Rostselmash will present highly efficient agricultural machines to Saratov farmers

On August 13 and 14, a large-scale “Field Day” will be held at the experimental fields on the bypass road between the Solnechny and Yubileiny microdistricts. Saratov-Agro 2020.” The Rostselmash company is taking part in this significant event for the region’s agro-industrial complex. The leading manufacturer of agricultural machinery will present a wide range of manufactured agricultural machinery and equipment for rural areas at the expo site.

At the company’s stand, farmers and exhibition guests will be able to get a detailed look at the models popular among agricultural producers.

Among them is a wide range of powerful and high-performance tractors:

— RSM 340; — RSM 2375; — RSM 3435; - DT 570.

Farmers will also be able to get detailed advice on the Rostselmash RSM 2375 tractor, which since April 2020 have increased warranty coverage - 2 years, or 2,000 engine hours (regardless of the production date).

At the Rostselmash exposition, a grain harvester will be presented - ACROS 585 with a universal rowless harvester of the Sun Stream series, designed to maximize the productivity of the combine when harvesting sunflowers. Also on site will be a wide range of trailed and mounted equipment that has long proven itself: roll and square balers, a grain thrower and a fertilizer spreader.

“We have been working with the Rostselmash company not long ago; based on feedback from colleagues, we have heard a lot about the high productivity and reliability of agricultural machines. This year we made a decision and purchased two Rostselmash RSM 2375 tractors. The equipment meets all the declared characteristics. I would also like to note the ease of its maintenance. I will not leave the official dealer of Rostselmash, the Agrosoyuz-Market company, without attention, thank you for the responsibility and efficiency, we were satisfied with the work. We will definitely visit the field day and the Rostselmash stand,” said the chief engineer of Avangard-Agro, Eduard Akbulatovich Ibrashov.

“By tradition, I visit the exhibition every year, the quality of Rostselmash equipment is excellent, the whole team performs its functions perfectly, I am very glad that I have this company’s equipment on my farm,” added the head of the peasant (farm) farm Agalarov Musaib Tagirovich.

During all days of the exhibition, a series of meetings with partners, heads of district administrations, agricultural enterprises, as well as consultations for farm specialists on the most optimal choice of a line of equipment, taking into account specific agricultural technological conditions, and effective settings of agricultural machines that ensure their maximum productivity are planned at the Rostselmash stand.

Rostselmash in 2020 will produce 100 seventh class combines

LLC "Combine" in 2020 will produce about 100 seventh-class combines - RSM 161, director of the company's marketing department Prokhor Darmov told the agency at the ceremony of launching conveyor production of the new model. According to him, 25 combines have already been produced and have customers, the remaining 75 units will be produced by the end of the year.

Photo: ITAR-TASS

According to Darmov, in 2020. The company estimates the projected demand for this model at 200-400 cars. “The goal is to double the number of harvesters produced every year over the next four years. Our conveyor can easily produce 5.4 thousand RSM 161s per year in one shift without any problems. But we must understand that the market does not yet need so many seventh-class machines,” he explained.

The amount of investment in the development project of this model is not disclosed. According to Darmov, the cost of one car is around 12 million rubles. The cost of owning a new model (consisting of the cost of purchase, maintenance, maintenance and the price of fuels and lubricants) is 75% lower than its foreign analogues. Of the 25 combines of this model produced, two remained in the Rostov region, one was sent to England upon request, and the rest were sent to other regions of Russia.

“This equipment will also be supplied for export. There are already preliminary applications. If we talk about orders for early models of Rostelmash equipment, then today the export growth has already doubled compared to last year. We expect to continue this trend,” said Denis Manturov, Minister of Industry and Trade of the Russian Federation, who was present at the conveyor launch ceremony.

RSM 161 is the first machine of the new global Rostselmash platform. In the medium term (until 2020), the company plans to develop and launch at least five more combine harvester models. The RSM 161 is capable of harvesting over 2 thousand hectares of arable land per season, its productivity reaches 45 tons per hour, which, according to company representatives, makes it one of the most highly productive combines in the world. In addition, this is the first combine harvester with a double-drum threshing system in the company’s model line. The machine was developed under a government contract, with the Ministry of Industry and Trade of the Russian Federation as a co-investor.

According to the acting governor of the Rostov region Vasily Golubev, the new model will in the future be included in the program of providing subsidies to agricultural producers from the regional budget in the amount of 20% of the cost of purchased agricultural equipment produced in the Rostov region. Over the 5 years of the program, a little more than 1 billion rubles were allocated for these purposes, of which 800 million rubles. — for the purchase of Rostselmash equipment.

Rostselmash plant – excursion

A great overview of the Rostselmash plant - the pride of our city, the largest and greatest plant not only in Rostov-on-Don and the region, but throughout the whole country! A complete story about the enterprise, its history, impressions after the tour and its current state. All this and a huge number of other interesting things inside the post:

A chidhood dream

Many Rostovites would like to visit this great plant, it will be said not without a joke - precisely as tourists, not as workers. So I had a childhood dream, to visit the factory, the walls of which are located right in front of my house, with a huge number of memories about it...

I remember that even in my youth we climbed over the fence into the territory of the plant, although this was a dangerous task, especially getting under the wheels of combine harvesters, but children’s interest always prevailed. With glowing eyes, the size of which were five rubles each, they looked into the cracks and holes in the fence, watching how huge green colossuses drove around the plant. We climbed into an abandoned overhead bridge (which I’ll tell you about later), almost every day we visited abandoned workshops, which at that time replaced a home for the children of our yard. Because of all these reasons, getting to the factory already in official uniform was a small dream of mine.

By the way, it will be said that when I asked to go on a tour, I was completely ignored. On the phone there were eternal “we don’t know anything, this is not for us, we don’t work here.” After a long search for “who to even ask,” I got pretty tired of it, so I decided to go to the plant administration and ask directly - how can I get on the excursion?

Who seeks will always find. There was a man who introduced himself as the organizer of excursions around the plant. During the conversation, he explained to me simple and not entirely joyful things for me: the excursion is only for a group of at least 10 people, united by one educational institution or some company. Not only did I now have to look for 10 volunteers, but I also had to collect certificates proving that we were all from the same educational institution, which was already quite difficult. Having spat on all this, I went home, postponing my dream for several years.

After some time, the organization of excursions to industrial Russia appeared, the plans of which included our city of Rostov and the Rostov region. Unfortunately, the list of enterprises was unknown, but knowing that they could not miss Rostselmash, the main plant of the city, I hoped for an invitation. In the end, I received it, and the visit to the factory that I had so dreamed about was also confirmed. So, I was once again convinced that dreams come true, you just need to put effort into it and wait a little.

Excursion

Having met our guide, I experienced the power that I had already seen him somewhere... After a while, I remembered that this was the same person whom I had been looking for for so long regarding the excursion (see the beginning of the blog).

“Now you won’t get away from me,” a thought involuntarily flashed through my head.

Soon we were allowed through the checkpoint, where we boarded our bus and began a walk around the plant. By the way, it will be said that the territory of the plant is almost 90 hectares, so it will not even be possible to travel around everything in one day, but nevertheless we managed to inspect as much as possible.

Our first location was a kind of museum of RSM equipment. Combine harvesters and other equipment produced by the plant in various years were presented here. I was pleasantly surprised by the truly dear Niva and Don 1500, as well as such rarities as Stalinets and many others.

Canadian Buhler-VERSATILE tractors produced by RSM:

"wheels" of the giant:

Vector 410:

Behind the new equipment there is a number of ancient combines, from the very first ones to the native Niva. It is these exhibits that cause some special interest and surprise, old school!

Stalinets-1, manufactured in 1947:

“luxury” of the control cabin:

and here is where it all began:

It’s surprising that the controls used to be not a steering wheel, but a kind of “steering wheel”, as well as just two pedals:

dear Niva:

Next to the museum there is a small parking lot of new Nivas, which have just arrived here from the assembly line. Apparently the main parking lot is already full of unsold combines, so they are being stored anywhere:

spraying machine models:

While everyone is busy climbing the combines, I accidentally noticed this interesting machine that I saw as a child:

Let's not focus on it and return to the museum. It may not be strange, but inside the combine harvester cabins it’s quite cozy. If here we were not allowed to sit inside, then directly inside the workshops we were still allowed to do so. It’s comfortable to work on a combine now, not like 30-40 years ago:

The girls also found something to do:

It was nice that you could look at all the exhibits with your own eyes, and also sit “at the helm.” The guide reminded us that time is not rubber, and there is still a lot to see, after which we got on the bus and drove on.

The next place was a warehouse. A separate word needs to be said about it - it was completely designed and built by the Germans, no matter how strange it may be. The scale really surprises him: if anyone has been to any other warehouse, imagine the same one, only on the usual shelves there are engines, wheels almost two meters high and much more. At the same time, the height of all racks is about 3-4 floors:

Due to such a huge height and size, special equipment is used here, and the building is also connected to the railway line.

special equipment for unloading and loading, also German:

After telling us how nice and cool the warehouse is (they need to at least somehow praise themselves), we went back out onto the street to continue the journey. On the way to the workshops, I managed to capture this pipe:

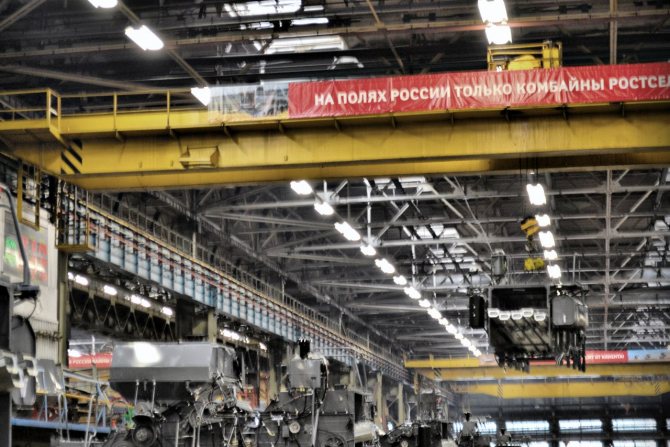

Our further path lay in one of the workshops where combine harvesters are assembled together. It was divided into new and old (divided into the condition of the workshop - repair, date of construction). Along the way, we constantly came across racks like these with “stamps” on them. These stamps were needed for the manufacture of a certain part - after all, the plant used to have old technologies, now all this has been replaced with more modern ones, and the old ones stand on the street, slowly rusting and taking with them the spirit of a bygone era:

Inside the workshop there was unprecedented noise and din from the boiling work, so, as with previous excursions, it was useless to listen to the guide (only if you were close). As usual, I chose my option - a visual inspection of everything. The scale of the workshops is very impressive; I have not seen such huge buildings for a very long time.

The large number of non-Russians immediately catches your eye... There are so many of them at the plant that I thought, “We’re probably a monkey with a grenade on a Tajik harvester.” I was sad and funny, it seemed like a laugh with a laugh, but then the product would come out like that – “funny.”

Then everything was better, but here’s another minus: almost all the buildings were very dilapidated and old, the plant needs urgent repairs, although everything inside is really at a high level.

After that, we were shown laser cutting, which is carried out by 18 devices, their total cost is about 43 million dollars, isn’t it an impressive amount? - Only we hear “German” again...

I was really surprised - during two days of traveling around factories and enterprises, all I heard was: German, German, German. There was a feeling that Germany won the Second World War and we are now working only for them.

another imported machines at the plant:

Walking through the plant, I paid special attention to the workers. They were all covered in fuel oil and dirt, and their hands were covered in huge work calluses. Among all this, their eyes were barely noticeable - full of melancholy and sadness. My whole family worked at this plant at one time, they were all proud of it at one time, but what now? - One disappointment. The well-known case of non-payment of wages forced my brother to quit the plant, who did not last even half a year here.

So far, there are still RSM combines in the fields of Russia, but what will happen next?

As far as I know, RSM has huge problems, what was the cost of the global crisis - when hundreds of worthy workers were fired... Empty promises are also offensive! Promising mountains of gold, easy work - all the “fools” who come here get exactly the opposite... - Only those who are especially persistent stay here, persistent both morally and physically. Or maybe there is no other way out?

huge and long workshops of the plant, the end and edge of which were not visible:

There was also one curious incident, or rather funny, from which all the participants in the excursion almost fell down laughing: our guide, telling regular fables “how wonderful everything is here,” began a story about wages, where he mentioned such figures as “the minimum salary is 20 thousand . per month". Having said these words, the worker behind him shouted the phrase “Don’t believe this motherfucker, I barely make five thousand!” That's it…

The time has come to say goodbye to the workshops in order to visit the factory canteen, to which we were never shown. As it turned out, it was already closed, although knowing its schedule, it should still be functioning. - Apparently, here too they were ashamed to show what they had left after the Soviet Union...

At the very end of the excursion we were invited to look at the painting rooms, the interest of which was reduced to zero. But on the way to them there were many other pleasant things, namely, a large number of living creatures: there were pigeons and cats, and somewhere there was even a dog running...

painting details:

Source