A hydraulic hammer is a multifunctional replaceable device that is equipped with excavators and hydraulic machines, including loaders, manipulators and other special equipment. Compared to other types of working units, hydraulic systems are considered active equipment that dynamically affects special equipment. Controlling the pressing force can be difficult for the operator, so the machine is suspended and supported by the hammer itself. This allows the lift-off height to be reduced as the unit deepens into the surface being treated.

Features of the design and operation of hydraulic hammers

Hydraulic hammers are used for:

- destruction of reinforced concrete buildings and concrete structures;

- loosening rocks and frozen soil;

- digging up underground communications, asphalt;

- driving piles;

- compaction of loose soil.

During long-term operation and high loads, working elements and components are subject to accelerated wear. The most reliable units, including Case, can fail or work incorrectly. If you need to change parts for Case equipment, it is advisable to place an order at the Snabavto store, since this company supplies original and high-quality spare parts.

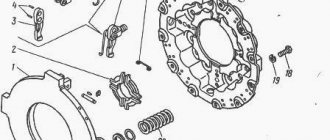

The hydraulic hammer design includes the following components:

- Pike . This tool is universal, made in the form of a metal rod equipped with grooves for fixing in the motor axle box. The impact component of the unit acts on the upper end, and the lower part interacts with the destructible surface (its shape can change - a rounded cone, a flat end, a pyramid with edges).

- Klin . This unit is recommended for use if it is required that the cracks on the surface being treated extend away from its blades. The latter can be placed lengthwise or across.

- Chisel . This tool belongs to the wedge category and is equipped with a sharpening angle of more than 30 degrees. The use of a chisel and a wedge is important for destroying road surfaces or loosening soils.

- Tamping part . Intended for soil compaction.

- Branch pipes, tongues and caps for piles.

Some manufacturers are trying to reduce the level of dynamic force on the working unit. To achieve this, the breaker part of the hydraulic hammer is installed in a special protective casing with the possibility of slight movement when the shock absorbers are activated. The latter are made in the form of springs, plastic or rubberized modules. The use of such devices makes it possible to reduce the force on special equipment if the deformation of the unit is no more than the amount of insertion of the unit per force. But since the energy intensity value is low, equipment with suspended wheels will not be protected if the working material is destroyed.

Operation of an excavator equipped with a hydraulic hammer.

Introduction

Construction equipment plays a very important role in modern life. For example, excavators. Excavators are indispensable when performing large volumes of excavation work at large construction sites, mining enterprises and forestry. Also tractors. Tractors are very widely used in modern life: for transporting goods (tractor trains), in construction, for plowing land on agricultural sites.

The scope of application of special equipment is varied. These are the construction of buildings and structures, road construction, logging, agriculture and public utilities.

The role of modern special equipment in human life is difficult to overestimate. The further technological progress advances in the production of special equipment, the less manual labor is used when performing work.

Today, manufacturers of special equipment offer reliable, high-quality machines that are easy to manage and operate. Further development of special equipment is aimed at improving machines already released on the market and creating radically new models that make human work easier.

Modern special equipment is very diverse. She works for the benefit of people in the following areas of activity.

Construction

The construction of buildings, structures and other similar objects is impossible without the use of construction equipment. Special equipment is used at all stages of construction. The main types of such equipment include a bulldozer, an articulated lift, an excavator, a construction crane, a loader, a dump truck, a concrete mixer and much more.

Logging

Special equipment is also used during timber harvesting, transportation and processing. Such equipment includes log loaders, felling machines, sawmill equipment, skidders, timber trucks, etc.

Road construction

Road equipment includes machines involved in all stages of road construction. The range of this technology is very diverse. The following machines are used in road construction: excavator, bulldozer, dump truck, front loader, motor grader, hydraulic hammer, soil compactor and other road-combined machines.

Agriculture

In agriculture, machines are used in both livestock farming and farming. Agriculture equipment includes seeders, machine-tractor units, planting machines, cultivators, sprayers, combines, mowers, etc. Livestock farming equipment includes milking machines, feed dispensers, various combines and many others.

Utilities

The functions performed by municipal equipment are very diverse. This includes landscaping, sewer cleaning, garbage removal, road maintenance, etc. For this purpose, the following types of machines are used: harvester, milling snow blower, aerial platform, bunker truck and others.

Thus, special equipment is used in many fields of activity and plays an important role in their further development.

Safety precautions when working on an excavator.

To ensure safe operation and prevent accidents during operation and maintenance, you should start working only after studying the design and operating rules of the excavator.

Before starting work, the driver carries out maintenance, makes sure that the excavator is in working order and complete, receives a task and precise instructions on the procedure for performing work in accordance with the production project and technological map, and, if necessary, receives instructions and communication diagrams.

The excavator must be equipped with a yellow or orange flashing light.

The driver (operator) must ensure that the working area is prepared, leveled and compacted, and fenced; the slope of the site should not exceed 5°, the face should be cleared of foreign objects, large stones, stumps that interfere with work. The wheeled excavator must be supported on all outriggers. If there are underground communications, the driver must be given their exact diagram, and communications in the area must be marked with poles.

The engine is started with the control levers in neutral position. Before turning on the mechanisms, the driver must make sure that there are no people in the work area and sound a warning signal.

During work, it is prohibited to work on a faulty excavator, leave the excavator while the engine is running, leave the cabin before the working tool is lowered to the ground, transfer control of the excavator to someone else, and get off (or climb on) the excavator while moving or working. No unauthorized persons are allowed on the excavator.

It is prohibited to turn the platform or move the excavator while digging, or to remove stones, reinforced concrete products, metal beams and other objects of unknown mass covered with earth or secured using the bucket of a single-bucket excavator, as this may cause overload and overturning of the excavator. You cannot transport cargo or soil in an excavator bucket, or work at night without proper lighting of the face.

It is not allowed to place an excavator in the collapse prism, for people to be in the danger zone, or to carry out excavation work in the area of underground communications without the permission of their owner and without diagrams of these communications. If underground structures, pipelines, gas pipelines, dangerous objects, or treasures are discovered during work, the work must be suspended, the immediate supervisor and relevant services must be informed, and security of the site must be organized.

When performing work on an excavator, the danger zone is the space around the excavator, equal to the radius of the boom plus 5 m. There should be no one in the danger zone, and if someone appears, the driver must immediately stop working.

The danger area must be fenced off.

When loading long cargo with a grab, or working with an electromagnet or hydraulic hammer, the danger zone increases due to the probability of flying off by 1.5 times. When moving the excavator along the face, the working equipment is installed strictly in the direction of travel, and the bucket is raised above the ground to a height of 0.5 ... 1 m, the turntable is locked.

When storing soil in a dump along the slope of a trench, the distance from the edge to the dump is at least 0.5 m, the height of the dump is no more than 2 m.

If there is a danger of spontaneous displacement (rolling away) of the excavator, stock stops are placed under the tracks or wheels. The distance between the rear part of the rotary platform of a single-bucket excavator and protruding parts of a building, structure, stacks of cargo, face wall and other objects must be at least 1 m.

The rules for the technical operation of consumer electrical installations along overhead power lines (power lines) establish security and danger zones in which the operation of excavators is prohibited. The dimensions of the security and danger zones depend on the voltage of the power lines. If it is necessary to perform work with an excavator in the security zone of a power line, you must obtain permission from the organization operating the power line; work is carried out under the supervision of a responsible person with the issuance of a permit.

The person responsible for the work determines the procedure for the safe performance of work, provides instructions, and indicates the installation location of the excavator. Carrying out work near existing underground communications (gas pipelines, cables) is carried out in the presence of a work permit, permission from the operating organization and the presence of the person responsible for the work.

To clarify the correspondence of passing communications with the diagram, pits or trenches are dug. Near communications at a distance of 1 m vertically and 2 m horizontally, work is carried out with hand or mechanized tools that cannot damage communications.

Persons who have experience working on an excavator of this type, who are additionally trained and certified in their knowledge of the Labor Safety Rules during loading and unloading operations, are allowed to perform work with load-handling parts.

After finishing the work, you need to put the excavator in the designated parking area; brake the car; lower the working element to the ground; put all levers in neutral position; turn off the engine; clean the machine from dust, material and dirt, lubricate; take the key from the lock, close the door, prevent unauthorized persons from accessing the car and preventing it from starting; hand over the keys and excavator for storage; Report any malfunctions to the manager and make an entry in the shift handover log.

Emergency situations include a traffic accident, rollover, fire, discovery or damage to unmarked underground cables, communications, explosive objects, harmful gases.

In any emergency situation, you must immediately stop the excavator, lower the working equipment to the ground (if work was being carried out), turn off the engine by turning off the fuel supply, turn off the “mass”, and leave the excavator.

It is necessary to eliminate the hazardous factor, put up a sign warning of the danger, inform the relevant services, notify the immediate supervisor, help the victims, take measures to preserve the situation (draw a diagram, take a photograph), record the data of witnesses to the incident.

In case of an accident while driving on the roads, or a traffic accident occurs, you should act in accordance with the Traffic Rules: stop immediately; display an emergency stop sign; inform your immediate supervisor; call a traffic police inspector of the Ministry of Internal Affairs of Russia; if there are victims, begin providing first aid and call an ambulance.

If unmarked underground communications are discovered during work, as well as if they are damaged, you must immediately stop work, lower the working tool, turn off the engine and leave the danger zone, notify your immediate supervisor, put up a fence, and guard the scene until the relevant supervisory authorities arrive.

Operation of an excavator equipped with a hydraulic hammer.

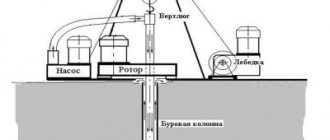

A hydraulic hammer is a replaceable type of working equipment for hydraulic excavators and loaders. Hydraulic hammers are designed for loosening frozen soil, crushing oversized hard and rocks, breaking up road surfaces and concrete structures.

The hydraulic hammer is installed in place of the removed bucket or handle, and is connected to the hydraulic system of the excavator. In winter, the use of hydraulic hammers reduces the cost of excavation work and increases productivity, which is especially necessary when eliminating accidents in underground communications.

Features of hydraulic hammer selection

When selecting a hammer, you need to consider the following parameters:

- Weight of special equipment . The mass of the working unit should be about 10% of the entire machine, but not more than a fully filled bucket. Lightweight hammers are convenient for transporting and moving equipment; this ensures less serious loads on the machine when pointing at a surface for crushing. However, with a large hydraulic hammer mass, the impact energy and productivity will be higher, and the pressing force will be lower.

- Oil consumption . This value must correspond to the power of the hydraulic pump of the equipment that supplies the pressure component of the hammer. If the pump is powerful, pressure surges may occur during operation of the machine, which will negatively affect the service life of not only the hammer, but also the working components of the excavator. If performance is low, the unit will function unstably.

- Operating pressure of the device . This parameter must correspond to the compression of the pump. If this value for a pumping device is 10–15% higher, then a special valve is provided in the hydraulic hammer to limit this parameter. If you do not use it, the studs that tighten the housing or the screws that secure the hydraulic distribution unit may break.

- The technical performance of the unit, which is determined by its power . This parameter is calculated taking into account the energy and frequency of impacts on the working surface. When the strength of the plane being destroyed is high, the impact force affects the performance.

- Ease of maintenance and repairability . The easier it is to access lubrication points and connections, the simpler the process of replacing units and components will be. Some hammer models are equipped with automatic shank processing systems, which greatly simplifies the maintenance procedure.

Also, when purchasing, it is recommended to pay attention to vibration and external noise indicators that affect the equipment.

Buy a hydraulic hammer for driving piles at a profitable price!

Purchasing a hydraulic pile hammer from the Ural plant of pile-driving equipment "Koprovik" has a number of undeniable advantages.

- A hydraulic hammer is an attachment for a pile driver. A pile driver consists of a base machine, a pile driver mast, a pile driver or a drill rotator. Typically, we install hydraulic hammers on the basis of a customer’s excavator weighing 30 tons or more. The offered hydraulic hammers are suitable for crawler excavators of various brands of Russian and foreign production: Hitachi, Caterpillar, Doosan, Hyundai, JCB, Komatsu, Liebherr, Volvo, etc.

- UZSO "Koprovik" is engaged in the design, manufacture and installation of pile driver masts of crane and excavator types. Hydraulic hammers weighing up to 3-5 tons are suitable for our production pile driver mast.

- The pile driver mast from UZSO “Koprovik” and the hydraulic hammer for driving piles are removable equipment. The basic excavator retains its versatility and can be used not only for piling work, but also for other purposes. Installation and dismantling of pile driver equipment is easily carried out in a few hours. You don't have to spend millions to buy a separate piling rig!

- Our pile drivers, equipped with a hydraulic hammer, are highly mobile. They can easily move around a construction site over distances of up to several kilometers. After dismantling the pile driver mast and hydraulic hammer, they can be transported on public roads on a trailer.

- The extensive experience of our specialists allows us to guarantee impeccable quality of installation and maintenance of the pile driver. We don't just sell hydraulic hammers. We connect them to the base, assemble the hydraulic equipment of the hammer, the pile driver and your excavator into a single system, and then carefully configure their control system. Buying a hydraulic hammer means getting a pile-driving complex ready for use.

- The Koprovik plant produces pile caps for hydraulic hammers at low prices - the piles will be reliably protected from damage during driving.

- The driving equipment, including a hydraulic hammer for driving piles, is equipped based on the specific situation of the customer - the assigned tasks and the capabilities of the basic equipment. The selection of attachments is based on calculations of the strength and stability of the base machine. Calculations are carried out by engineers from our design department using the latest software. For a minimal cost, you will get all the functionality you need and will not overpay for redundant options.

- Effective operation of expensive piling equipment without failures and downtime is only possible with a high level of training of the customer company’s specialists. An obligatory element of the supply of piling equipment from UZSO "Koprovik" is the training of your company's employees.

- UZSO "Koprovik" provides service and repair of hydraulic hammers for driving piles, provides spare parts and components.

Can your special equipment perform the functions of a pile driving machine with a hydraulic hammer? Call us or fill out our survey to receive a free estimate. Our designers will contact you within one business day

Fill out the questionnaire

Terms of payment

It is possible to pay for leasing through a partner, RESO-Leasing LLC, or through another leasing company of your choice.

Leasing conditions from "RESO-Leasing"

- Leasing term - from 12 to 48 months

- Annual increase in price – from 5% depending on the term of the contract and the amount of the advance

- Advance amount – from 15 to 50%

- Types of payments: equal, steps or recourse

- Early or partial early repayment is possible without penalties

UZSO "Koprovik" supplies drilling and piling equipment to all regions of Russia:

Benefits of Case hammers

Case hydraulic hammers offer the following benefits:

- high productivity and durability of units;

- ease of maintenance and use;

- quick payback due to design features;

- the ability to operate the unit in large quarries and during demolition of structures;

- increased service life;

- the ability to provide a circular sector of operation of basic equipment;

- high efficiency in loosening frozen soils;

- unhindered performance of any vertical and horizontal work due to the stability of the machine with the maximum reach of the unit;

- eliminating the negative effects of vibrations on the design of heavy equipment.

Case hydraulic hammers feature low operating noise, which helps reduce operator fatigue.

Causes of hydraulic hammer malfunction:

- closed or incorrectly configured valves;

- lack of correct connection of the high pressure hose;

- no oil for servicing parts;

- too much nitrogen in the pneumatic chamber of the device;

- the valve is damaged;

- the pressure in the battery differs significantly from normal;

- other reasons related to mechanical damage.

How to choose a hydraulic hammer?

13.09.2019

Home Brand How to choose a hydraulic hammer?

A hydraulic hammer is the second most popular attachment for special equipment after a bucket. Every year, more than 100,000 hydraulic hammers are produced worldwide, most of which are produced in South Korea, Japan, China and European countries.

How, among such a variety of offers from numerous manufacturers and suppliers, can you choose a truly worthy option that meets the requirement of the well-known price/quality ratio?

Customer Service

Experts, based on their own experience, will give practical advice on choosing such equipment.

Technical parameters of the hydraulic hammer

To begin with, you need to decide on the technical parameters of the attachment itself. One of the most important characteristics is the weight of the hydraulic hammer. To prevent the excavator from tipping over, it should not exceed 10% of the weight of the special equipment. In this case, the weight of the hydraulic hammer should not be less than 4-7% of the weight of the excavator, since the vertical loads on the body and the impact mechanism are structurally designed for a certain compression force.

Another key point is the performance of the excavator’s hydraulic system, which must correspond to the technical characteristics of the hydraulic hammer.

Low pressure and flow rates will not allow the hydraulic hammer to meet the stated requirements for energy and impact frequency, and excessive values can lead to breakage of the hydraulic hammer. Most often, a hydraulic hammer correctly selected for the weight of the excavator will always meet the required parameters for the hydraulic system.

For example, for owners of backhoe loaders, the most popular model Profbreaker PB70H will be the optimal hydraulic hammer, for owners of mini loaders - the Profbreaker PB50H model.

Owners of heavy excavators should pay special attention to the selection of a hydraulic hammer, since mistakes can have more serious consequences.

Experts recommend installing the Profbreaker PB360 hydraulic hammer on excavators up to 35 tons: Komatsu PC-300, Doosan DX-300, Hitachi ZX-330, Volvo EC-290, Hyundai R-330 and others. For heavier excavators up to 42 tons, there are two models to choose from: Probreaker PB420 and Profbreaker PB430.

Experts warn: it is necessary to compare hydraulic hammers with the same lance diameter, since some manufacturers make a cunning move: they indicate inflated values of the impact energy and weight of the hydraulic hammer, but with a smaller lance diameter, passing it off as a hydraulic hammer of a higher class.

Customer Service

As a rule, on paper this figure is overestimated due to the lack of opportunity to test it in practice, so it is impossible to compare hydraulic hammers in terms of impact energy. Only a small number of experienced and reputable manufacturers know the exact formulas for calculating impact energy, including.

A significant characteristic is the type of hydraulic hammer body. Each of them has its own advantages. Thus, a hydraulic hammer with an open body has the lowest cost, and besides, such equipment is convenient to inspect and maintain.

At the same time, the closed type housing provides additional protection of the mechanism from vibration and mechanical damage, and it is also more convenient to work with it within the city and at sites characterized by increased pollution. The closed housing guarantees lower noise levels and does not allow dirt and dust to get inside.

Well, a side-mounted housing gives access to the impact mechanism from three sides; moreover, such a housing is more compact and follows the geometry of the bucket.

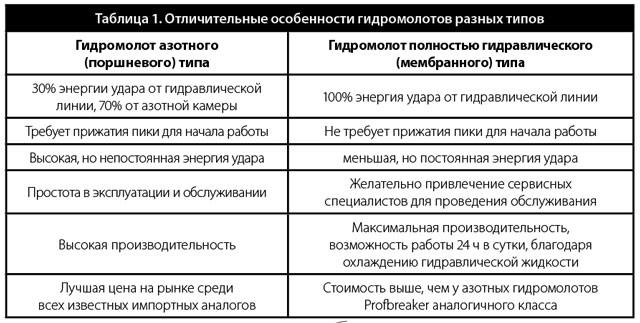

The operating features of a hydraulic hammer are also determined by its type. Comparative characteristics are presented in table. 1.

Choosing a hydraulic hammer manufacturer

We will talk about the key components that determine the cost of a hydraulic hammer.

Firstly, there is the cost of labor. It is obvious that small unknown factories cannot retain highly qualified specialists, and here the risk of human errors during assembly and production is very high. Large enterprises are trying to reduce the cost of labor per unit of output by increasing the total volume and conveyor belt of production. In this way, risks associated with the human factor are eliminated.

Thus, the bodies of Profbreaker light and medium hydraulic hammers of the RV50N, RV70N, RV150N, RV180N, RV180S series are welded without the use of labor at all using fully robotic welding machines.

The second component is the cost of metal and components. A reputable supplier will never use low-quality steel in the production of hydraulic hammer cylinders and pistons, as it values its reputation and its customers.

Profbreaker hydraulic hammers are produced in factories that use only high-quality Korean steel from the Hanlip concern (South Korea). All metal undergoes input control in our own laboratories.

Production peak at

And the third significant point is the marginal profit of the manufacturer, that is, the brand. A well-known brand, by all accounts, is always a guarantee of high quality, but this coin also has a downside. The more famous the manufacturer, the more so-called fakes and forgeries he has. A huge number of small manufacturers in China have built their business on stamping counterfeits and markings.

Experts advise not to work with small and little-known manufacturers. If you receive an offer for a hydraulic hammer at a low price, but cannot find information about this manufacturer anywhere, then you need to understand that low quality is behind this.

Choosing a hydraulic hammer supplier

Once you have decided on the technical characteristics of the hydraulic hammer, you need to choose a reliable supplier. Before purchasing a hydraulic hammer, you can check the contacts of the organizations operating this equipment to receive feedback on the operation of the hydraulic hammer and the supplier. Delivery experience is the first critical aspect of a supplier's performance that needs to be addressed.

Table 1. Distinctive features of different types of hydraulic hammers

The second is the availability of a spare parts warehouse. You should always be confident that your equipment will operate without downtime. Only a supplier with a spare parts warehouse and well-established logistics can ensure a low cost of ownership.

And the third is, of course, the presence of a customer service. Do not repeat the mistakes of others, do not buy equipment from companies whose staff includes only sales managers. Correct adjustment of the pressure and flow of the excavator hydraulics, operator training and consultations on issues that arise during work are the key to uninterrupted operation of the hydraulic hammer for many years.

Benefits of working with

- “Professional” is one of the leaders in the production of attachments in Russia, has production buildings with an area of 48,500 m2 and more than 1,100 employees. The sales growth of hydraulic hammers has doubled over the past 2 years.

- We offer high quality at a low price, as we carry out the largest annual volumes of purchases from global manufacturers of hydraulic hammers.

- We provide free installation supervision of hydraulic hammers and operator training. With 34 service teams, we quickly help our clients throughout Russia.

- We are always nearby: our warehouses and service centers are located in 35 regions of the country and neighboring countries. The total warehouse of spare parts and consumables for hydraulic hammers amounts to more than 100 million rubles, which allows us to respond to customer needs as quickly as possible.

- We are recommended: we provide contacts of real clients from every region of Russia and neighboring countries, and you can always convince yourself of our reliability by receiving “live reviews.”

LLC "Professional" Russia, Ivanovo, st. Collectivenaya, 3 b tel.: 8-800-775-80-50 e-mail www.profdst.ru

The article was published in the journal Extractive Industry No. 4, 2019

- Tags:

- hydraulic hammer

- professional