Every summer resident on his plot in the spring or autumn is faced with such a problem as dry branches on fruit trees and shrubs. Mostly, summer residents throw away or burn this material. Because sometimes they don’t have the strength or means to process them. But if you chop these branches, you will get excellent compost and fertilizer for your garden.

There are a huge variety of garden shredders, branches, grass and straw available for sale. But all these units cost money, and sometimes quite a lot for a simple summer resident, and our gardener is used to saving and doing everything himself, since the family budget does not allow him to walk in grand style.

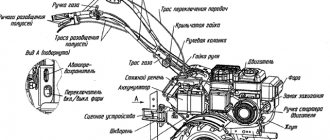

The author decided to construct his own wood chipper from what he had on hand. And the author had an old walk-behind tractor on his farm. It was on the basis of this unit that our designer decided to assemble a branch chopper.

The principle of this design is quite simple, if you understand everything thoroughly. The chopping apparatus itself consists of a drive shaft with knives, and a stationary knife, due to the torque of the drive shaft with knives, branches and bushes are crushed into small dust and chips. The drive shaft is driven by torque passing from the walk-behind tractor through the belt to the pulley of the rotating shaft, thereby bringing the grinding apparatus into action. For the convenience of supplying material to the chopping unit, he welded a receiving hopper from sheet metal, which is very convenient when you simply direct a branch into the hopper, and then slowly push it. That’s essentially the whole complexity of the design, and now let’s take a closer look at what he needed and how he designed his invention.

Materials:

walk-behind tractor, electric planer blades, pulley, shaft, bearings, channel, 3 mm sheet metal, bolts, nuts, washers.

Tools:

welding machine, grinder, hammer, set of wrenches, pliers, drill.

And so the author first welded the base from a channel, then installed a stationary knife, and the most important part is a drive shaft with knives from an electric planer, a pulley is installed on the shaft with a cutting apparatus to drive it from the torque supplied from the walk-behind tractor through a belt drive.

Then I welded and installed a receiving hopper for the convenience of chopping branches. And then I installed the grinding apparatus on the front part of the walk-behind tractor and pulled the belt drive onto the pulley. The walk-behind tractor was previously placed on a stump so that it would not move away))). That's essentially it, and that's all the branch shredder

The attachment to a walk-behind tractor for a branch crusher is another device needed in the household. With its help you can perform the following work on your site:

- clear the controlled areas of branches and garden debris (bush trimmings, etc.);

- prepare mulch for plants;

- grind uprooted stumps;

- process grass;

- prepare raw materials for making compost (plant fertilizer).

Types of garden wood chipper

There are several classifications of branch choppers for walk-behind tractors, differing

- by type of power plant;

- by motor performance;

- by quantity and quality of cutting knives;

- according to the operating principle of the unit;

- by appointment;

- with or without additional functions.

Let's look at each option in more detail.

Types of engines and their performance

For full operation of a garden shredder for a walk-behind tractor, motorized devices with the following power plants can be used:

- gasoline type;

- electric.

Gasoline engines are more efficient and do not require an electrical power source. Electric models are more unpretentious in maintenance and do not require special care; they are quiet, but will not work without being connected to an electrical outlet or to a battery.

Number of cutting edges, their features

Cutting mechanisms are of the following types:

- circular saws mounted on the shaft in the amount of 15-30 pieces;

- jointer knife with grooves, in quantities from 2 to 6 pieces;

- synchronously rotating shafts with knives.

Knives can be of two types:

- with one blade;

- with two blades.

The second option allows, if one cutting edge becomes dull, to turn the knife over and continue working with the second cutting edge. The knives are easy to replace and can be sharpened.

Is it possible to make a homemade circular saw with an engine from a walk-behind tractor?

On the Internet you can find many diagrams and descriptions for creating a circular attachment for a walk-behind tractor yourself. One option is to use a table made of beams. The structure is connected together using bolted connections. In this case, the motor is disconnected from the walk-behind tractor and secured directly under the tabletop on a transverse board. A specially made hinge will securely secure the power unit in a pre-marked location on the frame.

You will also need a spindle from a bicycle and a D8 or D6 sprocket from the motor. Naturally, you will need a shaft, a bushing, a metal plate 4-5 mm thick and the circular saw itself.

Peculiarities

The following attachments exist:

- Designed for chopping dry branches;

- Stump grinder for walk-behind tractor;

- Grass choppers for walk-behind tractor;

- Crushers working with raw material.

Specialized stores offer a full set of attachments that allow you to work with any material. Shredders for walk-behind tractors are capable of passing through branches with a diameter of about 5 cm, while the final product will reach a length of no more than 8 cm.

Chopper for a walk-behind tractor: which one to choose and how to make it yourself

A well-groomed area always attracts the attention of strangers with its cleanliness and order. However, not everyone thinks about how much time and effort is required to bring a large territory to an idyll. Various attachments on the walk-behind tractor, and in particular the branch chopper, play a big role in this matter. This is what we will talk about today.

Read also: Motoblock Khoper 900: owner reviews, description, technical specifications

Do-it-yourself branch crusher for a walk-behind tractor

Branch crushers can be made with your own hands; this will save the family budget and allow the owner of the walk-behind tractor to make the device according to his needs. For work on creating a chopper attachment, you will need:

- welding machine;

- Bulgarian;

- drill;

- bolted connections;

- corners;

- sheet steel, 5 mm thick;

- pulleys;

- bearings;

- circular saws from 15 to 25 pieces;

We suggest studying one of the diagrams, which shows the structure of the branch chopper:

After watching the video, you will understand how a branch chopper for a walk-behind tractor works.

Do-it-yourself branch chopper for a walk-behind tractor: a set of preliminary works

Before you choose the design of a garden wood chipper and begin assembling it, you need to decide on the goals of its creation:

- To obtain sawdust, which can be added to the soil as compost or used for fuel briquettes, the easiest way is to use a disc crusher for a walk-behind tractor;

- For the purpose of coarse crushing of branches into a large fraction - shredders acting as a jointer;

After that:

- Select a traction block - walk-behind tractors with a power of at least 5-6 hp are compatible with the chopper attachment. The most reliable designs are obtained on the basis of the Neva, Cascade, and Tselina walk-behind tractors;

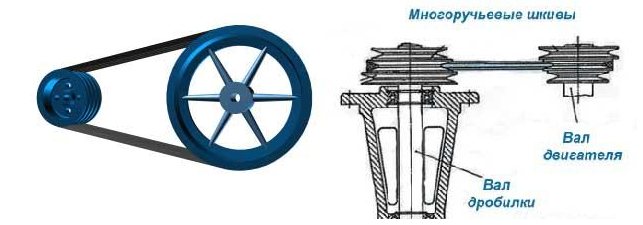

- They adapt the V-belt drive - in order for the cutting set to cut smoothly and not wear out the engine, it should account for half of the declared torque of the device. For example, for a walk-behind tractor with 3 thousand rpm, the rotation speed of the blades will be 1.5 thousand revolutions. At the same time, the length of the belts is adjusted: for the leader it will be 10 cm, and for the slave – 10 cm;

- Pulleys are modified - it is more effective if the pulley has 3-4 grooves. This will allow you to “maneuver” between revolutions and operating speeds only by re-throwing the belt, expanding the scope of application of the crusher.

Read also: Do-it-yourself mini tractor from a Neva walk-behind tractor, step-by-step instructions

Material and technical base:

- discs for circular saws with pobedite soldering;

- gasoline drive from a home walk-behind tractor;

- belt;

- pulley;

- bearings;

- M20 bolts along with fasteners;

- pipes;

- steel;

- electric welding and grinder.

The lineup

If you still want to purchase a ready-made branch chopper for your walk-behind tractor, then we offer a small list of popular models on the market:

Branch chopper "Premium" (without wood splitter)

Characteristics:

- Material: steel;

- Product weight: 75 kg;

- The pulley for the motor tractor is included in the kit.

Branch chopper with wood splitter (TYPE - 2) Premium

Characteristics:

- Material: steel;

- Cutting capacity: up to 50 mm;

- Knife thickness 12mm;

- Product weight: from 90 kg;

- Cutting mechanism type: knife system.

Branch chopper Volodar for walk-behind tractor RM-90D

Branch chopper Volodar for walk-behind tractor RM-90D

Characteristics:

- Output length of firewood from 80 to 170 mm

- Unit productivity 5 m³ branches per hour

- Weight 160 kg

- External dimensions of the receiving hopper: 470 x 420 mm

- Knife thickness: 8 mm

- Number of knives: 6 pcs.

- The thickness of the module plates is 20 mm

- Steel grade: 65G hardened

Chipper for walk-behind tractor RM-90 M

Often, after cutting firewood, tree trimmings and dry twigs remain on the dacha plot. If they are not removed in a timely manner, a whole mountain of unnecessary garbage may form. It is necessary to get rid of it. The easiest way is to compost unwanted wood. But the branches spoil the beautiful appearance of the dacha plot, and the process of such “cleaning” itself takes too much time.

Pendulum circular saw with electric motor

You can make a homemade circular saw quite easily to cut logs and pieces of wood, the thickness of which corresponds to the strength of the electric drive installed on it. If you intend to work with large and very thick pieces of wood, then you should equip your homemade saw with a truly powerful electric motor, as well as install a shaft and belt drive on it. The best solution in this case would be to install a special pendulum frame.

When making a pendulum circular with your own hands, only very strong steel corners should be used as the material for the frame. Next, on the finished steel frame you will need to place all the mechanisms necessary for the normal operation of a homemade circular saw. With this design, you can personally set the flight altitude of the cutting blade without any special effort, while avoiding excessive design difficulties.

Return to contents

general characteristics

A branch chopper for a walk-behind tractor is a special attachment (attachment) for walk-behind cultivators and walk-behind tractors. This device is mainly used:

- to chop brushwood specially collected from forest plantations;

- to process branches of bushes, fruit trees and young growth in gardens.

As a result of the operation of a branch chopper on a walk-behind tractor, finely chopped shavings are obtained. It can be used as mulch, or placed in a compost pit to produce humus (gardeners and gardeners very often use shavings to produce humus), that is, the shavings can be used as fertilizer. The diameter of the material crushed by a branch shredder attached to a walk-behind tractor is up to fifty millimeters.

The great advantage of a shredder attachment for a walk-behind tractor is that the branch chopper can be ideally suited to any type of motor-cultivator or walk-behind tractor (the most important thing is that the device is equipped with a belt drive from the motor pulley to the gear pulley).

A chopper for a walk-behind tractor allows you to forget about making fires, which are necessary for burning waste and garbage in your summer cottage.

Crusher for walk-behind tractor: design and types of designs

Garden shredders or shredders are a relatively new type of device on the domestic market. They are the most useful and simple alternative to recycling cut branches of trees and shrubs, as well as grass: they are crushed into mulch, which can be used as organic fertilizer.

Read also: Snow blowers: what are they, how to choose a snow blower and what equipment is best for removing snow?

Due to their high cost, not every owner has them at their disposal. But having a walk-behind tractor at hand, you can make it yourself. We will talk about the nuances of this process further.

A garden wood chipper is an automated device that operates from an electric or internal combustion engine and is adapted for crushing fallen leaves, branches of fruit crops, and mown grass into organic matter. It is available for sale as an independent device and as an attachment to a traction element - a walk-behind tractor or a mini tractor.

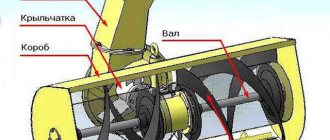

In both cases, the structure is:

- Engine;

- Metal carcass;

- Compartment for receiving sawdust;

- Operating shaft equipped with blades;

- Safety cover.

The chopper adapter for walk-behind tractors is not compatible with all of their modifications.

The minimum requirements for retrofitting are:

- Medium or heavy power class of a specific model;

- Engine with hydrocooling system;

- Front PTO, which is connected to the chopper via a belt drive.

Structurally, walk-behind shredders are classified into:

- knife - the cutting unit is represented by several saw blades, which are directly attached to the motor shaft. With the high power of the power unit and high-quality knives, they can easily grind fresh cut branches or soft components - dried hay, thin branches of bushes. The only limitation for this group can be the diameter of the branches: for dry – 25 mm, for fresh – 40 mm;

- milling shredders for a walk-behind tractor - similar to the first group, but instead of knives they contain a milling cutter - a gear with large teeth. Usually available in steel. They work slowly and smoothly, which is effective only for well-dried workpieces;

- universal shredders made from a walk-behind tractor - cope well with any organic mass that is prepared in several stages.

How to choose?

Before you buy such a unit, you first need to figure out for what purpose the grass and twigs will be chopped. The choice of device design and its type directly depends on this.

Branch choppers for walk-behind tractors are divided according to the following parameters:

- principle and type of operation of the grinding unit;

- engine type and power;

- type of motor (electric and gasoline).

An agricultural device with a gasoline engine processes large branches better. It is considered more mobile. It does not require electrical power to operate. It is better to use an electric unit if you need an attachment for a tractor or walk-behind tractor. The electric unit is compact and easier to operate, but its main disadvantage is its direct dependence on the electrical network.

When choosing an agricultural device, you need to pay attention to the blade design, which affects the quality of crushing. For example, some of these attachments are capable of processing branches up to ten centimeters long.

Stationary machine

A circular saw, as close as possible to factory models, requires a competent approach to assembly, so before making a stationary type circular saw, you need to think through everything down to the smallest detail. In principle, a tabletop mini circular saw differs from a stationary one in the height of the frame, which directly depends on the nature of the work performed and the dimensions of the workpieces that the device will process. One-time work can be carried out on a compact table saw, while a circular saw from a hand-held circular saw can be easily hidden in a shed or closet, and a carpenter who constantly manipulates lumber will need a stationary homemade circular saw. Below is a diagram that details all the elements and accessories for a circular saw of this type.

As can be seen from the figure, homemade circulars of this type have a clear design, and drawings like the one presented above greatly facilitate the process of assembling them. Before making a circular table, as well as mounting a circular table with your own hands, we will consider each part of the unit separately in order to know all the intricacies of its operation and installation.

Circular table

A table for a hand-held circular saw with a slot in the center is sometimes converted from an ordinary kitchen table or assembled from beams or metal profiles. Experts strongly recommend covering a table for a circular saw with a sheet of galvanized metal, since without a coating the base is at risk of abrasion in the center from constant friction of the lumber, which in turn will negatively affect the quality of the cut, and the depth of the cut will be uneven. It is better to make cross braces that strengthen the sawing table from a steel angle 60 - 80 mm with a horizontal segment outward in order to simplify the installation of the side stop. The homemade table on which the circular saw will be installed must be strong and stable, and it must also be securely fixed in a stationary position.

Saw blade

The toothed disk should rise above the surface of the table of the circular saw by a maximum of a third of its diameter, otherwise it will not cut the tree properly, and the process itself will become dangerous. If you need to cut a beam with a diameter of, for example, 100 mm, the same parameter of the cutter should not exceed 350 mm, however, a motor with a power of 1 kW will also be required. For workpieces with a diameter of over 150 mm, a mini circular saw made by hand is unlikely to be suitable. Some factory circular saws are equipped with a riving knife, which is installed behind the disk at a distance of 2 - 3 mm from the saw teeth. It eliminates the jamming moment due to the closure of parts of the sawn workpiece, so it can also be very useful in the case when a homemade circular saw is assembled.

Adjustable side support

It is possible to install a high-quality stop from a steel angle with a cross-section of about 80 mm, which is 3–4 cm longer than the table structure. The flat sides of the corner are bent down so that their width is one and a half cm greater than the thickness of the table. After installation, the emphasis is fixed on a homemade circular table in a given position using bolts. This element is adjusted according to a template placed between it and the cutter.

Shaft

The shaft installed on the circular saw is the most critical component, so its turning and testing together with the disk should be carried out exclusively by a specialist using special equipment. A pipe product with a carelessly fixed circle is immediately excluded, because the slightest errors in the operation of this element will result in major troubles such as equipment breakdown, damage to the workpiece and injury to the operator. The optimal solution would be to purchase a ready-made shaft with a seat for the cutter

. It is better to give preference to self-aligning ball bearings that have a curved inner surface, otherwise the unit you made yourself will quickly collapse and the shaft mounted on a homemade circular will become unusable.

Broadcast

In our case, the ideal option would be a V-belt drive, but it is better to refuse a rigid gear mechanism, since such a homemade product does not guarantee safety. If a nail suddenly gets caught in the lumber, the motor rotor will cause the disc to fracture, which can lead to injury. If the inner diameter of the belt drive pulleys is small, then slippage will be ensured, and the tensioned belt will serve as a kind of damper. The gear ratio is usually selected based on engine speed, always taking into account the permissible number of disk revolutions. The smaller the diameter of the saw wheel, the higher its rotation speed can be, and the cleaner the converted unit will cut.

Motor

Among home-made devices, the most popular is a circular machine assembled from a washing machine motor. This choice is explained by the fact that its operating scheme is best suited for such purposes. Unlike collector units, which are usually supplied with power tools, the engine from a washing machine operates at lower speeds, which means that it lasts longer, has increased efficiency and is not so susceptible to all sorts of blockages. You can also use a three-phase motor, but then additional costs will be required for the purchase of a starting and operating capacitor, so it is more economical to make do with a device from a washing machine. That, in general, is all the wisdom.

How can I make a circle with my own hands

?

Circular saw. This is perhaps one of the most useful and necessary tools for a craftsman engaged in the construction of private housing or the construction of his own country house. At the same time, many craftsmen are interested in how to make a circle with their own hands in order to save on purchasing it. Today there are a large number of different options available on the Internet, each master adds something to his design. We will not search for all available options, but we will look at the most popular ones, according to which many homemade circulars have already been made.

Is it possible to assemble the nozzle with your own hands?

Of course, you can make a branch chopper for a walk-behind tractor with your own hands, but it’s not easy. If you assemble a homemade structure strictly according to the instructions, no special problems should arise.

A branch chopper for a walk-behind tractor (homemade) is not just about saving money. A self-constructed unit has many advantages, in particular:

- allows the master to independently select the power required for the agricultural unit;

- allows you to equip the equipment with the number of knives required for work;

- allows you to determine the diameter of the sticks during the manufacture of such an agricultural machine;

- low cost of parts that are used in modeling this agricultural structure.

Installation procedure

To understand how to make a branch chopper with your own hands, you need to study the following algorithm of actions.

First, you need to secure the knives to the axle using washers and nuts. You should not place the cutting elements close to each other, as in this case the crusher will not function normally.

This is due to the fact that when placed close together, one knife will always cling to the other. It would be more correct to mount them on the axle with a small gap, for which you can use any plastic washers. It is not difficult to guess that their number should be one element less than the number of knives.

After this, the axle is equipped with a pulley. As mentioned earlier, the ease of rotation will be facilitated by equipping the pulley with two bearings with a diameter of 20 mm.

Next, you need to weld the frame on which the electric motor will be mounted in the future. The motor should be mounted so that during operation it can be easily moved within the entire structure. This will help change the degree of belt tension and allow you to control the process of chopping branches.

Working with the crusher will become more convenient if you attach a block made of profile metal to the frame. During chopping, the branches can be firmly fixed by resting them against this block.

Valiant grapes

Next, the cutting unit must be equipped with a casing that will protect the chopper knives.

It is important! Sheet metal is best suited for making a casing, since this material is more reliable compared to galvanized steel.

The wood chipper is almost ready. All that remains is to attach a receiving box to the body of the device, designed to load into it the branches required for chopping, and install the structure on a wheel mechanism for ease of movement. At this point the device can be considered ready for use.

Online store store service center website: we make any garden equipment “breathe”!

We are glad to welcome you to our website and thank you for your trust in our company!

Any garden equipment is, first of all, a complex mechanism that at certain times requires attention and, if you do not follow the rules of their operation and do not carry out timely technical inspection, repairs cannot be avoided. We are ready to help you with this!

We guarantee reliability and high quality of materials and work performed. We are representatives of most well-known brands in the city of Vladimir, which is why we have direct supplies of spare parts from manufacturing plants, and our craftsmen are constantly improving their skill level. All this helps us to repair any garden equipment efficiently and on time.

Repair of garden equipment in Vladimir. Why us?

- With us you can not only purchase high-quality products from the most famous manufacturers of gardening and agricultural equipment, but also use the services of our service center.

- Regulations of our work when equipment is received for repair. Technical inspection for faults, selection of spare parts, direct repair of faulty equipment.

- We pick up and deliver back your equipment. We understand how difficult it is sometimes to carry out the process of delivering large cargo to a service center, so we take on the solution to this problem ourselves.

- We not only eliminate typical malfunctions that arise during operation (the walk-behind tractor engine does not work, oil leaks from the gearbox, the carburetor is incorrectly configured, etc.), but we also quickly find a solution for non-standard problems associated with the operation of the tool.

- Replacement equipment during repairs. Our service center will provide replacement equipment for the duration of repairs to customers who purchased it in our store (primarily, this applies to walk-behind tractors and cultivators)

Frequently asked questions by owners of faulty equipment:

- Which engine is suitable for my walk-behind tractor or cultivator? The variety of engines makes your eyes wide open. Which one should I buy that is reliable and not expensive? Wherever I go, everyone praises his own!

- Where to buy spare parts for a walk-behind tractor or cultivator. Everywhere they sell only equipment, but no spare parts.

- Replace the engine on the walk-behind tractor, adjust the cables, buy an adapter for the new engine.

We recommend reading

- Secrets of the world and the universe, two questions about what happened after the flood

- Alexander Pushkin - Prisoner: Verse

- How to get rid of resentment How to get rid of psychological

- How to stop feeding at night

Large homemade circular saw

When making a frame for the top of the saw, it is best to use a metal corner 25 mm wide. In this case, the rectangle, which will represent the frame of the upper part of the homemade circular, should have dimensions of 600x400 mm. Next, four pipes are welded in the corners of this quadrangle, the diameter of which should be 17 mm and the height should be approximately 2.2 m.

After this, it is necessary to strengthen two corners on the frame, on which the bearings will later be fixed. The distance between these corners directly depends on the length of the shaft. To fix bearings, as a rule, clamps are used. It is best if the bearings installed on a homemade circular are closed. This way you won’t have to worry about wood chips getting into the space between the balls, rings and separator. Don't forget to also cut a thread at the very end of the shaft so that you can install a cutting blade on it later.

The lower part of the circular saw should be made much more massive, which will provide it with the necessary stability and reliability. Therefore, when making the lower frame, you need to take a corner with a width of at least 40 mm. Next, across the frame it is necessary to secure two additional corners, which will later support the motor of the homemade circular saw. The most suitable motor for a DIY circular saw is an asynchronous three-phase motor with a power of at least 1.5 kW and 1500 rpm. The pulley groove should be quite large, approximately 80 mm, and it should be mounted directly on the shaft itself. In addition, you will need to weld a fairly small metal platform to the frame on which the starting device will be placed. Large pipes 2.2 m long, which you previously welded in the corners of the frame, are necessary for high-quality tension of the belt so that the metal wings press the thin pipes.

Now you need to insert both the lower and upper parts of the homemade saw into the finished supports made of pipes, and then tighten and tighten the belt with metal wings. You can start the motor in this model of circular machine yourself using starting capacitors. In order to additionally load the motor and increase its torque, you can use a 220/36,400 W transformer.

Return to contents

Mini circular saw: manufacturing instructions

Return to contents

Mini-circular base

To make such homemade products you will need:

- two metal plates;

- wooden beam;

- spindle from a bicycle;

- star;

- chain.

The mini-circular saw should be placed on a strong and stable table, since any rocking can pose a danger to human health and also interfere with normal operation of the saw. Before you start making a machine from a hand-held circular saw, you need to make a special table. In this case, you can use metal sawhorses and a regular old kitchen table as a bed. To begin, you will need to connect the trestles to each other with a wide wooden board at least 50 mm thick, and then secure the kitchen table to this base.

You can make the tabletop itself from two metal (preferably steel) plates with a cross-section of about 4 mm. In addition, you can use thick wooden blocks for this purpose.

It is important not to forget to leave a small gap between the metal sheets, the size of which is usually 10-12 mm.

In this case, you need to make sure that the edges of the metal plates are perfectly parallel to each other. Now that the table is completely ready, you can begin attaching the circular saw itself to it. It is important to note that it should be secured from below, and in such a way that its cutting disk is directly in the gap between the two sheets of the tabletop.

A saw from a walk-behind tractor is a reality that has made it possible to further expand the functionality of this agricultural equipment. Now, having in your arsenal only one walk-behind tractor and various attachments, you can cope with any task at your dacha.

So, for example, using a circular saw attachment for a walk-behind tractor, you can process wooden beams for construction and prepare firewood.