A little about the rules for operating the node

Regardless of the manufacturer’s brand (Shtil, Husqvarna, Partner, Patriot, Makita), chainsaws are divided into household, semi-professional and professional. The difference, however, lies not in the quality of assembly or manufacturing of components, but in the class of tasks performed, performance and long-term drive power. This determines the choice of material for the drive sprocket for the chainsaw, its design and the design of the saw chain.

The performance of the tool will be determined by the way the chain-sprocket pair is used. In most cases, users use one of two options:

- The chain is used until the teeth are completely worn out, and then both the saw blade and the sprocket are replaced at the same time;

- Periodic replacement of chains that have different pitches, and each will require its own drive sprocket.

The choice of option is often determined by the owner’s attitude towards his instrument. If it doesn’t matter what to cut (wood or steel staples, screws, etc. stuck in it), then you can go with the first option. The chain, however, will have to be adjusted periodically, thereby reducing the performance of the chainsaw.

It is strictly not recommended to leave the old chain with the new sprocket and vice versa. If the saw blade is worn out, the probability that the tooth pitch will not match is almost one hundred percent. Therefore, at the initial moment of start-up, both components of the chain drive will be subject to significant dynamic loads. As a result, either the chain will stretch prematurely, “adjusting” to the sprocket, or one of the teeth on the drive sprocket will burst upon impact.

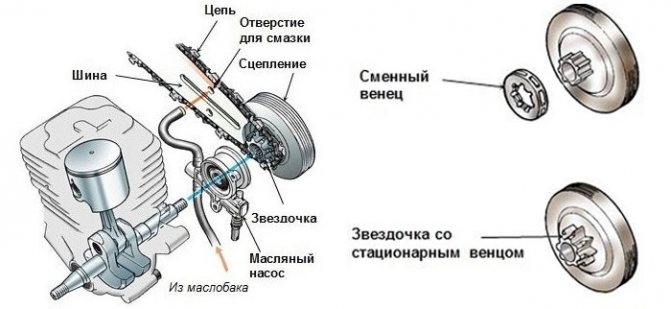

In addition, it is worth focusing on the operation of the bearing assembly of the drive sprocket shaft. When the saw operates at operating speed, only the crankshaft rotates. But all chainsaws periodically operate at idle speed when the bearing rotates. If there is a lack of lubrication, wear of the seat occurs, and - as a result - additional runout of the teeth of a still fully functional chain drive.

It follows from this that when replacing the chain and drive sprocket for a chainsaw, it is a good idea to simultaneously replace the bearing.

Design features of drive sprockets

Any manufacturer indicates the tooth pitch in the operating instructions. Considering that a driven sprocket is also installed on the saw bar (designed to create the necessary tension), the pitch here and there should be the same.

Chainsaw drive sprockets can be solid or prefabricated. In the first case, the sprocket includes a hub onto which a ring gear is pressed. This is exactly how the parts in Champion chainsaws are arranged. When replacing, the product should be removed completely, since at home it is almost impossible to maintain the tension value specified at the manufacturer. And purchasing a crown separately is also a problem.

In chainsaws from Stihl or Husqvarna, the replaceable crown is located directly on the drum shaft, and therefore replacing it does not present any difficulties.

Tooth wear is determined by the following criteria:

- There are clearly visible radii at the transition points from the tooth to the cavity.

- The width of the tooth is uneven in height.

- There are metal chips at the top of the tooth.

- There are numerous burrs and marks on the inner surface of the hole in the hub (a consequence of poor lubrication).

- There is a noticeable groove on the sprocket from the saw bar (the chain also needs to be changed).

- The chain jams at the initial moment of start-up.

If at least one of the above factors is present, the drive sprocket must be replaced.

Before starting work (especially if the chainsaw has been running for relatively little time), it is worth checking the fastening of the saw bar. The tensioner screw has come loose or the fastening nuts have come loose - the guide is no longer aligned with the longitudinal line of the saw blade. It begins to contact not with the center, but with the periphery of the teeth of the drive sprocket, provoking their intense wear. After tightening the specified elements, check the operation of the chainsaw: if the play is not eliminated, then the sprocket will have to be changed.

Regardless of the class and purpose of the chainsaw, the cutting device includes a guide bar and a saw chain with a tensioner. The instructions contain information on how to properly tension the chain on a chainsaw to eliminate additional loads on the engine and accelerated wear of the headset.

This element of the sawing mechanism is used under conditions of large variable loads, and therefore requires constant monitoring during operation. A characteristic feature of saw chains in use is an increase in size due to the formation of gaps in the link connections.

Malfunctions of Husqvarna Chainsaw 142

Content

DIY chainsaw repair Husqvarna 137, 142, 240, 365 - video

A chainsaw is an indispensable assistant for every real owner.

Since the instrument's inception, its popularity has grown rapidly.

Thus, the Husqvarna 142 chainsaw has the highest functionality. It is widely used not only in forestry, but also on private plots.

Choosing a chainsaw is quite simple. So, it is best to focus on well-known brands such as Husqvarna. This company produces a wide range of such tools. Husqvarna 240 and other models are of the highest quality and functionality. But, unfortunately, even such tools are not immune from breakdowns.

Possible faults

After a chainsaw appeared in the house, many owners breathed a sigh of relief.

After all, this tool allows you to solve complex problems quite quickly and simply.

But, here it is worth considering that the chainsaw often fails. This is due to the fact that it is subjected to enormous loads during operation. Therefore, it is necessary to always be prepared to eliminate breakdowns.

Now there are a huge number of workshops that offer their services for repairing chainsaws and other tools. But this does not mean that if a malfunction occurs, you need to immediately run to a repair shop.

READ Carburetor Adjustment Husqvarna 128 R

Some faults can be removed with your own hands. To do this, you just need to know the main reasons for the occurrence of breakdowns and the method of eliminating them.

Thus, during frequent use of the tool, breakdowns may occur:

- carburetor;

- muffler;

- oil pump;

- ignition and fuel supply systems.

Each of these breakdowns can be fixed with your own hands . The main thing is to know the sequence of work when eliminating a particular malfunction.

Read the article about self-repair of the Shtil 180 chainsaw here.

Ignition system

If the tool suddenly stops working, then the first thing you need to check is the ignition system. And you need to start with a candle.

The work must be done very carefully. A special hook is used for this. First you need to disconnect the wire and remove the spark plug.

If it is dry, it means that fuel is not entering the cylinder.

Disassembly and assembly of the HUSQVARNA 142 chainsaw

my chainsaw start?

.Cause.How to eliminate.

The chainsaw does not start or does not start well. Reason and how to fix it.

common problem of huswarna 137/142

.

If there is splashes on it, then the breakdown may lie in the carburetor or in the starting rule. To fix the breakdown, you need to wipe the spark plug and turn off the fuel supply. After this, the starter starts.

Thus, the combustion chamber is ventilated and excess fuel is removed. After this, the spark plug is installed in place and the chainsaw starts.

If there is carbon deposits on the spark plugs, this indicates that the Husqvarna 137 chainsaw runs on low-quality fuel. Carbon deposits also form as a result of an incorrect ratio of fuel and oil. In order for the tool to work as long as possible, you need to carefully study the operating instructions.

READ Hiller From Chainsaw Ural Do-It-Yourself

If there is carbon on the candle, it must be carefully removed. You can use an awl for this. The electrodes are carefully rubbed with sandpaper. After this, it is installed in place. You also need to fill in the fuel that is recommended for this model of chainsaw.

the article about repairing the Partner 350 chainsaw with your own hands here.

Problems with the fuel supply system

If the tool does not work, it may be due to the fact that there is no fuel entering the cylinder.

First of all, you need to check the fuel filter for contamination levels. To check this, you need to remove the fuel hose and check how fast the fuel flows.

If it is supplied under low pressure, then the problem lies in the filter.

In this case, you need to clean the filter. It is taken directly through the tank. The filter is cleaned and installed back. It is washed under running clean water.

After this, the filter is dried and carefully installed back. To prevent this problem from occurring in the future, it is necessary to periodically clean the filter.

If cleaning the filter does not give a positive result, then you should pay attention to the breather. A clogged hole in this hole causes insufficient air to enter the carburetor.

READ How to Correctly Put a Chain on a Chainsaw Video

Malfunction of muffler and carburetor

If the chainsaw is used frequently, muffler malfunctions may occur. This is very easy to determine.

If the tool works normally, but when the speed increases, it starts to stall, then the reason is the spark arrester.

Most often, the breakdown of this element is a result of clogging with combustion waste. You can easily solve this problem with your own hands.

First of all, you need to remove the muffler and disassemble it. It is worth considering here that in some models spark arresters are not disassembled. After this, the muffler is cleaned of carbon deposits. For this purpose, special detergents are used.

When the carbon deposits are removed, the spark arrestor is dried with a hairdryer. At the final stage, the muffler is installed in place.

As for the carburetor, its adjustment and repair can be done at home. But in order to perform such work efficiently, you need to know the structure of the carburetor and the principle of its repair.

Poor repairs can lead to serious damage to the device. Therefore, experts recommend that it be configured and repaired in special workshops.

As you can see, many chainsaw malfunctions can be fixed with your own hands. But to do this, you need to have certain information. If you are not confident in your abilities, then it is better to seek help from specialists.

Watch the video in which a specialist shows in detail the disassembly and assembly process for DIY repair of the Husqvarna 142 chainsaw:

Reasons for early failure of saw chains

Accelerated elongation of the part occurs during the running-in phase and in the last quarter of its service life. During these time intervals, the headset requires special attention and careful maintenance.

- The reason for rapid stretching of the saw chain may be poor quality of the material of the budget model, mismatch of the crown configuration and excessive wear of the drive sprocket, malfunction or ineffective operation of the lubrication system.

- The full operation of a chainsaw chain also largely depends on the condition of the tire and drive sprocket, the quality of the chain oil and the performance of the lubrication system, timely and competent sharpening of the edges of the cutting links.

Negative consequences of incorrect chain adjustment

Checking the condition and tension of the chain is included in the mandatory list of preparatory work.

How correctly you can install the chain depends on:

- the duration of its subsequent operation;

- safety of sawing operations of increased complexity;

- resource of the engine and chainsaw as a whole.

An overtightened headset sharply reduces work productivity and initiates excessive loads on the power unit and transmission. Tire overheating and excessive fuel consumption also occur.

A loose chain can fly off the bar or break. The formation of traumatic moments is partially or completely eliminated by emergency stop systems and catchers, which make it possible, with greater or lesser success, to untangle the chainsaw chain and determine its suitability for subsequent use.

Installing a part with damaged or deformed links can lead to uneven wear on the tire guide groove and other undesirable consequences.

Tensioners

The classic chain tensioner for a budget-class chainsaw is usually a threaded bolt with an adjusting component, standard or side-mounted. The chain tension is adjusted using the included key or screwdriver.

More expensive models are equipped with easy-to-use devices that allow you to tension the chain with one movement of a lever or turn of an adjusting dial.

In the first case, the degree of tension is fixed with a locknut, in the second, the bar and chain tensioner are locked in a given position by installing the cover. In both options, reliable fixation of the chain in a given position is guaranteed, the ability to compensate for its stretching with minimal loss of working time.

Advantages of producing a chain set

The chain and bar are included in the list of replaceable equipment, so the sawyer, depending on the specifics of the work, can use several sets of different lengths and performance. The average service life of wear-resistant branded tires allows you to work out the life of three saw chains.

The cutting edges of chain saw links require periodic sharpening. The undeniable advantages of using a set of several chains are uniform wear of the drive sprocket and good compatibility with the chains included in the additional set.

Features of manual and mechanized sharpening

Dullness of the cutting edges of the saw chain is manifested by:

- noticeable decrease in performance;

- ejection of small chips;

- the appearance of a characteristic smell of burnt wood.

To restore the cutting properties of chains, several types of sharpening devices are used.

In the simplest version, it is a holder attached to a tire complete with a set of special files; in another, it is a power-driven sharpening machine. Both technologies have their own advantages and disadvantages.

Low-productivity and time-consuming manual chain sharpening helps preserve its resource. The mechanized method provides good performance, but the lack of an individual approach to each cutting link of the chain negatively affects its durability.

Sequence for replacing and adjusting the saw chain

Changing the chain of a household and professional chainsaw yourself is technically easy. The key to successful completion of adjustment work will be strict adherence to the recommendations of the attached instructions.

Due to the thermal expansion of the metal, installation of the chain on the chainsaw and subsequent adjustments are made only with a cold bar.

- In the classic solution, the technology involves turning on a lock to prevent accidental engine starting, unscrewing the threaded fasteners, dismantling the tire and cleaning the guide groove from sawdust.

- Next, you should make sure that the dimensions of the shanks correspond to the width of the groove, determine which side to place the chain on the chainsaw, secure the bar and adjust the chain in the sequence specified in the instructions.

- Before putting the chain on the chainsaw, you should make sure that the direction of the chain on the chainsaw meets the stated requirements, and that the chain tensioning mechanism has sufficient free play.

After adjusting the new chain, it is recommended to run the saw at medium speed for 2-3 minutes, and then check the chain tension again. This point can be combined with visual monitoring of the operation of the lubrication system.

Chain Doesn't Rotate on Husqvarna Chainsaw Cause

Malfunctions of the Husqvarna 137 chainsaw

Question: A standard problem occurred with the Husqvarna 137 chainsaw (impulse channel seal). After the replacement, the saw developed an unknown malfunction.

It starts up perfectly, idles smoothly, but after 5 minutes of operation the power drops, the saw begins to operate at high speeds and swells. I assume that there is a problem in the carburetor settings, but I have no idea what exactly to adjust.

Answer: there may be an air leak through the same pulse generator. By and large, after replacing it is recommended to adjust the carburetor.

There is no point in adjusting it yourself; for this purpose you need a pressure gauge; if the mixture becomes lean, you will throw out the piston. Look at the carburetor mount; when the saw heats up, it starts to suck in air somewhere.

Question: I have a question about the Husqvarna 137 chainsaw. At first (when the problems started) the saw worked normally at idle, but at high speeds it worked very little and the speed dropped until the engine stopped, later at medium speeds it began to stop abruptly and it was impossible to start until I didn’t unscrew the spark plug, I didn’t screw it back in.

I removed the carburetor, disassembled it, washed it and blew it out. 0 results.

I disassembled the saw one hundred percent and found that the rubber tube that connects the carburetor and the sleeve (small) had worn out, the group is normal, there is also a gap in the ring, there is free play in the bearings (the unfamiliar ignition is more noticeable because 1 petal is broken off on the flywheel, I think that’s why reason and free movement) assembled, starts only on choke, runs for 3-5 seconds and stalls.

When you open the valve, it melts immediately; after several attempts, the spark plug and piston become wet. Why do you like it better?

? would you prefer air leaks from under the seals? Is the carburetor overfilling?

Answer: It is necessary to disassemble the chainsaw. A rubber tube connects the cavity under the piston to the fuel pump diaphragm in the carburetor. If the tube is torn, then dirt will be sucked under the piston, and the pump in the carburetor will not work.

I hope they changed the phone. Was the carburetor disassembled, were the idle speed screws turned out and the consistency properties? If the seals are sucked, the consistency will become depleted, and in theory the spark plug should not be filled. The fact that the blade on the impeller is broken is very bad. The imbalance at 11,000 rpm will be terrible, the bearing will wear out decently.

READ Cleaning the Carburetor of a Husqvarna Chainsaw

Husqvarna petrol saws?

137. I don’t remember how many years I saw. I sawed a lot. Recently it began to lose power, and a few days ago it stalled and stopped starting.

What was done: Changed the spark plug to the latest Bosch. Bottom line. zero. Removed the fuel filter. zero. They put it back. Dismantled. assembled the carburetor. (The screws were never touched). The membranes are intact. A set of membranes will arrive soon, we'd like to change them just in case. They changed the fuel.

We replaced the ignition coil from the 142nd saw. Bottom line. It starts, but before starting it is almost always necessary to pump the trigger. If you start up, the engine only works if you pull the trigger. That is, intermittently. Doesn't work at full throttle, at idle . Same. What else should I check?

Answer: Try to also check the muffler (if it is clogged with carbon deposits), the condition of the impulse channel hose, and in addition the presence of sufficient compression in the cylinder.

The chain on the chainsaw is jammed, we are looking for the cause. Part 1.

We remove the sprocket and at one time look at the condition of the oil pump. Link to mine.

The chain on the chainsaw/on the brake does not spin/consequences

Let's look at the consequences of using a chainsaw

with the brake on. And general tips for caring for benzos.

Question: chainsaw , of course the following symptoms: When starting the saw, the chain starts to spin, you give gas, the chain stops

.

When I stop sawing, the chain does not stop, it turns slowly. There is an option to pause it; if you touch a piece of wood without gas, the chain stops

, but then there are slippages at

idle

.

Answer: Maybe the clutch springs are weakened, it is possible, just obvious dirt in the cup. And the idle speed screw must be reduced so that the chain stops.

READ Adjusting the Chainsaw Carburetor Needle

Question: I have a problem with chain lubrication. I removed the oil pump, I don't understand why it doesn't pump oil. About 30 years ago, when I removed the pump, oil leaked out of the reservoir, but at the moment it doesn’t.

I stretched this device where the pump tip is inserted, blew it out, and no results. I used a wire to clean the plastic tube where, I think, air gets into the tank, but no results. What to do?

Answer: If air gets into the tank. the pump must pump. Is the oil pump gear intact? (the weak link in these saws). If even one tooth on the gear is licked off, no oil will be supplied.

And the gear should move freely, without the slightest jamming. The gear has its own place or position; there is a notch that should coincide with the cotter pin.

Question: The clutch spring broke on the Husqvarna 137 chainsaw. I removed the clutch spring. It will not affect idle speed

?

Answer: change the assembly and work quietly. I think a torn spring or its absence will affect the idle speed

.

Checking idle operation in this option is trivial: assemble the saw and start it with the bar and chain installed. Please adjust the carburetor if it has been disassembled.

Question: The Husqvarna 137 chainsaw starts every 15 or 20 times, although it works and cuts normally. what is the reason? Is it possible that I screwed it onto the ignition when I unscrewed it? What else is it called no?

Answer: Check the spark plug, if it is dry then the carburetor. If it’s wet, then your carburetor will overflow, or the ignition will malfunction.

First, check the ignition, make a gap of 0.7 mm on the spark plug and pull the starter, if the spark jumps in free air, then the ignition is OK. If there is no spark, change the module (the spark plug also needs to be checked). However, based on your description, I think the carburetor is to blame.

READ Why Oil Leaks From a Chainsaw

Tighten both screws fully (do little damage to the needles) and then unscrew them 1 or 1.5 turns. This will be the initial installation. Adjust the idle speed later.

Afterwards, start working on the working speed. They are similar saws, I think the carburetor is the same. When I adjust, I immediately unscrew both screws three turns. Further according to the circumstances (I turn it away, wrap it up). But I recommended it for you based on the annotation.

Question: Tell me, I put an 18 bar, a sprocket and a 3/8 chain on the saw, it cuts perfectly, unfortunately there is a problem with the lubrication, the chain is generally dry. I took off the entire body kit. It spurts out of the hole quite vigorously. The window on the tire also matches the hole. How do you like the challenge?

Answer: Right away the idea. check the oil pump, it may be clogged, the drive may be worn out, or it may not be designed for that length of tire at all.

HUSQVARNA

Technical characteristics of Husqvarna 137

Cylinder volume. 36.3 cm3 Power. 1.6kW (4.5.2.4 hp) Highest recommended motor speed. 13000 rpm Fuel tank volume. 0.41 l Oil tank volume. 0.2L Oil pump type. fixed flow Chain pitch. 0.325 Recommended tire length. 13-15 (33-38 cm) Sound level. 98dB(A) Noise level. 118 dB(A) Vibration, front/rear handle. 4.9m/s2 / 7.7m/s2 Weight (without bar and chain). 4.6 kg

Vibration absorption, and of course handles isolated from the motor.

Centrifugal air cleaning system for long intervals between filter cleanings, uninterrupted operation and reduced wear.

Curved front handle for best grip and natural working posture.

The narrow body, high center of mass and flat bottom make the chainsaw only comfortable to use.

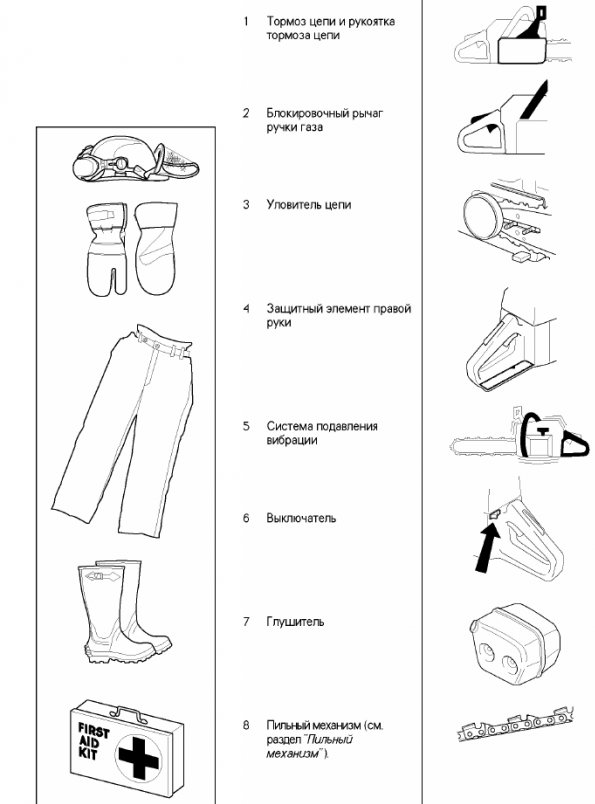

The double-action chain brake, right hand guard and chain stop increase the safety of working with the saw.

Forged three-section crankshaft, designed to greatly increase service life and is designed for operation in the most demanding conditions.

Low noise level.

Source

Ways to check the degree of tension

To check the degree of tension, it is enough to pull the chain in the middle part of the tire; the extension of the link shanks is allowed no more than 2/3.

- A properly adjusted chain should not bind when moved along the bar by hand.

- Creaking and other extraneous noise in the area where the drive sprocket is located is also eliminated.

- After running the chain, it is necessary to check the tightness of the threaded fasteners of the bar and the protective cover.

After long-term use, the chain does not tighten due to the lack of adjustable travel of the tensioning mechanism. The structural design of the chain allows its length to be reduced by removing several links. On the other hand, such savings result in a loss of smooth running of the chain and increased wear of the tire groove and the drive sprocket crown.

Husqvarna petrol saws are in great demand both among novice gardeners and experienced forest fellers. Models of the Swedish brand have a number of important advantages such as reliability, balance and high working life. Moreover, each Husqvarna chainsaw has a simple design, which makes it easy to maintain and quickly fix any breakdowns that occur.

Gasoline saw Husqvarna 455 Rancher

The best all-around saw rated is the Husqvarna 455 Rancher, one of their best-selling models and probably their best known.

It runs on a 3.5 hp engine. with a 20-inch long bar and a maximum speed of 9000 rpm, making it an ideal professional-grade saw, but it is also suitable for heavy-duty household work.

The ergonomic handle and LowVib system make it an excellent tool for long-term work, as these features prevent hand fatigue and allow you to hold the saw for a long time.

Like most other Husqvarna chainsaws, it has the X-Torq feature, which reduces exhaust emissions and also speeds up fuel injection.

In addition, it has a centrifugal air purification system that eliminates most large dust particles, which will reduce the need for frequent filter cleaning and also significantly increase the service life of the engine.

Advantages:

- Conveniently located chain tensioner

- Low fuel consumption

- Minimal exhaust emissions

- Reduced vibration

- Ergonomic front handle

Flaws:

- Quite heavy

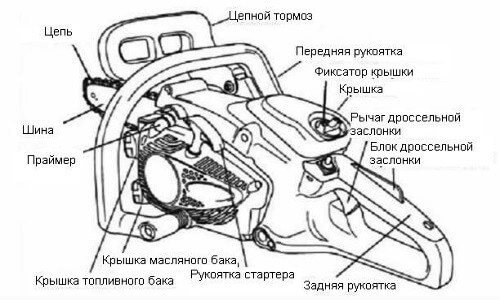

Husqvarna chainsaw device

Unlike chainsaws from other equally well-known manufacturers, models from the Swedish company Husqvarna have a fairly simple design, which greatly simplifies their self-repair. When assembled on chainsaws of the Swedish brand you can see:

- The housing, which includes protective covers that prevent damage to the main parts and mechanisms of the saw;

- Handles - on the front and rear sides, as well as a handle on the starter cord;

- Control buttons, switches and chain brake lever;

- Silencer that reduces noise level during operation;

- Bar and saw chain;

- 2 separate plastic tanks - for the fuel mixture and for oil;

- Shield protecting the operator's right hand.

The power unit, carburetor, starter and ignition system are placed under the reinforced body of the Husqvarna chainsaw. Depending on the model and its cost, a number of additional options may also be included in the design of the chainsaw.

How to Dilute Gasoline for a Husqvarna Chainsaw

Chainsaw Husqvarna

When talking about a unique tool, trying to reflect its convenience or ease of use, we use the epithet “extension of the hand.” The first thing that comes to mind when mentioning a chainsaw is the Russian pronunciation, really an extension of the hand. Gasoline for a chainsaw: how to fill it into a Husqvarna. Is it really only the successful ergonomics of the handle that is the advantage of these saws? Let's try to figure it out.

Husgvarna released the first chainsaw in the fall of 1959, making a techno revolution in this field. Although not the “parent” of the first chainsaw, the Husqvarna company was at the origins of its invention and is the creator of the layout of modern saws. Many technical solutions, first used on Husqvarna , over time have become an indisputable attribute of all saws, forcing a review and change of technical requirements for saws and their safe operation, in fact, throughout the world.

Husgvarna chainsaw lineup includes both household and professional saws, with differences, like any technically complex tool, in power, reliability and operating time. Therefore, if you choose a saw, then you should know why it is for you, and if you are the happy owner of such equipment, then how to use it correctly.

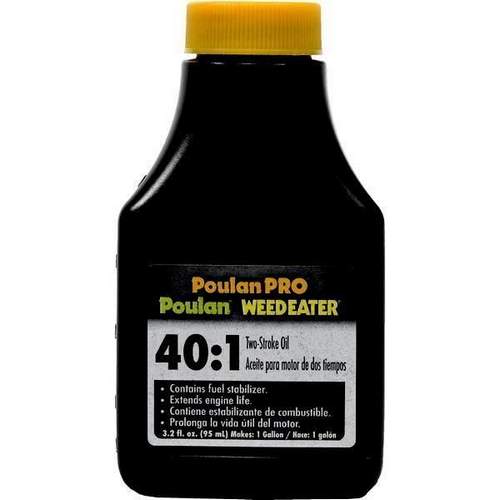

Professional chainsaws are even stronger than household chainsaws and have a power range from 2.7 to 8.2 hp (2-6 kW), are made with increased strength and wear resistance, with a total service life of up to 2000 hours. All Husqvarna chainsaws have a two-stroke gasoline engine, powered by a mixture of high-octane gasoline and special oil, in a ratio of 1:40 to 1:50, indicated in the passport for each model. The use of high-quality gasoline, special 2T oils and a forged three-section crankshaft allowed the manufacturer to obtain not only engine endurance in the most demanding conditions, but also a good weight-to-power ratio; 1959 standard saw was 11.5 kg and 4.6 kg for the Husgvarna 142 model. Oil pump for chainsaw China gc99458 but I don’t know how to replace or remove the oil pump. Two tanks for chainsaws, for fuel and oil, ensure the operation of the engine and lubrication of the saw chain, while the tanks are designed so that when the fuel is completely used up, there is little chain lubrication left. Do not try to “save money” by using lower than recommended gasoline and Russian oils, since they are not designed for the high speeds of chainsaw engines, burn out without lubricating the rubbing parts and reduce the service life of engines by 15%. It is allowed to use Russian motor oils to lubricate the saw chain, and even here it is better to use certified oils.

READ Ignition Adjustment of Husqvarna Chainsaw

Refueling a chainsaw

3-part course. What you need to know about chainsaws before using them. Join us on social networks!?????

Preparation of fuel mixture for two-stroke engines

The video shows how to make a fuel mixture for two-stroke engines. Calm chainsaw oil). How much oil to add to chainsaw gasoline? Refueling mowers and chainsaws

And

The use of a catalytic afterburner of exhaust gases, E-TECH technology, reduces their toxicity, is approved for use in all countries and allows us to talk about a qualitative improvement in working conditions. Gasoline for a chainsaw - what kind to pour? How to dilute gasoline for a chainsaw? (Husqvarna). We must pay tribute to the fact that Husgvarna always prioritizes improving the working conditions of its tools. 1959 saw had the lowest noise level compared to other saws, and since 1973, all saws have had an automatic chain brake to protect the saw operator from kickback. Modern chainsaws use a combined chain brake, which stops both manually - by resting your hand on the guard - and automatically, by the force of inertia of the saw's recoil. What oil to use for what oil to pour into gasoline for and husqvarna - for. Many manufacturers, to prevent kickback, eliminate the possibility of working with the toe of the saw and install a limiting shield. But Husqvarna saws do not have it, since Swedish safety standards allow working with the end of the bar. The ratio of gasoline and oil for a chainsaw: how and how to dilute gasoline for a chainsaw? Only first-class fellers are allowed to work in this way.

READ Carburetor Chainsaw Husqvarna 372 Video

In 1969, Husgvarna released a chainsaw with reduced vibration levels and since then its saws have been equipped with anti-vibration systems, the quality of which is gradually improving with the release of each new model. Today, the company installs the LowVib vibration damping system on saws, the principle of which is to balance one mass with another, the inertial interaction of two masses. The chainsaw parts are isolated from the handles by steel springs, and the total mass of the handles is the counterweight. But keep in mind that the quality of vibration damping on household saws is lower, since their operating time is much less than professional saws. It is impossible not to note the double air filtration, which allows you to increase the productivity of the logger and the engine, by reducing the time for servicing the chainsaw. How to properly refuel a chainsaw, prepare what fuel to use. How to dilute gasoline for a chainsaw? The narrow body, high center of gravity and flat bottom make the operation of Husgvarna chainsaws convenient and comfortable.

And the last piece of advice is suitable for all chainsaws, without exception. Don’t forget that according to statistics, approximately 90% of all saw breakdowns are the result of careless handling of the saw set and chain. If the chain is sharpened, then it works, and if not, then it is a person. You put more effort into sawing, increasing the load on the chainsaw, reducing the service life and the entire service life of the unit.

Source

Operating instructions for Husqvarna chainsaws

In order to extend the life of the chainsaw and reduce wear of its main parts, you must carefully study and adhere to all the tips specified by the manufacturer in the instructions for use. Below we list a number of the most common questions related to the operation of Chinese and Swedish chainsaws manufactured by Husqvarna, and give detailed answers to them.

What kind of gasoline should I put in my Husqvarna chainsaw?

To prepare the filling mixture for Husqvarna chainsaws, you should use AI-92 fuel. It is extremely rare that the operating instructions for newer models of this brand indicate that 95 gasoline can be used to prepare the mixture.

Proportion of Gasoline and Oil for Husqvarna Chainsaw

Oil and gasoline coefficients for chainsaws, oil selection, instructions

Maintaining the correct proportions of oil and gasoline

for a chainsaw allows you to avoid the vast majority of problems that arise with this tool. At the same time, it is necessary to select lubricants for the saw set and for the engine.

Ready solutions

The quality of the fuel mixture for a chainsaw depends on the continuity of its operation, the consumption of components and engine wear.

You can always find ready-to-use mixtures at various retail outlets. They have already reached the proportions of oil and gasoline

for a chainsaw. These include the mixture “Partner”, “Calmness”, “Husqvarna”.

However, the latter are not a cheaper analogue of the full purchase of oil and gasoline and homemade compounds.

Requirements for raw materials

The gasoline used to prepare the mixture must be at least grade A-92. For example, AI-92 or AI-95 can also be used. Their shelf life should not exceed three months. This is due to the fact that after its expiration in gasoline, the mass fraction of resin increases, which leads to the occurrence of polymerization reactions, which negatively affects the combustion chamber in which a layer of sediment is formed. The gasoline must be unleaded as using the above version will shut down the engine.

It is also necessary to observe the shelf life of the oil. To prepare the mixture, you can use any high quality two-stroke oil such as Partner, Calm or Husqvarna. The choice of oil should be determined by the fact that it is impossible to use the latter for four-stroke engines and boats to prepare the desired composition.

When preparing the mixture, you must read the instructions for accelerating the engine. The last figure shows the relationship between engine volume and power and maximum speed).

Characteristics of oil for the mixture

Chainsaws are equipped with two-stroke engines, so the choice of oil must be appropriate. They can be designed for them API-TA and API-TB classes, which are air-cooled and capable of operating under high loads.

READ How Much Oil Should You Fill Your Lawn Mower with?

from base and additives. The latter provide better oil

and gasoline. With their help, corrosion processes are prevented, as well as the formation of deposits, which reduces smoke output and keeps engine parts clean. The effect of the additives can be read on the packaging.

Types of oils

Mineral oil is suitable for use in the warm season. This is due to the fact that it has increased viscosity. These oils can be purchased from 113 rubles / l (TNK 2T).

Synthetic oil has excellent fluidity, which can be used in winter conditions at low temperatures, that is, throughout the year. It is mainly used for industrial chainsaws. This type is thermally stable and chemically stable. Their cost starts from 135 rubles / 0.2 liters (“Zubr-Expert”).

Refueling a chainsaw

3-part course. What you need to know about chainsaws before using them. Join us on social networks!?????

Preparation of fuel mixture for two-stroke engines

The video shows how to make a fuel mixture for two-stroke engines. Refueling mowers and chainsaws

And.

With not very heavy loads, semi-synthetic oils can be used for year-round use. They include mineral types as the main component to which synthetic ingredients are added. The cost of these oils ranges from 185 r / 0.946 l (Resoil Ultra 2T).

The oil makers come in different colors so you can control how you make the gas for your chainsaw.

The container capacity should be selected based on the use of the tool. With rare chainsaw use, 0.8-1 liters of volume per season is sufficient. For long hours of daily use, you need to focus on 5 liter jars.

READ Chainsaw Partner 371 Carburetor Adjustment

Chain oil

The headset saw is not lubricated with motor oils. To do this, use special chainsaw fuel, which is characterized by high adhesion to the surface. Chain oil reduces friction and wear of parts that come into contact with each other.

Modern brands of chain saws have a reservoir on the body that contains chain oil, with which the saw head is automatically lubricated.

During the cold season, choose semi-synthetic or synthetic oils for tools, and heat. mineral.

On some brands of oil, you may see a CEC label stating that they are plant-based and environmentally friendly.

Main Question

It consists of maintaining the proportions of oil and gasoline for the chainsaw. Excess of the first ingredient will cause sediment to form on the spark plugs and pistons. Excessive gasoline will cause the pistons to misbehave, leading to rapid engine failure. They indicate the exact proportions themselves and Stihl recommend taking 100 ml of oil per 4 liters of gasoline. This is typical for tools with motor power up to 1.5 kW. At higher power the proportion

should be 1/50. On average, answering the question “How to lift gasoline onto a chainsaw?” It is recommended to use the following proportions: 20-50 ml of oil per 1 liter of gasoline.

"Partner" and Jonsered recommend using 100 ml of oil with 3.3 liters of gasoline

.

As you can see, different manufacturers have different approaches to maintaining the proportions of oil and gasoline. Therefore, it is necessary to strictly follow the instructions that apply to the specific brands of the devices in question.

Mixing must be done in special canisters, which are marked with dimensional divisions, and there are two holes: one for oil, the other for gasoline. There are ingredients poured, the container is tilted and mixed with the lids closed. Do not throw water or solids into the prepared mixture.

READ How to Choose a Table Saw

However, these tanks have a minimum mark of 1 liter, so smaller volumes can be measured independently. To do this, you can take a plastic bottle with a capacity of 0.5-1 liters. Pour 102 ml of water into them (up to 816 ml) using a measuring cup. After filling each portion, make a mark at which they write numbers from 2 to 18 in increments of 2. To measure the oil, use a syringe without a needle in a volume of 10-20 ml. A step of 102 ml of water gives a ratio of 1/50. In other proportions it must be adjusted accordingly.

The finished composition is stored for no more than 1 month. It's even better to use it over several days. This is due to the fact that it carries oxidative processes that change its chemical composition. An ideal option for consuming the mixture. one day. If the engine breaks down due to overexposure to fuel, it will be considered a non-guaranteed event. If you leave the prepared mixture in the chainsaw after the end of the season, you must turn off the engine and remove the residue.

Finally

We found out that it is necessary to maintain the proportions of oil and gasoline for a chainsaw

. It is better to follow the instructions for the chainsaw and oil manufacturers. On average, the proportion of gasoline: oil should be 1/25-1/50. At the same time, gasoline should be A-92, AI-92 or AI-95. Oils can be mineral if their summer use is planned, synthetic or semi-synthetic for all-season use.

Typical faults and repairs of Husqvarna chainsaws

Owners of Husqvarna chainsaws rarely experience breakdowns of their tools. However, if this does happen, then you can try to fix the problem yourself. Let's talk in more detail about how to identify a breakdown and repair a Husqvarna chainsaw without the help of a specialist.

How to adjust the carburetor on a Husqvarna chainsaw?

In case the Husqvarna chainsaw does not start, or it does not develop speed, the reason for this lies in the violation of the factory carburetor settings. To do this, the tool has 3 screws, marked with the letters “H”, “L” and “T”.

To set up a Husqvarna chainsaw, you need to proceed in this order:

- Adjusting the saw's carburetor begins with warming up its engine for 5 minutes. After this, start turning the “L” screw until you hear the maximum speed generated by its motor. Then immediately turn the screw a quarter turn in the opposite direction;

- Then, with one hand, press and hold the throttle trigger for 10 seconds. At the same time, with your second hand, turn the screw “H” a quarter turn to create maximum load on the motor;

- After this, release the gas trigger and start turning the “T” screw in the direction of the clock hand. As soon as the chain begins to rotate along the bar, turn the screw in the opposite direction until the chain stops.

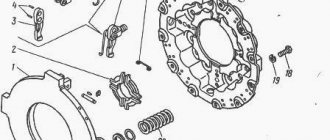

How to remove the clutch on a Husqvarna chainsaw?

- Remove the air filter and unscrew the spark plug. If necessary, wipe the area around the chainsaw spark plug;

- At the next stage, you will need to remove the sprocket from the Husqvarna chainsaw - this will make it possible to carefully inspect the mechanism for blockages;

- The clutch coil is unscrewed in the clockwise direction. Under it there is a pressure washer, which also needs to be removed;

- At the end, the sprocket is replaced and a new clutch is installed. Reassembling the Husqvarna chainsaw is performed in the reverse order.

The first few starts of the chainsaw engine will be accompanied by ringing sounds - this is due to the fact that the drive sprocket will rotate until it finally falls into place.

Oil does not flow to the Husqvarna chainsaw chain - reasons and solution

- First, remove the protective cover and starter spring, after which the chainsaw air filter is dismantled.

- Below it on the right side there is an oil pump, which needs to be inspected for cracks and other damage. If necessary, replace the pump;

- If you notice that the oil hoses have moved away from their base, then they will also need to be replaced with new parts.

After installing new spare parts, you can continue working with the tool. In the future, use only high-quality oil from trusted manufacturers. The correctly selected sharpening angle of the Husqvarna chainsaw chain is also of great importance, since the speed of movement and the intensity of lubrication of the saw element depend on it.

Disassembly and Assembly of Husqvarna Saw 5200

Content

, 142, 240, 365 with your own hands. video

Chainsaw. an indispensable assistant for every true master.

With the advent of the instrument, its popularity increased sharply.

Thus, it has high functionality. It is widely used not only in forestry, but also in households.

It's easy to choose a chainsaw. Therefore, it is best to pay attention to well-known brands such as Husqvarna. This company produces a wide range of such tools. Husqvarna 240 and other models are of high quality and functionality. But, unfortunately, even such tools are not immune to failures.

Possible faults

After a chainsaw appeared in the house, many owners breathed a sigh of relief.

After all, this tool allows you to solve complex problems quickly and easily.

But here it is worth considering that the chainsaw often fails. This is due to the fact that during operation it is subjected to high loads. Therefore, you should always be prepared to troubleshoot failures.

Today there are a large number of seminars that offer their services for repairing chainsaws and other tools. But this does not mean that if something malfunctions, you should immediately run to a repair shop.

Some problems can be fixed manually. To do this, you just need to know the main causes of failures and how to fix them.

READ Chain Sharpening Machine EZS 130m

Thus, if the tool is used frequently, failures may occur:

- carburetor;

- muffler;

- oil pump;

- ignition and fuel supply systems.

Each of these failures can be eliminated with your own hands. Main. know the sequence of work when eliminating a particular malfunction.

For an article on self-repairing a 180 chainsaw, read here.

Ignition system

If a tool suddenly stops working, the first thing to check is the ignition system. And you need to start with a candle.

The work must be done very carefully. A special hook is used for this. First you need to disconnect the wire from the electrical outlet and remove the spark plug.

Disassembly and assembly of the HUSQVARNA 142 chainsaw

Add to Friends Subscribe to the Chainsaw Repair

Repair of Chinese chainsaw Husqvarna 5200.1 part

Disassembly

Chinese (gypsy)

chainsaw

. We slowly disassemble the chainsaw.

If it is dry, it means the cylinder is not receiving fuel.

If there is a splash on it, the breakdown may be covered by the carburetor or in the starting rule. To fix the problem, you need to wipe the spark plug and turn off the fuel supply. After this the starter starts.

In this way, the combustion chamber is ventilated and excess fuel is removed. After this, the candle is inserted into place and the chainsaw begins.

If there is buildup on the spark plugs, this is an indication that your Huskvarna 137 gasoline is running on low quality fuel. In addition, the deposit is formed as a result of an incorrect ratio of fuel and oil. In order for the tool to work as long as possible, you need to carefully study the operating instructions.

READ Rip Saw

If buildup accumulates on the plug, it should be removed carefully. You can use awl for this. The electrodes are carefully rubbed with sandpaper. After this, it is installed in place. Additionally, you need to fill the fuel that is recommended for this chainsaw model.

Here you can read an article about your interlocutor.

Problems with the fuel system

If the tool does not work, it may be because the cylinder is not receiving fuel.

First of all, you need to check the fuel filter for contamination levels. To check this, you need to remove the fuel hose and check how fast the fuel flows.

If it is supplied under little pressure, the problem is with the filter.

In this case, you need to clean the filter. It goes straight through the tank. The filter is cleaned and returned back. It is washed under running clean water.

After this, the filter is dried and carefully installed back. To prevent such a malfunction in the future, it is necessary to clean the filter periodically.

If cleaning the filter does not give a positive result, then you should pay attention to a breather. If this hole becomes clogged, the carburetor does not receive enough air.

READ Stihl Ms 250 How to Identify a Fake

Malfunction of muffler and carburetor

If the chainsaw is used frequently, the muffler may malfunction. This is very easy to determine.

If the tool is running normally and when the speed increases it starts to stop, then the spark arrester is the culprit.

Most often, this element fails as a result of contamination by combustion waste. You can easily solve this problem yourself.

First of all, you need to remove the muffler and disassemble it. It is worth considering here that in some models spark arresters are not understood. After this, the muffler is cleared of carbon. To do this, use special detergents.

When the deposit is removed, the spark arrestor is dried using a hair dryer. At the final stage, the muffler is installed in place.

As for the carburetor, its adjustment and repair can be done at home. But in order to perform such work efficiently, you need to know the structure of the carburetor and the principle of its repair.

Poor repairs can cause serious damage to the device. Therefore, experts recommend performing adjustments and repairs in special workshops.

As you can see, many chainsaw problems can be fixed with your own hands. But for this you need certain information. If you are not confident in your abilities, it is better to seek help from specialists.

Watch the video in which a specialist shows in detail the process of dismantling and reassembling for DIY repair of the Husqvarna 142 chainsaw:

Chainsaws Husqvarna - model range of the Swedish company

The Husqvarna company is known for the huge range of branded chainsaws on the market. We bring to your attention a review of Husqvarna chainsaws with a detailed description of the most popular models.

Husqvarna 61

This Husqvarna chainsaw cuts through old thick branches efficiently and quickly and helps you prepare large quantities of firewood. Technical parameters of this popular model include:

- Power – 3.9 l. s./2900 Watt;

- Standard tire size – 45 cm;

- Reservoir for replenishing fuel – 750 ml;

- Oil tank – 400 ml;

- Ready-to-use weight: 6.6 kg.

This Husqvarna chainsaw is small in size, so even a small bag is suitable for transportation.

Husqvarna 136

This semi-professional Husqvarna chainsaw is primarily used for maintaining large garden areas. Technical characteristics of this Husqvarna chainsaw include:

- Power – 2.2 l. s./1600 Watt;

- Tire length per set – 45 cm;

- Fuel refill tank – 410 ml;

- Oil tank – 175 ml;

- Operating weight – 4 kg.

The design of this Husqvarna chainsaw is based on a forged piston group, which significantly increases wear resistance and increases the endurance of the model.

Husqvarna 235

This professional Husqvarna chainsaw has received the highest demand due to its well-thought-out design and balance. Technical parameters of this Husqvarna model include:

- Power – 1.7 l. s./1300 Watt;

- Factory tire size – 30 cm;

- Reservoir for replenishing fuel – 300 ml;

- Reservoir for lubricant – 200 ml;

- Operating weight – 3.5 kg.

The modest size of the chainsaw allows it to be easily placed in a carrying case.

Chainsaws Husqvarna 257 XP and Husqvarna 455 Rancher

These Husqvarna chainsaws do an excellent job of sawing small logs and cutting down old branches. The operating parameters of chainsaws are described in the table below.

Design and scope of application of the Husqvarna chainsaw

The Husqvarna professional chainsaw is used for felling forests and sawing large diameter logs. Its peculiarity is that it is able to work effectively in any conditions.

The reliability of the tool is achieved by the following design features:

Husqvarna 372 XP - its main components and protective elements for working with a chainsaw

- the crankshaft consists of three parts, which ensures its long service life;

- when designing the main working units, a fairly large margin of safety was provided;

- the chainsaw is equipped with an SEM AM50 ignition system and an HD68 carburetor;

- The standard package for the saw includes a transport cover, a key for assembly and instructions;

- a large fuel tank ensures uninterrupted operation over a long period of time;

- presence of NGK BPMR7A spark plugs;

- The crankcase of the 372 XP is made from an alloy of aluminum and magnesium. It is able to operate efficiently and for a long time at high speeds.