Plow overview

The plow is used to plow the land in almost any large farm, since without it it is almost impossible to plow the land efficiently, especially if it is dense soil or virgin soil.

During the first treatment, the upper layer is cut and divided into furrows. After the second pass, the lower layer of soil is lifted and mixed with the upper layer. This technique is very effective when fertilizers are scattered on the field and need to be mixed with the soil. The method is also suitable for deepening crop residues into the ground.

The following types of plows are distinguished:

There are also several ways to attach plows:

Branded model for MTZ walk-behind tractor

The manufacturer presents a universal model of the reversible plow PU-00.000-01, which is adapted for the Belarus MTZ 09N walk-behind tractor, but is suitable for any MTZ. It copes with plowing land of any density, including virgin soil. Features include the low weight of the plow, which is only 16 kg.

During plowing, the working area is 30 cm, which allows you to significantly save time. The maximum depth can reach up to 25 cm, but it can be adjusted using the stand and the holes on it. The design of the plow involves not only plowing, but also provides the opportunity to dig up root crops. And thanks to the simple fastening using a hitch, preparing the walk-behind tractor will not take much time.

The appearance of the plow is designed in such a way that the lower part cuts the layer of earth and grabs it, and the upper part throws the layer to the side. This design allows you to throw the earth to the side so that it does not crumble back into the laid trench. Thanks to the use of durable steel, the device does not deform over time and does not corrode, and can be used for a long time under any load.

Analogs for MTZ walk-behind tractor

As an alternative, which can be used together with the Belarus MTZ walk-behind tractor, the following plow models can be considered:

The P1-20/3 plow is produced by the Russian company, which is located in the city of Gagarin. The shape is similar to the branded model, but with some differences. Reduced weight to 8 kg. and the single grip of the ploughshare is 21.5 cm, which is almost a third less than that of PU-0000001. Because of this, it is more advisable to use the model in small areas with medium-density soil.

The double-body plow, due to its design, has special operating features. The pointed end of the plow easily enters the soil and is not immediately thrown to the side, as it does when using a universal model, but turns over. Due to this, it is possible to achieve improved soil mixing. The width of the plowshare of the tool is 15.5 cm, and plowing is carried out to a depth of 20 cm.

Despite the fact that the figure is slightly lower than that of the branded model, due to the design features, plowing is more efficient. The weight of the model is 12 kg, and production is carried out on Russian territory.

Devices made independently for the MTZ walk-behind tractor

The design of the plow is so simple that doing it yourself is not difficult.

The leading role is played by the ploughshare, which plunges into the ground and raises the layer. It, like the rest of the parts, can be made at home.

In order to make your own plow you need:

- Take metal from 3 mm. thick.

- Make a dump. To do this, a template is drawn on paper, and markings are made on it on the pipe and cut out. The recommended thickness of the share is 3-5 mm.

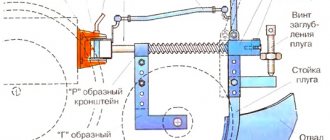

- Make a hitch in the shape of the letter G from a metal pipe.

- Weld the blade and ploughshare. Weld a pipe mount at the rear for subsequent connection of the parts with the hitch. Fastening is carried out using bolts, so that later it is easier to adjust the depth of the plow.

In order to correctly connect the plow to the MTZ walk-behind tractor, follow these steps::

- Remove the transport wheels and replace them with lugs. This is done so that the grip on the ground becomes better, and also to increase the stability of the Belarus due to the fact that the lugs are attached to the hubs, increasing the track width. If the plow and walk-behind tractor, in general, weigh little, weights should be used, since otherwise the device will not be able to effectively cope with the task.

- To connect the hitch to the walk-behind tractor, a standard hitch is used, which is secured with one king pin. In this case, there should remain 5% play, which provides shock absorption of the unit during soil resistance.

- Set the plowing depth. The depth is adjustable by attaching to the holes on the stand.

The plow adjustment occurs in the following order:

- Set plowing depth;

- Adjust the blade tilt;

- Adjust the field board.

If everything is done correctly, the walk-behind tractor with the attachment will move smoothly, without jumps or deviations to the side. And most importantly, the furrow will be straight. Such a unit can easily replace a tractor when plowing a personal plot or vegetable garden.

Video review

Below is a video where the owner talks about the modifications made and the result of plowing the land on an MTZ walk-behind tractor with a plow

Video review of the MTZ PV-1 plow for the MTZ walk-behind tractor

Owner reviews

Below are reviews from owners about working with the plow for your reference.

Oleg:

I decided not to buy a plow for the MTZ walk-behind tractor, but to make it myself. It seems like I did everything according to plan, but forgot to polish it. Therefore, it was difficult to work with the plow, dirt stuck to it and the soil did not lie nicely in rows, but was piled up in heaps. I had to bring the matter to fruition - clean and polish. Things got better.

Maksim:

It is important not only to adjust the plow correctly, but also to prepare the walk-behind tractor for work, namely, to inflate both wheels equally. If everything is done correctly, then Belarus will not jump while working, and the row will turn out smooth and neat.

Distinctive features

Equipment from the MTZ plant is produced on the basis of Belarus tractors. The devices are produced in auxiliary workshops. Today it is a large complex that produces a wide range of high-quality equipment.

The first walk-behind tractor went on sale in 1978. It was called a walking tractor. It was quickly appreciated, noting the excellent quality of land cultivation.

IMPORTANT!

The main distinctive feature of walk-behind tractors is the presence of a tractor chassis, due to which it can be used to transport trailers with large cargo.

The devices are capable of reaching speeds of up to 10 kilometers per hour thanks to four forward gears. For simpler work, a speed of 2.5 km/h is provided. Control is carried out by a convenient steering column. Elements that control movement are located at the top of the structure.

There are three modifications of the cutter measuring 42, 60 and 70 centimeters. The walk-behind tractors are equipped with four-stroke carburetor engines with a three-liter fuel tank.

Power ranges from 5 to 8 horsepower depending on the model. By adjusting the power, you can use not only attachments, but also mills and circular grinders.

Mechanical gear and closed-type multi-disc friction gearbox provide high-quality transmission.

Efficient operation is maintained by the constant presence of oil in the clutch. The equipment can be supplemented with quick-change additional parts.

The machine easily copes with plowing the land, processing potatoes, mowing grass and other tasks. Locking wheel blocks and an internal power take-off shaft ensure comfortable operation.

When developing the machine, engineers took into account the specifics of the Russian terrain, as well as different types of soil. Thanks to this, the device is equipped with a gearbox that allows it to work on heavy soils.

A durable multi-tooth differential increases the reliability of the cultivator, and a comfortable steering column and wide wheels improve cross-country ability and controllability.

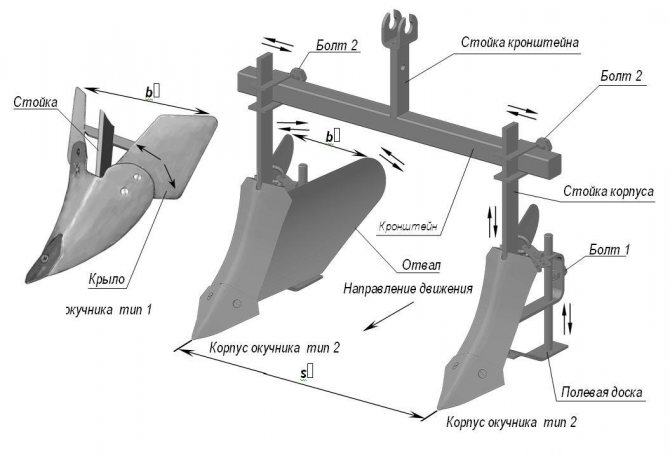

Hillers for MTZ walk-behind tractor

Hillers are important equipment for making agricultural work easier. With this tool you can quickly and easily make furrows for planting various crops. But they are mainly used for hilling potatoes.

There are several types of hillers:

- Reversible type, consisting of two plows and being the most common;

- Disc type - considered the most effective and making a furrow using two rotating discs.

- Active type - classified as a special hiller, since this hiller first raises a layer of earth, crushes it, and then only discards it.

From the manufacturer

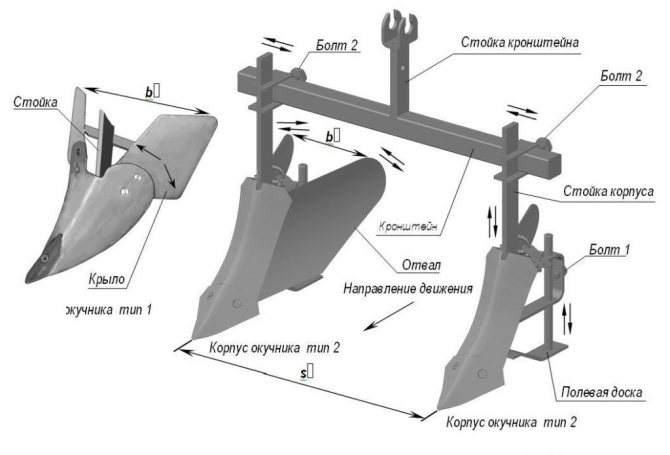

The proprietary model of the hiller, adapted for the Belarus walk-behind tractor, is OU-00000-01. The advantage of the model is the ability to adjust the distance between the two plows of which it consists. The width can vary from 45 to 70 cm, which is very convenient when the distance between the beds is different. The device itself weighs 20 kg, so Belarus can reach speeds of up to 4 km/h.

Analogs of hillers for MTZ walk-behind tractor

If you consider an alternative to branded models, then you should opt for the products of the Lida Mechanical Plant, which produces plows and hillers adapted for Belarus. The model is called OK-2 and has the same parameters as the branded hiller. In addition to the weight, which is 12 kg. and immersion depth, which is slightly less than the original and equal to 12 cm.

It offers a wide range of equipment, including disc and universal hillers. The consumer can choose the optimal size of the discs, which are available in various sizes from 18 to 36 cm in diameter; accordingly, they are immersed only half the diameter and process only one row.

Homemade hiller devices for MTZ walk-behind tractor

The easiest and least labor-intensive option is to make a reversible hiller, which consists of two plows. Making a disk and rotary hiller will require a lot of effort and patience.

Two plows are taken and attached to the frame, and then to the hitch on Belarus. The frame is made of a T-shape from a square pipe.

Video reviews

Video review of the operation of the MTZ 09N walk-behind tractor with a disk hiller

Video of planting potatoes

Video review of working with a universal hiller for the MTZ walk-behind tractor

Video review of working with a rotary plow

Owner reviews

Below are reviews from owners who have had experience working with hillers.

Rostislav:

If you are planning to buy a hiller for an MTZ walk-behind tractor, then choose a disk hiller, despite the fact that it is more expensive. It is much more efficient to work with it and there is no need to modify it, because it goes smoothly and does not cut the tubers. The same cannot be said about the hiller with plows. This happens because potato rows cannot always be planted straight.

Sergey:

For me, using a reversible hiller for the MTZ walk-behind tractor was a solution to problems with plowing and laying a furrow for potatoes. It’s quick to set up, and it’s simple, easy to use, and most importantly, even tracks. I connected it to the walk-behind tractor and drove off. So that the ruts are even, I pull the rope and ride along it.

Plows

The plow is an integral part of the walk-behind tractor and is required for use by every owner in Belarus. It is worth noting that they are different, and you should choose carefully.

Plows are:

- Reversible or they are also called rotary. Plowing is carried out using a blade;

- Disc (aka rotary). Plowed using rotating discs.

From the manufacturer

The official website presents one type of reversible plow - the universal PU-00.000-01 for the MTZ-09N walk-behind tractor. It is suitable not only for the MTZ-09N model, but also for any other MTZ walk-behind tractor. The universal plow is used by Belarus to plow any land, including virgin lands.

Features of the universal plow PU-00.000-01

- The reversible plow can be used both on new lands and on already plowed ones;

- The weight of the reversible plow is only 16 kg;

- The width of one track when plowing is about 30 cm, which means you can work with large areas;

- It is possible to work at a depth of up to 25 cm, the immersion is adjusted using special holes on the stand;

- Thanks to its shape, it is possible to use Belarus for digging up root crops;

- The light weight of the structure makes it easy to transport;

- Attaching to the MTZ walk-behind tractor occurs using a conventional hitch.

The main design feature of this model is the shape of the reversible plow. The ridge in the lower part captures the earth, and in the upper part it expands and dumps it. Thanks to this, the soil is thrown to the sides of the trench and is not backfilled.

It is made of high quality steel, and the design itself is simple and durable. Thanks to this, long-term reliable operation of the equipment is achieved instead of Belarus for a long time and under heavy loads.

Video review of the PU plow for the MTZ-09 walk-behind tractor

Analogs

Several other similar models of plows are compatible with Belarus.

Plow P1-20/3

This reversible plow is produced from Gagarin. It is made in the same shape as the PU, but only the one-time grip of the ploughshare is fixed and is 21.5 cm. And this is almost a third less than that of a universal plow.

The structure weighs 8 kg. It is worth using the P1-20/3 plow only when working in Belarus with small areas.

Double-furrow reversible plow

This model has features in its configuration. The share of this plow is made in the shape of a feather. Its tip enters the ground, and the earth is not immediately thrown to the sides, but turns over several times in front of the plow, and then leaves. Thanks to this, better mixing of the top layer of soil is achieved.

The maximum plowing depth is up to 20 cm, the width of the ploughshare is 15.5 cm. This is less than other models, but the plowing results in better quality.

This design weighs 12 kg, and the operating speed of Belarus together with a reversible plow ranges from 2 to 5 km/h. It is produced in Russia.

Homemade option

The design of the reversible plow is simple. Its main working part is the ploughshare. He plunges into the ground and plows. For MTZ-09N walk-behind tractors, you can do it yourself.

Stages of constructing a homemade plow

- This will require a steel plate. The metal must be thick from 3 mm. Because this element cuts the soil and there will be a lot of pressure on it.

- Next you need to make a blade. A metal pipe with a diameter of half a meter is perfect for its manufacture. It is enough to cut out a moldboard template from cardboard, transfer it to the pipe and cut it out. Do not use too thick metal; the recommended thickness of the plowshare for normal plowing is from 3 to 5 mm.

- Make an L-shaped hitch from a square metal pipe.

- The next step is to connect the blade to the plowshare by welding, and weld a small piece of square pipe at the back in order to connect it to the hitch using bolts. Then, using these bolts, it will be possible to adjust the depth of the plow.

Also on the forums there are a large number of different diagrams, drawings and videos on how to assemble a plow for Belarus with your own hands.

Homemade plow for MTZ walk-behind tractor

Plow adjustment

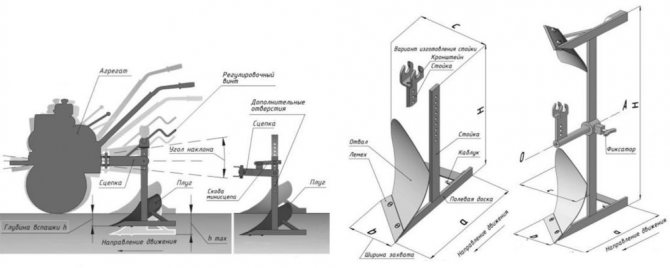

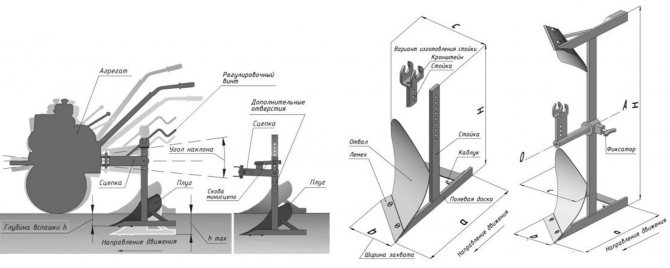

A properly adjusted plow is the key to successful plowing. Here's how it's done:

- Depth adjustment. The recommended level of immersion of a plow into the ground when plowing is considered to be 5-7 cm. Firstly, this is the average level of immersion of a shovel. Secondly, in this case it is impossible to touch the clayey rock that may be located below. Thirdly, with such a depth of plowing, the roots are not covered with a large amount of soil, and during winter they freeze.

- Adjusting the "angle of attack". This moment involves adjusting the angle of immersion of the ploughshare into the ground. If it is too big, instead of plowing it will be used as an anchor and simply pull Belarus towards the ground. If it is too small, it will slide across the surface instead of plowing.

- And one more piece of advice. The first track should be as smooth as possible. Because everyone else will follow it. After you make the first track, place the MTZ walk-behind tractor with one wheel in the track and continue working. If it is uneven, additional adjustment will be necessary.

Video reviews

Plowing with a Belarus MTZ-09N walk-behind tractor with a universal plow

Plowing the MZT-09N walk-behind tractor with a reversible plow

Reviews

There are many reviews on the Internet about the work of plows, for example:

Paul:

“After I made the plow with my own hands, I began to use it. But at the same time I forgot to sand it. As a result, dirt stuck to the plow and it worked like a bulldozer. As a result, I had to clean off all the rust and scale, then it became much easier.”

Maros:

“It is important to maintain the same tire pressure. Judging by my experience, a pressure of 2 atmospheres is considered ideal. If it is less, then the wheels will quickly wear out and come apart under the weight of Belarus himself; it is better to have them over-inflated than under-inflated. If the pressure is not the same, then the MRT will constantly go in one direction. And even better (if possible) replace conventional wheels with lug wheels, and work with the plow will go clearly and smoothly, the main thing is to adjust it correctly.”

Description of assembly work

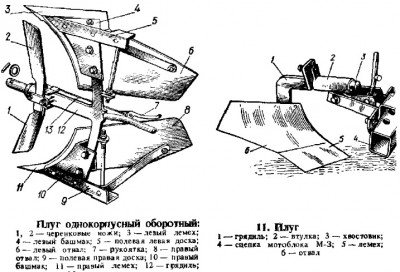

Drawing of a simple plow for a mini tractor and walk-behind tractor.

The main load-bearing element of the equipment in question is the frame onto which the remaining components are attached. It is made of a metal profile with a round or rectangular cross-section, 2-3 mm thick. The working bodies and auxiliary elements of the plow are attached to the frame part. The shape of the frame corresponds to the number of working tools of the plow and the selected control elements.

You can also look at the drawings and assembly of the plow for the T 25 mini tractor

Geometric features of the plow

Plow share diagram.

The presented drawing shows the structure of the plow blade body of the plow. The share (I) is the lowest part that cuts into the soil. The layer of earth moves to the dump (IV), which turns over, crumbles and moves the soil into the furrow. The field board (II) serves as a guide for the movement of the plow and does not allow it to move towards the uncultivated arable land. The stand (III) secures the working tool to the supporting frame and rigidly holds the knife in working condition. The share consists of a toe, blade and heel (1, 2, 3), which ensure successful penetration into the ground. The upper, furrow and field edges (6, 4, together with the wing (5) and the mouldboard chest (7) due to their geometric parameters ensure proper movement and loosening of the formation. The design of the plow with two bodies allows for optimal plowing of small plots of land using mini tractors. On the Internet you can find many videos describing the operation of such devices.

Plow shank attachment

The stand is equipped with adjustment holes to adjust the required plowing depth. It is made of a metal plate 8-12 mm thick to provide sufficient rigidity to withstand high loads during operation. The stand is bolted to the frame; the angle of inclination of the body should ensure normal penetration of the cutting edge of the ploughshare into the soil.

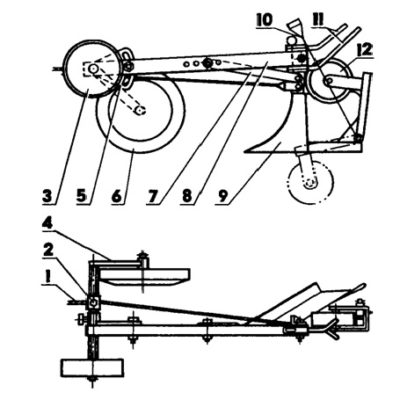

Making a drawbar and fastening a wheel

Connection of the main components of the plow.

The frame is attached to the mini tractor using a standard pin coupling device or a homemade drawbar. The first can be taken from old, worn-out equipment and welded to the front part of the supporting structure, the second can be made with your own hands in the form of a drawbar with a handle (examples can be seen in various videos on the Internet). There are straight and V-shaped drawbars, with the second being more preferable. It dampens lateral vibrations of the plow and ensures straight movement.

One of the additional and control parts of a homemade land implement is a field wheel. It serves to ensure ease of movement and prevent the working tool from sinking into the soil. These tasks can be performed by one wheel, but on advanced designs these functions are divided into two elements. The field wheel is attached to the frame with an adjustable bracket to ensure the required plow settings.

Fastening and manufacturing of the working body of the plow

To make the main working tool of a plow with your own hands, you need to make a ploughshare and a moldboard. The plow body must be made of alloy steel with improved strength characteristics. In Soviet times, methodological centers of agricultural engineering advised strengthening plow bodies with spring steel overlays when cultivating parched and virgin lands. A good workpiece for the production of cutting parts is a used circular saw blade, the material of which has increased strength and rigidity. The ploughshare has a wedge shape with a working angle of 40-42º. It is recommended to attach the ploughshare to the blade with bolts or rivets to allow removal and regular sharpening.

Blade installation

The blade is made of a metal sheet 3-4 mm thick, followed by bending by gas welding or on a roller machine. It’s easier to make a homemade dump from a pipe with a diameter of 500-600 mm. First, a template drawing is made, then it is applied to the workpiece, cut with a gas cutter and sanded. The blade is rigidly mounted to the plow stand by welding.

Adjustment of equipment for a mini tractor is carried out on a level area with a hard surface. The field wheel is installed on a stand adjusted to the plowing depth. The ploughshare is lowered until it stops with the supporting plane, and the heel should be parallel to the surface of the ground. The stand is fixed in the selected position and the equipment is ready for use. To check that the plow settings are correct, you need to do a test plow.

The plow assembly is shown in more detail in the video:

Hillers

Hillers allow you to cut furrows for planting crops, but their main use is hilling up potatoes to get a larger yield.

There are several types of hillers:

- Negotiable. This is the simplest type of hiller, which works using two plows.

- Disk. This option is more effective. It works using two rotating disks. Which rotate and loosen the soil.

- Active. This is a special type of hiller that works using propellers. If disk and revolving hillers simply turn over the top layer of soil onto the potatoes, then this one first chops it up and only then discards it.

From the manufacturer

The official manufacturer offers one version of the hiller - the universal reversible hiller OU-00.000-01.

It looks like two connected plows. It is possible to adjust the width of the rows by rearranging the plows at different distances from 45 to 70 cm. The plow is immersed in the ground to a depth of 10 cm. The average speed of movement of Belarus with a reversible hiller is 4 km/h. The structure weighs 20 kg.

Analogs

The best analogue for any factory-made attachments for MTZ is Lida products. Including hillers.

The OK-2 hiller is presented by a Lida company and has similar parameters to the universal hiller, except for the immersion depth. The maximum immersion of this unit is 12 cm. Accordingly, the speed in this case drops to 3 km/h.

Unfortunately, there are no special disc hillers for the MTZ walk-behind tractor.

You can always choose a universal option for a walk-behind tractor that will work successfully on it. The main thing is to choose a hitch.

Ukrainian offers a large amount of universal equipment, including disc hillers. Disc sizes can vary from 18 to 36 cm. Their maximum immersion level can be half the diameter. The disadvantage is that they are designed to process only 1 row, while reversible hillers work with two rows at once.

Homemade option

Making a disk hiller is problematic; a reversible hiller is much simpler in its design. To make it, it is enough to have two plows on hand, which are connected with bolts not to the Belarus, but to the frame. And the frame itself is already connected to MTZ.

The frame should be made from a square tube in the shape of the letter “T”. This design is simple but effective and has been known since Soviet times.

Video reviews

Review of the universal hiller OU-00.000-01 for the MTZ walk-behind tractor

Setting up hiller discs on a MTZ walk-behind tractor

An example of hilling with a Belarus MTZ-09 walk-behind tractor

Reviews

Here are some reviews from people who have already used this unit:

Gennady:

“When choosing between a disk and a reversible hiller, it is better to take a disk one. It is a little more expensive, but it works more stably and does not cut potato tubers. Based on practice, the rows are not always planted equally, and sooner or later you will hit some bush. But if you plant through a potato planter, I think there shouldn’t be any problems.”

Dmitriy:

“If you look at which hiller is better, then there is no definite answer, each is good in its own way. It is better to use the disk one until the potatoes have sprouted, or in the early stages of growth. It makes small lumps of soil, thereby saturating it with oxygen. After this, active growth of tubers occurs, and usually the next day sprouts are already visible from the ground. And with the current climate: plus 30 °C and no rain, this is what is needed. And the return one can already be used when the potatoes have grown and gained strength, without fear of damaging them.”

Homemade attachments

When the finished mini-tractor has passed all the tests, acquired the status of significance and earned the love of the entire family, the task of manufacturing attachments for it comes to the fore. And this depends on the intended crops and soil cultivation. If a walk-behind tractor was used to create a tractor, then there is a ready-made unit for coupling with agricultural implements. Otherwise, you will have to make a canopy with your own hands, a photo of which is presented.

It shows that the hitch has a three-point design. It must be movable both vertically and horizontally. Made from steel profiles using a welding machine. Needed for connecting units.

Of course, it is possible to make a single-point hitch unit, but this will greatly reduce the number of mounted agricultural machines and, consequently, reduce the versatility of the tractor.

There are several types of agricultural implements for cultivating land.

Types of plows

For homemade tractors, the following types of plows are most often used: single-body and double-body. The former cling to light and medium-sized walk-behind tractors, while the latter cling to more substantial equipment. For a mini-tractor, if it has a powerful engine and decent weight, multi-body moldboard plows are prepared, which are attached to a homemade hitch.

The plow is often made from the skimmer of a factory plow, which is usually used by the MTZ tractor. It is only necessary to slightly modify the plowshare and the correct bend of the blade. It is possible to use a horse plow.

For plowing heavy and hard soils, as well as soils with roots of trees and shrubs, homemade disc plows are used. They are a frame with sharp disks with a diameter of up to 40 cm, which cut into the soil at a slight angle relative to the direction of movement. This allows them not only to cut the roots, but also to loosen the soil.

Hillers and harrows

Any homemade hiller consists of a frame and two disks located at an angle to each other. This unit is used for hilling rows of potatoes and strawberries.

Harrows are designed to break up clods and loosen plowed soil. They consist of a lattice frame measuring 100x50 cm, welded from 50x50 mm corners, and sharp fingers up to 15 cm long, spaced evenly over the frame area. The harrows hitch behind the plow and work together with it.

Potato planters and diggers

This mounted trailed equipment is used for a specific crop – potatoes. It is powered by its own wheels, which allows the seeds to be evenly distributed along the furrow and does not depend on slippage.

A potato digger is a sharp knife 20-30 cm wide, which goes horizontally into the soil to a depth of 20-25 cm. Using an inclined grid, it pulls the potatoes to the surface. At the same time, the tubers are cleansed from soil and grass.

Other equipment

Depending on the purpose, other attachments can be used:

- Mounted mowers. They are used for making hay for domestic animals and removing weeds in the garden.

- Rake for raking up grass clippings. They are mounted and trailed. Trailed ones have two wheels. Hitches directly to the tractor.

- Mounted cultivators. They usually consist of a frame and 6-8 cultivator tines. The operating principle is similar to that of a flat-cut plow. They have two wheels with which the depth of cultivation can be adjusted.

- Garden sprayers. This is the required unit. They spray cultivated crops to protect them from pests, and also protect grains from weeds using special chemical compounds. Mainly used in farmers' fields.

- Bulldozer blades. They are hitched in front or behind the tractor. They are a shovel up to 1.5 m wide. They are made of steel 3-5 mm thick. Attached using a hinged device. Designed for clearing the area of snow and debris, as well as for leveling the surface of the site.

- Coons. This special device is used only for loading and unloading operations. Manufactured for a specific type of mini-tractor activity.

- Rotary brushes and snow blowers. They are especially necessary in winter on city streets. A tractor with such equipment is able to clear all the bottlenecks between houses and shops where it is difficult for an ordinary tractor to reach.

Assembling a simple unit, as well as homemade attachments for a mini-tractor, does not present any particular problems. All you need is time, desire, the necessary tools and materials.

How to make a reversible plow for a walk-behind tractor

To understand what a reversible plow is and how to make a reversible plow for a walk-behind tractor, let's look at the plowing process - the usual turning over of the earth, i.e. what was below turns out to be above, and vice versa.

After the plow passes through the ground, a furrow remains, dividing the area into plowed and not. Depending on the direction, the plow turns the earth either to the left or to the right. There are disadvantages to working on small plots of land. When you plow into a dump, when you turn the tractor, you get a small mound.

And when they plow sideways, they get a furrow in the middle. As a result, the garden turns out uneven. To avoid this, when using a walk-behind tractor or a walk-behind tractor, they try to back away and plow again. But there is idling, because when the tractor goes in one direction, it plows, but not in the other. To solve this problem, various reversible plows were invented. There are quite a few designs of such plows, but when using them, fuel and time are significantly saved and work becomes more convenient.

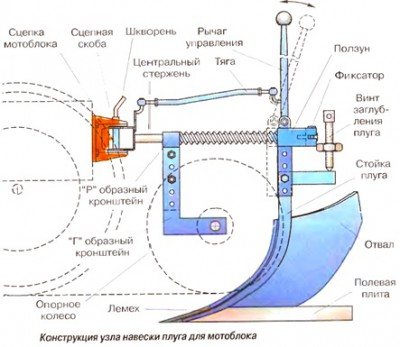

Installation of a reversible plow to a walk-behind tractor

Let's look at the design of a reversible plow for a walk-behind tractor using a specific example. The plow is designed for crumbling and turning the arable layer, and is recommended for use on soils that have already been cultivated.

- Plowing depth 20cm;

- Width of ploughshare (grab) 22 cm;

- To adjust the plowing depth, there are 3 holes in the stand;

- Height 76 cm;

- Width 32 cm;

- Length 48 cm;

The plow is connected to the walk-behind tractor using an appropriate hitch. The plow must be adjusted so that the side edge of the field board during operation is parallel to the direction of movement, i.e. along the wall of the furrow. And the support triangle formed by the cutting edge of the ploughshare, the heel and the bottom edge of the field board must be in a horizontal plane.

In order to adjust the plowing depth, you need to adjust the angle of inclination of the plow body in the vertical-longitudinal plane. To do this, use additional holes in the mini-coupler bracket and the plow stand, or use the hitch adjusting screw.

During operation, you can adjust the correct installation of the plow. The design of this reversible plow allows the soil layer to be dumped in one direction, both during forward and reverse strokes. To change the body of the reversible plow, it is enough to rotate it 180° around its axis and lock it in the working position. Before you start working with the plow, you need to equip it with lugs to ensure reliable adhesion of the unit drive to the cultivated soil.

Safety precautions when working with a reversible plow

Before starting work, check that all threaded connections are securely tightened. Remove all foreign objects from the treated area. When maneuvering the machine with the plow installed, as well as when reversing, be especially careful. To avoid injury from protruding sharp corners and edges, maintain a safe distance from the implement while operating.

Wear protective gloves when servicing the implement. When you have finished your work, you need to clean the plow. All parts and threaded connections that do not have a paint coating must be treated with lubricant. The plow must be stored indoors.

Do-it-yourself reversible plow for walk-behind tractor, drawings and description

If there is no experience in this type of activity, you should first consult with a specialist to understand the main complexities of the process.

Each type of plow has its own design features. The simplest design has a single-body plow, and this is the best option for beginners who do not have the appropriate skills in this matter. At the top of the reversible plow body there is a curved feather, which allows you to process the overturned layer of earth. Therefore, this product is optimal for processing hard soil.

In the process of manufacturing such a structure, it is very important to follow all instructions and carefully follow the drawing parameters. The slightest inaccuracy will significantly affect the characteristics of the product, and during operation will negatively manifest itself in the results of work.

To make a plow you need to use steel 3-5 mm thick. The ploughshare is made first. It must be removable. The cutting part must be beaten on an anvil and sharpened.

The next thing is to do the dump.

A pipe with a diameter of half a meter and a wall thickness of 5 mm is used as a blank. Using gas welding, the blade blank is cut out according to a template and subjected to grinding with a grinder. After manufacturing these two parts, the plow body is made from steel 2-3 mm thick and the structure is assembled.

Adjusting and setting up a plow for a walk-behind tractor

After the plow is made, you need to configure it. But before that, you need to configure the walk-behind tractor. After the walk-behind tractor has been taken out to the field, the wheels with rubber tires must be removed and replaced with wheels that are equipped with lugs.

Otherwise, during plowing, the walk-behind tractor with a reversible plow will begin to slip due to soil resistance. Then the plow for the walk-behind tractor is attached to the attachment. To adjust the device, the nuts on the mount are not fully tightened. Then, using two metal pins, we fix the unit with the motoblock mounting bracket. The quality of plowing directly depends on the most correct setting.

Basic steps for adjusting the plow

To carry out balancing, the walk-behind tractor is installed with its wheels on specially prepared stands. The depth of plowing depends on the height of these stands. For winter tillage, the height of the stands is 20-25 cm, for spring tillage - approximately 15-20 cm.

Using the adjusting bolts, you need to set the angle of the plow. We make sure that the “heel” of the plow remains parallel to the ground surface. After securing the plow, the walk-behind tractor is placed on the ground. The control handles are adjusted to the height of the plowman's lower back. At the last stage, we evaluate the correctness of the plow settings using an experimental method.

We plow two or three furrows and determine the cutting depth, the distance between the ridges and the quality of the soil dump. If the distance between the furrows is more than 10 cm, or they overlap, then repeat the adjustment.

Photo 2. Lamellar reversible plow for walk-behind tractor

Plow overview

The plow is used to plow the land in almost any large farm, since without it it is almost impossible to plow the land efficiently, especially if it is dense soil or virgin soil.

During the first treatment, the upper layer is cut and divided into furrows. After the second pass, the lower layer of soil is lifted and mixed with the upper layer. This technique is very effective when fertilizers are scattered on the field and need to be mixed with the soil. The method is also suitable for deepening crop residues into the ground.

The following types of plows are distinguished:

There are also several ways to attach plows:

Branded model for MTZ walk-behind tractor

The manufacturer presents a universal model of the reversible plow PU-00.000-01, which is adapted for the Belarus MTZ 09N walk-behind tractor, but is suitable for any MTZ. It copes with plowing land of any density, including virgin soil. Features include the low weight of the plow, which is only 16 kg.

During plowing, the working area is 30 cm, which allows you to significantly save time. The maximum depth can reach up to 25 cm, but it can be adjusted using the stand and the holes on it. The design of the plow involves not only plowing, but also provides the opportunity to dig up root crops. And thanks to the simple fastening using a hitch, preparing the walk-behind tractor will not take much time.

The appearance of the plow is designed in such a way that the lower part cuts the layer of earth and grabs it, and the upper part throws the layer to the side. This design allows you to throw the earth to the side so that it does not crumble back into the laid trench. Thanks to the use of durable steel, the device does not deform over time and does not corrode, and can be used for a long time under any load.

Analogs for MTZ walk-behind tractor

As an alternative, which can be used together with the Belarus MTZ walk-behind tractor, the following plow models can be considered:

The P1-20/3 plow is produced by the Russian company, which is located in the city of Gagarin. The shape is similar to the branded model, but with some differences. Reduced weight to 8 kg. and the single grip of the ploughshare is 21.5 cm, which is almost a third less than that of PU-0000001. Because of this, it is more advisable to use the model in small areas with medium-density soil.

The double-body plow, due to its design, has special operating features. The pointed end of the plow easily enters the soil and is not immediately thrown to the side, as it does when using a universal model, but turns over. Due to this, it is possible to achieve improved soil mixing. The width of the plowshare of the tool is 15.5 cm, and plowing is carried out to a depth of 20 cm.

Despite the fact that the figure is slightly lower than that of the branded model, due to the design features, plowing is more efficient. The weight of the model is 12 kg, and production is carried out on Russian territory.

Devices made independently for the MTZ walk-behind tractor

The design of the plow is so simple that doing it yourself is not difficult.

The leading role is played by the ploughshare, which plunges into the ground and raises the layer. It, like the rest of the parts, can be made at home.

In order to make your own plow you need:

- Take metal from 3 mm. thick.

- Make a dump. To do this, a template is drawn on paper, and markings are made on it on the pipe and cut out. The recommended thickness of the share is 3-5 mm.

- Make a hitch in the shape of the letter G from a metal pipe.

- Weld the blade and ploughshare. Weld a pipe mount at the rear for subsequent connection of the parts with the hitch. Fastening is carried out using bolts, so that later it is easier to adjust the depth of the plow.

In order to correctly connect the plow to the MTZ walk-behind tractor, follow these steps::

- Remove the transport wheels and replace them with lugs. This is done so that the grip on the ground becomes better, and also to increase the stability of the Belarus due to the fact that the lugs are attached to the hubs, increasing the track width. If the plow and walk-behind tractor, in general, weigh little, weights should be used, since otherwise the device will not be able to effectively cope with the task.

- To connect the hitch to the walk-behind tractor, a standard hitch is used, which is secured with one king pin. In this case, there should remain 5% play, which provides shock absorption of the unit during soil resistance.

- Set the plowing depth. The depth is adjustable by attaching to the holes on the stand.

The plow adjustment occurs in the following order:

- Set plowing depth;

- Adjust the blade tilt;

- Adjust the field board.

If everything is done correctly, the walk-behind tractor with the attachment will move smoothly, without jumps or deviations to the side. And most importantly, the furrow will be straight. Such a unit can easily replace a tractor when plowing a personal plot or vegetable garden.

Video review

Below is a video where the owner talks about the modifications made and the result of plowing the land on an MTZ walk-behind tractor with a plow

Video review of the MTZ PV-1 plow for the MTZ walk-behind tractor

Owner reviews

Below are reviews from owners about working with the plow for your reference.

Oleg:

I decided not to buy a plow for the MTZ walk-behind tractor, but to make it myself. It seems like I did everything according to plan, but forgot to polish it. Therefore, it was difficult to work with the plow, dirt stuck to it and the soil did not lie nicely in rows, but was piled up in heaps. I had to bring the matter to fruition - clean and polish. Things got better.

Maksim:

It is important not only to adjust the plow correctly, but also to prepare the walk-behind tractor for work, namely, to inflate both wheels equally. If everything is done correctly, then Belarus will not jump while working, and the row will turn out smooth and neat.

Types of plowing implements

To increase the efficiency of the work performed, it is extremely important to carefully consider the question: which agricultural implements are best to choose for motor vehicles. There are the following types of implements for plowing the soil:

There are the following types of implements for plowing the soil:

- double-body (2-sided);

- negotiable;

- disk;

- rotary (active);

- turning.

There are also several options for fixing them:

- trailed;

- mounted;

- semi-mounted.

Let's look at some soil cultivation devices in more detail.

Rotary (active)

A rotary plowing tool for motor vehicles is compared to an iron comb, which makes it possible to plow the soil. These types of agricultural implements of various modifications can have a variety of configurations. But these modifications are connected by the fact that their design becomes wider at the top, which makes it possible for these devices to pour soil to the side of the furrow.

An active plow actually has the same field of application as an ordinary implement for plowing the soil, with the only difference being that it functions faster and is more productive. However, there are certain features of its use. Thus, with a rotary device it is much easier to cultivate uncultivated lands that are abundantly overgrown with wild plants. The soil thrown away by the plowshares of this agricultural implement is better crushed and mixed, which becomes a plus when cultivating certain types of soil.

Reversible (rotary)

A tool for plowing soil of the reversible type is collapsible; this is probably the best option, since sharpening or rotation of the knife is possible.

You should decide what size the plow will be - which directly depends on what modification of motor vehicle you are using.

For more effective use of the implement for plowing the soil, it is necessary to adjust the tool; for this it is advisable to use a coupling device (it is possible without it).

To make adjustments more accurately, it is worth taking into account a number of basic provisions:

- it is necessary that the longitudinal axes of the unit and the regulator are aligned;

- vertical position of the beam.

Such an installation will make it possible to carry out agricultural work more productively. But it is also necessary to use extensions on the axle shafts and iron wheels with weights for all kinds of tasks.

With a drawing and certain skills, you can create a rotary plow yourself from steel with high structural strength. Therefore, it costs nothing for such a homemade device to withstand heavy loads while working on a plot of land.

When using this equipment for motorcycles, you must adhere to several recommendations:

- the device should not have a thin stand, a shortened blade, or a small thickness of the body sheet;

- An instruction manual must be present.

Double-body (2-sided)

Double-sided agricultural implements (hiller, also known as tiller, double-winged plow, tiller) are used to loosen the soil around plants, rolling it to the base of the stems of various crops. Additionally, weeds are eliminated between the rows. With such tools, you can cultivate the ground, cut furrows for planting plants, and then fill them up by turning on the reverse gear of the unit. Such designs are distinguished only by the width of the working grip - variable and constant. The difference between them is solely in the moving wings, which adjust the width of the working grip.

A device that, with a constant working width, operates with light motor vehicles (up to 30 kilograms), with a motor power of up to 3.5 horsepower. Their distinctive feature is 12 mm racks (protect the unit from overloads).

The most common types of hillers are devices with variable working width. Their only drawback is that soil falls into the furrow after passing. Such equipment comes with units weighing more than 30 kilograms, with motors with a resource of 4 liters. With. and more.

Original equipment

The manufacturer presents a multifunctional modification of the PU-00.000-01 reversible implement for plowing land, which is adapted for the heavy Belarus MTZ 09 N walk-behind tractor, but is not suitable for every MTZ. It can handle plowing soil of any density, including virgin soil. As a distinctive feature, you can focus on the small mass of the device, which is only 16 kilograms.

Hillers for MTZ walk-behind tractor

Hillers are important equipment for making agricultural work easier. With this tool you can quickly and easily make furrows for planting various crops. But they are mainly used for hilling potatoes.

There are several types of hillers:

- Reversible type, consisting of two plows and being the most common;

- Disc type - considered the most effective and making a furrow using two rotating discs.

- Active type - classified as a special hiller, since this hiller first raises a layer of earth, crushes it, and then only discards it.

From the manufacturer

The proprietary model of the hiller, adapted for the Belarus walk-behind tractor, is OU-00000-01. The advantage of the model is the ability to adjust the distance between the two plows of which it consists. The width can vary from 45 to 70 cm, which is very convenient when the distance between the beds is different. The device itself weighs 20 kg, so Belarus can reach speeds of up to 4 km/h.

Analogs of hillers for MTZ walk-behind tractor

If you consider an alternative to branded models, then you should opt for the products of the Lida Mechanical Plant, which produces plows and hillers adapted for Belarus. The model is called OK-2 and has the same parameters as the branded hiller. In addition to the weight, which is 12 kg. and immersion depth, which is slightly less than the original and equal to 12 cm.

It offers a wide range of equipment, including disc and universal hillers. The consumer can choose the optimal size of the discs, which are available in various sizes from 18 to 36 cm in diameter; accordingly, they are immersed only half the diameter and process only one row.

Homemade hiller devices for MTZ walk-behind tractor

The easiest and least labor-intensive option is to make a reversible hiller, which consists of two plows. Making a disk and rotary hiller will require a lot of effort and patience.

Two plows are taken and attached to the frame, and then to the hitch on Belarus. The frame is made of a T-shape from a square pipe.

Video reviews

Video review of the operation of the MTZ 09N walk-behind tractor with a disk hiller

Video of planting potatoes

Video review of working with a universal hiller for the MTZ walk-behind tractor

Video review of working with a rotary plow

Design and technical characteristics of MTZ walk-behind tractor models

This device operates under any temperature and weather conditions. You can also upgrade it yourself.

The technical characteristics of MTZ walk-behind tractors are not inferior to similar foreign-made models.

Technical parameters of the MTZ-05 walk-behind tractor:

This equipment is intended for the following types of work:

- plowing soil of low density;

- harrowing;

- cultivation;

- inter-row processing of various vegetable crops (due to the design, which does not have a frame, the plants are not damaged during processing);

- transportation of goods whose weight does not exceed 500 kg.

The package includes an instruction manual, which describes in detail all the capabilities of this technical tool and the safety measures that must be observed during the work.

Indicators of MTZ-06 equipment:

2 reverse gears

This model is a technique produced by MTZ with an engine running on diesel fuel and a built-in air-type cooling system.

You can install additional equipment on the walk-behind tractor, such as a lug, hillers, cutters, etc. Additional equipment is connected using a clutch cable.

Technical parameters of model 08:

To connect additional equipment, a special coupling is provided in the design.

On the top cover of the housing there is a steering-type rod, on which the controls for the walk-behind tractor are located. The power transmission of a walk-behind tractor consists of a clutch, gearbox, main gear, differential and final drives.

This walk-behind tractor model has the following characteristics:

Among the advantages of this model are:

- Unpretentiousness to fuel. The power plant runs on AI-92 and AI-95 gasoline.

- Reliable body made of cast iron.

- It is possible to adjust the engine speed.

- No cables.

- Low noise level during work.

- Ergonomic handle.

- Wide selection of additional equipment. For example, a soil cutter, a universal hiller, a mounted blade, etc.

- The cylinder has a cast iron liner, which makes it possible to use the unit in difficult conditions.

Technical parameters of the heavy walk-behind tractor MTZ-12:

The walk-behind tractor is equipped with pneumatic wheels and a handle that can be adjusted in height and tilt. A manual gearbox with constant mesh gears is installed here.

On the MTZ 12 you can install a lot of additional equipment, the weight of which should not exceed 30 kg, for example, it could be a hiller, a snow blower, a cultivator, etc. It is also possible to convert the equipment into a mini-tractor.