A firefighting vehicle of the gas and smoke protection service delivers combat crews and anti-tank equipment to the fire site and ensures the operation of gas-smoke protection units in a gas-polluted environment. It is the basic unit when deploying a gas monitoring station with additional lighting of the accident site and supplying electricity to the electrical equipment being removed.

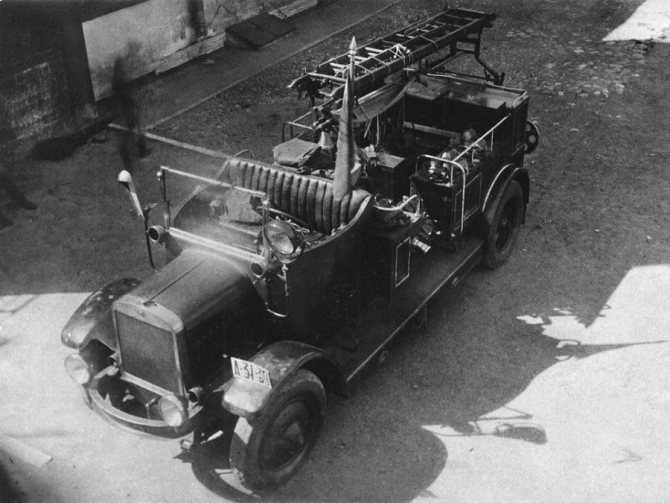

The first fire trucks for gas and smoke protection service in garrisons appeared in the 30s of the 20th century. The ZIS-5 was chosen as the base for them. It was a car with an open cabin. The equipment was adapted to allow up to 10 people to travel to the accident zone, which was equivalent to two units. The equipment used was: KIP-3 insulating gas masks, flashlights, entrenching tools, smoke refillers, as well as a novelty of that time - artificial respiration devices.

In the post-war period, vehicles on the improved ZIS-5 and GAZ-AA chassis entered service with the domestic GDZS. They received a closed body, which allowed them to expand the functionality of the vehicle. The gas and smoke protection service used not only AG fire trucks, but also adopted GAZ 03-30, ZIS-8, ZIS-16 buses. There was even a captured Mercedes-Benz in the Moscow garrison.

A specially designed smoke-protective firefighting vehicle appeared only in the 50s. The basis for it was the ZIS-150 chassis. It was equipped with an electric power plant, transformers, a spotlight, a smoke exhauster and electric saws. For decades, the equipment remained unchanged: it was later equipped with the ZIL-164.

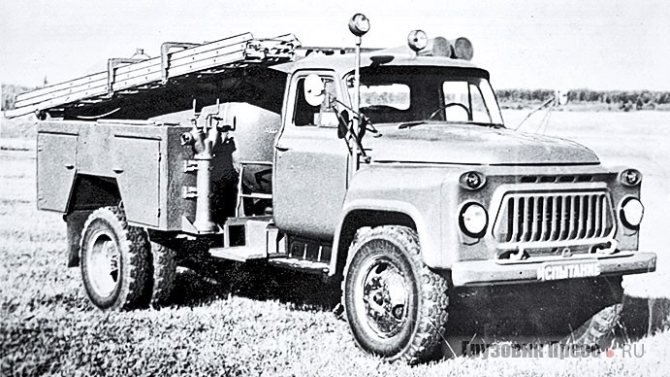

Only with the advent of the ZIL-130 did the re-equipment of vehicles take place. From 3 to 5 spotlights and two smoke exhausters appear. A real breakthrough was the serial production of AG equipment, since previously all samples were homemade. The most popular car was the AG-12 (130)-198. As equipment, he received a body from the 127 model, as well as a supply of oxygen cylinders, PD-14 smoke exhausters powered by the Druzhba gas-powered saw drive, a backpack autogen cutting unit, a signaling and intercom device, and an electric drive tool.

Gas and smoke protection service vehicles were also produced on the basis of PAZ-672 and PAZ-3205 buses. The most widely used buses are ZIL-Bychok.

From simplified to real

In 1970, at the Arzamas Municipal Engineering Plant, on the basis of documentation developed at the Pozhmashina Design Bureau, a prototype fire tanker of a simplified design ATSU-30/53A/-152 was built, designed to deliver a reduced combat crew of three people to the scene of a fire. -technical weapons (PTV), a supply of fire extinguishing agents (2600 liters of water + 150 liters of foaming agent). With such equipment, the vehicle, of course, had all the capabilities to extinguish a fire. This could be done in three ways: with water from a tank, from a reservoir or from a hydrant, or with air-mechanical foam.

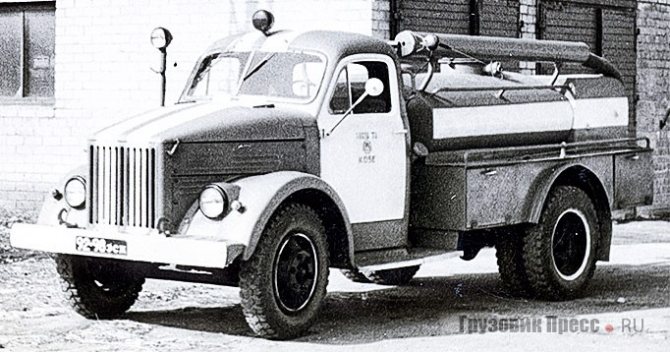

This machine was supposed to replace the ATsU-20(51)-60 in small settlements, which was produced by Vargashinsky from 1962 to 1968. Some design ideas contained in it were later embodied in the ATs-30 (53-12)-106G model .

Fire tanker

ATs-1.6-10 (GAZ-66) high cross-country ability with a 4x4 wheel arrangement, equipped with a fire pump PN-1200LA is intended for:

- extinguishing fires with fire extinguishing agents;

- delivery of combat crews, fire-fighting equipment and a supply of fire extinguishing agents to the fire site;

- supplying water and air-mechanical foam of low and medium expansion through pressure hoses and hand nozzles when extinguishing fires.

Tank truck

can be used as an independent combat unit with the intake of foam concentrate from a foam tank or external reservoir and the intake of water from a tank or reservoir. The tank truck is designed for operation in areas with a temperate climate at ambient temperatures from minus 40 to plus 40°C.

Tank truck

consists of the following main parts:

- chassis;

- pumping unit with drive;

- tanks with foam tank;

- water and foam communications;

- vacuum system;

- body;

- pneumatic system;

- additional electrical equipment;

- control systems;

- set of fire-technical weapons.

The modified chassis is equipped with: a fire pump drive, a pump, a tank with a foam tank, a vacuum system, a pneumatic system, a body, a control system and some electrical equipment.

The body compartments contain anti-tank equipment and electrical equipment elements.

Tank truck

equipped with a loud-speaking alarm system SGS-01 “Corvette”.

The main work of the tanker is to supply water or air-mechanical foam to the fire source with the help of existing equipment and accessories until the fire is completely extinguished.

The fire pump is driven from the chassis engine through a power take-off and a cardan drive.

The initial filling of the suction line and pump when drawing water from a reservoir is carried out by a gas-jet vacuum device built into the exhaust system of the chassis engine.

Tank truck

can perform the following operations:

- supply the foaming agent solution from the container;

- supply water from a tank or reservoir;

- work to pump water with other tankers at a significant distance from the reservoir to the fire site.

The electrical equipment of the tank truck consists of chassis electrical equipment and additional electrical equipment.

The tanker's consumers are powered by 12V direct current from the chassis' on-board network.

The electrical equipment of the tank truck consists of the following main components:

- in the body: control panel; compartment lighting lamps; work area lighting spotlight; terminal switch; license plate light.

- in the cabin: light-acoustic unit with beacons and speaker; spotlight; Control block; control panel for alarm acoustic installation; commander's lamp; circuit breakers; radio station connection socket.

Fire-fighting equipment on the tanker is located on the roof of the body and compartments. The PTV is securely secured with special mechanisms, clamps and other fastening elements. The PTV is placed taking into account convenient access and quick removal.

Realities of today

The start of serial production of AC-30 (53-12) - 106G coincided with the beginning of new economic realities that were difficult for the country, and therefore fire tanks, although they were in demand, with the transition to self-financing and self-sufficiency, many farms were content with what they had and were in no hurry to purchase new technology. This determined, among other things, the selective geography of their distribution. Thus, the RSFSR received the most of them, while other republics, for example, the neighboring Ukrainian SSR and BSSR, received several times less. Therefore, in the former Soviet republics they are very rare, and where they are preserved, they serve, as a rule, in the structure of the local fire department. Unlike other republics of the former USSR, they are still very common in the Russian Federation today. It is enough to type the request in any search engine: ATs-30 (53-12) - 106G to verify the validity of what has been said.

Some cars, after retirement, continue to work as water carriers or utility “emergency trucks”. The cars in the service of the water utility look very interesting. They are often painted blue or blue.

And some “106G” are even used as... vacuum machines - sewer trucks, judging by the ads on car sales websites. Others live quietly... And in order not to end the review of realities on such a sad note, I will say that according to information from colleagues from Siberia, they can see “106G-e” in the colors of the Ministry of Emergency Situations.

A further development of the 106G model was the appearance in the early 1990s of the new AC-30 (3307) - 226 on the GAZ-3307 chassis. The tanker was characterized by a tank enlarged to 3000 liters and the presence of a fire monitor.

Real fireman to scale

Two years ago, DIP models announced the launch of its “new line”: scale models of fire trucks on the GAZ-52 and GAZ-53 chassis. The first-born in this direction was the ACU-10 (52), and a year later the more advanced ACU-10 (53A) was shown. It is gratifying to note that it was on firefighters that innovations were introduced, which were then fixed on other DiP models. For example, more replica, made by photo-etching, brackets for exterior mirrors and bearings in the hubs of the front wheels became the basis for the “52” chassis, and the three-knee ladder was first shown on the special version of the ATSU-10 (53A), preceding its more widespread use in production of “deep” models.

History of Soviet and Russian fire trucks

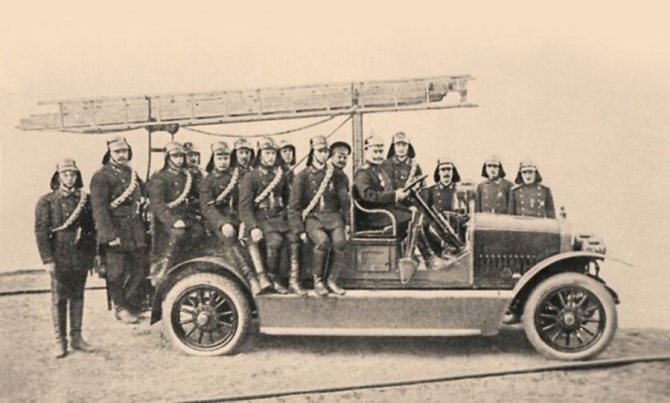

Moscow. Summer 1907. Along Myasnitskaya towards Lubyanka, a car with a ladder instead of a roof and firefighters in bronze helmets is rushing at a “crazy” speed - 20 versts per hour. A mustachioed fireman sits proudly next to the driver: he continually hits the ship’s bell, which has been polished to a shine... This is roughly what the first trip of a “horseless” crew to a fire in Moscow looked like.

Fire truck Lesner

In 1904, at the St. Petersburg factory of Peter Frese, the first Russian fire truck was built, equipped with a nine-horsepower single-cylinder French engine. The car had ten seats for the fire brigade, two wooden ladders, 170 meters of hoses and a stander - a column for installation on a water tap. On June 10, the vehicle was purchased by the Alexander Nevsky fire department and on the same day was used to extinguish the fire. As one would expect, the vehicle with the combat crew arrived at the scene of the fire a quarter of an hour earlier than the horse-drawn carriages. Thus began the era of the “red iron horses”: the car entered service in the fire department.

Pioneers of the Russian automotive industry - . Lesner and Puzyrev were actively looking for new clients and offering the fire department specially equipped vehicles of their own production. It was not only commercially profitable to produce fire trucks, it was a kind of promotional event: there were no car races in Russia, and fire trucks - bright, loud and fast - were an excellent “advertising on wheels.” However, domestic automakers were already losing to foreign competitors in productivity and, consequently, in production costs. In Tsarist Russia, it was more profitable to import cars than to build them ourselves. Therefore, vacant positions “in the service of the Tsar and the Fatherland” were occupied mainly by cars of French and German brands.

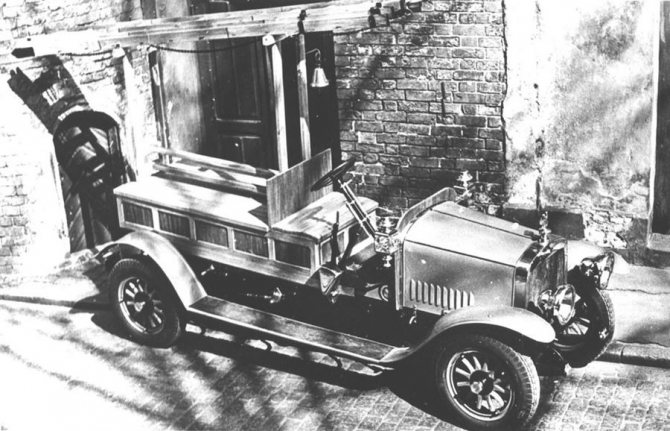

Russo-Balt D24-40

Even the country's largest Russian-Baltic Carriage Works (RBVZ), which mastered the production of fire trucks shortly before the First World War, was not able to radically change the situation. The history of the very first RBVZ fire line is indicative in many ways. The Russian-Baltic type D24-40 car was presented at a car exhibition in St. Petersburg in May 1913. From the capital he went back to his “small homeland” - to Riga, at the disposal of the Petrovsky Voluntary Firefighting Society. With the outbreak of the First World War, cars were mobilized, and the first “pozharka” was converted into a mobile first aid post. With a red cross on board, she was sent to the front line, which was just a stone's throw from Riga. At the front, her traces are lost. Looking ahead, we note that 65 years later, a team of enthusiastic trackers restored the scarlet D24-40 fire truck from original parts of that era: it received a registration in the Riga Automobile Museum.

Russo-Balt D24-40

Two revolutions and a civil war did not add new means of transport to the country. In 1918, on the initiative of the Moscow Council of Workers' and Soldiers' Deputies, the restoration and conversion of old decommissioned trucks into fire engines began, the shortage of which was extremely acute in the city. After the capital was transferred from Petrograd to Moscow, it was even more necessary to “keep up the brand,” so they tried to arm Moscow firefighters by all available means. As a result, by 1922, about thirty vehicles were in service in the city fire brigade - and this was for a population of two million! The importance of each fire crew was difficult to overestimate: firefighters were even honored to hold their own parades on Red Square.

Fire line produced by Avtopromtorg on a truck chassis from the Yaroslavl plant Ya-3

In 1925, it was created, specializing in the production of cars for the needs of the city. The plant, located on Miusskaya Square, produced rulers, car pumps, and mechanical retractable ladders. Soon the capital's car fleet was replenished with seventy more red cars from Avtopromtorg. They completely ousted the “old regime” horse brigades from the Moscow streets.

Firefighter AMO-F15

In 1928, the first Soviet model AMO-F-15, produced in Moscow, entered service with firefighters. The machines were equipped with rotary pumps capable of supplying up to 20 liters of water into the hoses every second. Three years later, the “tag” was replaced by a more advanced machine with a centrifugal pump - AMO-4. Soon it was replaced by the new powerful ZIS-11 - cars on the long-wheelbase chassis of the legendary three-ton ZIS-5.

Fire guide PMG-1 on GAZ AA chassis

The specialized fire trucks were simply called PMZ and PMG, which stood for “ZIS fire truck” and “GAZ fire truck.” Depending on the equipment installed on the vehicle, it was assigned an ordinal index. Thus, PMZ-1 and PMG-1 were rulers, PMZ-2 and PMZ-Z were autopumps with tanks. The fire service vehicle fleet grew with gas and smoke protection vehicles, searchlight installations, communication vehicles and carbon dioxide extinguishing vehicles. Stalin's master plan for the development of Moscow envisaged the construction of high-rise buildings, which were to be serviced in emergency situations by powerful and high-speed vehicles. With the beginning of the Great Patriotic War, it was PMZ and PMG that stood up to defend Soviet cities.

Fire truck on GAZ-63 chassis

After the war, it became obvious that it was necessary to delimit the “areas of responsibility” of PMZ and PMG vehicles, which differed significantly from each other in weight and carrying capacity. PMGs have found application in large cities, where the stairs must be higher and the pressure must be stronger, and simpler PMGs have been used in small towns and rural areas. Fire trucks created for the army, aviation, and oil production had their own specifics. There also appeared special off-road vehicles on the GAZ-bZ, ZIL-157, ZIL-131 chassis, airfield “firemen” on the chassis of multi-ton MAZs, Urals and KamAZs, tank-based vehicles for eliminating large-scale fires in oil and gas fields.

Fire truck on ZIL-130 chassis

And yet, the most famous and widespread have become the numerous variants of fire trucks based on the ZIL-130, which have been constantly on duty for almost half a century. Their main producers were the Priluki and Torzhok fire-fighting equipment plants.

The range of fire fighting vehicles produced in the Soviet Union was so diverse that it even included propaganda buses on the KAVZ-651 chassis, designed to carry out educational work among the population: it was believed that this would increase the efficiency of the fire service throughout the country. In the “stern” of such a bus there was a folding movie screen with side blinders, which made it possible to play films on the street even during daylight hours. Special staff vehicles and buses, communication and warning vehicles were also produced.

ATs-2 - Another very popular Soviet fire truck on the ZIL 131 chassis. Together with a small tank, it is immediately installed on a water source: a main hose is laid from the ATs-2 to recharge the ATs-1. In case of serious fires, AC-2 can immediately supply water or foam from a stationary monitor, thereby preventing the spread of fire, and only then can be installed at the water source.

AC-1 tank truck on the GAZ-33081 “Sadko” chassis. It is installed as close as possible to the burning object: the first barrel is supplied from the tank truck. AC-1 also serves to deliver personnel, fire extinguishing agents (water, foaming agent, powder), fire-fighting equipment and rescue tools.

Autoladder AL. Designed for lifting personnel and fire extinguishing agents to a height, evacuating people, moving cargo according to the principle of a crane (with knees shifted). It has mainly a hydraulic or electro-hydraulic drive. #firefighter #truck #zil130 #zil #zil131 #amo #lesner #USSR

Touches to the portrait

Most of the new cars, from the Gorky Automobile Plant, which supplied the chassis, were equipped with K-55A “all-terrain” tires, which significantly improved the cross-country ability of a rear-wheel drive vehicle in conditions of bad roads and seasonal off-road conditions.

The design of the fire truck model 106G on the GAZ-53-12 chassis is based on a welded metal tank of a suitcase-elliptical cross-section, made of St3 sheet steel 3 mm thick and secured to the vehicle frame using stepladders. To ensure a long service life of the tank, its internal surface is coated with coal tar varnish. A distinctive structural feature of the tank filler neck cover from those previously considered is the presence of an adapter connection for fastening a fire hose. The frame of the car in the rear part is extended to accommodate a centrifugal single-stage cantilever pump model PN-40UV, which is driven from the car engine using a separate driveshaft through the power take-off (PTO). Although the value “40” in the pump marking indicates the ability to supply forty liters of extinguishing agent per second, in combination with the “Gazon” carburetor engine with a power of 120 hp, its performance is only 30 l/s.

The pressure pipes are located at the rear of the tanker and are accessible from below the fire superstructure. In the rear part, directly above the pump room, there is a foam concentrate tank. On the sides of the tank there are rectangular compartments with various fire protection equipment. A pair of GPS-600 (medium expansion foam generator) is fixed on top of special brackets.

There are three staircases for different purposes on the roof of the superstructure:

- metal sliding three-legged ladder L-3KM/L-60, providing access to the windows of the third floor or to the roof of a two-story building;

- metal assault ladder LShM with a hook for access to the upper floors of buildings (as well as for working on steep slopes of roofs, for example, when opening the roof);

- folding ladder-stick (LP) - for lifting firefighters to the first floor through the window openings of buildings. In addition to its intended purpose, it can be used as a battering ram when opening doors. But it has one more important property - the ability to be used as a stretcher when carrying out victims.

Paying tribute to the certainly interesting versions that were released, having replenished their collections with ACU variants, collectors were also waiting for more familiar models of fire trucks on familiar chassis.

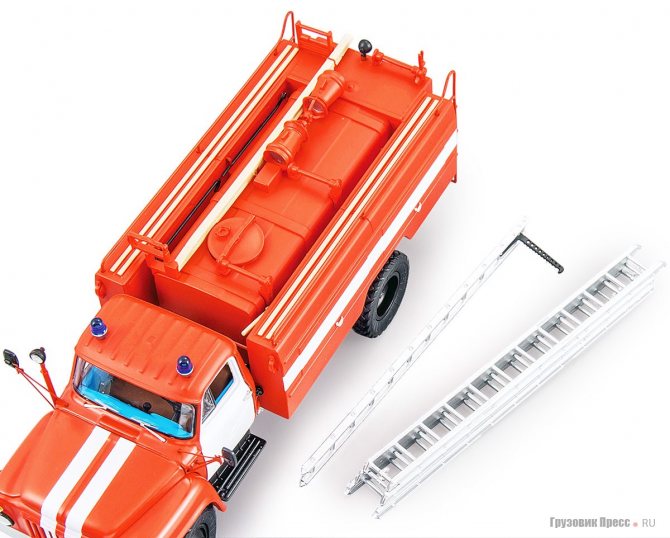

At the end of June 2020, everyone had the opportunity to purchase a long-awaited new product: a model of a real fire tanker ATs-30 (53-12) - 106G, albeit a single-cabin (according to some colleagues, a real “fire truck” should have a two-cabin). By the way, the start of sales was preceded by an early presentation of working samples, as a result of which some additions and corrections were made, and constructive wishes were taken into account.

The rear part contains such nuances as the features of attaching license plates on different models

Albert Volynsky, DiP models:

“A conventional mold is just a die and a punch that shapes two sides of the part, i.e. the part has flat outer sides. In our case, we also use external and internal wedges that shape the part on four sides, which gives the staircase such realism.”

The model AC-30 (53-12) - 106G, released in four basic versions, which were assigned the corresponding article numbers: 105330, 105331, 105332, 105333, was no exception in terms of new solutions.

Firstly, the body of the fire superstructure is made of ABS using die-cast technology. Secondly, the model received an extended rear overhang of the frame. Thirdly, very realistic foam generators with imitation mesh inside were used for the first time on the roof of the fire superstructure. Fourthly, “all-terrain” tires K-55A appeared on this model for the first time. Fifthly, for the first time in the DiP models production program, the SGU-60 with the FER “Ruhla” flasher is used. Sixthly, a “gas jet” appeared on the exhaust system. Starting with this series of models, license plates of state registration plates have imitation fasteners.

Detailing of fasteners and fire-technical equipment on the superstructure body

At first glance, all versions are very similar, but each of them is individual. And before we consider the features of individual options, let’s get acquainted with the general design solutions.

The position of the rear window has been changed and is now installed more realistically. Through the lowered side windows you can see that inside, like a real fire engine, the open metal parts of the cabin are painted in the base factory color, in our case “Adriatic”, and on the right side of the instrument panel there is a plate with markings. In addition to the searchlight, ladders, and foam generators, each option has additional equipment mounted on the inner walls of the body: a hook, two different crowbars, and a shovel.

All variants of the AC-30(53-12)-106G are presented in transport position and have real prototypes.

Traditionally, each model is accompanied by a corresponding certificate, certifying that a specific model with a certain article number is part of the overall limited edition.

Design features

The KamAZ-43118 firefighter has a modular firefighting superstructure, which is a collection of individual functional blocks that are reliably interconnected due to standardized connecting dimensions.

The vehicle is capable of delivering a combat crew consisting of seven people to a fire extinguishing site.

The water storage tank is made of carbon steel. If there is an open water source located near the vehicle, it is possible to extinguish the fire even after the tank is completely emptied.

The tank containing the foaming agent is made of stainless steel and therefore can serve for a long time even under conditions of very intensive use.

Fire-fighting equipment is fixed in the compartments of the existing fire superstructure. Each compartment is a reinforced structure using a high-strength steel frame. Panel metal doors are also available, which make it possible not only to quickly open or close compartments, but also provide excellent protection for fire equipment during transportation or storage. Each door has safety handles. The seats in the cabin are folding and equipped with seat belts. The crew cabin itself is insulated with Koflex or Penofol.

Pencil cases with suction sleeves located in them are fixed using a monomodular system, which, in turn, guarantees good ergonomics, compactness and reliable storage. The centrifugal type fire pump is installed at the rear of the vehicle.

ATs-30 (53-12) – 106G, article 105334

An early version of the fire truck produced in 1987 on the GAZ-53-12 chassis is a variant with one LBS-5 Elektra flashing light located in the center, equipped with black rims with K-55A all-terrain tires. On the cab and on the back there is the inscription “101 Volodarsk”. The double white stripe on the front is only on the hood, unlike the other options being considered. State registration number – 6229 GOC (Gorky region, RSFSR).

ATs-30 (53-12) – 106G, article 105335

The 1987 version of the fire truck on the GAZ-53-12 chassis is a variant with two LBS-5 Elektra beacons located in front of the cab roof, closer to its corners. It has yellow FG-16PP fog lights on the front bumper and red rims in combination with KI-63 universal tires. On the cabin doors and on the rear wall there is a note “47 Shukhobod”. In addition, above the front wheels there is an indication of the required tire pressure. State registration number – 1009 VOS (Vologda region, RSFSR).

Technical characteristics of retro fire equipment

History of the creation of the PMZ-2 (ZIS-5) car

The design of the AMO(ZIS)-5 car was actually re-created by AMO-ZIS designers E.I. Vazhinsky, V.I. Lyalin and B.D. Strokanov. The main emphasis when transferring the American model to domestic soil was on simplifying and increasing the maintainability of the design while simultaneously increasing load capacity and cross-country ability. For this purpose, it was boosted from 60 to 73 hp. engine, including the reconstructed radiator, carburetor and air filter, as well as the gearbox, driveshaft, strengthened frame and axle structures, increased ground clearance under the rear axle housing, hydraulic brakes were replaced with mechanical ones, the front bumper was retained only on export versions and buses chassis. Not being classified as an off-road vehicle, the ZIS-5, due to its low-speed, high-torque 6-cylinder engine (ZIS-5), was suitable for year-round use on roads of all categories. The traction capabilities of the truck were close to models with all driving wheels, and the installation of rear wheels with developed lugs and, especially, snow chains significantly increased its cross-country ability. A design feature - insufficient torsional rigidity of the frame, however, also contributed to increased cross-country ability, increasing the working strokes of the wheels when moving over road irregularities. The engine started easily in the cold and could run on any low-grade gasoline. A loaded ZIS-5 could tow a trailer with a total weight of up to 3.5 tons. The average mileage before overhaul was 70 thousand km. In 1942, the ZIS-5V was equipped with a 124 kg lighter cabin made of plywood and wood (“lining”), the wings were made by simple bending from ordinary sheet metal instead of deep-drawn stamped ones on the pre-war model, and the brakes were left only on the rear wheels.

The ZIS-5 was put on the assembly line without preliminary assembly of a prototype on October 1, 1933, and, according to the recollections of contemporaries, everything immediately went smoothly, without failures. The new car was put into production in the shortest possible time.

Car production was constantly increasing. In the first month, they assembled six to seven cars a day, then in dozens and hundreds. The car has proven itself well off-road and quickly gained a reputation as an unpretentious and reliable vehicle. As a rule, the ZIS-5 was loaded with four to five tons, although it was designed for three. And he transported the cargo calmly, without strain.

The car has found application in many areas. Trucks, buses, military equipment (including Katyushas), fire tanks, fire ladders, ambulances, etc. were made on its basis.

Fire truck pump ZIS-11 (PMZ-1)

Since 1934, the Stalin plant in Moscow began production of ZIS-11 - vehicles that were intended for the installation of fire equipment. Such vehicles were called PMZ-1, where PMZ stands for “ZIS fire engine.” The ZIS-11 was based on the chassis of the mass-produced ZIS-5.

Main technical characteristics

| Parameter name | Meaning |

| Year of issue | 1937 |

| Length with rear reel, mm | 7500 |

| Width, mm | 2300 |

| Height, mm | 2330 |

| Weight in combat readiness, kg | 6000 |

| Pump capacity, l/min | 1500 |

| First aid tank capacity, l | 360 |

| Crew, people | 14 |

| Gas tank capacity, l | 60 |

| Fuel consumption, l/100 km | 30 |

| Maximum speed with full load, km/h | 60 |

| Engine | Carburetor, 4-stroke, 6-cylinder |

| Power, hp | 73 |

Hose car AR-1.6(63)

The fire hose vehicle AR-1.6 GAZ-63 was produced in the USSR by the Gorky Automobile Plant from 1948 to April 1968 and was intended to equip fire departments with hoses when extinguishing fires in populated areas and industrial facilities. The vehicle worked in conjunction with a mobile pumping station and served to lay main hose lines from the pumping station, which was installed on a reservoir, to the fire site.

Main technical characteristics

| Parameter name | Meaning |

| Year of construction | 1956 |

| Chassis | GAZ-63 |

| Length of transported hoses, m | 1600 |

| Engine | GAZ-51 carburetor, four-stroke |

| Power | 70 hp |

| Transmission | 4-speed gearbox, 2-speed transfer case |

| Maximum speed, km/h | 70 |

| Control fuel consumption l. per 100 km. | 25 |

| Total weight of the fire truck, kg | 3400 |

| Overall dimensions, m | 5.53 x 2.2 x 2.25 |

| Combat crew, including driver, persons | 2 |

Hose vehicle ZIL-157 AR-2

Main technical characteristics

| Indicators | AR-2 (157) (model 121) |

| Chassis type | ZIL-157 |

| Number of seats for combat crew | 3 |

| Overall dimensions, mm: | |

| Length | 7000 |

| Width | 2650 |

| Height | 2900 |

| Weight with full load, kg | 9400 |

| Smallest turning radius, m | 11,2 |

| Maximum speed, km/h | 65 |

| Engine power, kW (hp) | 80 (109) |

| Control fuel consumption per 100 km, l | 42 |

| Fuel tank capacity, l | 150 |

| Length of transported pressure hoses, m, diameter, mm: | |

| 150 | 1500 |

| 110 | 1800 |

| 89 | 2200 |

| 77 | 2500 |

| Speed of laying out hoses in a line, km/h | 10 — 12 |

| Maximum time for mechanized installation of hose lines, min | 2,5 |

| Hose bridge, pcs. | 4 |

| Sleeve clamp, pcs. | 8 |

Fire tanker ATs-30(66)

The fire fighting tanker AC-30(66) is designed for extinguishing fires with water from the tank or from an external water source and air-mechanical foam using exported foam concentrate or taking it from an external container, as well as for delivering combat crews, firefighting equipment and technical equipment to the fire site. weapons, water and foaming agent.

Main technical characteristics

| Parameter name | Meaning |

| Length, mm | 5655 |

| Width, mm | 2342 |

| Height, mm | 2520 |

| Ground clearance, mm | 310 |

| Chassis | GAZ-66 |

| Turning radius, m | 9,5 |

| Rated engine power, l. With. | 115 |

| Fuel tanks, l. | 210 |

| Water tank capacity, l | 1600 |

| Foam tank capacity, l | 100 |

| Total weight, kg. | 6120 |

| Pump model | PN-30 |

| Maximum speed, km/h | 95 |

| Number of combat crew seats (including driver) | 2 |

| Fuel consumption per 100 km (base), l | 24 |

Fire tanker ATs-30(53)

The lightweight fire-fighting tanker AC-30(53) is designed to extinguish fires with water from the tank or from an external water source and air-mechanical foam using exported foam concentrate or taking it from an external container, as well as for delivering combat crews and firefighting equipment to the fire site and technical equipment, water and foaming agent.

Main technical characteristics

| Parameter name | Meaning |

| Length, mm | 6395 |

| Width, mm | 2380 |

| Height, mm | 2220 |

| Ground clearance, mm | 265 |

| Chassis | GAZ-53 |

| Turning radius, m | 8 |

| Rated engine power, l. With. | 115 |

| Fuel tanks, l. | 90 |

| Water tank capacity, l | 1900 |

| Foam tank capacity, l | 100 |

| Total weight, kg. | 6955 |

| Pump model | PN-30 |

| Maximum speed, km/h | 80 |

| Number of combat crew seats (including driver) | 2 |

43.mchs.gov.ru

AC-30 (53-12) – 106G, article 105336

The version of the fire truck, produced in 1991, on the GAZ-53-12 chassis has an SGU-60 on the roof with a beacon of the FER DDR Ruhla type, and a walkie-talkie is attached to the instrument panel. A pair of FG-16PP fog lights with yellow glass are installed above the front bumper. The radiator is covered with a protective apron, which displays a non-standard solution: a white double stripe as a continuation of the color scheme of the fire truck. The car is equipped with KI-63 tires on black wheels, and the rims are painted with white enamel. On the cabin doors the word is SPAS. But this is not an abbreviation like “Tsentrospas”, as you might think, but the name of a settlement in the Kolomyya region. State registration number – 6504 IFN (Ivano-Frankivsk region, Ukrainian SSR).

ANR on KamAZ-63501-3025-52 chassis

The AHP is equipped with a 4m long flexible hose with a quick-release connector for connection to the outlet pipe of the gas exhaust system.

Fuel volume in vehicle tanks: at least 500 liters . The design of fuel tanks makes it possible to seal the drain plug and filler plug in accordance with GOST R 53328-2009 .

The combined pumping unit supplies water and aqueous solutions of foaming agents at temperatures up to 30°C with a pH value of 7 to 10 pH, a density of 1100 kg/m3 and a mass concentration of solid particles of 0.5%, with a maximum size of 3 mm.

Maximum geometric suction lift of the combined pumping unit: 25 m . Supply of the combined pumping unit from a suction height of 25 m, nominal, 90 l/s . Supply of the combined pumping unit from a suction height of 10 m, nominal, 120 l/s .

The total length of the transported main pressure hoses with a diameter of 150 mm, nominal - 1200 m . The total length of the transported main pressure hoses with a diameter of 80 mm. - 240 m .

The pumping unit of the main fire pump is made in an anti-corrosion design and is capable of operating on contaminated and sea water, namely: - the shaft, pressure and suction pipelines are made of corrosion-resistant steel , the shaft seal is resistant to contaminated and sea water and does not require maintenance during operation; – shaft bearings that do not require lubrication and maintenance during operation.

The vacuum system for pre-filling the pump is automatic , with the possibility of manual shutdown.

The pumping unit has the following pipelines and shut-off valves: – two suction pipes with GMV-125 connecting heads and manually operated butterfly valves; – two suction pipes with GM-150 connecting heads and manually operated butterfly valves; – two pressure pipes with GM-80 connecting heads and butterfly valves with remote electro-pneumatic control; – two pressure pipes with GM-150 connecting heads and butterfly valves with remote electro-pneumatic control.

The pipelines contain anti-vibration rubber compensators.

The pumping unit of the main fire pump is controlled from the control panel. The drive of the main fire pump is a cardan drive , from a power take-off mounted on the base chassis and is designed to transmit torque from the vehicle engine to the fire pump.

The drive of submersible pumps is hydraulic , power take-off from the chassis engine. Submersible pumps are equipped with devices that allow them to be moved by combat crew personnel (holders, handrails, skids).

The drive of the combined pumping unit is turned on from the operator’s workplace. In this case, the presence of devices is provided that switches off the transmission of the base chassis and the drive of the combined pumping unit. Redundant engine control when operating a combined pumping unit from the operator's workplace ensures a smooth change in its rotation speed. The drive of the combined pumping unit ensures the operation of the combined pumping unit during standstill.

The ANR is equipped with a mechanized winch that provides lifting of submersible pumps to install them in the transport position.

The communications included in the main pumping unit provide: - filling the tank with water from the main pump or from a third-party source; — water intake by the main pump through suction hoses from a water source or from a third-party source, including from submersible pumps; — water supply through pressure pipes.

Shut-off valves with remote control allow you to control the pumping unit from the operator’s workplace. The use of manual duplication of ceiling reinforcement elements is provided.

The control system of the combined pumping unit provides: - control of pressure in the pressure pipelines of the main pump; — monitoring the pressure in the suction pipeline of the main pump; — control over the rotation speed of the main pump shaft; — car engine control; — switching on power take-off devices to drive the combined pumping unit; — control of a combined pumping unit; — in an emergency, an autonomous stop of the drive of the combined pumping unit is performed.

The height of placement of pressure and suction pipes relative to the ground (surface of the operator’s platform) is 1300 mm .

The hydraulic system is equipped with: — devices for releasing air from possible air accumulation; — devices for cleaning the working fluid from contaminants; — safety devices set to a pressure equal to the maximum short-term pressure; — indicators of the level of working fluid in tanks; — indicators of pressure and temperature of the working fluid; — signs with inscriptions explaining the purpose and procedure for manipulating control and monitoring devices.

Loads and deformations from other AHP units are not transferred to hydraulic equipment elements and pipelines. Elements of hydraulic equipment and pipelines are securely fastened and protected from mechanical damage. Placing hydraulic equipment on the machine makes inspections and repairs convenient.

The hose collection unit, roller type, provides: - mechanized lifting of pressure hoses with a diameter of 150 mm into the hose compartment - lifting of hoses from the left, in the direction of travel, side of the car - passage of connecting heads through the collection unit

The design of hose reels ensures that each reel contains 120 m of hose line , consisting of 20 m pressure hoses with a diameter of 80 mm . Hose reels must have devices (wheels) that make them easier to move manually when laying and assembling a hose line. In the transport position, the hose reels are placed on an external suspension on the body.

The glazing of the KBR salons is made of safety glass in accordance with GOST R 41.43.-2005. Visibility from the driver's workplace complies with the requirements of GOST R 51266-99. The seat cushion covering is made of breathable, non-toxic, softened material. Under the seats there are drawers for firefighting equipment or other equipment, while the seats are folding. To place PTV, tools or spare parts under the KBR seats, the seat cover is secured when it is lifted.

The internal door locks have a device that eliminates the possibility of their inadvertent opening while moving. The doors have devices that lock them in closed and open positions at 75°, and also have sliding windows. The footrests are made of anti-slip material with 2.5 mm high reefs and perforations. Door and hatch openings, places where controls, alarms and lighting are inserted have seals that prevent dust, dirt, precipitation and heat loss from entering the cabin.

The interior design meets the requirements of UNECE Regulation No. 29-02 regarding the protection of persons in the cabin of a cargo vehicle (preservation of living space in case of rollover, frontal collision, rear and side collisions).

The equipment in the cabin is placed in such a way that there are no sharp corners or edges that could cause injury to combat crews. Fastening the equipment eliminates the possibility of its spontaneous movement during movement.

Placement and connection of special light and sound alarms and their control panel are in accordance with GOST R 50574-2002 and the regulatory and technical documentation for this alarm. The cabin provides space for installing two fire extinguishers, one of which is located near the driver's seat. The cabin provides space for a medical first aid kit, measuring 360x200x100 mm . Internal lighting of the ANR ensures clear visibility of markings , divisions on scales of indicators, measuring and control instruments.

Illumination level: - for indicators, control and measuring instruments, marking of control system elements in the cabin and control panels of the combined pumping unit - 20 lux; — for the driver’s cabin and the CBD — 10 lux; — for body compartments with PTV — 10 lux.

The forces applied to the controls of special ANR units do not exceed the values established by the requirements of GOST 21752-76 and GOST 21753-76 . Ergonomic indicators of the operator’s working area comply with GOST 12.2.033-78 . Dimensions of lever handles and other manual controls are in accordance with GOST 21753-76 . The dimensions of brackets and handles intended for controlling, opening SBR doors and compartments, handrails and other elements make it possible to grasp them with a hand wearing an insulated mitten.

The body has separate compartments that are made of corrosion-resistant materials. The attachment of the body to the chassis frame contains damping elements that reduce body deformations from the impact of elastic deformations of the chassis frame on the body.

Body doors are curtain and swing type made of aluminum alloy. The body doors are equipped with locking devices that hold them in the closed position, and an alarm for the open position of the doors with an indication in the driver's cabin. The body doors are equipped with open position locks. Doors open when parked, which increase the overall dimensions of the car, are equipped with reflective elements indicating the dimensions of the car when the doors are open.

Door openings, hatch covers and other body elements have seals that protect the compartments from precipitation, dust and dirt. The shelves in the compartments used to accommodate PTVs have holes for draining accumulated residual water, foam solution and condensate. Axes, saws, scissors and other equipment with sharp edges are stored in covers and nests (cases) to prevent injury to personnel when operating in the area where they are located.

The ergonomic indicators of the body comply with GOST 12.2.033-78 .

In the compartments for placing fire protection equipment and other equipment in a visible place, index tables are used with a list of fire protection equipment and equipment indicating their location.

The design of the compartments for placing main hoses prevents spontaneous movement of the hoses during transportation.

The design and placement of hose compartments ensures the laying of hose lines with a diameter of 150 mm along paved roads at a speed of 20 km/h. To access equipment located at a height of 1800 mm from the ground, the ANR is equipped with steps with handrails. They are fastened in such a way as not to exceed the established dimensions of the vehicle in the transport position. ANR has a mechanized unit for collecting and laying hoses with a diameter of 150 mm.

Parts of the body intended for the movement of personnel do not have a lateral slope and elements that prevent feet from slipping (corrugations, notches, anti-slip coating). The width of one lane for moving is 400 mm.

Installation of the body does not violate the cross-country ability of the basic vehicle chassis.

The body compartments designed to accommodate the main pump and main hoses have thermal insulation and additional independent heating.

Additional electrical equipment provides: - illumination of the work area at night; — supply of special sound and light signals in accordance with GOST R 50574-2002 ; — lighting of work areas and compartments; — alarm in the driver’s cabin about open body doors and the lighting mast in the extended position; — operation of communication equipment and control devices.

Vehicle lighting and light signaling devices comply with the requirements of GOST R 41.48 (UNECE Regulation No. 48 with amendments of the 02 series). When installing additional electrical equipment and wiring, fire safety requirements are ensured.

The ANR is equipped with fog lights and searchlights in the front and rear of the vehicle. The front searchlight is controlled from the cockpit from the rightmost position. The CBD is equipped with internal lighting lamps with autonomous activation. In the area of the right outer seat in the driver's cabin (station commander's workplace) there is a local lighting lamp.

The AHP is equipped with a battery switch (mass switch) of the base chassis. The electrical wiring running inside the body compartments has connectors that allow you to dismantle the components and assemblies of the fire superstructure without dismantling the electrical wiring.

The ANR is equipped with a telescopic retractable mast: - at the top there are four floodlights with a power of 500 W each located in the same plane; — the height of the floodlights above the ground is 5.5 meters ; — the mast has a brake that fixes it at a given height.

To raise (lower) the mast to a given height, it is equipped with a lifting drive (manual mechanical). The design of the mast allows its operation without guy ropes at a wind speed of 10 m/s . Each electrical power circuit of any element of additional electrical equipment is equipped with a fuse. The ANR is equipped with a clamp in accordance with GOST 21130-75 for connecting protective grounding. The clamping location is marked with a grounding sign according to GOST 21130-75 . The location of the grounding clamp is electrically connected to the outlet pipes for supplying water from the pump.

Preparation of metal surfaces before painting - according to GOST 9.402-2004 . External metal surfaces are painted with two coats of primer. The lower surfaces of the bodies, cabins, steps, transmission elements, ANR chassis have paint coatings of class VI according to GOST 9.032-74

The design provides for filling the tank with water through a fire pump and from a hydrant with an automatic overflow control system. There are water level indicators on both sides of the tank.

ATs-30 (53-12) – 106G, article 105337

Version made in 1987 on the GAZ-53-12 chassis: “only from the factory”, without any designations or license plates. Equipped with two LBS-5 Elektra beacons located in the front of the cabin roof, closer to its corners. K-55A tires are mounted on black rims. But this particular option may bring a pleasant surprise to collectors. She represents a kind of transformer. That is, it can remain in the collection as a model of a new car “from the factory,” or it can become one of the options, as they say, “with a flick of the wrist.” The fact is that the kit includes decals for self-installation, allowing you to make the basic version one of two proposed ones: “36 Urschel” or “18 Vyazniki”.

The official distributor of DiP models products, the Adler-M company, as part of the general circulation of the specified article, offered an exclusive for those who prefer ready-made models: AC-30 (53-12) - 106G with state registration plates of the Russian Federation and symbols of the Ministry of Emergency Situations.

Fire tanker

Fire tanker

ATs-1.6-10 (GAZ-66) high cross-country ability with a 4x4 wheel arrangement, equipped with a fire pump PN-1200LA is intended for:

- extinguishing fires with fire extinguishing agents;

- delivery of combat crews, fire-fighting equipment and a supply of fire extinguishing agents to the fire site;

- supplying water and air-mechanical foam of low and medium expansion through pressure hoses and hand nozzles when extinguishing fires.

Tank truck

can be used as an independent combat unit with the intake of foam concentrate from a foam tank or external reservoir and the intake of water from a tank or reservoir. The tank truck is designed for operation in areas with a temperate climate at ambient temperatures from minus 40 to plus 40°C.

Tank truck

consists of the following main parts:

- chassis;

- pumping unit with drive;

- tanks with foam tank;

- water and foam communications;

- vacuum system;

- body;

- pneumatic system;

- additional electrical equipment;

- control systems;

- set of fire-technical weapons.

The modified chassis is equipped with: a fire pump drive, a pump, a tank with a foam tank, a vacuum system, a pneumatic system, a body, a control system and some electrical equipment.

The body compartments contain anti-tank equipment and electrical equipment elements.

Tank truck

equipped with a loud-speaking alarm system SGS-01 “Corvette”.

The main work of the tanker is to supply water or air-mechanical foam to the fire source with the help of existing equipment and accessories until the fire is completely extinguished.

The fire pump is driven from the chassis engine through a power take-off and a cardan drive.

The initial filling of the suction line and pump when drawing water from a reservoir is carried out by a gas-jet vacuum device built into the exhaust system of the chassis engine.

Tank truck

can perform the following operations:

- supply the foaming agent solution from the container;

- supply water from a tank or reservoir;

- work to pump water with other tankers at a significant distance from the reservoir to the fire site.

The electrical equipment of the tank truck consists of chassis electrical equipment and additional electrical equipment.

The tanker's consumers are powered by 12V direct current from the chassis' on-board network.

The electrical equipment of the tank truck consists of the following main components:

- in the body: control panel; compartment lighting lamps; work area lighting spotlight; terminal switch; license plate light.

- in the cabin: light-acoustic unit with beacons and speaker; spotlight; Control block; control panel for alarm acoustic installation; commander's lamp; circuit breakers; radio station connection socket.

Fire-fighting equipment on the tanker is located on the roof of the body and compartments. The PTV is securely secured with special mechanisms, clamps and other fastening elements. The PTV is placed taking into account convenient access and quick removal.