MTZ-892 is one of the successors of the MTZ-80 (MTZ-82) and MTZ-50 (52) tractors, which is still in production (as of 2020). The decision to modernize agricultural machinery was made back in 1966, but new models were introduced into wide circulation only in 1972.

Tractors labeled as MTZ were produced at the Minsk Tractor Plant, so giving them a second name - “Belarus” - seemed more than logical.

Device, spare parts and components.

SPARE PARTS FOR TRACTORS

ADJUSTMENTS OF MTZ TRACTORS ___________________

DIESEL ENGINE PARTS ___________________

MTZ SPARE PARTS CATALOG ___________________

TECHNICAL CHARACTERISTICS OF TRACTORS ___________________

SPECIAL EQUIPMENT BASED ON MTZ AND ATTACHMENTS ___________________

AGRICULTURAL MACHINERY AND EQUIPMENT ___________________

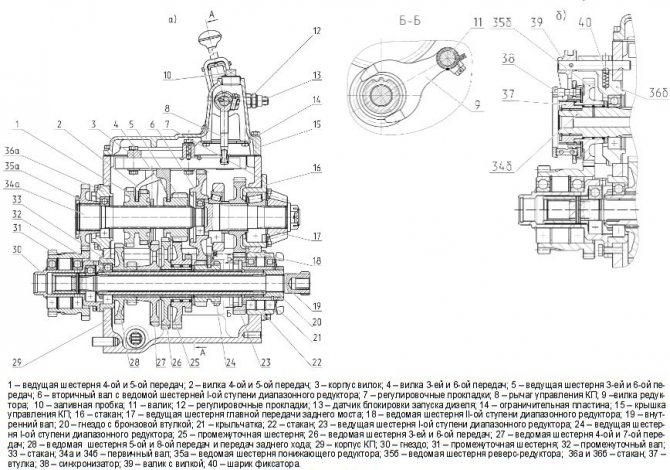

MTZ-892 tractor gearbox

The gearbox (Gearbox) is an element of the transmission of the MTZ-892 tractor and is used to change transmission gear ratios and ensure movement reversal.

In addition, the design of the gearbox provides a drive for synchronous rear and side semi-independent power take-off shafts (PTO), and also provides the ability to obtain additional speeds in the first and second gears of forward and reverse when the tractor is equipped with a creeper (hydraulic creeper).

On tractors it is possible to install either a creeper (hydraulic creeper) or a side semi-independent PTO.

Both the speed reducer (hydraulic speed reducer) and the side semi-independent power take-off shaft are attached to the left side plane of the gearbox instead of the cover.

It is also possible to install a manual step-by-step dual-range gearbox with a right-hand control lever.

The following versions of the MTZ-892 gearbox are provided:

– 9F/2R with mechanical overdrive; – 9F/2R with mechanical reduction gearbox; – 9F/2R with synchronized reduction gear; – 9F/9R with reverse gear.

The gearbox shown in Fig. 7 is a complex unit consisting of mechanisms of two groups. The first group - the mechanical transmission unit - includes mechanical gears that serve to transmit and transform the power flow.

The second group - gearbox control - includes lever mechanisms, the design of which provides the operator with high-quality control of the gearbox (selection of the required gear, its reliable inclusion and exclusion of self-switching).

Mechanical transmission unit of the MTZ-892 gearbox

The mechanical transmission unit consists of primary 34a and secondary 6 shafts located in the gearbox housing 29 (Fig. 7), as well as an intermediate shaft 32 and a 1st gear and reverse shaft 27 parallel to them (Fig. 8).

The primary shaft 34a (Fig. 7) is mounted on two ball bearings. One of the bearings is placed in a cup 36a, which is installed in the bore of the front wall of the gearbox housing 29 and is attached to it with bolts. The second is in the boring of secondary shaft 6.

The driven gear of the reduction gearbox 35a is fixedly mounted on the splines of the front console of the input shaft.

In the span between the supports of the input shaft there are installed a double-crown drive gear of the 4th and 5th gears 1 and a drive gear of the 3rd and 6th gears 5, which are able to slide along the axis of the shaft along its splines.

The design of the front part of the input shaft of the 9F/9R gearbox of MTZ-892 tractors equipped with a reverse gearbox is shown in Figure 8. It has the following differences compared to the 9F/2R discussed above with a mechanical overdrive gearbox.

The driven gear of the reverse gearbox 35b (Fig. 7) is installed on the smooth neck of the front console of the input shaft of the gearbox 34b and is able to rotate freely on a roller bearing. Gear 34b is in constant mesh with the large rim of the intermediate gear of the gearbox 31.

A synchronizer 38 is installed in front of the driven gear of the reverse gear 35b, the movable carriage of which is always connected to the input shaft 34b through a splined sleeve 37 fixedly mounted on it. To control the synchronizer, a fork 39 is used, into the groove of which the disk of the synchronizer hub 38 fits.

The fork 39 with the roller has the possibility of axial movement in the hole of the cup 36b of the input shaft. On the roller 39 there are two transverse holes into which the spring-loaded ball of the latch 40 fits. The holes provide the roller 39 and the fork associated with it with two fixed positions.

The supports of the secondary shaft 6 are two tapered roller bearings, one of which is located in the housing bore 29, and the second in a cup 16, which is installed in the bore of the rear wall of the MTZ-892 gearbox housing and is attached to it with bolts.

Structurally, the secondary shaft is made integral with the driven gear of the first stage of the range reducer. The gear ring of the gear is located cantilevered in the front part of the secondary shaft 6.

In the span between the supports of the secondary shaft, the driven gear of the second stage of the range gearbox 18 is fixedly mounted on splines, which is also the drive gear of the synchronous drive of the rear PTO.

On the rear console of the secondary shaft, drive gear 17 of the main transmission of the rear axle (small bevel gear) is mounted motionless on splines.

In the front part of the hollow intermediate shaft 32, a double-crown driven gear of the 5th and 8th gears and reverse gears 28, a driven gear of the 4th and 7th gears 27 and a driven gear of the 3rd and 6th are fixedly mounted on its splines gear 26, on the hub of which a double-crown intermediate gear 25 rotates freely on a needle roller bearing.

Gear 25 is in constant mesh with gear 25 (Fig. 8), providing the ability to engage low gears and reverse gears, as well as the GCU drive, through gear 26.

In the rear part of the intermediate shaft 32 (Fig. 7), a sliding gear 23 is installed on its splines - the drive gear of the first stage of the range reducer.

Technical characteristics of MTZ 892

MTZ 892 (BELARUS 892) is a class 1.4 tractor with a semi-frame frame, the nominal traction force is stated at 14 kN. The frame is semi-framed. The front wheels are driven and steered, the rear wheels are driven. Wheel formula – 4×4. The vehicle speed can reach 36.6 km/h, reverse – 5.36 km/h, and can ford up to 0.85 m.

The standard equipment of the tractor includes a 4-cylinder D-245.5 engine. The arrangement of the cylinders (their working volume is 4.75 l) is in-line vertical. The rated power of the diesel engine is stated at 65 kW, operational - 62 kW. Among the additional technical characteristics, we note the nominal crankshaft speed (it is 1,800 rpm). Preference was given to a combined lubrication system for the power unit: some parts are lubricated under pressure, the rest - by splashing. The diesel engine is started using an electric starter. The cooling system is closed type.

Maximum torque

11.2-20; 13.6-20; 360/70R20; 13.6R20

15.5R38; 16.9R30; 18.4R34; 9.5-42; 11.2R42

Load capacity of the rear linkage on the suspension axis, not less

Hydraulic tank capacity

The model is equipped with dry-type double-disc brakes. Trailer brakes are single-actuated pneumatic. A special feature of the MTZ 892 (BELARUS 892) is the front drive axle, which is equipped with bevel gearboxes. Additionally, it is possible to install a creeper, ballast weights on the wheels, and spacers for doubling the wheels.

Photo source: youtube.com, iron slavon Photo MTZ 892

The hydraulic mounted system is a separate unit. Control of the processing depth is power and positional; a mixed control system is available upon special order.

Maximum permissible weight

Overall length(without front ballast)

Cabin height

Front wheel track

Smallest turning radius

Agrotechnical clearance under the rear wheel sleeves

The maximum permissible weight of the MTZ 892 (BELARUS 892) tractor reaches 7,000 kg. The structural weight is significantly less - 3,900 kg. The distribution of operating weight across the axles is as follows: front axle – 1,370 kg, rear – 2,780 kg. The tractor can be used to tow trailed vehicles up to 9,000 kg. And such a technical characteristic as the load capacity of the rear linkage on the suspension axis exceeds 3,000 kg.

A few words about the electrical equipment of the tractor. The rated supply voltage of the on-board network, as well as the rated starting voltage, is 12 V.

Cost of the Belarus MTZ-892.2 tractor

The price of the new MTZ-892.2 tractor from official dealers of the Minsk Tractor Plant starts from 1,300,000 rubles. A used tractor of this brand, in good technical condition, can be purchased at prices ranging from 700,000 to 1,000,000 rubles.

On electronic bulletin boards there is also a large amount of additional equipment for aggregation with MTZ-892.2. Including front-mounted (loaders, hay blowers, etc.)

In general, the worthy technical characteristics of the MTZ-892, its advanced capabilities and low operating costs have provided the tractor with a well-deserved reputation as a reliable, economical and highly productive machine - both among domestic and many foreign consumers.

Since Belarus MTZ-892.2 will cope with large volumes of agricultural work on impressive acreage slowly, its “element” is small and medium-sized peasant farms.

Tractor MTZ 892 - areas of use. This type of human activity as agriculture has deep roots in the past. Previously, our ancestors did not have any technology, of course, all types of such work were performed by manual labor. Now, in our modern times, there are huge production facilities and wide areas of application of agricultural machinery , thanks to which manual labor was completely replaced by technical devices and machinery. One of these fruits of technical progress is the tractor model of the Minsk Tractor Plant - MTZ 892 . This is a universal type of agricultural machinery, thanks to which it is possible to perform multidisciplinary work in many areas of human activity. In particular, in agriculture it is able to take on a significant number of functions: this includes preparing the soil for sowing work, and cultivating and treating with fertilizers many crops, and it is also used in the harvesting process. On farms it is used to prepare animal feed.

Read also: Hidden recorder in a car

In the municipal sector, it is also widely used as a snow, leaf, debris remover in the areas of streets and parks, trench excavator and many other works. In forestry, it is used for transporting wood, harvesting wood, clearing sites and other various works of this specific nature. Also, the area of application of the MTZ 892 tractor is construction, where it carries out work on the transportation of building materials, loading and unloading work, cleaning and transporting garbage, etc. The tractor can perform all these types of work due to its good compatibility in the basic configuration with different types of attachments.

Gearbox diagram

The MTZ 892 (BELARUS 892) tractor is equipped with a manual step transmission. The number of forward gears is 18, reverse – 4. The clutch is a single-disk friction clutch, the type is permanently closed, the control is performed mechanically. The clutch is equipped with non-asbestos linings; metal-ceramic linings are available upon additional order.

Diagram of the MTZ 892 gearbox with an overdrive gearbox

MTZ 892 (BELARUS 892) can be supplied with a gearbox with a mechanical reduction gearbox. In addition, two more options are available - a synchronized reduction gearbox or a reverse gearbox.

Service

Every 10–12 hours (in shifts) you need to routinely inspect the machine for any malfunctions, fuel and lubricant levels. The tractor has special needs only immediately after leaving the assembly line (the need for initial running-in without a load) and when cleaning the machine, if its operation is interrupted for a long time. In this case, it becomes necessary to preserve the tractor: completely clean it, drain the fuel, and lubricate the parts. It is important that when servicing the tractor, only use fuel and lubricants of those brands specified in the operating instructions.

Main faults - repair

An experienced tractor driver can fix most minor breakdowns on the spot without taking the tractor to a service center. Mostly, malfunctions are associated with incorrect operation:

- untimely oil changes;

- lack of control over fuel level;

- lack of control over wear of parts.

MTZ-892 “Belarus”, as a rule, has a good build and a good supply of engine hours (5000). With timely maintenance and care, it can last much longer.

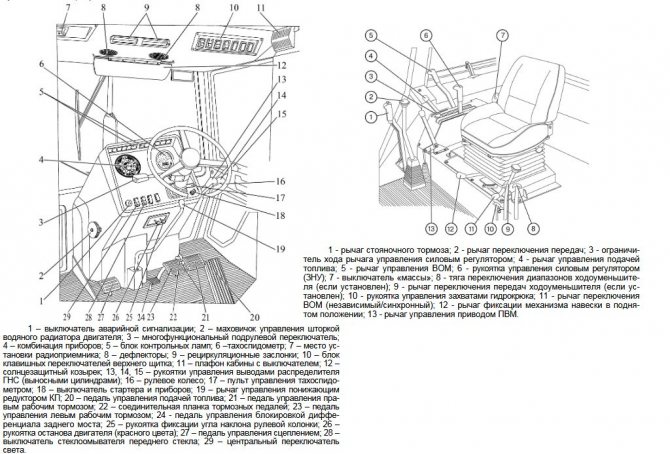

MTZ 892 controls

The steering of this tractor is hydrostatic. A gear power pump with a left-hand rotation direction is installed. As a turning mechanism, one double-acting cylinder Ts50×200 and a steering linkage are used.

Layout of controls in the cab of the MTZ 892 tractor

It is possible to supply MTZ 892 (BELARUS 892) both with a cabin (single-seat, with a rigid frame) and with an open awning. The tractor is equipped with various options, such as rear-view mirrors, windshield wipers, etc. It is possible to install a second seat.

Features of operation

The main “profession” of MTZ-892 is agricultural work:

- soil cultivation, plowing, harrowing;

- cultivation, watering and mowing;

- harvesting (especially row crops - corn, potatoes, melons, sugar beets).

"Belarus" is actively used in public utilities, construction, and transport work.

“Belarus” does not have any critical features. This is a real “workhorse” - low maintenance, showing good performance and very passable. The 892 has larger wheels than its predecessors, so it's more gentle on the soil and can handle almost any slippage.

Another positive property of the MTZ-892 is its ability to work in almost any weather conditions. If cars of earlier years were difficult to start in cold weather and this was not always possible, then Belarus can work even in unfavorable climates. If it is still difficult to start it in winter, the issue can be solved by using a heat-retaining cape. With proper care of the tractor, it will be able to transport heavy loads in any weather and on any road.

Video

The MTZ 892 tractor produced by the Minsk Tractor Plant is a modification of the legendary version MTZ 82, which has been produced since 1974. The technical characteristics of the MTZ 892 included in the design make it possible to use it not only in agriculture, but also in other industries where there is a need to use universal vehicles with increased cross-country ability.

The Belarus 892 MTZ differs from the base model in the following parameters: the presence of a turbocharged engine with an intercooler, which increases the torque of the power unit by 30%, an installed MTZ synchronized gearbox, and an increased standard size of standard tires.

Analogs

This group includes MTZ tractors of modifications - 82.1, 82.2, 82.R and a number of others. From the import list, American prototypes of the John Deere 6 Series, as well as several models of Chinese tractors of the Photon and Dong Feng brands, have identical characteristics.

The demand for American cars is limited by the high cost of the tractors themselves, consumables, and maintenance. The quality and durability of more affordable Chinese cars, which remain idle for a long time due to a lack of spare parts, leave much to be desired.

Read also: DIY Niva 2121 suspension lift

Characteristics of the main units of MTZ 892

Engine.

The Belarus 892 tractor is equipped with a D-245.5 engine. This diesel four-cylinder power unit with a turbine has a power of 65 hp. With. and volume 4.75 l. The engine is water-cooled, has a fuel consumption of 225 g/kW hour, and a rotation speed of 2200 rpm. The fuel supply is located in a tank with a volume of 130 liters.

Transmission and chassis.

MTZ 892 is an all-wheel drive agricultural vehicle, in which a self-locking differential is used in the design of the front axle. It has three technical operating options: off, on and automatic. The differential is automatically engaged in cases of slipping of the rear wheels of the tractor. Another feature of the rear wheels is their ability to double, which increases cross-country ability and stability. The ground clearance of the 892 is 0.65 m.

The transmission uses:

- manual transmission;

- clutch;

- brake system;

- power take-off shaft (PTO).

The MTZ 892 gearbox is made in a 9-speed version, with a multiplier. The clutch is used in a dry and single-disc version. The PTO operates in two modes: independent and synchronous.

Hydraulic system

MTZ 892, a tractor that is equipped with a hydraulic system of a separate aggregate type and is equipped with a hydraulic lift. The design features of the system include duplicated outputs for the rear hydraulic lift.

The rear linkage has a lifting capacity of 3.2 tons. The highest pressure in the system is 20 MPa. The hydraulic system gear pump capacity is 45 l/min, and the oil tank capacity is 25.5 l. The hydraulic distributor used is made in three sections.

Cabin.

The cabin installed on the 892 model provides high comfort and safety for the operator. It has good visibility (360 degrees), is equipped with a technical system for air filtration, heaters for operation in the cold season, glass washers, electric windshield wipers, a convenient instrument panel, and the ability to open side windows. The operator's seat is spring-based and allows for adjustment. The steering column can also be adjusted for ease of control.

Main technical characteristics

For MTZ 892, technical characteristics and design properties provide high functionality and versatility. The characteristics have the following parameters (except for the parameters already indicated in the data of the main units):

- Dimensions:

- Base – 2.44 m.

- Length – 3.97 m.

- Width – 1.97 m.

- Height – 2.85 m.

- Common data:

- Weight – 3.90 t.

- Turning radius – 4.10 m.

- Load capacity – 3.20 t.

- Soil pressure –140.0 kPa.

- Movement speed:

- The smallest forward is 2.10 km/h.

- Lowest reverse – 5.35 km/h.

- Maximum forward – 36.60 km/h.

- The highest back is 10.25 km/h.

Advantages and disadvantages of Belarus 892

The main advantages of MTZ 892 include its versatility and multifunctionality. This is achieved due to its technical characteristics, design features, convenient switching scheme and rearrangement of additional equipment. All this allows him to work together with more than 50 different types of equipment. The main units of such trailed, mounted and semi-mounted equipment should be considered:

In their reviews, owners often indicate the following positive characteristics of the Belarus 892:

- comfortable cabin, unified with the MTZ 622 tractor (installation of an air conditioner is additionally possible);

- long engine life (5000 h);

- comfortable entry and exit from the cabin;

- general reliability inherent in the design;

- high cross-country ability;

- a successful electrical circuit that ensures reliable operation of all electrical equipment;

- good maneuverability and controllability characteristics;

- good maintainability due to the availability of spare parts, a detailed operating manual for the MTZ 892 and a description of the technical systems used;

- economical technical characteristics during operation;

- Possibility of year-round use.

Among the shortcomings, the owners identify and describe the following points:

- difficulties starting the engine in winter (can be eliminated by using a special heat-retaining cape on the tractor);

- lack of a technical device in the hydraulic system for cleaning and cooling hydraulic oil;

- inconvenient location of the differential lock switch

Purchase of Belarus 892

It is better to purchase new MTZ modifications 892 and 892.2 in the showrooms of official dealers. This is due to the following advantages:

- lowest cost;

- obtaining warranty and post-warranty service;

- possibility of purchasing on credit or in installments;

- simultaneous purchase of the necessary additional equipment for the tractor

The cost of the new Belarus 892 starts from 1.25 million rubles.

Price

Since the Belarus MTZ-892 was supposed to be a mass development, much attention was paid to ensuring that its design was as economical as possible. Now this machine is quite expensive for a private individual, but acceptable for a company engaged in land cultivation or construction.

The cost of a new MTZ-892 varies depending on the modification from 800 to 1,500 thousand rubles, but a used tractor can be bought even for 300 thousand.

Despite the cost, MTZ-892 fully pays for itself, since it can operate almost uninterruptedly for many years and even decades.