Caterpillar D8R is a bulldozer machine with an upgraded cooling system and an efficient power plant. Grade Control technologies allow the operator to perform more operations per unit of time. In the basic configuration, the model has a relatively small blade, but this does not prevent it from performing significant amounts of work.

Cat D8R is produced by a well-known American manufacturer whose products are characterized by reliability and high quality. Caterpillar equipment has a stable demand in Europe and America, and the Cat D8R model is rightfully considered one of the most successful in the brand’s line.

The scope of application of the bulldozer is extensive thanks to the large line of attachments. The machine can be used in difficult conditions to perform the following functions:

- movement of various types of cargo (category 1-3, rocks, bulk materials);

- earthworks (layer-by-layer cutting of soil layers, leveling of large construction zones, quarrying, etc.).

The Caterpillar D8R is in greatest demand among organizations working in the field of construction and mining. The profitability of equipment increases when large volumes of work are performed, which is why it is more popular among medium and large companies.

Modifications and features

Cat D8R, like most models of the brand, is available in several modifications.

Caterpillar D8R STD is the basic and most common version. In addition to it, there are 3 more main modifications, differing in the characteristics of the working environment:

- swamp variation (LGP), designed for use on wet and soft soils;

- modification for working with waste;

- version for use in desert climates.

When creating the model, American developers took into account safety and environmental standards. The equipment has received ISO certification for the protective structure that protects the operator in the event of a rollover. The Caterpillar D8R cab meets industry standards for its class and provides Category 2 falling object protection. Harmful emissions from the engine do not exceed the limits approved by the American Environmental Protection Agency.

Other features of the bulldozer include:

- productive and economical motor of our own production;

- modular principle of construction of main units;

- easier access to service points and diagnostics;

- ease of operation and maximum operating comfort;

- the latest Cat Connect technologies;

- wide dealer network covering more than 50 countries.

Specifications

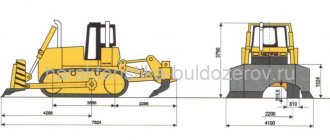

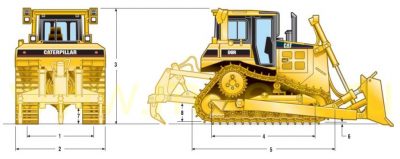

Dimensions:

- length – 7650 mm;

- width – 3940 mm;

- height – 3510 mm;

- ground clearance - 606 mm;

- front track – 2080 mm;

- rear track – 2080 mm;

- track width – 560 mm.

The operating weight of the Caterpillar D8R in the standard version is 38351 kg, the ground pressure is 86.4 kPa. The length of the track contact area with the surface is 3207 mm.

The bulldozer is capable of moving in the following speed mode:

- forward direction – 3.4-10.6 km/h;

- rear direction - 4.5-14.2 km/h.

The technique is used with various equipment. Capacity of the most popular dumps:

- 8A – 4.7 cubic meters;

- 8U – 11.7 cubic meters;

- 8SU – 10.3 cubic meters;

- 8SU (version 8SU) – 9.9 cubic meters.

Volumes of filling containers:

- cooling system – 62 l;

- power transmission – 155 l;

- final drives (each) – 12.5 l.

Advanced Cat D6K2 Dozer

June 23, 2014

There is another addition to the Caterpillar bulldozer regiment - a new version of the Cat D6K2 bulldozer, adapted for work in countries with less stringent environmental legislation, has been launched into the markets of Africa, the Middle East, the CIS, Latin America and Asia. The machine received many innovations, the main of which affected the blade control system, efficiency of work and operator comfort.

It is worth noting that the Cat D6K2 bulldozer first appeared on the market back in 2012 as a replacement for the outdated D6K model. Now the company offers a slightly modified version, equipped with a Cat C7.1 ACERT diesel engine with 130 hp. (97 kW). The environmental standard of this engine meets the requirements of Tier 3 or Stage IIIA, which is quite sufficient for the above markets. Other features include an air-to-air turbocharger and a new fuel system with greater filtration capacity for better reliability.

The Cat D6K2 combines these innovations with proven K-Series features such as single-lever drive and steering, single-lever blade control, a spacious, ergonomic cab and the signature heavy-duty track chassis that adds a second carrier roller and an eighth track roller.

Blade control is simplified with Stable Blade Control, which reduces control input and operator fatigue while increasing productivity, especially in precision grading applications. Also added is the ability to manually change the angle of the blade forward/backward to achieve optimal efficiency depending on the type of work and soil conditions.

The blade itself became slightly larger in size, which made it possible to increase the maximum prism for drawing material, and as a result, increase the productivity of the bulldozer by 8%.

Eco mode is available in both forward and reverse gears and, according to Cat, can reduce fuel consumption by up to 18% in some cases compared to the base D6K model. Adding to the economy is a hydrostatic transmission with an operator-activated traction control system that, by controlling the rotation speed of the tracks, reduces the likelihood of them slipping when driving at maximum load. As a result, there are fewer times when the operator has to raise the blade to prevent the tracks from slipping. At the same time, several variants of the bulldozer chassis are offered: the XL modification - with an extended caterpillar belt, and the LGP - with wide 760 mm shoes, providing the machine with low specific ground pressure.

As for operator comfort, the Cat D6K2 bulldozer can be equipped with a heated and ventilated seat at the customer’s request. There are also new adjustable armrests and vibration-isolated built-in controls.

To further increase productivity during grading work, the proprietary AccuGrade automated blade control system is available as an option for the bulldozer. The system can use a laser, total station or satellite positioning system to operate, and eliminates the need for geodetic surveys, eliminates re-grading and relieves the operator of complex high-precision finishing work, Caterpillar says.

The main technical characteristics of the Cat D6K2 bulldozer are as follows:

| Operating weight: - in XL modification - in LGP modification | 13,311 kg 13,948 kg |

| Engine power | 130 hp (97 kW) |

| Drawing Prism (XL/LGP) | 3.07 / 3.35 cubic meters |

| Blade width (XL/LGP) | 3,196 / 3,683 mm |

| Specific Ground Pressure (XL/LGP) | 39.8 / 30.7 kPa |

Photo

Design and operating features

The design of the Caterpillar D8R is based on a reinforced frame that absorbs torsional forces and severe loads. Cast elements provide additional strength to the balance bar support and main crankcase. The swing axis of the equipment runs along the entire length, so shock loads are distributed evenly across the crankcase, and the negative impact is reduced.

The tubular frame with 8 road wheels is perfect for maneuvering and working on rough terrain. The hinged mounting of the balancing weight ensures constant contact of the track with the surface and allows the carts to swing exclusively in the vertical direction.

A special feature of the Cat D8R chassis is the high location of the drive sprockets. Such a decision leads to the realization of 2 goals:

- increasing the service life of chassis components;

- improving equipment balancing.

Rigid fixation of fingers in the track tape, which is proprietary to Caterpillar, allows the structure to withstand enormous force loads. The box-section frame spars retain the geometry of the units, and additional reinforcement of the elements with steel castings provides the strength necessary for this technique.

The bulldozer operator is provided with a differential braking and steering control mechanism, through which a continuous supply of force is achieved on both tracks. To make a turn, the following method is used: the speed of one track increases, while the second track slows down. This allows you to change the direction of movement almost on the spot and better withstand loads.

The Caterpillar D8R features a new transmission that features electronic shifting for easier, smoother operation. The element is based on a planetary gearbox with the ability to shift under load. A special feature of the transmission is a torque divider, transmitting 70% of the power through a torque converter, 30% through a planetary gear. Due to this, the efficiency of the bulldozer increases.

The model also features raised final drives to minimize shock loads and provide ground isolation. Precise clutch modulation makes gear shifting smoother.

The bulldozer uses a hydraulic system with power control based on load for maximum efficiency of equipment operation. The main element is a piston pump with a capacity of up to 300 l/min. The system pressure is 24.13 kPa.

The bulldozer uses box-shaped blades made of special high-strength steel. Hardened cutting edges and reinforced construction ensure long service life. The most common attachment for the Cat D8R is the hemispherical blade. Spherical and rotary blades are also used. Single- and multi-post parallelogram rippers with a large penetration depth can be installed at the rear of the bulldozer. A winch and rear counterweight are used with the machine.

The Caterpillar D8R cabin is installed on insulating supports, which significantly reduces the level of vibration and noise in the cabin (no more than 85 dB). A comfortable comfort class seat reduces driver fatigue and allows you to work several shifts without reducing productivity. Built-in protection (ROPS) provides safety, and large windows provide the operator with the visibility he needs. The cabin has an air conditioner and heating system that maintain the required temperature conditions.

An improved monitor complements the controls, providing all the information on machine operating parameters.

In the process of developing controls, preference was given to a single handle with push-button speed switching. You can operate it, changing the direction of movement and selecting the required gear, with one hand. To increase safety, the creators added a mechanism for locking the working equipment.

The modular principle allows the unit to be dismantled without affecting other elements. Quick diagnostics are performed using a laptop computer. These solutions facilitate bulldozer maintenance and reduce operating costs.

Bulldozer D6R Caterpillar

Bulldozer D6R Caterpillar is a universal bulldozer of traction class 10. The bulldozer has high performance, efficiency and environmental friendliness, and is also able to work in various climatic conditions.

Thanks to its excellent balance of power, reliability and productivity, the Caterpillar D6R bulldozer can be used in various types of industrial work in the oil and gas, road construction and mining industries, as well as in the development of various heavy and frozen soils.

The Caterpillar D6R Bulldozer is designed specifically for harsh conditions, which ensures trouble-free and optimal operation of the CAT D6R Bulldozer, regardless of operating conditions and complexity of the job.

Advantages

- 192 hp Cat C9 ACERT engine;

- Updated cabin;

- Reliable running system;

- Ease of operation;

Bulldozer D6R Caterpillar | Price — 15,500,000 rub.

The price of a D6R Caterpillar bulldozer with a Cat C9 ACERT engine with a power of 192 hp, with bulldozer and ripper equipment, an operating weight of 19,500 kg is 15,500,000 rubles. The price of a used D6R Caterpillar bulldozer starts from 4,750,000 rubles.

Bulldozer D6R Caterpillar | Specifications

The Caterpillar D6R bulldozer has excellent technical characteristics, a powerful engine and a reliable running system. Thanks to its performance, reliability and ease of operation, the Caterpillar D6R bulldozer is one of the best bulldozers in its class on the market.

Engine

D6R Caterpillar Cat C9 ACERT bulldozer engine with 192 hp. and meets high environmental standards and Tier 2 / Stage II / China Nonroad II emission requirements.

| Engine power, hp | 192 |

| Engine displacement, l | 8,8 |

| Engine crankshaft speed, rpm | 1900 |

| Cylinder diameter, mm | 112 |

| Piston stroke, mm | 149 |

Transmission

A reliable and time-tested transmission with an electronic gearbox of the Caterpillar D6R bulldozer with three forward speeds and three reverse speeds provides precise and smooth control of the movement of the bulldozer, regardless of work under load.

Engine

The D8R is equipped with a Caterpillar 3406C powerplant with electric fuel injection via unit injectors, turbocharging and charge air cooler. The engine crankshaft is made of heat-treated carbon steel, and the cylinder block is made of gray cast iron with high tensile strength. The number of mechanical connections has also been reduced, making the unit more durable.

The service life of the unit elements is increased due to the use of water cooling of cylinder liners and oil-cooled pistons. This solution ensures efficient heat removal. The Caterpillar 3406C uses an AMOCS cooling system with increased air flow. Thanks to this, the bulldozer can work at its maximum capacity for a long time.

The unit complies with EU Stage II and US Tier 2 standards.

Characteristics of the Caterpillar 3406C motor:

- working volume – 14.6 l;

- rated power – 245(328) kW (hp);

- rated speed – 2100 rpm;

- number of cylinders – 6;

- cylinder diameter – 137 mm.

The fuel tank of the car holds 625 liters of fuel.

Cat D9R Dozer Operator Station

D9R bulldozer operator station is designed to provide the highest possible comfort with exceptional ease of use.

Control system developed by Caterpillar

Constantly informs the operator about the current state of the machine systems, and also registers in the memory increased and decreased readings of instruments for diagnosing and controlling the operation of the chassis.

The monitoring system includes dial indicators for the temperature of the engine coolant, hydraulic system oil and power transmission oil, as well as the fuel level in the tank.

The system is equipped with warning indicators to monitor engine oil pressure, intake manifold temperature, coolant flow, electrical system and transmission oil filter status, as well as an air filter service indicator, engine warning light and steering control filter indicator. braking (only with differential steering and braking control).

There are also devices for displaying tachometer readings in digital and analogue form.

Comfort at work

The cabin, mounted on insulated supports, provides reduced vibration and noise levels of 84 dB(A).

The cab is equipped with 12 or 24 V wiring leading to a radio recess in the cab roof lining.

Low-effort controls

Conveniently located and easily accessible, which allows you to reliably and accurately maneuver the machine with less operator fatigue.

Caterpillar Comfort Seat

The seat of the new series, characterized by increased comfort, is fully adjustable.

The seat and back cushions are thicker and designed to relieve pressure on the lower back and hips without restricting arm and leg movement.

Control via onboard clutches and brakes

CAT D9R bulldozers are equipped with levers that allow you to both disengage the side clutches and brake each of the caterpillar tracks.

Changing the direction and speed of movement is provided by one gearbox control handle.

Unobstructed all-round view

The machine's sloped hood and recessed fuel tank provide clear forward and rear visibility from the operator's seat.

The rear window provides the operator with a clear view of the ripper tooth tip, and the wide one-piece door windows allow him to see everything that is happening in the tanks, including in the immediate vicinity of the machine, without changing his position in the seat.

Rocker switch

The engine speed is controlled using the rocker switch and decelerator pedal. Switching on high or low idle speed is done with a light touch of your finger.

Work equipment control lever limiters

When engaged, the stops prevent unintentional movement of the work equipment control lever.

These restraints can be locked with standard Caterpillar locks.

Cat D9R Dozer Cab Interior and Exterior Equipment

Elements of internal and external cabin equipment include:

- Intermittent windshield wipers;

- 12 V electrical outlet;

- Small compartment under the seat for storing a first aid kit, etc.;

- Handles for opening doors from the inside;

- Lunchbox fastening;

- Glass holder;

- Ashtray;

- Standard converter from 24 to 12 V;

- Power socket behind the seat;

- An internal cornice located around the perimeter of the cabin with a niche for installing a radio receiver, loudspeaker and antenna.