In 1975, Promtractor OJSC, at that time the Cheboksary Industrial Tractor Plant, began production of the T-330 heavy industrial tractor platform.

The unit was created by specialists from the Chelyabinsk Tractor Plant as the lead example of a family of industrial tractor platforms, including machines of various traction classes with a single layout and unified components and mechanisms .

According to the developers, a line of models based on the T-330 served as the basis for creating units that carry attachments: bulldozers, rippers, cranes, and pipe-laying equipment.

The machine was considered a replacement for imported units with a high price in convertible currency. The country carried out large-scale projects for the laying of railways, oil and gas pipelines, and the construction of large industrial facilities.

Heavy equipment created on the platforms of DRESSTA, CATERPILLAR, LIEBHERR, KOMATSU, and other concerns was widely used. The acquisition and maintenance of equipment that had no analogues in the country required significant expenditures of foreign currency.

The assembly of the T-330 was transferred to a new machine-building enterprise in Cheboksary. The production used components and assemblies from domestic factories.

The machine with a traction class of 25 turned out to be quite productive, with a level of energy saturation slightly lower than that of foreign competitors, but the price was 2 times higher.

The tractor has been in operation for more than 30 years; some examples are still working on construction sites.

Designers and specialists of Promtractor OJSC, based on the T-330, have created and are offering on the market a series of Chetra T machines - modern tractors with both bulldozer and ripper attachments.

Application area

Important! The bulldozer is designated by specialists as T-330Р1-01. The unit is used for layer-by-layer removal of soils of I-IV density categories, leveling the territory of the working site.

The T-330 is used for overburden of rocks in open-pit mining, in the construction of industrial facilities, and in road work.

Purpose of the unit:

- removing soil from the surface of the site in layers and moving the soil mass, gravel, crushed stone and other material across the working area;

- backfilling a excavation, pit, trench, etc.;

- leveling the surface of the working site in accordance with the design marks;

- construction of embankment dams, construction of dams, solid foundations for road surfaces, etc.;

- stacking and mixing of non-metallic building materials;

- construction of pits for foundation elements;

- cleaning the territory of construction sites, uprooting bushes and small forests;

- snow removal, elimination of the consequences of ice conditions.

Specifications

| Motor installation | |

| Plant - Volgograd | |

| Designation | 8DVT-330A |

| Description of the motor | Diesel, 8 cylinders in a V-shaped block, 4 power strokes, supercharged. Air cooling system |

| Power at crankshaft speed 1,700 per minute, kW | 250 |

| Cylinder group | 2 rows of 4 per side of V-block |

| Fuel use, g/kW. hour | 230 |

| Total displacement of the cylinder group, l | 22,6 |

| Product weight, kg | 2 600 |

| Hydraulic system components | |

| Pumping units | NSh-250, NSh-50U3-L |

| Performance parameter, dc3/min | 430 at crankshaft speed 1,700 per minute |

| Triggering of protection valves when the moldboard device is skewed, moldboard device and ripper, kg/sq. cm | 160 |

| Moldboard cylinders, pcs. | 2 |

| Ripper cylinders, pcs. | 2 |

| Cutting angle adjustment cylinders for ripper | 2 |

| Bulldozer equipment | |

| Knife blade | Hemispherical type |

| Width of blade blade, m | 4,86 |

| Blade height, m | 1,82 |

| Prism of cut soil by volume when moving, m3 | 13 |

| Blade lift, mm | 1 530 |

| Immersion of the blade blade into the ground, mm | 650 |

| Angle of displacement of the dumping device on the sides, degrees. | 12 |

| Product weight, t | 7,030 |

| Loosening equipment | |

| Ripper design | Adjustable loosening angle, parallelogram canopy |

| Zubiev | 1 |

| Ripper lift, mm | 950 |

| Depth into the ground, mm | 1 380 |

| Change in loosening settings, deg. | +14 |

| Application of force, kg during deepening during extraction | 15 300 56 400 |

| Product weight, t | 6,489 |

| General parameters of the unit | |

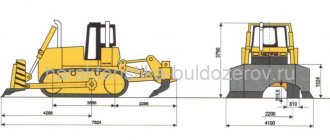

| Dimensions (LxWxH), m | 9.33x4.762x4.23 |

| Forward/reverse speed, km/h I gearbox mode II gearbox mode III gearbox mode | 3,5/2,9 6,4/5,4 13,0/10,8 |

| Weight of the tractor ready for work, t | 41,8 |

| Weight parameter with moldboard and ripper, t | 54,8 |

| Impact force of caterpillar tracks on the soil, kgf/cm2 | 1,127 |

Characteristics of the T-330 tractor

Catalog of parts and assembly units of the T-330 tractor

The professional industrial tractor T-330 has found its application in large-scale excavation work in construction, land reclamation and mining. The constructive use of air cooling of the engine made it possible to operate the tractor in harsh weather conditions: at low temperatures up to −50 degrees, and in heat up to +50 degrees.

The tractors of this model are equipped with a 330-horsepower four-stroke 8-cylinder air-cooled diesel engine.

| Engine make | 8DVT-ZZOA | YaMZ 240 NM2 |

| engine's type | 4-stroke, turbocharged, air-cooled | 4-stroke, liquid cooling, turbocharging, direct injection |

| Engine power, kW | 250 | 368 |

| Rotation speed, rpm | 1700 | 2325 |

| Number of cylinders | 8 | 12 |

| Cylinder diameter, mm | 150 | 150 |

| Piston stroke, mm | 160 | 160 |

| Specific fuel consumption, k/kW.hour | 230 | 230 |

| Oil consumption for waste, from fuel consumption, % | 0,3 | <0,3 |

| Working volume | 22,6 | 22,6 |

| Engine weight, kg | 2600 | 1790 |

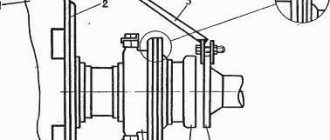

The hydromechanical transmission includes in one autonomous unit: a double-sided six-shaft gearbox with helical gears of a continuous clutch, hydraulically pressed disk clutches for gears and a reverse mechanism, a system of band stopping brakes and reverse brakes for each side. The gearbox provides three forward and three reverse gears. Thanks to the use of a hydromechanical transmission, the ability to effectively use engine power in any gear is achieved. The reversible system allows for separate drive of each track.

| Travel speed | forward, km/h | back, km/h |

| 1st gear | 3,5 | 2,9 |

| 2nd gear | 6,4 | 5,4 |

| III gear | 13,0 | 10,8 |

Tracks with joints sealed and lubricated for the entire service life, with a detachable closing link of the tracks.

| Tractor caterpillar link pitch, mm | 250 |

| Number of bulldozer track shoes | 42 |

| Track lug height, mm | 90 |

| Track shoe width, mm | 650 |

| Ground contact area, m2 | 4,86 |

The semi-rigid chassis system of the T-330 tractor consists of two tracked bogies swinging around the axis of the drive wheels.

The hydraulic system includes gear pumps NSh-250, NSh-50UZ-L:

| Pumps for tractors, bulldozers | Gear NSh-250, NSh-50UZ-L |

| Pump capacity at rated engine speed, l/min | 430 at 1700 rpm |

| Set pressure of safety valves, kg/cm2 | Blade skew-160, blade and ripper-160 |

| Hydraulic cylinders for raising/lowering the blade: - diameter and stroke of the piston, mm | 2 160x1250 |

| Blade skew hydraulic cylinder: - piston diameter and stroke, mm | 1 220x300 |

| Hydraulic cylinders for raising/lowering the ripper: — diameter and stroke of the piston, mm | 2 220x560 |

| Hydraulic cylinders for changing the cutting angle of the ripper: - diameter and stroke of the piston, mm | 2 |

The control of absolutely all tractor mechanisms is remote and partially automated. The controls located in the tractor cabin do not have a mechanical connection with the actuators; the tractor cabin, in turn, is mounted on rubber shock absorbers. This greatly simplifies the driver’s work and virtually eliminates the transmission of vibrations from operating tractor units to the cabin.

Design of main components and assemblies

The bulldozer is assembled using a modular layout, which greatly facilitates maintenance and replacement of spare parts. Numerous hatches and installation windows are provided for access to the units.

Frame and motor installation

The welded frame was assembled from a pair of steel box-shaped spars, which were connected by cross members in the front, middle and rear parts. A balancing beam was attached to the front, supported by crawler tracks.

The tractor was equipped with an 8-cylinder V-shaped 4-stroke diesel turbocharged engine with an air cooling system.

The power plant easily started at temperatures below -30° C. The engine operating time before major repairs was indicated by documentation at 6,000 engine hours; in actual operation, this parameter was halved.

Cabin and power train

The location of the cabin in the front part of the platform and the degree of its glazing provide the bulldozer driver with full control over the operation of the dump device.

The sprung, vibration-protected platform dampens impacts from the power plant and transmission units, creating normal working conditions for the driver.

Important! Protection against rollovers or rock fragments entering the cabin is provided by a metal frame behind the machine's blade.

The design of the hydromechanical transmission is modular with a separate drive on each side. The torque energy of the diesel engine is supplied to the sprocket drive wheels of the caterpillar tracks and the pump unit of the hydraulic system through: a torque converter, a gearbox, a matching gearbox, and cardan drives.

The torque converter continuously changes the transmission modes of power torque from the diesel engine in accordance with the load size.

There is one gearbox on two sides, reversible. In the box, the power flow is bifurcated, which allows you to change the direction of rotation of the drive wheels, regulating the movement of the machine and its turns on the spot.

The gearbox is controlled by hydraulic disc couplings, stopping and reversing band brakes.

Final drives and chassis system

The side transmissions are of a two-stage design: gears with external gearing interact with the planetary unit, the carrier of which is braked. The star gear assembly of the drive wheels is bolted, which makes it possible to replace it.

The running system is semi-rigid and is assembled from two crawler bogies. The final drive axes on which the bogies rest allow them to swing.

The bearing assemblies of all rollers and wheels contain a lubricant that ensures the operation of the mechanisms for the entire service life. There are 14 support rollers.

A hydraulically driven mechanism allows you to ease the tension of the caterpillar track. The caterpillar track is detachable and assembled from 42 shoe links with a pitch of 250 mm. The width of the link is 650 mm, the contact from one track with the soil is 4.86 square meters. m.

Control

The tractor and attachment controls do not have mechanical drives. The actuators are controlled through electrical and hydraulic systems.

Attachments

The unit is supplied:

- with a hemispherical type bulldozer blade device , forming a displacement prism with a volume of 13 m3, changes position within 12 degrees to the sides of the longitudinal axis of the tractor;

- with single-tooth ripper equipment , changes position within 12 degrees to the sides from the longitudinal axis of the tractor.

Performance of the tractor, its Russian and foreign analogues

The performance of machines with bulldozer equipment depends on 4 parameters:

- The volume of soil mass in the drawing prism, shifted by the moldboard device.

- The power of the bulldozer power plant, which ensures the speed and maneuvers of the machine.

- The length of the working strip, which determines the cycle time and loss of soil mass from the displacement prism.

- Properties of the soil rock of the site.

For a specific machine, the volume of processed soil per unit of time (productivity) is formed by the second and third parameters, mostly the energy saturation of the machine. Blade parameters are also determined by engine power.

Photo: modification of the T-330 GR1 bulldozer

Characteristics of the T-330 bulldozer

| Length | 9330 mm. |

| Width | 4762 mm. |

| Height | 4230 mm. |

| Full mass | 42 t. |

| Specific ground pressure | 0.57 kgf/cm2. |

| Ground clearance | 570 mm. |

| Fuel tank volume | 670 l. |

| Speed range | Forward – from 0 to 16.7 km/h Reverse – from 0 to 13.7 km/h |

| Traction class | Nominal thrust – 25 t. Maximum thrust – 66 t. |

Selected parameters of Russian and foreign cars

| Manufacturer | Model designation | Weight, t | Power parameter, l. With. | Volume of dumping device, m3 |

| Komatsu Limited | D575 | 114–152 | 1150 | 69 |

| Komatsu Limited | D475 (A‑5) | 108,4 | 860 | hemisphere 27.4 sphere 34.4 |

| Caterpillar Inc. Company | D11 | 104–113 | 862 | 43,6 |

| Industrial tractor | T-330 | 58 | 405 | 13 |

| ChTZ | T‑800 | 76–106 | 820 | 26,2 |

| Chetra | T40 | 69 | 590 | 21 |

The energy content of foreign bulldozers is higher, the volume of drawing prisms formed by dumps is greater than that of the T-330 and other Russian machines.

Russian tractor manufacturers use parts and assemblies from foreign companies in their machines. The CHETRA T25 bulldozer uses a power plant from the USA QSX15-C440 from Cummins and pump units from David Brown.

Cars produced in Russia use transmission units from BOSCH-REXROTH and SAUER-DANFOSS, and other equipment from abroad. As a result, you can buy products, but at a higher price.

You may be interested in: buy exhaust gas removal at an affordable price

Bulldozer engine T-330

The T-330 is equipped with a YaMZ-240NM2 diesel engine

Liquid-cooled and turbocharged, delivering excellent power and traction across a wide rpm range.

| Manufacturer | Yaroslavl Motor Plant (YaMZ) |

| Brand | YaMZ-240NM2 |

| Type | Diesel turbocharged |

| Volume | 22.3 l |

| Maximum power | 500 hp at 2100 rpm |

| Maximum torque | 1815 N*m at 1600 rpm. |

| Configuration | V12 |

| Cooling | liquid |