The air entering the compressor contains water vapor, impurities - oil vapors, dust, industrial gases. In compressed air their concentration increases.

In compressor units, air dryers are used to separate impurities - filtering water, oily, greasy or aggressive condensate.

The volume of condensate at the compressor outlet depends on the temperature of the intake air, humidity, and its quantity. To generate 1m3 of compressed air (10 bar), the installation requires 11 m3 of atmospheric air.

Working principle of a home dehumidifier

Schematic diagram of the dryer device

The operation of the device is based on the condensation effect. Humid air is forced into the device, where it is driven through two heat exchangers. In the first, it is cooled to the “dew point” (the temperature at which moisture in the air turns into condensation). In the second, it is heated again and returned to the room. In this way, the air is dehumidified without affecting its temperature. The collected liquid can be drained using a drainage pipe, or collected in a special container, which must be emptied periodically. Productivity is measured in the amount of liquid extracted by the device from the air per unit of time (usually in liters per day).

The design of an air dryer varies depending on its power and performance. There are adsorption, freon and combined types of structures.

Freon (condenser)

Once inside the device, moist air is cooled by passing through an evaporator filled with refrigerant (freon). A sharp temperature change converts excess moisture into condensation, which settles in a special container. Next, the cooled air flow enters the condenser, where it is heated. Condenser dehumidifiers are most often used in rooms with small cubic capacity, apartments, and offices.

Adsorption

The main element of this type of dehumidifier is a rotor coated with a substance that effectively absorbs moisture. Two air flows pass through it without intersecting each other, due to the use of special seals. The first is dried air, from which the adsorbent absorbs liquid. The second is a regenerating air flow, which dries the water-saturated adsorbent, returning its moisture-absorbing properties. The process of absorbing moisture and drying the sorbent takes place continuously, which distinguishes this type of dehumidifier with high productivity.

Combined

It is a combination of freon and adsorption-rotary type designs. Its peculiarity is that the air goes through two stages of drying. First, it is cooled to the “dew point”, then undergoes adsorption, heating, and returns to the room. Thanks to the use of two drying methods at once, the productivity of such a device is very high, and the moisture-absorbing sorbent can last up to 10 years. Typically, dehumidifiers of this type are used in large industrial and warehouse premises.

Compressed air dryers

Compression of air in a compressor unit is accompanied by its heating with subsequent formation of condensate. A separator is standardly used to separate moisture before releasing air to the consumer. However, in most cases it is not enough.

Additionally, special equipment is installed - compressed air dryers.

Depending on the operating conditions, purpose, and performance of the compressor, compressed air dryers use 3 basic drying principles:

- Assimilation;

- Absorption;

- Condensation.

The assimilation type of dehumidifier works based on the property of warm air to contain more water vapor relative to cold air. They have low efficiency at the same time as low efficiency and high energy capacity. The result of this type of work depends on air temperature, humidity, etc. (exposure to atmospheric conditions). The operation of such equipment in conditions of high humidity is difficult or impossible.

The condensation type of dryer works based on the phenomenon of vapor transition from gas to liquid. The main element is the refrigerating condensing chamber. Cooling in it, the air reaches the dew point temperature and condenses on the walls of the chamber.

The efficiency of the condensation type dryer is higher than the assimilation type. The disadvantage is that efficiency decreases as the incoming air temperature decreases.

The adsorption type of dehumidifier works on the principle of adsorption - the absorption of moisture by an absorbent substance. Able to work at low temperatures and high air humidity.

In addition, additional compression . The air is compressed even more, forming condensation. After this, the air expands to operating values. The dew point with this method can reach -60°C. The main disadvantage of this method is its high cost.

The vortex type separates water from air by creating vortices in a chamber. The air swirls after passing through the blade impeller. Centrifugal force pushes moisture particles onto the walls of the housing. Moisture condenses on it, flows to the bottom, from where it is removed through the plug.

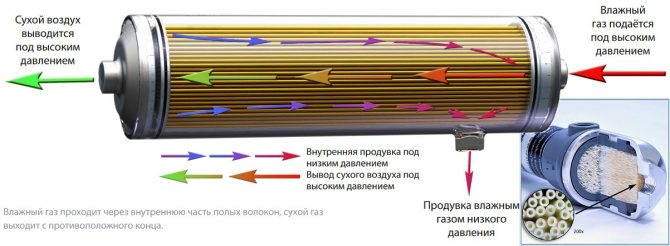

Membrane compressed air dryers

Membrane compressed air dryers differ from other types of water separators in their operating principle. The device reduces air humidity without lowering the temperature to the dew point.

The membrane dryer contains a large volume of bundled fibers made from Flemion fluorine resin. Fibers can be placed in:

- Bidirectional cassette module;

- Flexible pipe;

- Cylinder.

Air passes into the inlet, through a porous or monolithic structure, leaving water or nitrogen molecules on them. Vapors pass through membranes from a high-pressure area to a more rarefied environment. Dry and humid air is used for work.

The amount of vapor inside the cavity begins to exceed the amount on the outside of the membrane, after which the fluoride fiber releases the vapor to the outside. In this way, the vapor concentration is balanced.

The released water molecules are carried away by the air flow from the outlet of the membrane cavity. Expanding in the outer cavity of the membrane, it creates a flow, carrying moisture away from the desiccant.

Membrane compressed air dryers have the following advantages:

- No electricity needed;

- Relatively small size;

- Quick installation/replacement;

- No moving parts;

- Can work in aggressive, dangerous environments;

- Slight pressure drop.

Flaws:

- Low bandwidth;

- Not used for highly contaminated gases.

Compressed air adsorption dryers

In conditions where it is impossible to use dehumidifiers with a dew point of +3°C, adsorption compressed air dryers are used. The dew point temperature range of such installations is from -25°C to -70°C. The moisture-absorbing element is an adsorbent - a substance with a large surface area. The installation consists of two tanks - for drying and regeneration, respectively.

There are two types of adsorption dryers:

- With cold regeneration;

- With hot regeneration and vacuum cooling.

enters cold regeneration dryers through a pre-filter of 0.01 microns. The air passes through a container with an adsorbent (silica gel), freeing itself from some of the moisture. In it, the air is cooled to a certain dew point temperature. About 15% of the dried air is transferred to the second tank (regenerating).

The moisture accumulated by the adsorbent is carried out into the atmosphere by dry air. After the first tank gets wet and the second one dries, the compressed air is redirected between the tanks. The process is repeated cyclically.

Hot regeneration dryers are cheaper to operate when preparing large volumes of gas with low dew point temperatures (up to -70°C). After passing the first tank, the air is heated to the dew point (-40/-70°C). Regeneration of the second tank is carried out by atmospheric air drawn in by a vacuum pump and a heated electrical element.

Otherwise, the operating principle of this type of adsorption compressed air dryer is similar to the first type.

Which dehumidifier is suitable for the garage?

There are special models for garages

First of all, it is important to take into account the presence of heating, because... if the temperature inside your garage does not drop below +15 C, you can safely purchase a household condenser dehumidifier (at lower values the device will be ineffective).

Also, when choosing a dehumidifier for a garage, you need to select a capacity that matches the cubic capacity of the room. This will help you avoid purchasing a device that is too “weak” or overpaying for a device that is too powerful.

Attention! To save yourself from the need to regularly empty the container of collected liquid, choose a model equipped with a water drainage system. After all, if the container overflows, the device will automatically stop working.

For unheated rooms, the best solution is a desiccant dehumidifier. It can effectively process rooms with a large area, any level of air humidity (from 2 to 100%), and its operating temperature range is from -20 C to +40 C. They are reliable and durable. At any time of the year, the device will effectively remove moisture and dampness, prevent the occurrence and development of corrosion on metal parts and structures, extending the life of the car, as well as the contents of the garage as a whole.

DIY air dryer diagram

Below we will look at how to make a simple and budget-friendly adsorption dehumidifier at home.

Materials

- Two identical plastic bottles with a volume of at least 2 liters.

- Wire or knitting needle.

- Silica gel (250-300 g). It will absorb moisture.

- A small fan, for example, a cooler from a computer.

- Scotch.

Assembly of the structure

- At the bottom of one of the bottles you need to make holes with a hot knitting needle or wire.

- Then cut it into two halves. Make several holes in the upper half; silica gel will be poured here.

- Screw the lid on.

- Place the top of the bottle in the bottom, neck down, and fill it with silica gel.

- Cut the second bottle, we only need the bottom part. Secure the fan at a distance of 10cm from the bottom. It must drive air through the adsorbent.

- Connect the parts of the desiccant by placing the part with the fan above the part with the adsorbent. Secure with tape.

Having figured out how to triple a dehumidifier, you can assemble a silent and fairly effective dehumidifier from scrap materials. Silica gel that has absorbed moisture does not need to be replaced with new materials; it is enough to dry it to restore its absorbent properties.

Alternatively, in places with constantly high humidity, for example, in the bathroom, you can simply place a container filled with silica gel so that the moisture is absorbed naturally. However, you should not expect this method to be highly effective in solving the problem of high humidity in your home.

How to choose the right room dehumidifier

Pay attention to the size of the container where the condensate will collect

In hardware stores and in retail stores there is a fairly wide selection of models of household dehumidifiers. They have different characteristics, design, size, installation method and, in addition to dehumidification, are supplemented with other skills that are useful in everyday life. How not to get confused and buy exactly the device that you need? To make the right choice, you should consider the following parameters when purchasing:

- Device power. The productivity of freon dryers varies from 10 to 40 liters per day. As a rule, the manufacturer indicates in the instructions the area of the room for which the power of this device is designed. This also includes the amount of electricity consumed.

- Water drainage system. Typically, dehumidifiers are equipped with a drainage system or a container to collect condensate, some with both. When choosing a model with a reservoir, remember that the collected liquid will need to be poured out regularly, otherwise the device will stop working. Choose a container size that is convenient for you.

- Operating temperature range. It is important to pay attention to this, because... not all models are effective at low room temperatures.

- Additional functions (the price of the device will depend on their availability: air purification, ionization, aromatization; the ability to select an operating mode; built-in hygrostat, which allows you to constantly monitor the humidity level, reduced noise level, automated control, etc.

Please note that you need to take into account individual factors: temperature, humidity level, its sources. A properly selected dehumidifier will become an indispensable assistant in the fight against excess humidity and help create a comfortable microclimate in your home.

Repair prices

| Site visit and diagnostics in Moscow | 4000 rub. |

| Refrigerant charging | from 12000 rub. |

| Soldering the Schroeder valve | 1000 rub. |

| Evacuation of the refrigeration circuit | from 1000 rub. |

| Finding Freon Leaks | from 3000 rub. |

| High pressure nitrogen testing | from 6000 rub. |

| Removing/installing the fan motor | 3500 rub. |

| Compressor replacement (work) | from 12000 rub. |

Prices are for work ; the cost of spare parts and consumables is taken into account separately and depends on the manufacturer and type.

We draw your attention to the fact that this site under no circumstances constitutes a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation.

Prices on the website are provided as reference information and depend on factors such as:

- Equipment Manufacturer

- Availability of access to equipment

- Complexity of work

- Number of pieces of equipment, etc.