything - at least, practically nothing has changed in the truck standings. The main rivals remain the Dutch private traders De Rooy and Stacey and the Czech Loprais. True, KAMAZ has ceased to be the only factory team; the Belarusians from MAZ are now interested in the rally raid, but they have not yet reached the podium.

Factory support remains another important advantage factor. Eternal competitor Gerard de Roy complained that he could not afford to participate in a large number of rally raids per year and regular trips to training camps. Despite close cooperation with Iveco, de Rooy covers half of the team’s budget on his own - the Dutch extreme racer has to spend time managing his own transport company, and rally raids are still an expensive hobby for him. For comparison, de Rooy’s team employs six people on a permanent basis, while KAMAZ has 108.

Specifications

Motors are the pride and at the same time the most vulnerable component of KAMAZ. Thanks to financial resources and factory support, it is possible to independently modify engines to suit the characteristics of the truck, which provides the vehicles with reliability and good cross-country ability in the deserts of all continents.

The problem is that the Dakar regulations are updated every few years, requiring a reduction in engine size. In order to comply with the rules, KAMAZ had to abandon cooperation with the Tutaevsky Motor Plant and purchase, and then significantly modify, German Liebherr tractor engines with a volume of 16.2 liters. The modernization of the engines, according to the leaders of the concern, took several million euros, but in 2018 at the Dakar the requirement to exhibit cars equipped with an engine of no more than 13 liters comes into force, which implies a completely new development of power units. Kogogin calls these changes “sabotage” and threatens to allow two Dakars to pass. 7-time Dakar winner and now team leader Vladimir Chagin is a little more optimistic: “These are very expensive changes that we may not be able to afford. However, we will continue to work diligently.” In the current situation, KAMAZ is the only team that is not ready for the new regulations.

Many other parts, like the engines, are purchased abroad: shock absorbers are purchased in Holland, brakes are Belgian, and the gearbox is German. But it cannot be said that Russian trucks are technically significantly ahead of their competitors; for example, cruise control on KAMAZ trucks was installed only for the 2020 Dakar - much later than their rivals.

In Naberezhnye Chelny, where the whole hodgepodge of imported spare parts is assembled, they are constantly working to improve the stability and controllability of the truck. So, before the last Dakar, the location of the fuel tank and spare wheels was changed to lower the center of gravity.

Dependence on Dakar conditions

The success of the Russian team also depends on the route of the rally raid. Pilots and team representatives associated the sensational defeat at the 2020 Dakar with the track being too simple and flat.

Chagin said: “We expected that there would be difficult off-road conditions in the mountainous terrain in Bolivia, but the organizers laid out the route along flat areas with winding roads and many speed limit zones... Our engine performs well off-road, in sand, and on draft vehicles. On short stretches where acceleration is needed, rival engines are better. Well, braking: the engines of all our rivals are equipped with an engine brake, this is a modern feature that gives a good effect during braking. Unfortunately, our engines don’t have this.”

In 2020, the Dakar organizers corrected themselves and prepared a more difficult route for the participants, where KAMAZ could fully utilize its advantage in suspension and those same Dutch shock absorbers.

This year, the Blue Armada was partially lucky with the weather conditions. Due to the washout of the track, the longest special stage, where Gerard de Roy hoped to win back, was canceled.

Future of the team

The possibility that KAMAZ will not have time to prepare a 13-liter engine for the next Dakar really exists. In this case, the team is unlikely to rent a third-party engine that cannot be upgraded. Most likely, they will skip the race, focusing on the less strict “Africa” and “Silk Road”.

But, firstly, we have a whole year to solve the problem. Secondly, the new regulations may speed up the appearance of a widely announced new product at the Dakar - a hooded truck. De Rooy and Loprais have long switched to a new type of cab, which provides the trucks with better handling and protects the spines of the crew.

It seems that the bonnet has only one drawback - it will be completely different from the same KAMAZ that brings sand to our dacha and forces us to close the damper when it is standing in front of us in a traffic jam.

How is the KAMAZ civilian truck the best in the world? Or only in racing?

The reputation of civilian KAMAZ trucks on Russian roads is directly opposite to the reputation of their sports counterparts in the world’s deserts. The most popular Russian trucks are catastrophically unreliable during operation, so the initial advantage over imported competitors in the low cost of vehicles is completely offset by regular expenses for repairs. Of course, there is a convenient counterargument about the availability of spare parts and the expression that a KAMAZ can be repaired even in the field,” but, probably, it is better not to stall in the field.

KAMAZ vehicles are often punished for their indecently low level of comfort in the cabin. A driver who has not yet saved up for some “used Swede” will find it hot, cramped and painful during a summer flight. Even the joint project with Mercedes of the KAMAZ 5490 tractor, in which practically no fruits of the Kama Automobile Plant’s labor remain, is criticized for the low level of noise and heat insulation in the cabin.

Despite all its shortcomings, KAMAZ can boast (and boasts in high-profile advertising campaigns) of truly high cross-country ability. Foreign manufacturers rely more on providing a comfortable ride on straight roads and do not even try to compete with Russian cars on off-road. The advantage in cross-country ability allows KAMAZ trucks to remain indispensable in hard-to-reach objects.

Photo: Gettyimages.ru/Dan Istitene (1-3); kamazmaster.ru

Hodovka

Running component:

- The car is assembled on a frame consisting of 2 channel-type spars, fastened in several places by transverse cross-beams. The frame is made by stamping. In the front part, a buffer with towing devices is attached to the frame. In the rear there are 2 similar towing devices;

- The front suspension is dependent, consists of 2 semi-elliptical springs, each with fourteen leaves, operating together with four hydropneumatic shock absorbers. A transverse beam is attached to the springs using stepladders, and the chassis is assembled on it. The rear suspension consists of 2 semi-elliptical longitudinal springs, each with ten leaves, operating together with four hydropneumatic shock absorbers. The rear axle is connected to the frame by several longitudinal reaction rods;

- the wheels are assembled on disks with a removable bead, split locking rings, with toroidal landing shelves, made of duralumin with dimensions 10.75 - 20, thanks to which it is possible to change a tire with a wheel on a car;

- tires are tubeless, radial, with variable pressure, dimensions 14.00 R20. Standard pressure is 5 kgf/cm2, with the possibility of reducing to 1 kgf/cm2 for movement over rough terrain. The wheel inflation system is centralized, divided into front and rear axles, and controlled from the vehicle cabin.

Product N149 Kamaz-4911 “Kamaz-Master” – “King of Dakar”

"A machine ready for exploits." “Spread the wings of your imagination and experience unknown dimensions of speed and space.”

In September 1988, the debut of the team from Naberezhnye Chelny took place at the Jelch rally in Poland. In that first rally-raid in their history, KAMAZ athletes performed on serial all-wheel drive SUVs KAMAZ 4310. Already in the early 90s, in close collaboration with factory designers and testers, the team created their own sports trucks: KAMAZ 49250 and KAMAZ 49251. The basis for These vehicles were equipped with the most advanced equipment of the Kama Automobile Plant at that time.

In 1994, the team competed in a vehicle with pronounced sporting characteristics, fundamentally different from ordinary production trucks - KAMAZ 49252. It had a 750 horsepower engine, the vehicle had a mid-engine layout and large 25-inch wheels. The SUV's sloping platform, designed to reduce aerodynamic drag, is an original step in sports truck design that remains in history. In just a year, three new generation sports trucks will carry KAMAZ crews to the victorious podium of the Paris-Moscow-Beijing motor marathon. A few months later, in January 1996, the team would become the winner of the legendary Dakar rally marathon for the first time.

Experiments with technology were sometimes even too daring. For example, the sports KAMAZ 49255 had a twelve-cylinder engine with a capacity of 1050 horsepower. Its hyper-powerful heart broke the transmission, which is what happened at the 1998 Dakar. Very often cars were born in an extremely short time. Thus, in 2002, the FIA vetoed the participation in Dakar of trucks with a mid-engine configuration, which ensures good weight distribution and stability. The Kamaz truck was just like that. But the biggest difficulty was that these innovations became known only six months before the start. In a short time, the KAMAZ 49256 combat sports truck with an 830 horsepower engine was created. It was born in agony; after each test, the car was taken away from the test site on a trawl. And only a few hours before the team was sent to Dakar, the error was found and corrected. As a result, the car passed the strength test, bringing the KAMAZ team another Dakar gold.

A year later, the KAMAZ-master team made a new qualitative leap by creating a new model of a sports car. KAMAZ 4911 EXTREME has become a combat vehicle that has no analogues in cross-country ability, maneuverability and dynamics. For its unique technical and operational qualities it was called a “flying truck”. And indeed, in the hands of such masters as pilot Vladimir Chagin, this car easily took off from the ground at speed, pushing off from natural springboards. With an 850 horsepower engine, the car accelerated to 100 km/h in ten seconds.

The classic rectangular platform was returned to the car. This happened because the Dakar organizers once again demanded that the participants bring their sports heavy-duty trucks in line with regular production trucks designed for transporting cargo. In order to reduce weight, a thinner frame was installed on the truck, which, due to additional inserts, did not lose its power. The car has become “softer”, the ride has improved due to longer springs (1900 mm) and modernization of hydropneumatic shock absorbers. The car was able to jump from great heights, landing softly on its wheels, without breakdowns or damage to the crew.

The debut race of the heavy truck brought the team first and third places at the Telefonica-Dakar 2003 rally. On a route with a total length of more than eight and a half thousand kilometers, connecting two continents and five countries, the KAMAZ team in Extreme “brought” their closest pursuers more than an hour. Left behind were competitors in fifty trucks of famous brands: DAF, MAN, Mercedes-Benz, Renault, Scania, Tatra, Mitsubishi... By the way, KamAZ-Master is the only team that entered more than one vehicle that finished in full force. In the same year, victories followed at the Russian Cup, the Russian Championship, the Khazar Steppes rally, the Cappadocia 2003 rally and the Desert Challenge. For several years, after each Dakar rally, the KAMAZ 4911 SUV was subject to modification and modernization.

Over the entire 30-year history of the legendary KAMAZ-Master team, six drivers won the Dakar, but exactly half of the 14 victories were won by Vladimir Chagin’s crew.

Vladimir Gennadievich began his ascent to the racing Olympus “King of the Desert,” as he was nicknamed at the bivouac, as a mechanic, and only in the mid-90s he got the opportunity to drive a truck from Naberezhnye Chelny. Successes were not long in coming - already in 1996, the future seven-time Dakar winner won the Master Rally World Cup stage, which took place along the route Paris-Ulyanovsk-Ulaanbaatar, and in 2000, together with the team leader, co-driver Semyon Yakubov, and mechanic Sergei Savostin brought KAMAZ its second victory at Dakar” after the triumph of Viktor Moskovskikh in 1996.

The Chagin-Yakubov-Savostin line-up was destined to become gold. Together they won four more Dakars - in 2002, 2003, 2004 and 2006. Chagin won two more victories after the rally raid moved to South Africa, but already together with Eduard Nikolaev (2010) and Ildar Shaysultanov (2011) as mechanics, while Savostin replaced Semyon Yakubov as navigator.

At Dakar 2011, Vladimir Chagin set several new records. He won the 63rd special stage victory and won the truck category for the seventh time, ahead of the Czech Karel Loprais, who drove a Tatra from 1986 to 2006.

After this race, Chagin decided to end his career, but remained in the KAMAZ-Master team and a year and a half later, in July 2012, he headed it after Semyon Yakubov retired. At the same time, until Dakar 2017, Chagin remained the only one who managed to win seven victories in one category.

Even for people far from motorsport, his name has forever remained inextricably linked with the “flying” Kamaz 4911. Many automobile companies have produced a model of this famous truck, winner of the Lisbon-Dakar 2006 race under the number “508”.

It was this legendary racing Kamaz-4911 with the number “508”, the “understudy” of the main starting car, that was discovered by employees of the Smirnov Design Bureau in the city of Moscow and arrived under its own power in St. Petersburg for restoration and subsequent transfer to our customer, who collects domestic sports cars with glorious racing history.

Unlike a number of exhibits in this unique collection, which were left in their original “combat” condition, it was decided to completely restore this car and bring it to new condition.

This concept, in addition to full maintenance carried out on the basis of recommendations and with the support of specialists from the Kamaz-Master team and the official representative office of a well-known manufacturer of oils and lubricants, required a number of works to restore the paintwork of the cab and truck body with complete disassembly and dismantling of a large number of parts and nodes Some cosmetic defects were eliminated. Quite a lot of attention was paid to recreating the sponsorship symbols. The number of multilayer sponsor stickers exceeded one hundred. This operation was greatly complicated by the inability to use ready-made design layouts, due to their loss in the manufacturer’s archives. Therefore, they were recreated in the graphics program again. The headlights, front fog lights, and rear lights were replaced. The generator was repaired, a new cockpit hatch mechanism was installed, the deflector-fairing on the top of the cab was replaced, and all the boots of the original hydropneumatic shock absorbers were replaced, which were kindly provided to us by representatives of the team’s technical support group.

An unexpected pleasant and memorable moment in this work was the meeting with the legend of the team - a mechanic of the technical support group, participant, prize-winner and winner of the stages of the Russian Championship, stages of the World Cup of Off-Road Rally, and the Paris-Dakar motor marathon. Kubrak Mikhail Aleksandrovich is a specialist, on whose shoulders fell the entire heavy burden of repairing racing equipment during night stops at bivouacs. This exhausting work, squeezed to the limit by the lack of time, importance and variety of tasks, erases all the usual boundaries of the labor intensity of preventive maintenance and car repairs. It requires not only deep professional knowledge, but special dexterity and skills to do in a matter of hours what would normally take days. To do this, you need to have excellent physical data, remarkable endurance and psychological attitude. Mikhail Alexandrovich is from the breed of just such people. A barge hauler of his trade, he has been pulling this burden for many years.

At the Lisbon-Dakar 2006 rally, the Kamaz team was confronted by almost seven dozen eminent rivals. Almost no team was able to maintain its full combat strength on the way to the finish line due to equipment failure and the impossibility of its restoration. Kamaz workers were in the same conditions. Only the word “impossible” is not in the vocabulary of its mechanics and Mikhail Kubrak among them. That is why all three combat trucks triumphantly raised the national flags of Russia and Tatarstan at the finish line of Dakar.

AWARDS for Mikhail Kubrak:

- 1991 - Order of Honor

- 1996 - Medal of the Order “For Merit to the Fatherland, 2nd degree”

- 2000 - Certificate of Honor of the Republic of Tatarstan

- 2004 — Certificate of Honor from KAMAZ OJSC

- 2005 - medal “In memory of the 1000th anniversary of Kazan”

- 2007 - Medal of the Order “For Merit to the Fatherland, 1st degree”

- 2008 — insignia “For services to the city”

Working to improve the design of sports cars, Kubrak made a number of proposals that made it possible to increase the reliability of individual components and simplify the repair of automotive equipment. Participated in the manufacture of all new models and modifications of racing equipment - KAMAZ-49251, KAMAZ-49252 and KAMAZ-4911 EXTREME vehicles, which took part in international rally marathons, and today compete on an equal footing with the world's leading automakers.

It was Mikhail who directly handed over to us some important parts for the repair and maintenance of our exhibit. We asked Mikhail Alexandrovich to leave an autograph in the car’s service book, which he did, wishing him success.

This car was solemnly handed over to the customer, who expressed a desire to immediately conduct a series of test runs, as a result of which we received a lot of positive feedback on the work done, and the “flying truck”, which once again confirmed its title at one of our tests, took its honorable place place in a unique collection of sports cars.

Specifications:

- Length, mm – 7300;

- Width, mm – 2550;

- Height, mm – 3590;

- Weight, kg – 10500;

- Maximum speed, km/h – 200;

- Engine – petrol;

- Engine capacity, cm3 – 17240;

- Power, hp - 850;

- Number of cylinders – 8;

- Years of production – 2002-2007;

- Circulation, copies - 4;

- Year of manufacture – 2002.

Brake system

The system is dual-circuit, one circuit activates the brake elements of the front wheels, the second is responsible for the brakes of the rear bogie. Drum brakes with wheel pads inside. The diameter of the brake drum is 40 cm. The brake linings of the brake pads are 22 cm wide.

Parking (auxiliary) brake system

The parking brake consists of energy accumulators, which are initially compressed springs of the brake chambers. The parking brake is controlled from the driver's cab using a pneumatic valve.

The pneumatic drive consists of:

- a two-cylinder compressor that pumps air into the brake system;

- oil – a moisture separator responsible for the cleanliness of the environment;

- safety valve maintaining constant pressure;

- set of receivers;

- 2-section brake valve;

- brake chambers - with energy accumulators for the rear axle and front wheels.