Snow blower transmission - how to choose a mechanism?

A modern snow blower has many components, the coordinated operation of which ensures the uninterrupted functioning of the entire unit. One of the most important mechanisms of the machine is the snow blower transmission. It is responsible for selecting and transmitting a given speed of movement directly to the wheels of the unit. Some modern snow blowers are equipped with modified transmissions that allow them to move in a fairly large speed range. Snow blowers equipped with these mechanisms are distinguished by better maneuverability and efficiency when working in hard-to-reach places.

Snow blower transmission device

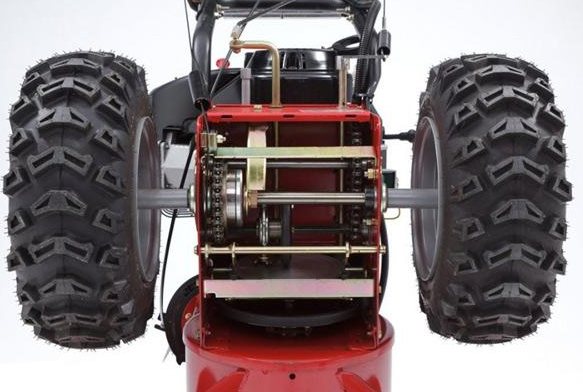

The transmission of a snow blower is a set of gears that are located in the housing and are connected via a drive to the engine and drive wheel gearboxes. The number and size of gears depend on the number of gears - the speeds at which the snow blower can move.

Most often, there are snow blowers on sale whose transmission is designed to operate in one specific speed mode. The advantage of such a transmission is the simplicity of its design and ease of self-repair. The downside is high fuel consumption in situations in which it could not have been avoided.

More modern snow blowers come with improved transmissions. These mechanisms consist of a large number of gears, making them much more difficult to repair. At the same time, modern mechanisms make it possible to move in a wide range of speeds - often from 2 to 6 forward and reverse gears. Due to this, the unit moves more slowly when cleaning heavy wet masses, and faster when clearing the area from light, freshly fallen snow. The ability to adjust the speed of movement of the snow blower makes it possible to save fuel and reduce wear on important working parts of the unit.

Repair of tracked snow blowers

Large snow blowers with a track-driven or chair-based operator are often called snowblowers . Repairing track-type snow blowers often requires special lifting tools. The engines on such snow blowers can reach a power of 15-20 horsepower, and the drive unit has a complex gear mechanism. This technique is used in parking lots, country roads and other large areas where periodic cleaning is required without the involvement of large cleaning equipment.

Such equipment must be serviced every year: postponing an oil change until the next season and storing it with fuel during the off-season is completely unacceptable. Such errors by equipment maintenance personnel can lead to an expensive service at the service center, such as repairing a snow blower .

Our workshop provides additional . The driver will arrive at a time and place convenient for you (in agreement with the logistics department), pick up the faulty equipment, and after repair, deliver it back with a full set of documents.

The warranty period for snow blower repairs and replaced spare parts does not depend on the type of equipment and is 60 days. submit a request for repair of a snow blower either through the website or by multi-channel telephone.

If you refuse the service center's fee will be charged for troubleshooting and clarifying the cost of repairing the snow blower .

Snow blower transmission - how to choose a mechanism?

Regardless of whether a person buys a new snow blower or a transmission for an existing unit, it must meet certain requirements.

Their list includes:

- absence of large oil stains on the surface of the housing and between the gears - there should be a little oil inside the protective housing, which plays the role of lubricating the gears. If there is too much lubricant, this indicates a leak or a break in the oil hose;

- integrity of the lubrication system hoses - there should be no cracks or holes on the walls of the tubes through which oil can spill. Each hose must fit tightly at the connection point. The channel seats must be treated with a special sealant;

- type of elements of the working mechanism - all, without exception, gears and other parts of the snow blower assembly must be in full working order. There should be no signs of corrosion, cracks or bulges on the mechanism parts. The teeth of all gears must be in place;

- absence of too large grooves - the distance between the gears and other elements of the snow blower transmission should not be more than 5 mm. If the grooves between the parts are larger than this value, then over time this will lead to failures when switching speeds;

- reliability of fastening of parts - each of the elements of the snow blower mechanism must sit tightly in its seat. The gears should not wobble, and there should be no play when they rotate;

- gear sizes - inside the protective housing of the snow blower transmission there must be parts of the same sizes as indicated in the operating manual. If the diameter of the gears differs from the declared sizes, this indicates that the snow blower transmission parts have been replaced;

- absence of extraneous noise - during operation, the new mechanism should not make creaking or rustling sounds. If they are, then this indicates an incorrectly adjusted position of the gears or the presence of foreign objects between them.

A careful inspection of the case and checking the internal parts will help determine the serviceability of the transmission and the ability of the mechanism to be used intensively in the future.

Snow blower gearbox

The efficiency and productivity of a commercial snow blower depends on the proper operation of many of its mechanisms. One of the main ones on their list is the gearbox. This factory unit is needed to receive and transmit torque from the standard internal combustion engine to the working parts of the snowplow - the auger and rotor. To ensure proper operation, the factory snow blower gearbox requires regular maintenance on a regular basis. Proper care of the mechanism guarantees its stable, uninterrupted operation under any operating conditions.

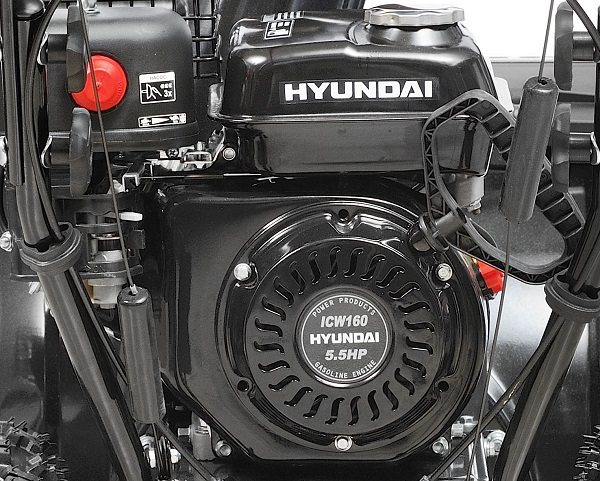

Repair cost for Hyundai snow blowers*

The final cost of the necessary repair of a Hyundai snow blower largely depends on the prices of spare parts and is agreed upon with the customer over the phone after diagnostics have been carried out by a technician.

The cost of repairing Hyundai snow blowers is from 500 rubles.

| Name of repair work for Hyundai gasoline snow blowers | Cost of services, rub.* |

| Carburetor adjustment | 1900-2300 rub. |

| Starter replacement | 1100 rub. |

| Starter repair | 900-1300 rub. |

| Replacing the spark plug | 100 rub. |

| Replacing the carburetor | 1700 rub. |

| Replacing the ignition coil | 900 rub. |

| Ignition adjustment | 1100 rub. |

| Replacing the impeller | 1100 rub. |

| Replacing the throttle control cable | 1300 rub. |

| Adjusting the throttle cable | 500 rub. |

| Replacing the air filter | 100 rub. |

| Comprehensive maintenance of Hyundai gasoline snow blowers (work) | from 1900 rub. (from model) |

| Name of repair work for Hyundai electric snow blowers | Cost of services, rub.* |

| Replacing the power cable | 1100 rub. |

| Replacing the power button | 900 rub. |

| Replacing the drive belt | 900 rub. |

| Replacing the impeller | 900 rub. |

| Replacing the drive control cable | 1300 rub. |

| Adjusting the ride control cable | 500 rub. |

| Comprehensive maintenance of Hyundai electric snow blowers (works) | from 1100 rub. (from model) |

Snow blower gearbox design

The proper operation of the standard mechanism of a snow blower is ensured by the arrangement of parts, each of which plays its own specific role in the design of the unit. The main element is the gearbox. It is made from different materials, but most often in the configuration of snow removal equipment there are bronze gears with 20 teeth. The choice of this soft metal is mainly explained by the fact that, in the event of an accidental jamming of the auger-rotor mechanism, the built-in internal combustion engine of the machine will remain undamaged.

As standard, the factory snow blower augers are attached to the shaft with shear bolts. Their function is to initially protect the node. If the operator encounters a curb or any other mechanical impact to the snow blower, the bolts are automatically cut off, thereby preventing engine damage. If this does not help, then the rest of the impact force acts on the engine.

All internal parts of the mechanism are protected by a durable case. For household and semi-professional snow blowers, it is made of silicon-aluminum alloy. Machines of this type are equipped with a prefabricated gearbox consisting of two halves bolted together. Professional-type snow blowers are equipped with factory-made housings made primarily from cast iron and other heavy metals.

Depending on the basic equipment of snow blowers, their gearboxes can be large or small. In mechanisms of the first type, the built-in gear is large. In small units, the gear sizes will be appropriate.

Classification of snow plow gearboxes

Modern snow blowers are equipped with built-in gearboxes of only two types.

These include:

- served – as the name suggests, mechanisms of this type require periodic maintenance. The special design of their design provides for the possibility of independently disassembling these units to apply lubricant or replace worn components. A well-maintained gearbox for a snow blower can last quite a long time. Most of its components are made of bronze, which is why they are much smaller and slower to wear;

- unattended – units of this type do not require maintenance. Their device does not provide for the possibility of disassembly, so their working life is significantly lower than that of serviceable ones. In the event of any breakdown, the gearbox must be replaced immediately.

Maintenance-free mechanisms are included in the basic initial equipment of inexpensive household and semi-professional snow blowers made in China and Korea. More expensive serviceable components are used to equip higher quality and longer lasting German, Japanese and American snow blowers.

Pre-season snow blower maintenance

So, friends, winter is gaining momentum, it’s time to get your winter helpers in order and put them to work. The key to the durability and reliability of a snow blower (like any equipment) is proper and timely maintenance.

In this article we will look at the algorithm for preparing a snow blower before the winter season.

- We carry out an external inspection of the condition of the snow blower: the condition of the intake augers, adjustment of the “skis” and the height of the snow intake. We also check the operation of the snow ejection chute adjustment and the absence of gasoline or oil leaks on the engine. We carry out a test run, the operation of the drive cables and stable operation of the engine.

2. Wheel pressure and external inspection.

An important point in operating a snow blower is periodic monitoring of tire pressure (usually 2 atm).

This simple procedure will allow you to avoid premature replacement of tires, the cost of which is quite high.

3. Oil change.

It should be noted that one of the main conditions for the durability and reliability of the engine is an annual oil change (or every 50 hours of operation).

Unfortunately, a small percentage of snow blower owners follow this rule. In the future, this leads to quick and expensive repairs. Below is a link about the detailed oil change process.

For more information, read the article on how to properly change the oil in a snow blower

4. Spark plug.

Monitoring the condition of the spark plug (no carbon deposits or damage) will ensure stable and quick engine starting. Remember, this is a consumable item and needs periodic replacement.

5. Drive belts

Be sure to check the condition of the drive belts (it is necessary to remove the protective cover) - if there is damage, it is necessary to replace the damaged belt.

The markings can be found both on the belt itself and in the instruction manual.

6. Drive cables

Unfortunately (in Chinese inexpensive snow blowers) this spare part can be called a consumable. The workmanship is not the highest. Before the season, you need to check their condition, if there is damage, stock up on new ones and be ready to replace them.

7. Gearbox shear bolts.

Never use alternatives (nails, rods, etc.)! These shear bolts are made of soft metal in order to prevent the possibility of breakage of expensive gearbox parts if heavy objects get into the snow blower intake (stones, bottles, etc.).

Before the season, it is advisable to stock up on a certain number of shear bolts so that if they break, you can quickly replace them with new ones.

What kind of lubricant should be added to the gearbox itself? Famous manufacturers recommend Shell art. 737-0168, quality manufacturer.

8. Air filter.

Perhaps the most controversial issue in the operation of a snow blower is the use or absence of an air filter. Some manufacturers equip their equipment with filters, others claim that the need to use an air filter in winter does not make sense (since the accumulation of snow on its surface prevents the flow of air into the engine and disrupts the operation of the engine.) It is very difficult to say who is right: since On the one hand, a filter is still necessary, on the other hand, in order to prevent snow from sticking and further freezing on the surface of the filter, it is necessary to remove the foam insert. A paper element inside the filter housing will be sufficient to protect the engine from abrasives.

We recommend that equipment owners who use a filter periodically monitor its condition.

9. Remaining fuel from last season.

In any snow blower operating instructions, the first rule before a long pause without operation is to use up all the fuel in the engine and not to store the snow blower with fuel during the summer.

Unfortunately, not all owners follow this rule, so the first launch can be difficult and problematic. If there is old fuel left in your snow blower's engine, it is imperative that you drain it.

This can be done by unscrewing the carburetor sump bolt (located at the bottom) and draining the old gasoline.

Remember: following simple operating rules will ensure stable operation of the snow blower for many years. These procedures will not take much time, but will help you enjoy working with the unit in a snowy winter.

Typical snow blower gearbox failures

Serviced mechanisms are deservedly considered the most reliable and durable. However, they are not always able to withstand long-term intensive use under high loads. There are a number of standard gearbox failures that owners of commercial snowplows most often regularly encounter.

These include:

- sudden appearance of sharp knocking sounds in the mechanism body - the cause of this malfunction most likely lies in wear of the bearings. Often knocking noises appear because the worm gear has begun to wear out. Replacing the bearings or worm gear will help solve the problem;

- rapid heating of the unit - if the gearbox begins to heat up intensely, this indicates wear of the built-in factory bearings. Another reason is the lack or loss of properties of the lubricant. To repair a faulty mechanism, you need to completely disassemble and inspect the bearings. If necessary, they need to be replaced and oil added;

- the appearance of strong vibration inside the gearbox - this sign indicates a violation of the axis on which the engine and the snow blower shaft are located. To eliminate the malfunction, you will need to adjust the alignment of the elements;

- leakage of lubricant from the housing - this problem manifests itself when the standard drainage hole located inside the vent is severely clogged. To repair a snow blower, the vent will need to be thoroughly rinsed with clean gasoline. After this, the operator must wipe it with a dry cloth;

- wear of one or more gears - any of the parts on which defects have formed will need to be replaced. In this case, new components must have the same dimensions as the spare parts that have become unusable.

Another typical breakdown of a built-in serviceable gearbox is wear of the shaft on which the gears and bearings are mounted. This happens as a result of operating the snow blower under constantly high loads. The essence of the breakdown itself lies in the formation of burrs and abrasions on the shaft walls, due to which the gears begin to slip when moving. Complete replacement of the shaft will help you fix the problem yourself.

Repair of sanding machines for parquet SO-206 / SO-155

| Name of works | Price | |

| 1 | Diagnostics of PSM | 500 rub. |

| 2 | Adjustment and configuration of the PShM | 350 rub. |

| 3 | Complete repair of fan unit SO-206/SO-155 | 750 rub. |

| 4 | Replacing the fan assembly | 200 rub. |

| 5 | Removing the drum | 350 rub. |

| 6 | Replacing the rubber coating of a 200 mm drum | 1,500 rub. |

| 7 | Replacing the drum pinch roller | 300 rub. |

| 8 | Installation of special clamping roller for broken socket | 500 rub. |

| 9 | Complete repair of the drum shaft block | 1,100 rub. |

| 10 | Replacing the glass with shaft assembly | 500 rub. |

| 11 | Replacing bearings in the adjusting wheel | 200 rub. |

| 12 | Replacing bearings in a dead wheel | 400 rub. |

| 13 | Replacing wheel tires | 350 rub. |

| 14 | Replacing the side wheel assembly | 400 rub. |

| 15 | Replacing the rear wheel assembly | 150 rub. |

| 16 | Replacing the Horn Bracket | 300 rub. |

| 17 | Replacing the Drum Front Cover | 300 rub. |

| 18 | Replacing the drum lift rod | 350 rub. |

| 19 | Replacing the drum lift handle | 500 rub. |

| 20 | Replacing the transfer handle | 400 rub. |

| 21 | Installing the dust collecting plate of the PShM housing | 200 rub. |

| 22 | Replacing the drum pulley | 300 rub. |

| 23 | Removing/installing the electric pulley. engine | 350 rub. |

| 24 | Replacement el. engine | 500 rub. |

| 25 | Replacing the electric motor platform | 300 rub. |

| 26 | Electrical repair PShM parts | 500 rub. |

| 27 | Prevention of PSM | 200 rub. |

Snow blower gear lubrication

Stable operation of the unit depends on many factors, the main one of which is high-quality lubrication. The oil used to service the snow blower mechanism must have the following properties:

- frost resistance - since the snow blower is used at extremely low temperatures, the lubricant for its gearbox must retain its structure under constant exposure to frost;

- high fluidity - the oil must quickly penetrate into the smallest grooves and holes, thereby ensuring continuous lubrication of rubbing parts;

- viscosity - the working fluid must be thick enough to cover the working parts of the unit with a durable, homogeneous oily film.

To do this you need to act in this order:

- First you need to remove the screws and remove the casing;

- After this, the operator will need to unscrew the bolts located directly behind the “snail”;

- Then you need to carefully remove the factory auger belt installed on the factory pulley;

- Next, you need to unscrew the bolts one by one, which firmly secure the shaft of the built-in auger;

- After this, you need to carefully turn the “snail”, and also remove the auger and the impeller installed on it;

- Then you will need to unscrew the standard shear bolts and completely disassemble the mechanism shaft;

- In the end, the operator will have to completely disassemble the built-in gearbox itself.

After this, you will need to thoroughly rinse the mechanism parts. The operator can then reassemble the factory snow blower gearbox and apply new lubricant.

How much does it cost to repair a snow blower?

| Name of works | price, rub. |

| Replacement of drive shaft, c/u | from 2620 |

| Replacing the air filter | 284 |

| Replacement of switch, bathroom | from 284 |

| Replacement of muffler, s/u | from 528 |

| Replacing the carburetor | from 1320 |

| Replacing the starter starting cord, c/o | from 792 |

| Replacing magneto (ignition module), c/o | from 1320 |

| Change of oil | 792 |

| Replacing the primer, c/o | 528 |

| Replacement of gearbox, c/o | from 3300 |

| Replacing the belt, c/o | from 1320 |

| Replacing the spark plug, c/o | 282 |

| Replacement starter, c/o | from 282 |

| Replacing the fuel filter, c/o | from 1320 |

| Replacement of fuel hose, c/u | from 792 |

| Flushing/purging the fuel system | from 660 |

| Carburetor adjustment | 1320 |

| Carburetor repair | 1320 |

The cost of maintenance of a snow blower under the promotion is 1920 rubles.

Prices shown do not include the cost of spare parts.

Order

Video: snow blower repair, belt replacement

To ensure the functioning of your snow thrower, we recommend that you regularly bring it to our company’s service center for timely repairs and maintenance.

Call our service manager in St. Petersburg, and he will answer all your questions.

We try to provide the highest quality of service, so we have created a Quality Control Service especially for you.

How to remove the gearbox on a snow blower?

In some cases, the snow blower owner may need to completely remove the gearbox. This is quite easy to do if you have a flat and shaped screwdriver on hand.

The procedure is as follows:

- First of all, you will need to hold one specific part of the factory shaft motionless with a hand vice;

- Next, you need to unscrew the 6 screws that connect both parts of the mechanism together;

- Then you need to lightly tap the assembly body with a hammer and carefully remove the gearbox.

The dismantled mechanism will need to be disassembled and the parts laid out on a flat surface. This will help identify the worn part. After replacing faulty spare parts, you can assemble the unit and install it in the regular place provided in the snow blower.

How to make a gearbox with your own hands?

In the event of a serious breakdown of the unit, it can be assembled from improvised means.

This will require the following components:

- solid bronze gear - you can buy it ready-made or order the production of a part from a turner;

- shaft - a pipe made of 45 steel is suitable directly for the manufacture of the element;

- bearings - closed roller type elements are suitable. They can be purchased as a set so that, in case of wear, you can quickly replace the spare parts with new components;

- oil seals - gaskets of suitable size made of dense frost-resistant rubber will cope with their role;

- case - it is best to buy a ready-made silicon or aluminum box.

The procedure for assembling a homemade unit is as follows:

- First, you will need to securely secure the bearings and the previously purchased gear on the pipe used as the shaft. To do this, the seats must be machined so that the parts fit tightly and do not fly off the pipe;

- Next, one of the shaft parts needs to be attached to the aluminum housing. This must be done in such a way that the installed bearings and bronze gear are located inside the housing itself;

- Then both parts of the shaft will need to be sealed with oil seals - this is necessary so that the lubricant used does not leak out of the mechanism during its operation;

- The operator will then need to install the second body part and attach it to the first using a bolted connection.

Provided the correct procedure is followed, the manufacturer will be able to assemble a simple serviceable unit that can transmit force from the motor to the factory snow blower auger.

The transmission of a snow blower determines its functionality and snow removal speed.

The climate on our planet is rapidly changing, and those areas where until recently there were almost snowless winters are now covered in snow. A shovel cannot cope with such loads, and it is being replaced not only on the streets of big cities, but also in villages, holiday villages and individual cottages by snow removal equipment. Every buyer expects to purchase convenient, reliable and inexpensive equipment. As practice shows, the successful operation of snow removal machines largely depends on the type of transmission, each of which has its own characteristics.

Classification of Hyundai snow blowers

There are:

- Hyundai gasoline purifiers, which are characterized by the presence of a displacement internal combustion engine and a multi-stage gearbox;

- electric snow blowers – develop low power and depend on power supply;

- Electroshovels are portable devices that can remove only shallow snow in a small area.

Let's take a closer look at the advantages of Hyundai snow removal equipment using specific examples.

Types of transmission

As a rule, snow removal equipment uses one of the types of transmission, each of which has its own characteristics:

- single-speed snow blower transmission, which is its simplest type and is usually installed on manual mechanisms that operate due to human physical strength;

- gear, which usually has several speeds and is used in self-propelled vehicles;

- hydraulic transmission of a snow blower: it is installed on a new generation device.

Advantages and disadvantages

Each type of transmission has its own advantages and disadvantages, so the decision on which snow removal mechanisms to purchase naturally remains with the buyer, who will weigh the pros and cons.

- A manual snow blower with a single-speed transmission is inexpensive and easy to use, but it requires significant physical effort to set it in motion. In addition, such a mechanism is not mobile: it moves only forward, and it is impossible to adjust it with different densities of snow cover.

- The snow blower's transmission, which is self-propelled, has four to six forward speeds and one or two reverse speeds. Forward speeds allow you to regulate work with snow of different densities, as well as drive the machine to the desired location. Such a machine will cost more, but it will also last longer.

- Hydraulic transmission is a new word in ensuring the reliability and durability of snow removal equipment. It is installed on a new generation device and has fundamental differences from existing mechanisms of this type today, the main one of which is the absence of the need for additional technical configuration. Equipment with such a transmission lasts a long time and is safe to use.

Review of the Hyundai snow blower lineup

Like all brand products, the selection of snow blowers is striking in its diversity. At the same time, of course, there are models that rightfully deserve the title of bestsellers. Today we will look at the models of Hyundai snowblowers that have received the greatest recognition from consumers.

S 5555

The main advantage of the Hyundai S 5555 petrol snow blower is its compactness. This model has the most modest dimensions of the entire line and was designed for use in small areas that require maneuverability. S 5555 is optimal for cleaning local areas and parking lots, driveways and park paths. The unit copes well with loose snow and starts easily even at the lowest temperatures.

Equipped with ice pick augers, which makes it easy to remove not only loose snow, but also ice. The design is equipped with guide skis located on both sides of the snow receiver. The gearbox has six forward speeds and two reverse, making it easy to adjust for optimal performance. The gearbox is protected from overloads, and the carburetor is equipped with a heating system.

Snow blower transmission design and options

The simplest configuration option for the unit is still the snow blower transmission with one fixed gear. Such a unit is capable of moving and functioning at only one speed. This often leads to high fuel consumption where it could have been avoided.

More expensive snow blowers are equipped with an improved transmission, which makes it possible to move in 2–6 forward and reverse speeds. Thanks to this, the machine moves slowly when clearing hard snow and faster when you need to get rid of freshly fallen snow masses. When moving slowly, fuel consumption is reduced and important parts of the snow blower motor wear out less.

Regardless of the number of speeds, the transmission of the unit consists of the gearbox itself, inside of which there are gears that have different shapes and different numbers of teeth. The more speeds, the more gears. When changing gears, parts switch, new gears of the box come into motion, and the wheels begin to spin faster or slower. The transmission of the selected speed to the axle with wheels is carried out through couplings. They are mounted on the bridge shaft and rotate along with the gears.

S 5555

A prominent representative of gasoline cars in the company’s assortment is the Hyundai S 5555.

The unit is equipped with a winter engine with a characteristic overhead valve placement according to the OHV system.

All models, not excluding the one under consideration, are assembled using the latest developments at the time of their creation, which ensures the greatest efficiency and a significant period of trouble-free operation.

What is noteworthy about this model is that it begins a series of two-stage snow blowers.

The first car came off the assembly line in 2012 and immediately earned recognition from consumers around the world.

On the Russian market, S 5555 is in particular demand due to its compact size. This factor makes the model suitable for use in a small private household, home or cottage.

The main task of the device is to clean paths in the garden, driveways to the garage and approaches to the porch.

Despite its main household purpose, according to technical criteria the model can be compared with devices of a higher class.

Operating Parameters

The power of the power unit installed on the snow blower reaches 5.5 liters. With. The targeted use of a frost-resistant engine makes it easy to start the device and get to work.

The automatic decompression valve used in the S 5555 design provides the machine with simplified starting. This is also facilitated by wide oil channels, permanent carburetor heating, a large starter lever and a primer used for fuel injection.

A perfectly balanced snow blower with an optimal center of gravity ensures comfortable operation and excellent maneuverability.

The model guarantees no slipping thanks to X-Track tires with pronounced winter tread.

Durable, intensively rotating augers are ideal for clearing both soft fresh snow and compacted and frozen snow. In case of overload, the gearbox of the device will be protected by the shear bolts that secure the main tool.

To ensure that the coating being cleared of snow does not suffer from the impact of metal parts, the manufacturer has provided special slides that are designed to adjust the level of the bucket in relation to the ground. This is especially important when cleaning tiled paths.

The durable knife of the device can leave scratches or even chips on the surface.

The model allows you to select a gear. The main criterion for such a decision is the depth of the snow cover.

The device has all the necessary certificates, and the selling company is obliged to provide the future user with a warranty card.

You will find a description of the Husqvarna 276 EP snow blower in our article. And here you will find out how much you can buy a Patriot Pro 650 for.

Among the technical features, the self-propelled nature of the device should be noted. Performance indicators:

- cylinder volume – 163 cubic meters. cm;

- power – 5.5 l. With.;

- maximum grip – 55 cm;

- cleaning height – 49 cm.

The device is equipped with six forward speeds and two reverse. Manual launch makes working with the model clear even for a novice operator. There is no electric start in a snow blower equipped in this way.

The snow discharge pipe is made of durable metal and does not corrode for a long time. You can control the reset directly from the operator panel. The model can throw snow at a distance of up to 10 m.

The fuel tank capacity is 2.6 liters, which, with optimal fuel consumption, allows you to work for a long time without refueling. The device weighs 72 kg.

The special structure of the model’s engine allows the device to be used even in the most severe frosts. This is facilitated by heating the carburetor.

The device does not require an air filter. Synthetic oils can be used to operate S 5555.

The serviceable gearbox is characterized by a reinforced structure and transmits torque from the motor without loss.

Efficient operation is facilitated by a convenient control panel, where all machine controls are located at the operator’s fingertips.

The directional shape of the snow ejection chute ensures the best discharge of mass far from the area being cleared. Durable material significantly increases the period of effective use of this unit.

What requirements must a snow blower transmission meet?

The transmission of a snow blower plays an extremely important role in the design of the unit. Because of this, when buying a car, you should pay quite a lot of attention to this element. There are a number of factors to consider when purchasing:

- Appearance of transmission parts - ask the seller to remove the protective covers and disassemble the transmission. You must ensure that all gears are intact and have all teeth on them;

- No oil leaks on the surface and between the gears - oil should be present, but only in small quantities. If it flows down the gears, it means there is a hole or crack in the reservoir. As a result of leaks, the oil will dry out on hot gears, which will lead to a deterioration in their interaction;

- Lack of grooves more than 5 mm wide – there should be narrow grooves between some transmission parts, but if the distance between the elements is too large, this can lead to failures when shifting gears;

- All parts must be firmly fixed in place and not wobble to the sides - if you tug the gears a little and they start to wobble, this will lead to a very quick breakdown of the unit. These snowblowers should be avoided;

- Compliance of gears with the dimensions specified in the technical data sheet - quite often sellers change gears or install missing parts from other units into the transmission design. The data sheet of the selected machine should indicate the size of each gear and the number of teeth on it.

If the transmission of the selected model has no signs of defects or damage, then it will last a long time without repair or replacement of parts.

Electric snow blower

The optimal solution for owners of small country houses and private houses. Operates silently, without gas emissions. Carefully removes snow and does not leave damage on the surface.

Snow blower "Hyundai" S400

Advantages:

- Hyundai electric motor with thermal protection;

- a rubberized auger that collects snow cleanly;

- polymer body, which is not subject to adverse atmospheric factors;

- work area lighting;

- ergonomic handles.

Technical parameters of S 400:

- Motor – 2 kW;

- Working strip size – 0.4 m;

- Cleaning height – 0.25 m;

- Maximum power: 2 kW / 2.7 hp

- Number of gears: mechanical

- Processing width: 45 cm

- Processing height: 27 cm

- Snow throw distance: 10 m

- Snow collection system: single stage

- Weight: 14.2 kg

The electric s400 easily copes with removing snow drifts. The rubber auger removes everything to the ground without damaging decorative steps, asphalt, paving slabs, or roofing. Lightweight, compact, easy to operate. There is protection against accidental activation and remote control of snow emission. The impact-resistant plastic case of the model is not subject to erosion, which significantly extends its service life.