Setting the ignition timing of UAZ-3151

1. Disconnect the wire from the negative terminal of the battery.

2. Remove the distributor cap.

3. Rotate the crankshaft until the compression stroke begins.

To determine this moment, you need to unscrew the spark plug of the 1st cylinder and close the hole for the spark plug with your finger.

At the beginning of the compression stroke, air will begin to escape from under the finger.

4. Carefully rotate the crankshaft until the second mark on the pulley coincides with the boss on the camshaft sprocket cover.

This mark corresponds to an ignition timing angle of 5° on an engine with an exhaust gas recirculation system (for engines without exhaust gas recirculation systems, install the pulley so that the middle of the pulley between the second and third marks is against the tide on the camshaft sprocket cover, which corresponds to an ignition timing angle of 2°) .

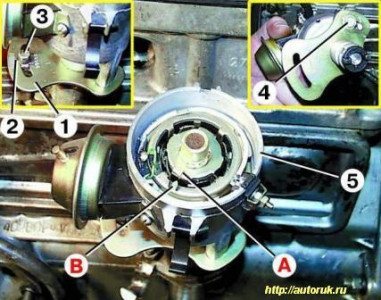

5. Loosen bolt 3 securing the distributor. Set pointer 2 of the octane corrector to the middle of scale 1 and tighten bolt 3.

Loosen bolt 4 securing the octane corrector plate to the distributor body.

Lightly press the slider with your finger against its rotation (clockwise) to select the gaps in the drive.

Holding the slider, slowly turn the distributor housing 5 until the red mark “ A”

on the rotor with arrow "

B"

on the stator.

Tighten bolt 4 securing the octane corrector plate to the distributor body.

6. Install the distributor cap and connect the high-voltage wires in accordance with the operating order of cylinders 1-2-4-3.

7. Check the ignition timing setting. To do this, warm up the engine to a temperature of 80-90 °C and, moving on a flat road at a speed of 30-40 km/h, sharply press the accelerator pedal all the way.

In this case, detonation should be heard briefly.

If detonation is not heard, it means the ignition is late.

If the detonation is too strong, it means the ignition is too early.

When igniting early, turn the distributor body one scale division towards “+” (counterclockwise), and when igniting late, turn towards “-” (clockwise).

Then check the ignition timing again while the car is moving, as described above.

8. More precise setting of the ignition timing can be done using a strobe in accordance with the instructions included with the strobe.

Homemade ignition system repair, do-it-yourself assembly

Disassembling the ignition distributor –

not the most time-consuming procedure; the need to replace the distributor may be indicated by increased fuel consumption and decreased acceleration dynamics. Also, the engine may simply not start. Also, in cars such as the VAZ-2109 with a carburetor engine, it is possible that oil from the engine gets into the distributor. In this case, it usually turns out that the carburetor seal has leaked. It is necessary to clean the small hole in the base of the carburetor. View valve operation.

To repair the distributor you need to remove it. To do this, you need to follow the procedure:

- disconnect the negative contact of the on-board battery;

- disconnect the high-voltage wires and vacuum corrector hose from the distributor;

- remove the throttle holder cable;

- unscrew the bracket with wires;

- Mark the position of the distributor before removing it using a marker;

- remove the connector with wires from the ignition distributor;

- Remove the crankshaft plug from the clutch housing, then rotate the shaft to set the piston of the first cylinder to the top point. Unscrew the nuts securing the distributor and remove it. The device is assembled in the reverse order.

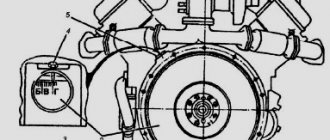

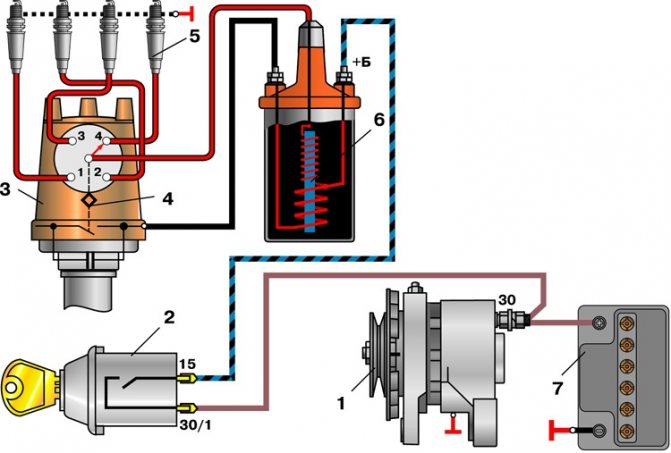

Ignition system UAZ 469

To start the engine of any vehicle, it is necessary that the combustible mixture ignites at the right moment in the combustion chamber. Effective operation of the piston system is achieved by correctly setting all parameters. The UAZ 469 ignition system allows you to operate the vehicle regardless of climate, temperature, humidity and other external factors.

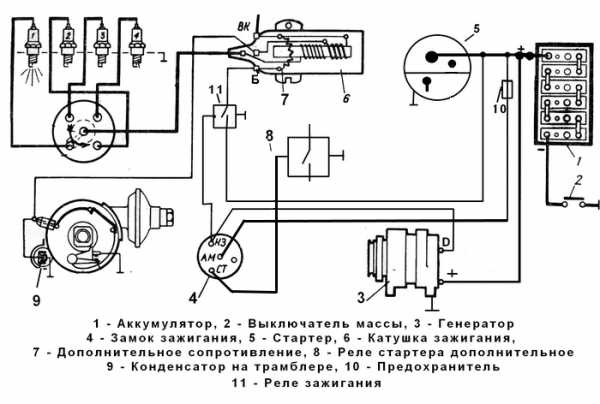

The ignition of the UAZ 469 ensures that all elements are in good working order and flawlessly perform their assigned functions. For UAZ 469, the ignition circuit consists of the following components:

- ignition coil UAZ 469;

- distributor;

- tourniquets;

- switch;

- candles.

Each individual component of the electrical circuit must not allow breakdown to the car body and current leakage.

The ignition of a UAZ 469 car includes the following elements:

- battery;

- mass button;

- voltage regulator relay;

- generator;

- ammeter;

- ignition switch UAZ 469;

- breaker-distributor contacts;

- distributor;

- capacitor;

- ignition distributor-distributor cover;

- slider;

- spark plug;

- high voltage wire;

- additional resistance;

- additional starter relay;

- ignition coil;

- starter.

The ignition order of the UAZ 469 is strictly regulated; the spark occurs exactly in the specified sequence. An important point is not only the timeliness of the spark supply, but also its size. If the slightest interruption occurs, the entire chain is reconfigured.

A car battery is not designed to produce sufficient current and voltage required to ignite a combustible mixture. The charging current is only capable of spinning the engine flywheel for a short time. For stable operation of the engine, the entire ignition system of the vehicle must begin to fully function.

This important component of the machine is designed to significantly increase the power characteristics of the battery. Proper ignition, together with the battery, sends the spark plugs the sufficient volume and current required to reliably ignite the fuel mixture.

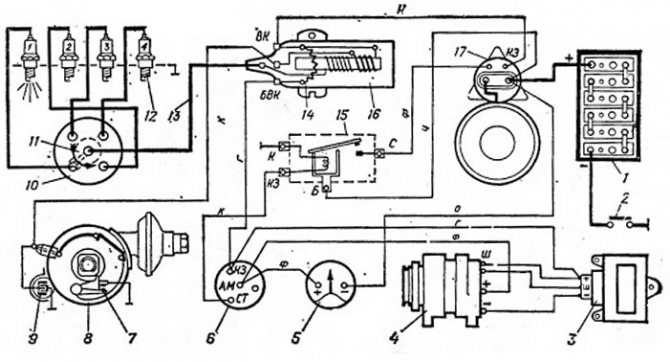

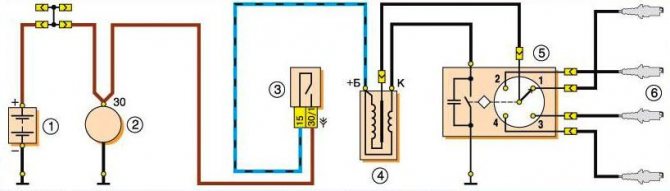

Classic contact ignition circuit

- Battery

- Generator

- Ignition switch

- Ignition coil

- Distributor

- Spark plug

Ignition on VAZ, GAZ, UAZ cars can be contact or non-contact. The machines are equipped with a four-stroke internal combustion engine; the purpose of the ignition system is to supply a high-voltage electric discharge to the spark plug of the required cylinder at a certain moment in the compression stroke to ignite the working mixture. Ignition on a classic, like on another car, works according to the same principle: a control pulse is generated for the ignition coil, which in turn transmits a high-voltage discharge to the distributor, where it is then distributed among the spark plugs.

The electrical diagram of the ignition equipment on the classic is shown in the figure. The ignition circuit is a system consisting of a battery (7), an ignition switch (2), an ignition coil (6), and a distributor (3). You can learn how to install the ignition from the article - installing the ignition.

The average power consumption of this circuit is 5-10A; the main source of power consumption is the ignition coil. Items shown in the picture:

- Generator

- Ignition switch

- Distributor

- Distributor contacts

- Candles

- Ignition coil

- Accumulator battery

The diagram did not show the capacitor, which is located on the distributor; it plays an important role in the ignition system, and sometimes it can create problems when you check the ignition, look at the spark supply to the distributor, the spark output to the spark plugs seems to be fine, the spark is bright, stable, but the car still works intermittently, tears, twitches. This is just a possible manifestation of a bad capacitor that has dried out and just needs to be replaced. Without a load, looking at the spark, it will be bright and good, but in the engine under load...

How to set the ignition correctly

In order to set the ignition on the UAZ 469, you must adhere to the following recommendations:

- Remove the distributor cover with the rotor. Check the size of the gap between the contacts. It can be adjusted. Between the contacts, separated as much as possible, there should be a gap of 0.35 - 0.45 mm. Adjustment is best done with a set of feeler gauges. Too small a gap produces a weak spark. If the gap is large, there may be no spark at all. Having made a normal gap, the rotor can be installed in its normal place.

- Using a spark plug wrench, unscrew the spark plug of the first cylinder. Close the candle hole with your finger. Using the starting handle, turn the crankshaft until the pin is pushed out by compressed air. This moment is called the beginning of the compression stroke of the first cylinder.

- Continue turning the crank until the hole on the pulley and the pin on the timing gear cover align. The rotor should be located opposite the internal contact of the cover, connected to the high-voltage wire from the spark plug of the first cylinder.

- Rotate the octane corrector plate together with the distributor so that the mark coincides with the middle mark on the scale of the plate.

- Lightly turn the timing mechanism housing counterclockwise. Scroll until the contacts of the distributor close.

- Connect the control light with socket. Connect one contact to the low voltage terminal of the distributor, the second to the ground of the machine. You can connect the warning lamp to the car body.

- Turn on the ignition and carefully turn the distributor clockwise. Rotate until the indicator light comes on, then stop rotating. It may be that the lamp does not light up. Repeat all steps from the very beginning.

- Tighten the distributor mounting bolt. Place the cover with the central wire in place. Check the adjustment starting from the first cylinder. The check is carried out counterclockwise.

Why turn on the ignition?

With the ignition set correctly:

- The engine operates efficiently, steadily and stably in all modes. Otherwise, the engine functions intermittently, knocking, and popping. Unstable engine operation causes many problems and reduces vehicle dynamics and speed characteristics.

- After correct ignition adjustment, starting a cold power unit is significantly improved.

- When the ignition is misregulated, fuel consumption increases. After adjustment it decreases significantly.

- Engine power also increases noticeably in a car after proper ignition adjustment.

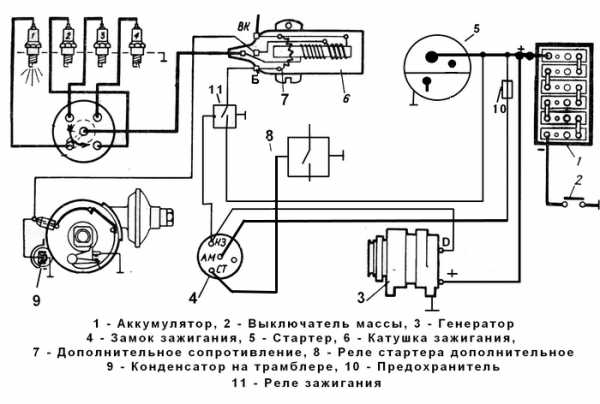

Contact ignition

Comfortable driving, moderate fuel consumption, easy engine starting, all this ensures well-regulated ignition. The ignition system on carburetor cars comes in two types: contact and non-contact. In the first case, the supply of current to the ignition coil is regulated by contacts installed in the distributor; in the second case, a Hall sensor is installed in the distributor, which responds to magnetic pulses, which are supplied to the switch in the form of a control signal. In this article, I will look at the principle of operation of contact ignition on a classic.

What are the ignition systems on the UAZ 469

Contact ignition on UAZ 469

. Now it is recognized as obsolete. However, domestic manufacturers continue to use it. The system launches a pulse of a certain power. This impulse comes from the ignition distributor. The contact ignition circuit of the UAZ 469 is simple and uncomplicated. This is its advantage. The driver can fix any malfunction and make adjustments with his own hands. The prices of components are low.

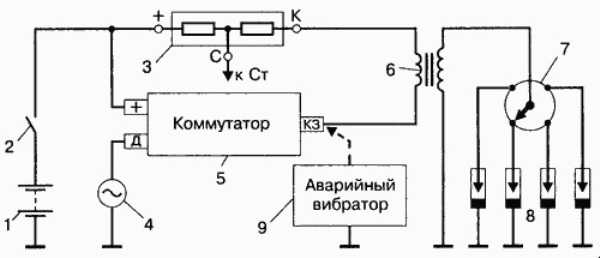

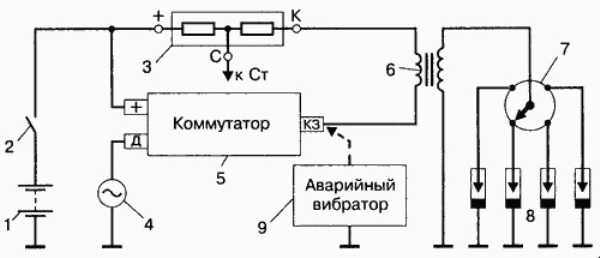

Transistor or contactless ignition of UAZ 469

. Contactless ignition systems are installed on many types of vehicles. It has a number of advantages over the contact design. The spark produced by such a device is much more powerful. This occurs due to an increased level of electrical voltage in the secondary winding of the ignition coil. The transistor ignition system is equipped with an electromagnetic mechanism. It ensures stable, constant operation of the entire system, uninterruptedly transferring energy to components, parts, and mechanisms. Correctly configured ignition with an efficient internal combustion engine guarantees high power and significant fuel savings. Long-term reliable performance is ensured by compliance with the frequency of maintenance of the distributor drive. It must be lubricated and adjusted every 10,000 km. The difficulty of repair is a disadvantage of the contactless ignition system. It cannot be repaired independently, since this requires special diagnostic equipment, available only in service centers and service stations.

What is electronic ignition

The term "electronic ignition" means the same as "contactless ignition". The BSZ unit is assembled from electronic (semiconductor) components, which is reflected in the name of the system. “Contactless” ignition is called because the closing and opening of the low-voltage circuit is carried out by an electronic switch by locking and unlocking the transistor, and not by the distributor contact.

The electronic ignition system of the VAZ 2107 for the carburetor and injection versions is different. Perhaps this is the reason for the erroneous opinion that electronic and contactless ignition are different systems.

Adjusting the UAZ ignition

Adjusting the ignition timing SEQUENCE OF ACTIONS

Using the starting handle (from the car tool kit), set the crankshaft to the position corresponding to the ignition timing angle of 5°.

For this…

...align the middle mark on the crankshaft pulley with the boss on the block cover at the end of the compression stroke in the first cylinder.

If the distributor sensor is not removed from the engine, then the compression stroke of the first cylinder is determined...

...by removing the distributor cap.

The slider should stand against the internal contact of the cover, connected by a wire to the spark plug of the first cylinder. Or we turn out the spark plug of the first cylinder. Closing the hole with a paper stopper, rotate the crankshaft. The moment the plug comes out corresponds to the beginning of the compression stroke.

Use a 10mm wrench to loosen the octane adjuster bolt...

...and set its scale to zero division (the middle of the scale).

Use a 10mm wrench to loosen the bolt securing the octane corrector plate...

...and, turning the housing of the sensor-distributor, we align the marks (the red line on the rotor and the arrow on the stator). Holding the sensor in this position, tighten the bolt.

Make sure that the slider is located against the contact of the cover of the first cylinder and check that the high-voltage wires of the remaining cylinders are connected correctly - counting counterclockwise from the first cylinder in the order 1-2-4-3. We recommend that you additionally check the correct ignition timing while the vehicle is moving. To do this, moving in fourth gear at a constant speed of 50–60 km/h, sharply press the gas pedal. If in this case detonation (the sound is similar to the knocking of valves) appears briefly - for 1-3 s, then the ignition timing is chosen correctly. Prolonged detonation indicates excessive ignition timing. We reduce it with an octane corrector by one division. The absence of detonation requires an increase in the ignition timing, after which the test must be repeated.

Instructions for installing and configuring the ignition on a UAZ

Starting the engine of any car is possible due to the ignition of the combustible mixture in the cylinders of the power unit. To ensure normal operation of the engine, proper adjustment of the ignition system (IS) is necessary. In addition, all elements, including the coil, distributor of the UAZ vehicle and other components must always be in working order.

Description of SZ on UAZ

How is the ignition circuit installed, configured and adjusted on the AUZ 417 or any other? We will talk about this below. But first, let's understand the principle of operation of the node, as well as the types of SZ.

Operating principle of SZ

As already said, the ignition on an UAZ performs one of the main functions when starting the power unit. Thanks to this system, the procedure for igniting the air-fuel mixture in the cylinders of the power unit is carried out by supplying a spark. The spark is directly supplied to the spark plugs; one spark plug is installed on each cylinder. All of these safety devices operate in sequence mode, igniting the combustible mixture in the required period of time. It is also necessary to take into account that the ignition system on cars not only provides a spark, but also determines its strength.

order and ignition circuit, adjustment and configuration of the lock

The UAZ distributor is considered one of the important components of the ignition system in a vehicle. Correct adjustment of this mechanism ensures optimal operation of the power unit as a whole. You can learn more about the principle of operation of the ignition system and how to set it up correctly with your own hands from this material.

Review of SZ on famous UAZs

What is the connection diagram for electronic or contactless ignition on a UAZ 417, how to convert contact ignition to contactless? Why does the coil heat up and how to adjust and adjust the advance angle? First, let’s look at the main points regarding the action and types of SZ.

Operating principle of SZ

Contact system diagram

The ignition system, or rather its correct setting, plays a big role in the operation and starting of a car engine. With correct adjustment, the combustible mixture will burn correctly in the power unit as a result of the supply of charge through the spark plugs. A spark plug is placed on each cylinder of the UAZ engine, each of which is turned on in a certain order, in turn, delivering a discharge to the cylinder after a certain time. It must be taken into account that any SZ makes it possible not only to deliver the required discharge, but also determines its strength.

Due to its technical characteristics, the car’s battery cannot produce the voltage and current required to ignite the mixture. This is due to the fact that the battery can only produce a current of a certain strength. And thanks to the correct operation of the system, the current value increases significantly, which allows you to successfully ignite the air-fuel mixture.

The operating principle of the system consists of several stages:

- First, the driver inserts the key into the ignition and turns it, electrical energy is stored in a coil.

- Then the coil converts the low-voltage voltage in the on-board network of 12 volts into high-voltage. As a result, the voltage value increases to 30 thousand V.

- After this, the discharge is distributed and supplied to one or another spark plug.

- The candle itself produces a spark that ignites the mixture.

Diagram of the UAZ contactless system

What types of SZ are there?

Domestic UAZ vehicles can use one of three ignition systems; let’s look at each of them in detail:

- Contact view. This type of SZ is outdated, however, it is used on most machines. In such a system, the principle of operation is to issue a certain impulse that is formed in a distributor - a distribution device. The contact system is considered one of the simplest in terms of design, which is an advantage, since if a malfunction occurs, the car owner will be able to independently check and repair the system. In addition, prices for structural parts of the contact system are usually affordable, which is good news. The contact SZ includes a coil, a switchgear, a breaker, a capacitor and spark plugs.

- Non-contact type, also called transistor type. Compared to the contact system, the contactless system has more advantages. Emerging

autocentrum.ru

How to set it correctly?

After connection, how is the ignition installed for proper engine operation?

What is the procedure and how to correctly set the node settings, read below:

- To begin, the vehicle must be secured in place, and turn on the handbrake. The piston of the first cylinder must be installed at top dead center; note that the hole on the crankshaft pulley must coincide with the mark located on the timing gear cover.

- The cover must be removed from the switchgear. Having done this, you will see a slider located opposite input 1, inside the cover. If it is not there, then the crankshaft must be turned 180 degrees and the octane corrector set to 0. Using a wrench, screw the pointer to the distributor controller body so that it is aligned with the middle mark on the octane corrector. Loosen the screw securing the plastic to the distribution controller housing a little.

- Carefully turn the housing, holding the slider with your finger so that it does not rotate. This way you can eliminate gaps in the drive. The housing is rotated until the sharp part of the petal on the stator is aligned with the red mark on the rotor. Secure the plate with a screw to the controller body.

- The next step will be to install the controller cover in place and diagnose the high-voltage wires. They must be installed in accordance with the order of operation of the cylinders, that is, first, second, fourth, third. When the ignition timing is set, it is necessary to diagnose the correctness while driving.

- Start the power unit and warm it up for about ten minutes until the temperature is about 80 degrees. Moving on a flat and straight road at a speed of approximately 40 km/h, sharply press the gas pedal. If, when accelerating to 60 km/h, you feel or hear detonation, it should be short-lived, then everything has been done correctly. If the detonation is very strong, then the distribution controller must be turned half or one division counterclockwise. In the complete absence of detonation, the set advance angle should be increased, that is, the controller should be turned clockwise.

order and ignition circuit, adjustment and configuration of the lock

The UAZ distributor is considered one of the important components of the ignition system in a vehicle. Correct adjustment of this mechanism ensures optimal operation of the power unit as a whole. You can learn more about the principle of operation of the ignition system and how to set it up correctly with your own hands from this material.

Content

Open full content

[Hide]

Review of SZ on famous UAZs

What is the connection diagram for electronic or contactless ignition on a UAZ 417, how to convert contact ignition to contactless? Why does the coil heat up and how to adjust and adjust the advance angle? First, let’s look at the main points regarding the action and types of SZ.

Operating principle of SZ

Contact system diagram

The ignition system, or rather its correct setting, plays a big role in the operation and starting of a car engine. With correct adjustment, the combustible mixture will burn correctly in the power unit as a result of the supply of charge through the spark plugs. A spark plug is placed on each cylinder of the UAZ engine, each of which is turned on in a certain order, in turn, delivering a discharge to the cylinder after a certain time. It must be taken into account that any SZ makes it possible not only to deliver the required discharge, but also determines its strength.

Due to its technical characteristics, the car’s battery cannot produce the voltage and current required to ignite the mixture. This is due to the fact that the battery can only produce a current of a certain strength. And thanks to the correct operation of the system, the current value increases significantly, which allows you to successfully ignite the air-fuel mixture.

The operating principle of the system consists of several stages:

- First, the driver inserts the key into the ignition and turns it, electrical energy is stored in a coil.

- Then the coil converts the low-voltage voltage in the on-board network of 12 volts into high-voltage. As a result, the voltage value increases to 30 thousand V.

- After this, the discharge is distributed and supplied to one or another spark plug.

- The candle itself produces a spark that ignites the mixture.

Diagram of the UAZ contactless system

What types of SZ are there?

Domestic UAZ vehicles can use one of three ignition systems; let’s look at each of them in detail:

- Contact view. This type of SZ is outdated, however, it is used on most machines. In such a system, the principle of operation is to issue a certain impulse that is formed in a distributor - a distribution device. The contact system is considered one of the simplest in terms of design, which is an advantage, since if a malfunction occurs, the car owner will be able to independently check and repair the system. In addition, prices for structural parts of the contact system are usually affordable, which is good news. The contact SZ includes a coil, a switchgear, a breaker, a capacitor and spark plugs.

- Non-contact type, also called transistor type. Compared to the contact system, the contactless system has more advantages. The resulting spark has a higher power, which is achieved due to the formation of high voltage in the secondary winding of the coil. Also, contactless systems are equipped with an electromagnetic device, which makes it possible to achieve more stable operation of the engine. Ultimately, if the UAZ power unit is configured correctly, then by using a contactless system you can not only increase its power, but also achieve fuel savings, albeit insignificant. Also, such systems are easier to maintain. One of the main nuances in terms of maintenance is the need to periodically lubricate the distributor drive - at least every 10 thousand kilometers. One of the main disadvantages is the difficulty of repair. In practice, repairing a contactless SZ will be problematic, since diagnosing the system will require equipment that is usually available at a service station.

- The ignition system can also be electronic. This option is currently considered one of the most progressive and expensive; it is installed mainly on new cars. Compared with contact and non-contact systems, the electronic system has a more complex structure. The main advantage of this system is that, if necessary, the process of adjusting the ignition angle will be much easier. In addition, there are no contacts in the electronic system that are susceptible to oxidation. It should also be noted that in practice, the combustible mixture in the cylinders of a power unit with an electronic system almost always burns completely. But despite all the advantages, electronic repair systems also have their disadvantages, which relate to device repair. It is almost impossible to repair such an SZ with your own hands, since to perform this task, again, you will need equipment (video published by Nail Poroshin).

Expert recommendations on how to configure correctly

So, how to set the advance angle yourself in order to achieve proper operation of the UAZ engine:

- First of all, you must lock your car in one place by pulling the parking brake lever. Rotate the crankshaft so that the piston of cylinder 1 reaches TDC (top point). In this case, you need to ensure that the hole on the crankshaft pulley coincides with the mark marked on the timing gear cover.

- After this, remove the cover from the distribution mechanism. After dismantling, you will be able to see the slider, which is located inside the cover itself, opposite the contact. If there is no slider, you should turn the crankshaft 180 degrees again, and then set the octane corrector to 0. Using a wrench, you will need to screw the pointer to the distribution mechanism housing so that it aligns with the middle mark. When these steps are completed, the fastening bolt with which the plates are attached to the distributor body must be loosened slightly.

- Then, holding the slider in one place with a finger to prevent it from rotating, you need to carefully rotate the housing itself, this will allow you to remove possible backlash in the drive. The housing must be rotated until you achieve alignment of the sharp end of the stator mechanism petal with the red mark located on the rotor device. After this, the plate itself must be secured to the body using the appropriate bolt.

- Once you have completed these steps, you need to replace the controller cover and check the high voltage cables. You need to make sure that these wires are installed in the correct sequence, taking into account the firing order of the cylinders. When you manage to correctly adjust the lead angle, you need to make sure that the entire procedure was performed correctly.

- To diagnose the correctness of the actions performed, you need to start the engine of your UAZ and wait about 5-10 minutes until the power unit warms up. The operating temperature of the engine is about 90 degrees; you can wait until the internal combustion engine warms up to 80 degrees. Then you need to drive onto a flat road and accelerate the car to 40 km/h, after which you should sharply press the gas. At this moment, the car will accelerate and if, when the speed increases to 60 km/h, a short-term detonation (metallic knock) is heard from under the hood, then this indicates that all actions were performed correctly. If the detonation is too long, the system will need to be adjusted. To do this, the housing of the distribution mechanism will need to be turned one notch or half, and it must be turned counterclockwise. If the diagnostics showed that there is no knocking of the “fingers” at all, then the advance angle should be increased. To do this, the mechanism should be turned in the opposite direction.

Photo gallery “How to adjust correctly”

A guide to replacing a distributor with an oil pump drive

Before installing a new distributor with a drive, you need to weigh your strengths, since it is not recommended to make mistakes when performing work.

So, how to replace and install the distributor:

- Turn off the ignition and remove the distributor cover; the tips and high-voltage cables are connected to it.

- Then you need to disconnect the wire connected to the switch from the distribution mechanism. You also need to disconnect the pipe connected to the vacuum regulator.

- Taking a 13mm wrench, unscrew the two nuts securing the device and remove the mechanism along with the oil pump drive from the power unit.

- After completing these steps, you will be able to see the gasket located under the drive. If as a result of these actions the position of the crankshaft has not changed, then simply install a new mechanism, making sure that the slider is located opposite the mark. All actions are performed in reverse order. When the installation is completed, the advance angle is adjusted.

- If, as a result, the location of the shaft has changed, then before installation it is necessary to move the piston of cylinder 1 to top dead center. You need to ensure that the marks on the pulley align with the pointer on the motor itself.

Video “How to install electronic ignition on a UAZ”

If you don’t know how to install an electronic ignition with your own hands, then read the instructions in the video (video filmed by the Auto Garage channel).

avtoklema.com