Manufacturers of tracked equipment for the Neva walk-behind tractor

At the moment there are a large number of different tracks for walk-behind tractors on the market. They are all similar in their design, but may differ in the size of the track, the number of rollers, the quality of materials and the operating principle.

Among the domestic snowmobile modules, the following can be noted:

- Lynx;

- Ant;

- Buran.

Among the foreign models, the products of the manufacturer Talon and its models are in demand: Talon 380, Talon WT and others.

All these models are simple and reliable to use. But for long-term and correct use, you should follow a few simple rules:

- Periodically check the track tension. If it becomes loose, it must be tightened immediately.

- All gears and rollers must be lubricated regularly for smooth operation.

- Before each departure, it is necessary to visually inspect the condition of the tracked module.

The tracked module is perfect for use on any surface, including asphalt:

About manufacturers and device features

Before choosing a specific brand, it must be clearly stated: the set-top box is always supplied in a factory-assembled version. This eliminates errors and problems caused by self-assembly.

Differences between individual models include:

- size of the tape with caterpillars;

- characteristics of materials;

- number of rollers;

- startup methods.

Among Russian companies, Ant, Lynx and Buran have proven themselves to be excellent; Among foreign suppliers, Talon is preferable.

You can install rubber tracks on a Neva walk-behind tractor for about 28,000 rubles.

If you mount the driver's seats, you can bring the structure closer to a caterpillar mini tractor. If the design does not have the ability to add a driver's seat, it will cost slightly less.

Despite their reduced functionality, such propulsors operate quietly in winter conditions. They confidently overcome both off-road areas and snowy areas. A big problem is the relative high cost of the structures. They often struggle with it when trying to make caterpillars with their own hands.

How to make a caterpillar module for a walk-behind tractor with your own hands?

The cost of materials for making a caterpillar with your own hands is much lower than buying ready-made equipment. Therefore, you can try to assemble it yourself.

Here are the most common variants of such models:

Production from car tires.

In this case, they all have a fixed width. Often they have to be brought to the desired size manually. This is a labor-intensive procedure. However, the final product is a durable model.

Lugs with straps

This is a very simple option when several grousers are connected with one tape. This design is easy to manufacture, but not reliable enough. Because the connecting tape often breaks.

Chains with steel plates

This is a very cheap version of tracks, and anyone can make them. After all, consumables are almost always at hand.

Conveyor belt and bushing chain with rollers

This option is the most popular. It can be used at any time of the year. This type of tracked module is very simple to manufacture, but the connections are not very reliable.

You should choose an option based on what functions the tracked module will perform and what the power of your walk-behind tractor is.

For small capacities, simple designs can be used; they can withstand standard loads. But for more powerful units, more durable models should be used.

Algorithm for completing parts

There are several proven ways to make a caterpillar with your own hands. They have proven themselves to be the most reliable.

Application of conveyor belt

It is considered one of the simplest methods . In addition to the transport belt, you will need a bushing roller chain. The simplicity in this case lies in the fact that manufacturing does not require a large number of auxiliary materials and tools. To extend the life of the transport belt in the device, you need to circle its edges with fishing line. It is important to ensure a step of 10 mm. To connect the ribbons, in this case you need a ring, you need to stitch it along the ends or use hinges.

Particular attention is paid to the thickness of the transport tape. The level of load on the unit directly depends on this. The optimal choice would be to select a tape with a minimum thickness of 7 mm. Among other things, you will have to take care of an additional wheel on each side. You can remove it from an old car, but it is important that its diameter matches the same parameter as the wheel on the walk-behind tractor.

Read also How to get a garden plot

Using a tire

For walk-behind tractors, tracks are often taken from tires. Craftsmen claim that the design is highly reliable when the specified element is included in it. In order for the resulting walk-behind tractor to be practical, you must take care of the quality of the car tires. They must have the correct tread pattern. In this regard, tires from large cars and tractors are preferable. The tread pattern is of key importance, as it acts as a lug.

The manufacturing process can be divided into several stages . Here they are:

- After finding suitable tires, a track for the tracks is cut out of them. This is labor-intensive work that will take a lot of time.

- Use a well-sharpened knife for cutting. It's better to take the one that shoemakers use. From time to time it must be moistened in a soap solution. This will make the rubber easier to cut.

- Both sidewalls are cut off the tires. To make the process easier, you can use a fine-tooth jigsaw for this. Remove excess fragments inside the tire if necessary. If the track turns out to be too hard inside, this manipulation can be repeated.

The advantage of this method is that there is no need for a ring connection. The tire already has a closed structure.

Thanks to this, it is possible to improve the reliability of the tracks, which is especially important under heavy load conditions. And yet such caterpillars are of rather limited length. It corresponds to a similar parameter for a car tire.

From chains and belts

All-terrain vehicles with tracks are often manufactured using conventional V-belts. They are connected to each other by means of lugs. The straps are attached with screws or rivets.

An additional method is to use chains of the same size. This material is often found in large quantities in gardeners' garages. The manufacturing process boils down to the following points:

- Take 2 chains of the same size. The last links are broken, after which they are combined into a closed ring. The links are clamped and welded.

- The lugs connect the chains to each other and provide reliable fastening. These devices can be made from simple steel plates of suitable thickness. They are connected using bolts.

If you don’t want to make tracks yourself, you can take such products from old equipment. For example, a walk-behind tractor on Buran tracks demonstrates good efficiency. It makes sense to use old parts, since new Buranovsky tracks are quite expensive.

Popular factory models

This agricultural equipment is produced by both domestic and foreign manufacturers. Let's list some models:

Talon 380 Track Attachment

Characteristics:

- track height - 300 mm;

- track width - 190 mm;

- total length - 1035 mm;

- total width - 680 mm;

- track track - 300 mm.

Talon WT track module for walk-behind tractor

Characteristics:

- The nature of the engagement is lantern

- Number of steps - 62

- Caterpillar weight - 34 kg

- Dimensions: Length - 154″ (3886 mm)

- Width – 20″(500 mm)

- Pitch - 2.86″(73mm)

- Grouser height - 1.25″ (32 mm)

Crawler drive “Lynx-500”

Crawler drive “Lynx-500”

Characteristics:

- Length: 3937mm.

- Width: 500mm.

- The lug height is 22.5mm.

- Manufacturer Composite.

Motoblock crawler attachment “Buran”

Motoblock crawler attachment “Buran”

Characteristics:

- Length: 3686 mm.

- Width: 380 mm.

- Grouser height: 17.5 mm.

- Manufacturer Composite.

Attachment “Ant” to the walk-behind tractor

Attachment “Ant” to the walk-behind tractor

Characteristics:

- The nature of the engagement is lantern

- Number of steps - 44

- Caterpillar weight - 7.7 kg

- Length - 2222 mm

- Width - 220 mm

- Pitch - 50.5 mm

Track attachments CAM

CAM tracked attachments are aggregated with almost all walk-behind tractors from domestic and foreign manufacturers.

Characteristics:

| Parameter | Meaning |

| Nizhny Novgorod | |

| Manufacturer country | Russia |

| Applicability | Chassis |

| Compatibility | Walk-behind tractors |

| Suitable for | MB Favorit, Skif |

| Working speed | 15-18 km/h |

| Length | 1000 mm |

| Height | 340 mm. |

| Width | 600 mm. |

| Weight | 37 kg. |

Characteristics:

| Weight of the attachment without propeller: | 37 kg. |

| Movement speed: | 15-18 km/h |

| Fuel consumption: | 1.5-2 liters per hour |

| Towed load weight: | 200 kg. |

| Full assembly time: | 10 minutes |

| Turning Radius: | 2 meters |

Characteristics:

| Parameter | Meaning |

| Nizhny Novgorod | |

| Manufacturer country | Russia |

| Applicability | Chassis |

| Compatibility | Walk-behind tractors |

| Suitable for | Agate, Salyut, Tarpan, Omich. |

| Working speed | 15-18 km/h |

| Length | 1000 mm. |

| Height | 340 mm. |

| Width | 600 mm. |

| Weight | 37 kg. |

Characteristics:

| Track length | 2222 mm |

| Track Manufacturer | LLC NPO Composite, Kursk |

| Track width | 220 mm |

| Load capacity: | 200 kg |

| Maximum fuel consumption: | 1.5 – 2 l/hour |

| Dimensions: | 1000*600*340 mm |

| Weight: | 37 kg |

Characteristics:

| Weight of the attachment without propeller: | 37 kg. |

| Dimensions without propeller: | 1000x600x340 mm. |

| Movement speed: | 15-18 km/h |

| Fuel consumption: | 1.5-2 liters per hour |

| Towed load weight: | 200 kg. |

| Full assembly time: | 10 minutes |

| Turning Radius: | 2 meters |

| Dimensions in packaging: | 75x400x200 + 2 tracks |

Characteristics:

| Build time | 10 minutes. |

| Speed | 15-18 km/h. |

| Load capacity of towed sleds | 200 kg. |

| Turning radius | 2 meters. |

| Track width | 220 mm. |

| Weight | 37 kg. |

We offer a table of correspondence between CAM tracked attachments and brands of walk-behind tractors:

| Modification of the console | List of compatible walk-behind tractors or cultivators |

| SP-MB-1 | OKA, CASCADE, BEAM, FORZA, |

| SP-MB-2 | NEVA |

| SP-MB-SP-PN | PATRIOT, DOKOTA, NEVADA |

| SP-MB-S | SALUTE, AGATE |

| SP-MB-U | URGA |

| SP-MB-F | FAVORITE, SKIF |

| SP-MB-C | VIRGIN |

Differences in technical characteristics

So, when buying a tracked attachment for a walk-behind tractor, first of all you should pay attention to what specific equipment it is intended for. The GP-N1 attachments are universal and can be mounted on almost any walk-behind tractor. The SP MB models are designed, depending on the series, for equipment with output shafts of different designs and diameters.

As for the technical characteristics, they are usually similar for modern tracked drives. The depth of snow and mud in which a walk-behind tractor with a tracked attachment can be used most often varies between 45-50 cm. The load capacity of such accessories is approximately 200 kg. At the same time, walk-behind tractors with this addition can move at a speed of 18-20 km/h.

Triangular tracks for walk-behind tractors usually provide better load capacity, weigh more and cost more. This is explained primarily by the fact that they have a more complex design. In general, the price for domestically produced tracked drives in Russia today fluctuates between 24-35 thousand rubles.

What materials are required

To convert wheel modules into tracks, a powerful engine is required. It must have an axle block. Power is important, since the walk-behind tractor will be driven on difficult roads. Without improvement, it is impossible to achieve good maneuverability. Basic building materials required:

- Motoblock machine with gearbox, 4-stroke engine, axle block option.

- Several extra wheels to put the caterpillar on.

- The track attachments themselves.

Depending on the building material used in the manufacture, two tires of good diameter and a transport belt may be useful. If you include a platform here, you get a compact tractor.

On a note! An additional platform will allow you to use the vehicle as an all-terrain vehicle when moving along a snowy road.

When selecting building materials to make tracks for a walk-behind tractor with your own hands, it is important to take into account that it should not be heavy. The walk-behind tractor is not equipped with a powerful engine; it simply cannot cope with a heavy load and will break. Tracked modules are made from:

Tracked modules are made from:

- Motorcycle tires.

- Chains.

- Tubes.

- Belts.

- Conveyor belt in symbiosis with a bushing and roller chain.

Usually, attachments for walk-behind tractors are made from tires - these elements can be converted without any problems. It is correct to choose tires for large trucks, taking into account the existing tread pattern and shape, because the pattern will improve traction with the road. Tractor tires or elements from other large machines are perfect.

The tread pattern can provide full contact with wet ground, icy roads, and snowy roads. In addition to the materials for the tracked module, to create a full-fledged device you need a walk-behind tractor with a gearbox, as well as several car wheels. If necessary, they secure the cart and, if desired, even on runners in order to transport significant weights through the snowdrifts.

Motoblock on tracks (tracked): drive, module, homemade

It seems quite a difficult task to process a site, even if it is a small area. It may be impossible to make do with improvised tools in this matter. Loosening, weeding and digging a garden without additional equipment is quite difficult.

If you have the opportunity to purchase a walk-behind tractor that will become an indispensable assistant on your site, then you need to do just that. However, you can make the work easier with the help of self-made equipment. In this article we will talk about a crawler walk-behind tractor.

If you need tracks for the Neva walk-behind tractor, the price of this device should interest you. However, you can do it yourself. It is necessary to begin work on assembling the walk-behind tractor from the drive shaft. The housing with bearings should be fixed to it, overrunning clutches should be installed and the sprocket should be welded. The clutches will act as a differential during operation.

The structure is then completed with a frame and wheels. You need to install a telescopic rod, steering wheel and plow on the frame. If we are talking about an agricultural walk-behind tractor, it is complemented by special wheels that facilitate traction with the ground. In order to connect the frame with the suspension and the frame of the scooter, if one is present in the design, a pair of arc-shaped pipes should be used. There should be space between them for the fuel tank.

When a walk-behind tractor is built on tracks, the arrangement of the engine is accompanied by the installation of brackets, which are completed with steel axles. Their length should be 150 mm. The bracket must be welded to the U-shaped frame in a cantilever manner. An engine with suspension is installed on the axle itself. The structure is connected by frame arches, only then can you begin installing the secondary shaft. Then the master will have to tighten the chains and stretch the cables.

When a walk-behind tractor is manufactured on tracks, at the next stage it is necessary to supplement it with an appropriate design. A variety of materials are usually used for this, but the low engine power must be taken into account, which indicates the need for lightweight tracks.

You should not use tracks borrowed from a collective farm bulldozer, as they will destroy the engine. For this purpose, car tires are usually used, for example, off-road tires. It is suitable for the reason that the tread in this case has an aggressive pattern, which indicates reliable grip.

In order to make homemade tracks for a walk-behind tractor from a bushing-roller chain and a conveyor belt, there is no need to use special tools and machines. To extend the life of a homemade device, it should be stitched with fishing line along the edges. It is important to maintain a distance of 2 cm.

When a walk-behind tractor is made on tracks according to this principle, the connection of the tape into a ring can be done in different ways, this can be a hinge or stitching the edges. The last option cannot be called reliable. If you have a high-power unit, then you can use a tape whose thickness varies from 7 to 15 mm. It is usually used in conjunction with agricultural machinery. However, such a tape must be installed carefully, because its weight is quite impressive.

Another way to make tracks is to use automotive treads. The advantage of this technology is expressed in the absence of the need to manufacture lugs. When running a walk-behind tractor on tracks, at this stage it is necessary to prepare a path from an old tire by separating the side surfaces. This task is quite difficult. Some craftsmen use a knife for this, but the process is delayed.

For accurate cutting, you must use an electric jigsaw. You can reduce the friction of the tool blade by wetting it in a soap solution or water. As soon as the sides can be removed, excess layers should be removed from the wrong side of the workpiece. This procedure will be necessary if the path is too hard.

When the tracks on a walk-behind tractor are made using this technology with your own hands, they will have a closed loop, which indicates high reliability. However, there are also disadvantages, which are expressed in the limited width. However, this problem can be avoided if you use a double or triple tread.

Caterpillars can also be made from belts. This method is convenient and simple. Belts must be of a wedge-shaped profile. The connection in this case is carried out with lugs, which are fixed with screws or rivets.

Such tracks are perfect for the Neva walk-behind tractor. However, those made from the same old circuits will be considered more reliable. One tape will require two chains. To do this, use a product of the required size, the links are unclenched, the chains are folded into rings, the edges must be clamped and welded.

The resulting structure is fastened with lugs, which should be made of thick steel plates. They need to be drilled in advance. When making tracks for a walk-behind tractor with your own hands, at the last stage the products must be placed on both sides of the chain links and secured with bolts and nuts.

Before you start creating tracks, you must remember that the device should not be too high, as this will shift the center of gravity of the equipment. As a result, you will face the risk of the walk-behind tractor tipping over in difficult areas, sharp turns and inconvenient roads. Caterpillars for a walk-behind tractor, the price of which is 26,500 rubles, can be purchased in the form of a universal attachment.

However, if you decide to make them yourself, then to increase stability you need to make the second driven axis slightly larger; its dimensions should differ by several tens of millimeters. It is not necessary to grind the sleeve yourself; it can be purchased at the store. It is located on the drive shaft. If your vehicle does not have a differential, you can increase maneuverability using a rotating extension.

You can make tracks for a walk-behind tractor, the price of which is quite high, yourself. You should not use air cooling of the engine, because such a motor will not be able to cope with the increased load. Experts recommend using water cooling, as it will allow the engine to be more durable during long-term operation.

The tracks for the Neva walk-behind tractor, the price of which was mentioned above, can be made by you yourself. They make the unit easier to operate and prevent it from getting stuck in difficult places.

Materials: https://www.syl.ru/article/300774/kak-sdelat-motoblok-na-gusenitsah-svoimi-rukami

Tips for use and after

When using tracked modules for a walk-behind tractor, you should fully check and carefully look at how high-quality the chain tension is, and also systematically treat with machine oil the elements whose friction occurs when the walk-behind tractor moves. In addition, it is necessary to check each time before use to see if there are any breaks in the chain.

After operation, it is also necessary to check the equipment and tracks, carry out a technical inspection in order to timely find damage or broken load hooks

When using a walk-behind tractor, it is important to avoid driving into the rhizomes of centuries-old trees and rocky embankments, as well as stumps, otherwise the tracks will break.

Note! In order for the caterpillar base for the motor cultivator to last as long as possible, it is important to guarantee the module comprehensive, complete care

Need to:

- Monitor the level of adjustment and tension of the chain.

- Externally, make sure that when driving a technical device, the chain is intact.

- All contacting parts and mechanisms must be lubricated with machine oil.

Basic care recommendations will help reduce to zero the risk of failure of finished walk-behind tractors and, in particular, the caterpillar unit. A walk-behind tractor on tracks will become a powerful assistant for accomplishing tasks.

Connecting tracks to a walk-behind tractor makes it possible to significantly change maneuverability and maneuverability. This leads to an increase in the range of potential operations that the device can handle. Tracks outperform traditional wheels in some positions. Regarding the remodeling process, it is quite simple, but you need to have experience, knowledge, prepare materials and tools, and if you wish, be attentive to the work and the task at hand, everything will definitely work out.

From wheeled to tracked and back

The purchased wheeled model can, if desired, be converted into a tracked one: to do this, attach an additional pair of wheels, connecting them in pairs with tracks. Such restyling will not be cheap, but if you wish, you can look for the necessary spare parts on the farm, ask your friends, and save significantly on purchases.

Read also: Planting vegetables in a greenhouse compatibility

When the tracks are not needed, they can be removed. By making the second pair of wheels add-on, you can easily return the walk-behind tractor to its original appearance if necessary. True, such a rework will be more labor-intensive. In most cases, this option is implemented by attaching wheels to an existing axle through a transmission. The transmission can be flexible or rigid.

The mounting method will require a lot of thought, but it will eliminate the need for welding. Yes, and ready-made drawings can be found freely today if you have access to the Internet. Have you decided to improve your walk-behind tractor? Consider what type of track will suit the equipment you have.

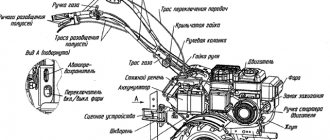

Track module design

At the moment, there are two options for manufacturing a tracked module. What are their designs and features?

First option

The track module is an axle. There are 4 rollers connected to this axis at the bottom. These rollers serve to create tension on the track.

Tracked module for Neva walk-behind tractors

There are 2 gears on the left and right edges, which fit into the grooves of the tracks and serve to tension the tracks and set the module in motion. The gears move in a horizontal plane using a special frame, which, after installation, is secured with bolts.

On one side, a gear transmission is welded to the shaft with gears.

Using a chain, the articulated drive drives the entire tracked unit.

The caterpillar belt has V-shaped inserts. These rates should be set with the tip of the V in the direction of movement of the walk-behind tractor.

Second option

This design has a slightly different appearance. Instead of wheels, a large gear is installed, which is attached to the axle, and at the bottom of the frame there are 8 rollers (two on each side of the belt). They keep the caterpillar belt taut and allow the Neva walk-behind tractor to move without interruption.

The caterpillar attachment is sold ready-made. Thanks to this, there is no need to assemble it on site. And you can eliminate damage caused by improper assembly.

It is sold disassembled, see how such a tracked module for the Neva walk-behind tractor generally looks and works, see the video: