For any all-terrain vehicle, a decisive condition for excellent cross-country ability

is to use the right tires.

But the cost of a suitable kit is considerable, because it is often produced either in small quantities or by special order.

But it ’s quite possible to make low-pressure tires yourself

. This work is labor-intensive and requires patience and attention. The finished product has a characteristic name - odorishi.

Tires (also known as low-pressure tires) are huge tractor, truck or helicopter tires that have been stripped of excess rubber.

Thanks to the large area of such wheels and their low pressure on the surface, an ordinary passenger car equipped with them becomes a real SUV

.

With encouragement, Niva and UAZ can overcome a wide variety of obstacles - fields, deserts, rocky and marshy soil.

It is difficult for hunters and simply those who like to ride in difficult terrain to do without wheels with low pressure.

Making such tires yourself is not a problem. common tools like a knife or winch will be enough.

. It will still take a little skill.

Before you start creating low-pressure tires, you need to clearly understand what exactly they are needed for.

, that is, under what conditions, where exactly they will be used.

- primarily for driving on dirty, bumpy roads and rural roads - then you need to use a self-cleaning tread;

- If we go through swamps on tires, we will need to lower the tread grooves a little so that the grip becomes as good as possible;

- It is better to drive on sand and on tires on which the tread pattern elements are as close to each other as possible.

You need to think about the above in advance.

The process of creating low pressure tires

To make low-pressure tires for a UAZ, Karakat or Niva, you need to create the tire itself, as well as a strong metal base to attach it to.

To create your own wrappers you will need:

- The main material

is old tires for trucks such as Gaza-66, Kraza 255 (VI-3 tires), ZIL 131. Tires from helicopters, tractors and small aircraft are also perfect. If the tires have a “chewed” inner part, they should not be used. A hole may form in such rubber after the top layer is removed. As a result, they will simply have to be thrown away. - An awl, a knife

(construction knife), a set of blades and a sharpener for straightening them. When in contact with durable truck tires, the blades quickly dull and become unusable, so you can’t do it alone. - A special template

made of a thin steel sheet or thicker cardboard, as well as chalk or a marker for outlining the template. - Clamps

(maximum strength).

The best ones are those that straighteners use to clamp the bodies of crumpled vehicles when they try to straighten them. A standard clamp will also work

for stripping tires , but you will need to be very careful. You can use the workflow with ordinary wire cutters. - A winch

(automatic or manual) and a cable to tension the part of the tread that we will cut off. It can also be tightened using a manual gearbox.

You may also need a hammer (for straightening).

To make the tires airy, large tires will need to be freed of excess rubber on the tread and sidewalls. It is also necessary to remove the seat cores and the base of the cord.

(inner protective layer of the tire).

- thoroughly clean the tire from all dirt

and then dry it; - using a template, using a marker or chalk along the entire circumference of the wheel, we create a tread pattern

(the way it will become after some of the unnecessary rubber is removed).

- We make a cut along the inner perimeter of the tire to get rid of the wire

. It is better to make the cut with a construction knife. It is convenient because you can set the length of the blade on it. - In the area of the cut, mark rectangles with a marker and begin cutting

. - Through the holes formed in the tire we will be able to see the wire, which we will get rid of.

- We fix the tire with an iron rod so that it does not move, and pry up the wire with a hook

, and remove it from the tire with a winch. You can also remove it with a screwdriver, but this will require a lot of effort.

Now we start stripping the tire:

- We make cuts

along the perimeter of the tread circle we drew , digging a little deeper into the rubberized base of the cord; - using pliers we fix the resulting hole

; - and

peel off the rubber that has peeled off using a winch .

To make things go easier and faster, we cut it with a knife.

- gradually peel off unnecessary layers

of rubber and cord from the tread surface and sides until only one frame remains; - clean the surface using sandpaper

(if necessary, straighten it with a hammer).

The camera for the future wheel is ready.

- We create a new tire frame

. We weld the wheel rims with the plates. You can also create low-pressure rims yourself. For this, the most ordinary aluminum basin and fire hose (for fastening) will do. - Grinding the frame

. - We put

the support camera on the frame.

We pump the tire and can install it on our car.

Let's make some refreshments

To make your own low-pressure tires you will need:

- used truck tires (for example, from Gaz-66 or VI-3 tires installed on Kraz 255). If you buy tires specifically for tires, then choose rubber that is not “chewed” inside. Otherwise, after removing the top layer, you will get a weak spot or even a hole that will have to be vulcanized;

- a construction knife and a set of replacement blades, since the construction of the tire uses fairly strong threads that quickly dull the blades;

- a template that can be made from thick cardboard or sheet steel. In order for the tires to be not only effective, but also to look good, the tread must be cut as evenly and symmetrically as possible. You will also need a chalk or marker with which you will outline the template;

- durable clamps. These are often used by straighteners to clamp body panels when restoring damaged cars. An ordinary clamp will do, but in this case you need to act more carefully;

- a manual or mechanical winch, as well as a cable that pulls the cut piece of the tread layer. You can use a manual gearbox or a winch mounted on a vehicle. You won’t be able to manually create force to make the rims, since the layers of rubber are very tightly bonded.

Article on the topic: How to overcome the fear of driving

Self-production

To make rims, the first step is to pull out the side metal cord. To do this, make a cut, departing approximately 10 mm from the inside of the tire. Hook the cord with a screwdriver, and then, hooking it with a hook, pull out the metal rim using a winch.

Using a template, apply the future outline of the tread along the entire perimeter of the wheel. Some obradyshas can be seen with the protector left in the center. It is along the contour of the outline that it is necessary to make cuts in the rubber. For this, it is best to use a construction knife, as you can control the depth of the cut by setting the required blade length. If you are confident in your abilities, you can use a grinder. To avoid cutting through the tire, use the sound as a guide. As soon as you cut through the rubber layer and reach the metal cord of the tire, the sound will acquire the appropriate color.

Cut the tire profile along the inner perimeter (where the metal wire ring used to be). It is the cut section that must be grasped with the clamp. Use a winch to create tension, and then use a utility knife to gradually trim off the peeling piece. After stripping the entire tire, you will get strips. Please note that when tension is created, the tire will tend to lean in, so it is necessary to implement a stop.

When working, do not stand in the direction of the winch tension so that the hook does not break and cause injury to you. Of course, it is worth thinking about the safety of things located in the affected area.

Particular attention should be paid to this point if you do the lifting using a winch installed on the car. It is not necessary to create a lot of force for peeling. For extra safety, place an old jacket on the cable, which will serve as a kind of damper if the clamp does break.

Discs

The video clearly shows the process of making discs with your own hands. Since the tire becomes elastic after stripping, it is necessary to ensure good side support. To ensure that when the pressure decreases, the rims do not deflate and do not tend to be dismantled, a special sealant is used during installation. If all recommendations are followed, self-made low-pressure tires are practically not inferior to factory-made analogues.

Share with friends on social networks:

Telegram

Advantages and disadvantages

wheels:

- Price. All-terrain wheels are very expensive, which can’t be said about the wheels.

- Such wheels have excellent adhesion to almost any surface, which significantly reduces the risk of accidents.

- The husks weigh relatively little. An “unpumped” passenger car engine will be quite capable of cranking them.

- Low surface pressure due to the large tire area. With encouragement, muddy terrain, quicksand and deep snow become quite passable obstacles. The tire pressure on the surface can be adjusted. They just need to be pumped up or lowered a little.

- Tires with low pressure do not harm the surface soil layers in any way, so you can safely drive an all-terrain vehicle with tires across plowed fields or use it as a tractor in agriculture.

Not without courage and some shortcomings

:

- You should try to ride less on hard asphalt and concrete surfaces. Otherwise, they will have to be changed very soon

. - A car on such wheels is not very stable. It’s better not to make sharp turns on it, and you shouldn’t drive it fast at all.

- Wheels wear out much faster

than normal ones. - Encouragement is a considerable burden. Transmission and suspension parts with such wheels will have to be changed and repaired more often.

- Low pressure tires are very flexible. This increases their permeability. But due to their increased stretchability, tires get punctured more often

than regular tires. - The car will have to be re-registered

- “upgraded” to the status of an all-terrain vehicle.

Peculiarities

- The wheels have a large contact area with the surface, which ensures easy movement in hard-to-reach places;

- A wide range of applications, for example, in agriculture a minimum load on the soil is required, in military affairs - cross-country ability of heavy trucks in mountainous and swampy areas, hunting and fishing - driving on snow and water surfaces;

- Driving an all-terrain vehicle with low-pressure wheels requires certain skills, since the vehicle is not at all designed for driving at high speed (turns are very dangerous), on asphalt and concrete (quick wear).

Tires for UAZ all-terrain vehicle

Created taking into account off-season weather conditions, therefore they are suitable for traveling along rain-washed country roads and bumpy ruts. The basis is a flexible rubber-cord shell. It is thanks to this that the wheels, without sinking into the ground, glide over the surface and easily adapt to road unevenness. The sealed connection to the rim prevents rotation, thereby ensuring low pressure - from 0.1 to 0.6 kPa. This guarantees efficiency - with a small impact on the ground, energy losses due to resistance are prevented.

Tires for the UAZ “Bukhanka” all-terrain vehicle and other models of the manufacturer have another feature - they are easy to use. Since they are tubeless, this reduces their weight and allows minor damage to be repaired without dismantling.

Tire classification

Tires are classified according to the type of construction.

Today, car owners use the following types of ultra-low pressure tires:

- Arched tires. The standard pressure in such tires is no more than 0.05 MPa, but they are 3-5 times wider than traditional tires and have a height of approximately 80 cm.

- Thyroid tires can be tubed or tubeless. They are distinguished by high reliability and versatility.

- Wide profile tire. The pressure in the tire is 2 times lower than in conventional tires, because the tire is deformed upon contact with holes, bumps and freely overcomes obstacles.

You may be interested in Viatti - characteristics of winter tires

In addition to these types of tires, you can find pneumatic rollers on sale. These tires are very voluminous, have pronounced lugs, and a reliable cord. They are considered very durable.

For hunting and fishing

Fishing and hunting farms have already appreciated the advantages of UAZ snow and swamp-going vehicles. The model range includes a whole range of swamp and snow and swamp-going vehicles, for which TREKOL wheels have become the key to high cross-country ability. Low pressure and elasticity allow you to move without problems on virgin snow, wetlands or sandy soil. Even when driving on weak soils, low-pressure tires do not cut a rut, which ensures fuel savings and preservation of vegetation.

Ultra-low pressure tires - the car will go anywhere!

Cars on large wheels are increasingly appearing on domestic roads these days. They are used on huge low-pressure tires on both factory-made vehicles (for example, all-terrain vehicles) and homemade ones. In most cases, SNDs for them are manufactured to special order, which, naturally, requires significant financial costs.

If you wish, you can save money and try to make low-pressure tires with your own hands. We will talk about the process of making them yourself below, providing a video of this operation. Now let’s describe the main advantage of SND. It lies in the fact that the low specific pressure on the ground (road) of such SUV tires allows you to create real all-terrain vehicles from ordinary cars that are not afraid of driving over rough terrain.

Cars with ultra-low pressure tires can easily overcome any off-road conditions and swamps; they can be used on country roads and agricultural land.

It has been proven that the cross-country ability of vehicles equipped with low-pressure tires is 20–40 percent higher than the cross-country ability of similar cars with standard tires.

In addition, the described tires (both homemade and made in production conditions on a special order) are characterized by a high rate of contact with the road. Due to this, when the tire hits any obstacle on the ground, it takes on its shape - “envelops” it, thereby increasing the area of contact of the low-pressure motor with the obstacle, which makes it possible to drive through it without difficulty.

For professionals and amateurs

Low-pressure tires included in the UAZ configuration will allow you to drive off-road. Professionals, fishing, hunting and traveling enthusiasts have already appreciated the benefits of low-pressure tires.

The legendary car is back at the peak of popularity

Nowadays, off-road vehicles are gaining particular popularity. This type of transport, such as an all-terrain vehicle based on a UAZ car, can be created with your own hands. It is a cheap form of transport and convenient. Most car owners who have such a car in their garage can be proud of it, because they created this miracle with their own hands. At this stage, there are already many exhibitions and forums have been created for craftsmen who share their experience with beginners.

Such all-terrain vehicles are most often created on the basis of UAZ, from older models to newer ones, the main thing is that they are in working condition. UAZ 469 cars are being converted to be equipped with low-pressure tires. In this case, the car turns into an all-terrain vehicle, capable of driving in the most impassable places.

Tires on a UAZ are quite expensive, so many people are starting to think about how to use their money more economically. And everything is quite simple: make low-pressure tires with your own hands. But in order to “change the shoes” of the car, equipping it with this type of tires, you will have to redo various suspension elements and body parts, and re-equip the axles. All this is caused by the fact that colossal loads are created on various systems due to frequent shifts in the center of gravity in the car.

Axles installed on the UAZ 469 model can fail due to constant driving in off-road mode, and the clutch system will quickly fail. Therefore, converting a car into an all-terrain vehicle on low-pressure UAZ Patriot tires for driving in difficult areas must be approached in detail and all issues must be resolved in a comprehensive manner.

- the vehicle's cross-country ability increases;

- the pressure in UAZ tires allows you to create better traction with any moving soil by increasing the traction plane;

- lugs specially provided for in the design of the low-pressure tire make the UAZ 469 more responsive;

- it becomes possible to use the car in agricultural production, since due to the low pressure in the tires, the UAZ has less impact on the ground and does not crush plants when driving through fields, leaving them viable;

- Due to the larger width, ground clearance increases, which ensures better vehicle stability on the road.

These tires are intended for off-road use only.

However, low-pressure tires on UAZ have a number of disadvantages:

- to install them, you will have to make quite a lot of modifications to the car, requiring large financial investments;

- the car becomes higher, as a result of which the center of gravity shifts, which can lead to the car tipping over;

- due to their greater softness, tires wear out greatly during long-term driving on asphalt;

- the tires are not suitable for high-speed driving, but only for off-road driving, which is a limitation in the use of the car;

- Due to greater vibration and a shift in the center of gravity of the UAZ 469 vehicle, when driving in off-road mode, the load on the transmission and other components increases. But the most critical increase in load is felt when driving on terrain that requires tires with a high tread depth.

The choice of low-pressure tires for the UAZ 469 is influenced by the temperature indicators of the region in which the vehicle will be used. To operate a car on this type of tire in both winter and summer, you must have two sets of tires. Although in this case there is no clear division between summer and winter tires. It is important that at sub-zero temperatures the rubber does not increase rigidity. Excessive rigidity reduces cross-country ability, since the ability of tires to be flexible is the key to off-road driving. If it is impossible for a hard low-pressure tire to deform on an UAZ, the contact patch on the ground or snow will decrease.

There are several UAZ tread patterns on low-pressure tires. Each of them is designed for a specific type of soil on which it is planned to move on such wheels. Moreover, a tire with a deeper tread is not always better. The wheels of the UAZ 469 with large tread interact more effectively with the ground, providing good traction, but at the same time create excessive load on the transmission. Therefore, it is very important that the pressure in UAZ tires has a certain indicator.

Soils vary in consistency, which must also be taken into account when choosing a low-pressure tire for the UAZ 469, UAZ Patriot.

Design options

Since in our case we are interested in the process of making all-terrain tires with our own hands, we will not dwell on factory design options. Types of low-pressure tires that are available for self-production:

- a tube made from a tire of the required size is used as a base. In this case, you can completely make the disk yourself or retrofit the finished wheel with the necessary stops and fasteners. Since the chamber is very elastic, it needs additional support, which will prevent it from breaking under lateral loads. Along the perimeter of the contact patch, the camera is tied with pieces of dense material or chains, which is necessary not only for attaching the camera to the disk, but also to create the effect of lugs. The ability to cling is important not only on sand, loose soil or snow, but also on water;

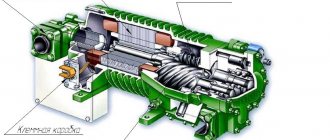

- Low pressure hydrators. Truck tires are used as a base, from which part of the tread and profile layer is cut off. As a result, the tire becomes lighter and acquires additional elasticity. To reduce the risk of disassembling the wheels when driving at low pressure, as in the previous case, it is necessary to make an additional side stop. We'll look at how to make the pads, as well as the design of the disc, in the photos and videos below.

Article on the topic: Making carbon fiber at home

Chamber version

First of all, you need to select or grind your own discs that will fit the parameters of the hubs of your vehicle. What to do if you need to adjust the width of the disk to the camera:

- cut the disk, cutting out the inner part of the required size, then welding the disks again if it is necessary to reduce the seat size;

- if the width needs to be increased, then a part of another disk is welded between the two cut halves. These wheels can be made to order for you, since making welding joints is quite common class=”aligncenter” width=”600″ height=”390″[/img]

To manufacture the type of low-pressure wheels we have chosen, metal rods will be required (the safe thickness depends on the size of the chamber, as well as the frequency of the jumpers). The side supports are welded to the base of the disk, and then transverse jumpers are attached to them, which will be the seat on the disk for the camera. For improved lateral support, the entire system is reinforced along the inner perimeter of the tire profile with a circular rod.

Some inventors use chains for jumpers that go around the contact patch. The solution is not bad, since it allows you to get additional snow, water and lugs. You can also use tow ropes, which, after tying, will cover the portion of the camera, preventing it from being damaged.

Most likely, it will be superfluous to remind you that all fasteners facing the camera should be fairly flat. Otherwise, when driving over uneven surfaces, there is a high probability of breaking through the camera.

Tire manufacturing instructions

Homemade low pressure tires

To manufacture low-pressure tires for UAZ, it is necessary to find the source material. You can use cameras for helicopters and airplanes: they meet quality requirements and will last a long time. The high cost and shortage of this product is an impetus for searching for other, more affordable options. One of the best solutions in this case may be to use truck tires. Of course, to convert them, it will be necessary to make considerable efforts, both physical and temporary, but this will reduce the costs of converting vehicles based on the UAZ 469.

We prepare the necessary tools (knives, a picker, a sharpener, a hammer, an awl, wire cutters) and determine the size of the required tire. To remove layers from the tire, we use a hoe - a fixed winch with an electric drive and a start button located at the workplace. Now we need to remove the outer bundle of wire cord. To do this work, we will cut a window, thanks to which we will cut one of the turns with wire cutters, wind the wire around the pliers and pull it out. It is advisable to perform these manipulations along the entire length of the wires. We cut the entire sidewall from the cord to the tread with a distance of 7-10 cm and go deeper to the first layers of the cord.

We use pliers to undermine the fang; this should be done only along its edges, and strictly clockwise, because the top layer of cord will appear on the right side.

Graphic markings are the basis for tread formation. The pattern in such tires is determined by their functional purpose. Herringbone is one of the simplest and most common options. Having finished the drawing, we cut out its contours. The tread section must have the shape of a regular trapezoid. Having finished the work, we begin stripping. The longest part in this process is preparation, but it is this that affects the speed and quality of work. It is necessary to avoid cutting the tooth protector, since the slightest mistake threatens us with irreparable consequences. After processing the last canine, the layer of cord on the right will also disappear.

Using pliers, you need to pick up the fang and slowly, increasing the tension of the winch cable, cut the side edges. This work is relatively easy to complete, but you need to work with concentration and attention, focusing your attention on the smallest details. Otherwise, your low pressure tires will start to delaminate.

When selecting low-pressure tires for an UAZ, you should focus on many indicators, including environmental factors and the vehicle’s application. Particular care must be taken in choosing the tread of an off-road tire.

Don't forget about disks. They can be made using standard analogues, having previously adjusted them to the desired size and proportions. You can secure discs and cameras using straps or a fire hose.

In recent years, the use of wide-profile low-pressure tires has been especially dynamic among owners of SUVs and all-terrain vehicles. Such tires are mass-produced in modern tire factories, such as the AVTOROS brand, in compliance with high quality standards and with high performance characteristics. This type of tire assumes very low pressure inside the wheel with adjustment, thereby increasing the area of contact of the tires with the ground and increasing the vehicle's maneuverability. Among off-road enthusiasts, the term “flap” is also used - this is a used tire from a KRAZ truck, from which several layers have been “stripped off”. As a rule, such a tire is installed when it is not possible to purchase new high-quality low-pressure tires.

Necessary actions

Having started directly making low-pressure tires with your own hands, you need to perform certain actions in strict sequence.

- Preparatory stage. To begin stripping a tire, it must be thoroughly cleaned, washed and dried. After this, markings are applied to the surface with a marker.

- Contour section. It is easiest to make a cut in the side of the tire, so after cutting to the depth of the first layer of tire cord threads, you need to begin to remove the metal fibers, first cutting the wire with wire cutters. Based on the previously drawn sketch, a wide cut is made that passes through the treadmill and the sidewall. Using pliers, the surface of the tire is cut and part of the casing is torn off. If there is a winch, increase the cable tension until the layered rubber element, called the fang, is completely separated.

After completing the job, it is extremely important to make sure that the base of the homemade low-pressure tire is not damaged anywhere. Otherwise, all the work will have to be done again with a new tire.

- After the previous steps, the tire is sanded with sandpaper and slightly straightened with a hammer.

Specifics of use

It must be remembered that in addition to numerous advantages, there are also some specifics to using such tires. Therefore, car owners who intend to buy new low-pressure tires or use used tires for their SUVs and all-terrain vehicles need to remember the following nuances:

- Low pressure tires reduce the speed of the vehicle;

- tires or tires on UAZ and Niva are subject to severe wear when driving on concrete and asphalt;

- acceleration and braking of the car must be extremely smooth;

- you should turn smoothly and along the maximum trajectory, since the sidewall of such tires is prone to transformation under load.

Acquisition

Our company produces and sells all-terrain vehicles; in addition, our customers can also buy separately all-terrain tires for Niva, UAZ, GAZ 66 and other car models. The rubber for all-terrain vehicles produced by our company is of high quality and wear resistance, and the affordable price of AVTOROS low-pressure tires makes purchasing our products very profitable. For our company's clients, we offer various promotions and competitions with valuable prizes.

Many car enthusiasts who are interested in fishing or hunting, as well as those who live in rural areas, often think about how to increase the cross-country ability of their car. Many people are interested in whether it is possible to turn an ordinary car into an all-terrain vehicle with their own hands.

UAZ brand cars are a very well-known domestically produced model, which was produced specifically for conditions requiring increased cross-country ability.

Patriot on low-pressure tires

This is the UAZ-452, the so-called loaf - one of the first models with increased cross-country ability. “Bukhanka” has been used for more than 50 years in difficult traffic conditions, especially in villages. These are also newer models “Hunter” and “Patriot”, released after 2000.

As you know, one of the factors that significantly increases the cross-country ability of a car is.

Many car enthusiasts manage to make a UAZ with their own hands on low-pressure tires, turning it into an excellent all-terrain vehicle that is not afraid of either muddy roads or snow piles.

Hunter on low pressure tires

List of events

1. Preparation. For the stripping process of a future low-pressure tire, it must be cleaned, washed and dried. Then its surface is marked with a marker.

2. Cutting the outline. It is easier to cut the sidewall, so work begins from this place. Make a cut to the depth of the first layer of tire cord threads. The wire is cut through it using wire cutters. The metal fibers are pulled out one by one.

According to the sketch, a wider cut is made, passing through the treadmill and sidewall. Using wire cutters, cut the surface and tear off part of the casing. If there is a winch, the cable tension is gradually increased until the goal is achieved - complete separation of the layered rubber element, called the fang.

The entire surface is treated in this way. Upon completion of work, the tire must be carefully checked for cutting the base . If such an incident occurs, then time is wasted, and you need to get a new tire for work.

3. The structure is cleaned with emery cloth and lightly straightened with a hammer.

Manufacturing the disk and assembling the structure

For the base of the frame, a ready-made structure is most often taken. As a rule, it is cut lengthwise and an additional metal insert is inserted for expansion or a rigid structure is created by welding a series of pins (or rods).

The wheel is mounted using belts wrapped in rubber rings and a disk. A fire hose, a thin belt from an industrial conveyor, and tarpaulin strips are used as auxiliary means.

Sometimes aluminum is cut into strips. Each of them is secured with bolted connections or rivets. Installation begins on one side of the disc, then goes around the rubber and ends at the other base. The minimum number of tapes is 12.

Read more: In what cases can a car be towed?

The final stage of work is tire inflation. The convex places will become planes in contact with the road, and the wheel structure will be more elastic.

This is where the information on how to make tires for pneumatics or a conventional unit with your own hands ends.

Take risks, experiment and win the chance to experience new sensations from driving your vehicle.

Using the right tires is one of the main conditions for good cross-country ability for any all-terrain vehicle. Since the cost of a specialized kit, often manufactured in small batches or even to order, cannot be called humane, let’s look at how to make low-pressure wheels with your own hands. In the video we will demonstrate the process of transforming standard truck tires into tires.

Advantages of installing low-pressure tires on a UAZ

Let's look at the benefits we get by installing low-pressure tires on the UAZ:

- the vehicle's maneuverability is significantly improved;

- tires of this type increase the grip patch on the ground;

- in such cases, special lugs can be installed that make the machine more squat;

- the use of this type of rubber reduces the negative impact on the soil, which is very important in terms of environmental performance;

- There is an increase in ground clearance, which inevitably occurs when tires with low pressure are installed.

Advantages of installing low-pressure tires on a UAZ

Disadvantages of installing low pressure tires on a UAZ

However, tuning of this kind also has its drawbacks. These may be the following factors:

- To install such wheels, you will need to make a number of serious changes to the design of the car. This is quite labor-intensive and entails significant financial costs;

- a higher location of the vehicle’s center of gravity negatively affects its stability;

- If we are talking about driving on asphalt, you must take into account that it wears out low-pressure tires a lot. Therefore, it is not recommended for all-terrain vehicles of this kind to travel frequently and for long periods of time on asphalt surfaces;

Disadvantages of low pressure tires on UAZ

- You will also have to be careful with speed. Low-pressure tires are not intended for high-speed travel - here the main task is driving on off-road surfaces and overcoming obstacles;

- the increased load on transmission units should be taken into account. When driving on soils that require high profile treads, critical load values may occur.

What you will need to consider when remodeling a car

If you decide to convert your UAZ into an all-terrain vehicle by installing wheels with low-pressure tires, you will have to take into account some factors:

- Be prepared for the fact that you will have to make a number of serious changes to the transmission, axles and body parts of your car. This is especially important when it comes to converting cars such as the “loaf”. The UAZ "Patriot" on low-pressure tires will require much fewer design changes than the "loaf". This is explained by the fact that at the time when the old models were produced, modern technologies and materials had not yet been used;

Choosing tires for UAZ

- When choosing rubber, it is very important to take into account the temperatures in which they are planned to be used. For summer and winter use of the vehicle you will need at least two sets of tires;

- Low-pressure tires do not have a clear division into summer and winter options. For winter, types are used that do not become hard at subzero temperatures. This can negatively affect the vehicle's maneuverability;

- When choosing a tread pattern, remember that “deeper” does not always mean “better.” Increasing the depth of the pattern increases the load on the transmission - take into account the soil on which you plan to move and choose the optimal option for the depth of the pattern.

All work on the production of an all-terrain vehicle based on a UAZ vehicle can be divided into several conventional stages. Let's look at them one by one:

- Choosing a base. If there is no UAZ in the garage suitable for turning into an all-terrain vehicle, we will have to find the necessary base. Remember that the older the model, the more changes will have to be made.

- We manufacture the rear axle and suspension. Here it is better to use an independent design. Its production will entail an increase in labor costs, but this will increase the maneuverability of the machine. The suspension is connected to the rear axle with a special strut and steering bushing.

- We attach the wheels to the suspension. Metal hubs are required here. We can use cameras from trucks like the Ural.

- We select the engine, carry out installation and design the cooling system.

- After installing the engine, we install the exhaust and brake systems and clutch. We install the headlights and connect all the switching.

- We carry out all the necessary tests of the resulting all-terrain vehicle, eliminating shortcomings and defects. After making all the corrections and positive test results, we can consider the work completed - our all-terrain vehicle is ready to overcome difficulties.

Work on the production of an all-terrain vehicle based on a UAZ vehicle