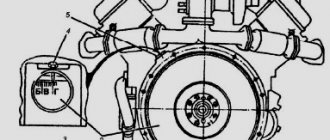

Engine YaMZ-236 NB-2

The six-cylinder V-shaped (camber angle 90°) four-stroke diesel engine with turbocharging and air-to-air charge air cooler, liquid cooling YaMZ-236 NB-2 of the Yaroslavl Motor Plant has the following characteristics.

| Technical characteristics of YaMZ-236 NB-2 | |

| Engine displacement | 11.15 l |

| Bore and stroke | 130 mm x 140 mm |

| Maximum torque | 736 Nm at 1200-1400 rpm |

| Operating power | 110 kW (150 hp) at 1800 rpm |

Chetra T15 description

Chetra T15 bulldozers have a double-glazed cabin, providing maximum visibility of equipment and work areas. The cabin, mounted on rubber shock absorbers with noise-absorbing upholstery, and a sprung and adjustable seat minimize noise and vibration, providing a favorable working environment. At the customer's request, an additional autonomous heater and air conditioner can be installed. Three-point semi-rigid suspension with a remote bogie swing axis and micro-sprung tension wheel provides high traction properties, reduced shock loads on the chassis system, and improved working conditions; The use of economical diesel engines from the Yaroslavl Motor Plant, such as YaMZ-238ND4-1, and QSC 8.3-C245, provides increased traction properties during heavy work. The modular design of all components and systems of an industrial tractor - transmission, chassis system, working equipment, cooling system, cabin and tractor control ensures simplified and convenient maintenance when checking and refueling all systems of an industrial tractor, the ability to remove and install power transmission units in separate modules, and their subsequent repair in rooms specially equipped for this purpose with their testing before installation on the machine.

A full flow filter cleans the oil. The heat exchanger operates on a liquid-oil mechanism. The fuel injection system is automatic and diagnoses the condition of the engine.

Engine QSB6.7-C165

Six-cylinder four-stroke diesel engine with turbocharging and air-to-air charge air cooler, liquid cooling QSB6.7-C165.

| Technical characteristics of Cummins QSB6,7-C165 | |

| Engine displacement | 6.7 l |

| Bore and stroke | 102 mm x 136.4 mm |

| Maximum torque | 800 Nm at 1300-1500 rpm |

| Operating power | 110.3 kW (150 hp) at 1800 rpm |

Engine with the Quantum system, containing electronic fuel injection, diagnostics, engine protection and engine management systems.

Oil purification system with full flow filter. Liquid-oil heat exchanger for cooling engine oil.

24 volt electric starting system.

ENGINE

Six-cylinder V-shaped (camber angle 90°) four-stroke diesel engine without turbocharging, liquid cooling YaMZ-236 NB2 from the Yaroslavl Motor Plant.

| Bore and stroke | 130 mm x 140 mm |

| Engine displacement | 11.15 l |

| Operating power | 110 kW (150 hp) at 1800 rpm |

| Maximum torque | not less than 736 Nm at 1300…1500 rpm |

Six-cylinder four-stroke diesel engine with turbocharging and air-to-air charge air cooling, liquid cooling QSB6.7-C165.

| Cylinder arrangement | Row |

| Bore and stroke | 102 mm x 120 mm |

| Engine displacement | 6.7 l |

| Operating power | 110 kW (150 hp) at 2000 rpm |

| Maximum torque | 800 Nm at 1300…1500 rpm |

Engine with the Quantum system, containing electronic fuel injection, diagnostics, engine protection and engine management systems.

Oil purification system with full flow filter. Liquid-oil heat exchanger for cooling engine oil.

Transmission

Hydromechanical transmission of the CHETRA T9, T-9.01 bulldozer produced by Promtractor OJSC. Planetary power shift gearbox with 345 mm diameter oil operated clutches with high torque transmission capability, providing three forward and three reverse gears. Gear shifting is electrohydraulic. Structurally, it is combined with a matching gearbox and main gear into a single power unit installed in the bore of the rear axle. Three-element, single-stage torque converter with an active diameter of 390 mm, maximum transformation coefficient K0 = 2.539 with a pump drive gearbox, connected to the gearbox with a splined clutch, installed on the front wall of the rear axle. The torque converter is connected to the engine through a cardan drive and an elastic coupling mounted on the engine.

Technical characteristics of the gearbox | ||

| Broadcast | Forward travel | Reverse |

| 1 | 3,8 | 5,0 |

| 2 | 6,9 | 9,0 |

| 3 | 11,1 | 14,4 |

TRANSMISSION

Planetary power shift gearbox with 345 mm diameter oil operated clutches with high torque transmission capability, providing three forward and three reverse gears. Gear shifting is electrohydraulic. Structurally, it is combined with a matching gearbox and main gear into a single power unit installed in the bore of the rear axle. Three-element, single-stage torque converter with an active diameter of 390 mm, maximum transformation ratio Ko = 2.539 with a pump drive gearbox, connected to the gearbox with a splined clutch, installed on the front wall of the rear axle. The torque converter is connected to the engine through a cardan drive and an elastic coupling mounted on the engine.

| Broadcast | Forward movement CHETRA 9 | Reverse gear CHETRA 9 |

| 1 | 3,8 / 4,0 | 5,0 / 5,3 |

| 2 | 6,9 / 7,2 | 9,0 / 9,5 |

| 3 | 11,1 / 11,6 | 14,4 / 15,1 |

The traction force depends on the weight of the tractor and the traction force.

Chassis

Suspension : three-point semi-rigid with a remote rolling axis of the bogies provides high traction properties, reduced shock loads on the chassis system, and improved working conditions. Support, support rollers and idlers are lubricated for a lifetime with self-clamping double cone seals.

| Number of road wheels | 6 |

| Number of support rollers | 2 |

Tracks : Prefabricated with a single grouser and a seal to hold liquid lubricant in the joint. Track tension is easily adjusted with a grease gun.

Characteristics of the T-9.01 bulldozer caterpillar | |

| Link pitch, mm | 190,5 |

| Number of shoes | 39 |

| Height of lugs, mm | 55 |

| Shoe width, mm | 560 |

| Base, mm | 2 470 |

| Support surface area, m² | 2,766 |

| Ground pressure, kgf/cm² | 0,607 |

Features of the Chetra T9 bulldozer

The weight of the machine—16.8 tons—allows it to be delivered to the desired location by rail, trawl, and, if the soil is unstable, by helicopter. This fact makes the technology a priority for geological prospectors whose activities take place in such conditions. If you drive models T9 and T11 into a wetland, most likely it is the first that will be able to stand on soft ground, and the second will get stuck. This is due to the difference in their mass.

Chetra T9 has a three-point semi-rigid suspension. The result of the design solution is good traction and grip properties, reduced shock loads on the unit, and increased operating comfort. The bulldozer is equipped with an economical diesel engine.

Hydraulic system

Characteristics of the CHETRA T9 separate-unit hydraulic system:

- Gear pump S1A5070 with a capacity of 120 l/min at 1700 engine rpm.

- four-section valve, consisting of one valve and three spool sections

- maximum response pressure of the safety valve - 20 MPa (200 kgf/cm²)

- hydraulic tank capacity (welded tank, adapted for mechanical cleaning of internal surfaces) - 85 l

| Spool sections | Distributor spool position | Number of cylinders | Cylinder diameter, mm |

| Blade lift | lift, neutral (hold), lower, float | 2 | 80 |

| Blade misalignment | right, neutral, left | 1 | 125 |

| Raising the ripper | lift, neutral, lower | 2 | 100 |

Bulldozer hydraulic system

Separate-unit hydraulic system:

- gear pump NSh71, with a capacity of 120 l/min at 1700 engine rpm;

- four-section distributor, consisting of one valve and three spool sections;

- maximum response pressure of the safety valve is 20 MPa (200 kgf/cm2);

- hydraulic tank capacity (welded tank, adapted for mechanical cleaning of internal surfaces) - 85 l.

| Spool sections | Distributor spool position | Number of cylinders | Cylinder diameter, mm |

| Blade lift | lift, neutral (hold), lower, float | 2 | 80 |

| Blade misalignment | right, neutral, left | 1 | 125 |

| Raising the ripper | lift, neutral, lower | 2 | 100 |

Ripping equipment

Depending on the operation of the CHETRA T9, T-9.01 bulldozer, one, two or three teeth can be mounted on the ripper, which allows for high productivity.

| Ripper type | Non-adjustable, multi-tooth |

| Number of teeth | 3 |

| Weight, kg | 890 |

| Max. lifting height, mm | 543 |

| Max. depth, mm | 455 |

| Max. pullout force, T | 11,6 |

| Max. penetration force, T | 5,22 |

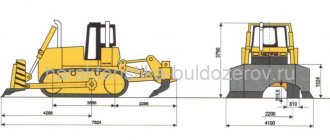

BULLDOZER CHETRA T-9 characteristics, description

ENGINE

YaMZ -236-NB-2 110 kW (150 hp) QSB6.7 - C165 110 kW (150 hp)

TRANSMISSION

Hydromechanical transmission manufactured by OJSC Promtractor. Planetary power shift gearbox with 345 mm diameter oil operated clutches with high torque transmission capability, providing three forward and three reverse gears. Gear shifting is electrohydraulic. Structurally, it is combined with a matching gearbox and main gear into a single power unit installed in the bore of the rear axle. Three-element, single-stage torque converter with an active diameter of 390 mm, maximum transformation ratio Ko = 2.539 with a pump drive gearbox, connected to the gearbox with a splined clutch, installed on the front wall of the rear axle. The torque converter is connected to the engine through a cardan drive and an elastic coupling mounted on the engine.

| Broadcast | Forward travel | Reverse |

| 1 | 3,8 | 5,0 |

| 2 | 6,9 | 9,0 |

| 3 | 11,1 | 14,4 |

CHASSIS

Suspension:

three-point semi-rigid with a remote swing axis of the bogies provides high traction and grip properties, reduced shock loads on the chassis system, and improved working conditions. Support, support rollers and idler wheels with one-time lubrication for the entire service life with self-clamping “double cone” seals.

| Number of road wheels (each side) | 6 |

| Number of support rollers (each side) | 2 |

Caterpillars:

prefabricated with one lug and a seal to hold liquid lubricant in the hinge. Track tension is easily adjusted with a grease gun.

| Link pitch | 190.5 mm |

| Number of shoes (each side) | 39 |

| Height of lugs | 55 mm |

| Shoe width | 560 mm |

| Base | 2470 mm |

| Supporting surface area | 2,766 m2 |

| Ground pressure | 0.607 kgf/cm2 |

FINAL TRANSMISSION

The final drive is two-stage, the 1st stage is external gears, the 2nd stage is planetary according to the “to +1” scheme (with a stopped ring gear). To facilitate replacement in the field, the drive sprocket is made of five sectors that are secured with bolts.

HYDRAULIC SYSTEM

Separate-unit hydraulic system:

- gear pump S1A5070, capacity 120 l/min at 1700 engine rpm

- four-section distributor, consisting of one valve and three spool sections

- maximum response pressure of the safety valve 20 MPa (200 kgf/cm2)

- hydraulic tank capacity (welded tank, adapted for mechanical cleaning of internal surfaces) - 85 l

| Spool sections | Distributor spool position | Number of cylinders | Cylinder diameter, mm |

| Blade lift | lift, neutral (hold), lower, float | 2 | 80 |

| Blade misalignment | right, neutral, left | 1 | 125 |

| Raising the ripper | lift, neutral, lower | 2 | 100 |

RIPPERING EQUIPMENT

Ripper: single, three-prong

BULLDOZER EQUIPMENT

Blade type: hemispherical blade, rotating blade (mechanical), straight blade, rotating blade (hydraulic).

WEIGHT

Total weight 17500 - 20220 kg.

CHETRA SUPPLIERS CHETRA SPARE PARTS Return to list

vsyatekhnika.ru

Bulldozer equipment

The large capacity of the hemispherical blade of the CHETRA T9, T-9.01 bulldozer ensures increased productivity; the applied design of the blade ensures its effective use both in transporting cargo and when digging pits, planning sites and constructing roads.

| Blade | SU blade |

| Blade length x height, mm | 3160 x 1272 |

| Dump capacity, m² | 4,28 |

| Lifting height, mm | 1000 |

| Depth, mm | 500 |

| Max. misalignment, hail | ±7° |

| Blade weight, kg | 2118 |

Bulldozer Chetra T-9

ENGINE

Six-cylinder V-shaped (camber angle 90°) four-stroke diesel engine without turbocharging, liquid cooling YaMZ-236NB-2 from the Yaroslavl Motor Plant. Bore and stroke 130 mm x 140 mm Engine displacement 11.15 l Operating power 110 kW (150 hp) at 1800 rpm Maximum torque no less than 736 Nm at 1300…1500 rpm

Six-cylinder four-stroke diesel engine with turbocharging and air-to-air charge air cooling, liquid cooling QSB6.7-C165.

Cylinder arrangement In-line Bore and stroke 102 mm x 136.4 mm Engine displacement 6.7 l Operating power 110 kW (150 hp) at 2000 rpm

Maximum torque 800 Nm at 1300…1500 rpm

Engine with the Quantum system, containing electronic fuel injection, diagnostics, engine protection and engine management systems.

Oil purification system with full flow filter. Liquid-oil heat exchanger for cooling engine oil.

TRANSMISSION

Planetary power shift gearbox with 345 mm diameter oil operated clutches with high torque transmission capability, providing three forward and three reverse gears. Gear shifting is electrohydraulic. Structurally, it is combined with a matching gearbox and main gear into a single power unit installed in the bore of the rear axle. Three-element, single-stage torque converter with an active diameter of 390 mm, maximum transformation ratio Ko = 2.539 with a pump drive gearbox, connected to the gearbox with a splined clutch, installed on the front wall of the rear axle. The torque converter is connected to the engine through a cardan drive and an elastic coupling mounted on the engine.

| Broadcast | Forward travel | Reverse |

| 1 | 3,8 | 5,0 |

| 2 | 6,9 | 9,0 |

| 3 | 11,1 | 14,4 |

The traction force depends on the weight of the tractor and the traction force.

FINAL TRANSMISSION

The final drive is two-stage, the 1st stage is external gears, the 2nd stage is planetary according to the “to +1” scheme (with a stopped ring gear). To facilitate replacement in the field, the drive sprocket is made of five sectors that are secured with bolts.

CHASSIS

Suspension: three-point semi-rigid with a remote swing axis of the bogies provides high traction properties, reduced shock loads on the chassis system, and improved working conditions. Support, support rollers and idler wheels with one-time lubrication for the entire service life with self-clamping “double cone” seals. Number of support rollers (each side) 6 Number of support rollers (each side) 2

Tracks: Prefabricated with a single grouser and seal to retain liquid lubricant in the joint. Track tension is easily adjusted with a grease gun. Link pitch 190.5 mm Number of shoes (on each side) 39 Height of lugs 55 mm Shoe width 560 mm Base 2470 mm Supporting surface area 2.766 m2 Ground pressure 0.62 kgf/cm2

HYDRAULIC SYSTEM

Separate-unit hydraulic system: gear pump S1A5070, capacity 120 l/min at 1700 rpm engine four-section distributor, consisting of one valve and three spool sections maximum response pressure of the safety valve 20 MPa (200 kgf/cm2) hydraulic tank capacity (welded tank , adapted for mechanical cleaning of internal surfaces). . . 85 l

Spool sections Position of distributor spools Number of cylinders Cylinder diameter, mm Blade lift lift, neutral (hold), lower, floating 2 80 Blade skew right, neutral, left 1 125 Ripper lift lift, neutral, lower 2 100

REFILLING CAPACITIES

Fuel tank 300 l Cooling system 75 l Engine 21 l Torque converter, gearbox, bevel gear 85 l Final drive (each side) 2 x 10 l Attachment hydraulic system 115 l

BULLDOZER EQUIPMENT

The large capacity of the blade provides increased productivity, and the use of diagonal traction when transmitting lateral forces from the blade to the left side member of the tractor frame ensures maximum proximity of the blade to the tractor hood and maximum pressure force on the blade blade.

Hemispherical blade: 3154x1273, mm (DxH), volume 4.28 m3 Straight blade: 4185x1002 mm (DxH), volume 3.26 m3 Straight blade with mechanical rotation: 3977x1110 mm (DxH), volume 3.7 m3 Direct rotary hydraulic blade : 4032x1100 mm (LxH), volume 3.7 m3

RIPPERING EQUIPMENT Ripper: single-tooth, three-tooth.

WEIGHT

Operating weight (with attachments), kg: 17500 (20220) kg.

Model: T-9.01 Engine: YaMZ-236 NB-2 QSB6.7-C165 Engine power (kW/hp): 112/152 109/148 Unit weight (kg): 16800 16500 Spec. ground pressure (kgf/cm²): 0.61 0.60

The Chetra T9 bulldozer-ripper unit has greater productivity thanks to the use of advanced design and technological solutions and can be used in industrial, oil and gas, hydraulic engineering, road construction, mining and urban construction for earth-moving work.

The three-point semi-rigid suspension of the Chetra T9 bulldozer with a remote bogie swing axis provides high traction properties, reduced shock loads on the chassis system, and improved working conditions; Using an economical diesel engine: - YaMZ-236 DK-7-150 (Yaroslavl Motor Plant) with an operating power of 103 kW (140 hp) at 1900 rpm; The modular design of all components and systems of an industrial bulldozer - transmission, chassis system, working equipment, cooling system, cabin and Tractor control ensures simplified and convenient maintenance when checking and refueling all systems of an industrial Tractor, the ability to remove and install power transmission units in separate modules, and their subsequent repair in rooms specially equipped for this purpose with their testing before installation on the machine.

karteh.com

Modifications and equipment

CHETRA T-9.01 bulldozers are supplied in the following modifications and configurations:

| Modification | Equipment | Engine power, kW/hp | Weight, kg |

| T-9.01Ya1B-1 | YaMZ-236NB-2, hemispherical blade, trailer hitch | 110/150 | 17150 |

| T-9.01YA1BR-1-01 | YaMZ-236NB-2, hemispherical blade, ripper 3 teeth | 110/150 | 17920 |

| T-9.01Ya1BL-1 | YaMZ-236NB-2, hemispherical blade, winch | 110/150 | 18270 |

| T-9.01YAMB-3 | YaMZ-236NB-2, straight blade, low pressure. to the ground, trailer hitch | 110/150 | 19090 |

| T-9.01YAMBR-3-01 | YaMZ-236NB-2, straight blade, low pressure. On the ground, ripper 3 teeth | 110/150 | 19875 |

| T-9.01YAMBL-3 | YaMZ-236NB-2, straight blade, low pressure. on the ground, winch, ripper 3 teeth | 110/150 | 20220 |

| T-9.01KB-1 | Cummins QSB6,7-C165, hemispherical blade, trailer hitch | 110/150 | 16560 |

| T-9.01KBR-1-01 | Cummins QSB6,7-C165, hemispherical blade, ripper 3 teeth | 110/150 | 17345 |

| T-9.01KBL-1 | Cummins QSB6,7-C165, hemispherical blade, winch | 110/150 | 17700 |

| T-9.01KMB-3 | Cummins QSB6,7-C165, straight blade, low pressure. To the ground, trailer hitch | 110/150 | 19090 |

| T-9.01KMBR-3-01 | Cummins QSB6,7-C165, straight blade, low pressure. on the ground, ripper 3 teeth | 110/150 | 19875 |

| T-9.01KMBL-3 | Cummins QSB6,7-C165, straight blade, low pressure. on the ground, ripper 3 teeth, winch | 110/150 | 20220 |

TECHNICAL CHARACTERISTICS OF CHETRA T-15

Engine model: YaMZ-238 ND7-1 / Cummins QSC8.3 Engine power, kW (hp): 184 (250) / 193 (263) Total weight, kg: 28300 / 29980

| Model | T-15.02Ya | T-15.02K | T-15.02YAM | T-15.02KM |

| Type | Crawler | |||

| Traction class | 15 | |||

| Engine, make | YaMZ-238 ND7-1 | Cummins QSC8.3 | YaMZ-238 ND7-1 | Cummins QSC8.3 |

| Rated power, kW (hp) | 184 (250) | 193 (263) | 184 (250) | 193 (263) |

| Operating power, kW (hp) | 174 (235) | 180 (245) | 174 (235) | 180 (245) |

| Engine displacement, l | 14,86 | 8,3 | 14,86 | 8,3 |

| Specific fuel consumption at operating power, g/kWh. (g/hp.h), no more | 230 (169) | 227 (167) | 230 (169) | 227 (167) |

| Transmission, type | hydromechanical | |||

| Tractor idling speed, km/h, forward/reverse gears | ||||

| 1st gear | 3,9 / 5,1 | 3,9 / 5,2 | 3,9 / 5,1 | 3,9 / 5,2 |

| 2nd gear | 6,9 / 9,0 | 7,1 / 9,1 | 6,9 / 9,0 | 7,1 / 9,1 |

| III gear | 11,1 / 14,2 | 11,1 / 14,7 | 11,1 / 14,2 | 11,1 / 14,7 |

| Chassis | Three-point semi-rigid suspension with remote rolling axis of bogies | |||

| Number of road wheels (each side) | 7 | 7 | 8 | 8 |

| Number of support rollers (each side) | 2 | |||

| Caterpillars | prefabricated with one grouser | |||

| Height of lugs, mm | 70 | |||

| Shoe width, mm | 560 | 560 | 810 | 810 |

| Ground clearance, mm, not less | 490 | |||

| Tractor track, mm, not less | 2000 | 2000 | 2 150 | 2 150 |

| Base, mm | 2865 | 2865 | 3 022 | 3 022 |

| Supporting surface area, sq.m. | 3,21 | 3,21 | 5,50 | 5,50 |

| Ground pressure, kgf/sq.cm. | 0,87 | 0,87 | 0,43 | 0,43 |

| Fuel tank, l | 400 | |||

| Ripping equipment | ||||

| Type | Fixed single/multi-tooth | |||

| Number of teeth | 1 / 3 | |||

| Weight, kg. | 2265 / 2475 | |||

| Max. depth, mm. | 700 | |||

| Bulldozer equipment | ||||

| Blade | hemispherical | |||

| Length x Height, mm. | 3,794 x 1,544 | 3,794 x 1,544 | 4,100 x 1,542 | 4,100 x 1,542 |

| Capacity, sq.m. | 6,8 | 6,8 | 9,2 | 9,2 |

| Lifting height above the supporting surface, mm. | 1 105 | 1 105 | 890 | 890 |

| Blade depth, mm. | 555 | 555 | 440 | 440 |

| Max. tilt adjustment (skew), degrees | ±10 | |||

| Weight, kg. | 3 810 | 3 810 | 3 610 | 3 610 |

| Winch | ||||

| Maximum force of the traction unit winch, kgf, not less than: | 30000 | |||

| Winch rope length, m | 75 | |||

| Winding speed of the first layer of rope onto the winch drum (calculated), m/min, not less: | 10 | |||

| Overall dimensions of the tractor without attachments no more than | ||||

| length, mm | 4 520 | 4 520 | 4 900 | 4 900 |

| width, mm | 2 640 | 2 640 | 3 010 | 3 010 |

| height, mm | 3 812 | 3 812 | 3 832 | 3 832 |

| Total weight (standard configuration, fully loaded, blade, ripper, driver), no more than kg. | 28 300 | 28 300 | 29 980 | 29 980 |

INSTALLED EQUIPMENT CHETRA T-15

Front Attachment / Dimensions (WxH) / Blade Capacity (m3)

- hemispherical blade / 3794 x 1544 / 6.8

- hemispherical dump (reclamation) / 4100 x 1542 / 9.2

- straight blade / 3880 x 1530 / 5.8

- spherical blade / 4058 x 1555 / 8.5

Rear attachment

- ripper 1 tooth

- ripper 3 teeth

- winch

Other possible equipment

- air conditioner

Chassis design Track shoe width, mm

- standard 560

- reclamation 810

Optional equipment

- Automatic fire extinguishing system

- Automatic lubrication system

- Video review system

- Automatic control system for the mining and transport complex ACS GTK "Karyer"

- Spark arrestor

- Cabin guards

- LED headlights

- Radio station

- Fast fuel filling system

All other options available upon request

Standard equipment

- Double glazed cabin

- GLONASS/GPS satellite monitoring system

- Dependent and independent cabin heater

- Engine preheating system

- Temperature design -50С +35С

- Audio system

- Automatic reverse horn

- Forward horn

- Side mirrors

- Micro-suspended seat with air suspension

ADVANTAGES OF CHETRA T-15

- Solutions for centralized transmission diagnostics have been implemented. Transmission diagnostic points are located in one place for ease of access;

- The use of air-to-air coolers and fuel coolers in the radiator installation increased engine efficiency and reduced the level of emissions of harmful substances into the atmosphere;

- Additional fuel filters with water separation and fuel heating functions are installed. The transparent filter cover provides a visual indication of the service life of the filter element;

- Modular design of all components and systems;

- A welded-cast frame body is used (the rigidity of the structure is increased, oil leaks are eliminated);

- Three-point semi-rigid suspension with remote bogie swing axis;

- Support and support rollers and idlers with one-time lubrication for the entire service life with self-clamping “double cone” seals;

- Hydromechanical transmission with planetary gearbox and two-stage final drive;

- The cabins are installed on hydraulic supports, equipped with double-glazed windows, a microclimate system (air conditioners and heaters), windshield wipers and washers, sun shades, and audio systems;

- Large capacity fuel tanks, which reduces technological downtime of equipment;

- A GLONASS-based equipment monitoring system was installed;

- Frame elements ROPS-FOPS.

Standard Equipment

The standard equipment of the CHETRA T-9.01 bulldozer includes:

- Adjustable operator's seat with soft cushion

- Air purifier

- Cab heating fan

- Decelerator

- Sound signal

- Front tow hook

- Motor protection

- Hydraulic device for track tensioner

- Lighting system

- Multi-layer protection

- Muffler

- Parking brake

- Power train protection

- Replaceable ring gear segments

- ROPS/FOPS protective structure

- Safety belt

- External power socket 24 V

- 24 V power socket

- Alternator 75 A

- Rechargeable batteries (2), 12 V, 190 A*h (on-board voltage 24 V)

- Cigarette lighter

- Starter

- Electric hour meter

On the instrument panel:

- tachometer

- coolant temperature gauge

- engine oil pressure gauge

- engine oil temperature gauge

- onboard voltage indicator

- fuel level indicator

- transmission oil temperature gauge

Indicators on the instrument panel:

- emergency engine oil pressure

- engine coolant overheating

- lack of battery charge

- air filter clogged

- clogged filter in the hydraulic tank

- overheating of oil in the hydraulic tank

- clogging of the transmission filter

- minimum transmission oil temperature

- overheating of transmission oil

- clogged engine oil filter

- emergency transmission oil pressure

Bulldozer Chetra T9

ENGINE

Six-cylinder V-shaped (camber angle 90°) four-stroke diesel engine with turbocharging and air-to-air charge air cooler, liquid cooling YaMZ-236 NB2 from the Yaroslavl Motor Plant.

| Bore and stroke | 130 mm x 140 mm |

| Engine displacement | 11.15 l |

| Operating power | 110 kW (150 hp) at 1800 rpm |

| Maximum torque | not less than 736 Nm at 1200…1400 rpm |

Six-cylinder four-stroke diesel engine with turbocharging and air-to-air charge air cooling, liquid cooling QSB6.7-C165.

| Cylinder arrangement | Row |

| Bore and stroke | 102 mm x 136.4 mm |

| Engine displacement | 6.7 l |

| Operating power | 110 kW (150 hp) at 1900 rpm |

| Maximum torque | 800 Nm at 1300…1500 rpm |

Engine with the Quantum system, containing electronic fuel injection, diagnostics, engine protection and engine management systems.

Oil purification system with full flow filter. Liquid-oil heat exchanger for cooling engine oil. 24 volt electric starting system.

TRANSMISSION

Planetary power shift gearbox with 345 mm diameter oil operated clutches with high torque transmission capability, providing three forward and three reverse gears. Gear shifting is electrohydraulic. Structurally, it is combined with a matching gearbox and main gear into a single power unit installed in the bore of the rear axle. Three-element, single-stage torque converter with an active diameter of 390 mm, maximum transformation ratio Ko = 2.539 with a pump drive gearbox, connected to the gearbox with a splined clutch, installed on the front wall of the rear axle. The torque converter is connected to the engine through a cardan drive and an elastic coupling mounted on the engine.

| Broadcast | Forward travel | Reverse |

| 1 | 3,8 | 5,0 |

| 2 | 6,9 | 9,0 |

| 3 | 11,0 | 14,4 |

The traction force depends on the weight of the tractor and the traction force.

STEERING AND BRAKING CONTROL

Side clutches are multi-plate clutches that are hydraulically actuated. Stopping brakes are multi-disc clutches that are permanently closed by spring force. Onboard clutches and brakes are cooled by oil under pressure and do not require adjustment during their entire service life.

FINAL TRANSMISSION

The final drive is two-stage, the 1st stage is external gears, the 2nd stage is planetary according to the “to +1” scheme (with a stopped ring gear). To facilitate replacement in the field, the drive sprocket is made of five sectors that are secured with bolts.

CHASSIS

Suspension: three-point semi-rigid with a remote swing axis of the bogies provides high traction properties, reduced shock loads on the chassis system, and improved working conditions. Support, support rollers and idler wheels with one-time lubrication for the entire service life with self-clamping “double cone” seals.

| Number of road wheels (each side) | 6 |

| Number of support rollers (each side) | 2 |

Tracks: Prefabricated with a single grouser and seal to retain liquid lubricant in the joint. Track tension is easily adjusted with a grease gun.

| Link pitch | 190 mm |

| Number of shoes (each side) | 39 |

| Height of lugs | 55 mm |

| Shoe width | 560 mm |

| Base | 2470 mm |

| Supporting surface area | 2.76 m2 |

| Ground pressure | 0.63 kgf/cm2 |

HYDRAULIC SYSTEM

Separate-unit hydraulic system:

- gear pump S1A5070, capacity 120 l/min at 1700 engine rpm

- four-section distributor, consisting of one valve and three spool sections

- maximum response pressure of the safety valve 20 MPa (200 kgf/cm2)

- hydraulic tank capacity (welded tank, adapted for mechanical cleaning of internal surfaces) 85 l

| Spool sections | Distributor spool position | Number of cylinders | Cylinder diameter, mm |

| Blade lift | lift, neutral (hold), lower, float | 2 | 80 |

| Blade misalignment | right, neutral, left | 1 | 125 |

| Raising the ripper | lift, neutral, lower | 2 | 100 |

REFILLING CAPACITIES

| Fuel tank | 300 l |

| Cooling system | 75 l |

| Engine | 21 l |

| Torque converter, gearbox, bevel gear | 85 l |

| Final drive (each side) | 2 x 10 l |

| Attachment hydraulic system | 115 l |

RIPPERING EQUIPMENT

Depending on the operating conditions of the ripper, one, two or three teeth can be mounted, which allows for high productivity.

| Ripper type | Number of teeth | Weight, kg | Max. lifting height, mm | Max. depth, mm | Max. pullout force, T | Max. penetration force, T |

| Non-adjustable, multi-tooth | 3 | 892 | 535* | 455* | 11,6 | 5,22 |

* - with submerged lugs.

BULLDOZER EQUIPMENT

The large capacity of the straight blade ensures increased productivity; the applied design of the blade ensures its effective use both in transporting soil and when digging pits, planning sites and constructing roads.

| Blade | Blade length x Blade height H x H, mm x mm | Dump capacity, m3 | Lifting height above ground, mm | Blade depth, mm | Angle of rotation | Highest reg. tilt (skew) deg. | Weight, kg |

| S-blade | 3160 x 1272 | 4.28 | 1000* | 500* | 25° | ±7° | 2118 |

* - with submerged lugs.

WEIGHT

| Tractor | 14200 / 13900 kg |

| Total weight (standard configuration, fully loaded, SU-blade, three-tooth ripper, driver) with YaMZ / Cummins / Sisu engine | 19840/19410/19875 kg |

karteh.com

Equipment for working in arctic conditions

To operate in arctic climatic conditions, the CHETRA T-9.01 bulldozer is additionally equipped with:

- Pre-starting liquid heater PZD 30L, HYDRONIC M-II, HYDRONIC 35

| Heating capacity, kcal/hour | 30 000 |

| Fuel consumption, kg/hour | 4,95 |

- Independent cabin air heater AIRTRONIK-2D

| Heating capacity, W | 2 200 |

| Fuel consumption, kg/hour | 0,28 |

- Cabin heater powered by engine coolant

- Insulating cover

- Engine radiator shutters

Technical characteristics of the bulldozer Chetra T-11

The T-11 bulldozer was created to work in all climatic zones; the machine feels great both at -50 in the north and in southern latitudes at temperatures up to +50. Maintainability and ease of maintenance are ensured by the modular design of the tractor components and parts. Each module can be separately dismantled and transported to a repair shop, leaving a multi-ton machine in place.

The tractor was developed together with the German concern Sauer Danfoss taking into account modern requirements, therefore the T-11 includes components and assemblies of domestic and foreign production.

Let's look at the bulldozer in more detail.

Dimensions and weight of the tractor:

- Length – 6588 mm;

- Width – 3854 mm;

- Height – 3412 mm;

- Base – 2616 mm;

- Weight with ripper, blade and internal combustion engine, YaMZ/Cummins – 20785/19975 kg.

Engine of the bulldozer Chetra T-11

CHETRA T-11 is equipped with diesel engines of two different brands:

- Domestic YaMZ-236ND2;

- American Cummins QSB6.7-C204.

The Yaroslavl Motor Plant provided a V-shaped, four-stroke, six-cylinder, liquid-cooled diesel engine. With an engine capacity of slightly more than 11 liters, its power was 136 (185) kW (hp), with an engine speed of 1900 rpm. The cylinders have a diameter of 130 mm and a piston stroke of 140 mm. Torque produced at engine speeds of 1200-1400 rpm, approximately 883 Nm.

American machine manufacturers supply a six-cylinder, four-stroke, in-line unit with supercharging and liquid cooling. Thanks to supercharging and other design features, it was possible to extract 137.5 (187) kW (hp) from a volume of 6.7 liters at a maximum of 2000 rpm. The ratio of cylinder diameter and piston stroke is 102/136.4 mm. Torque at nominal engine speed of 1500 rpm, about 938 Nm.

The American diesel is slightly superior in characteristics to its Yaroslavl counterpart, and is also considered more reliable and economical. However, YaMZ is much easier to maintain and repairs are much cheaper; in addition, Yaroslavl diesel engines have passed more than one inspection by the north and received mostly positive reviews. Therefore, it is not easy to give a definite answer which engine is better, the main thing is that there is a choice.

Gearbox of the bulldozer Chetra T-11

The gearbox on the T-11 bulldozer is of a planetary type and has the ability to shift gears under load. The couplings operate in oil and are distinguished by their ability to transmit high torque values.

Provides the tractor with three speeds forward and the same number in reverse, the travel speed ranges from 3.7 to 11 km/h forward and backward from 5 to 14.4. The box, together with the main gear and matching gearbox, forms a single module installed in a special bore of the rear axle.

We recommend reading: AGRITECHNICA 2020: CLAAS innovative developments received three silver medals