Industry plays a special role in the economic state of any state. It is an indicator of power and solvency. A properly functioning industrial sector makes it possible to receive a significant increase in funds for the state treasury.

To form a properly functioning complex, it is necessary to have special auxiliary mechanisms and devices. Cranes, in this regard, play a leading role. They are often used in construction and installation work, in the production and industrial cycle.

Overhead crane, features

An overhead crane is a device designed to lift and move loads . It is a gripping type device that is located on a trolley that moves along a bridge or beam. The beam is a structure made from very strong steel.

The overhead crane can be equipped with various devices:

- With a ladle.

- Magnet.

- Grab.

- Grasping pliers.

- Device for working with containers.

The history of the production of overhead cranes began in Soviet times; the peak of popularity was in the 80s of the last century. At that time, the industry produced up to 9,000 different modifications of this unit per year. Modern factories produce overhead cranes, but in much smaller volumes - 1000-1500 units per year .

Grab overhead crane

Bridge cranes can be different:

- Depending on the design features - single-beam and double-beam.

- According to the method of movement - supporting and suspended.

- By area of use: deck, construction, workshop, transport.

- Depending on the type of grip - hook, magnetic, cast, special and grab.

In addition, design features may influence the method of their installation:

- Support bridge cranes are designed to move along rails, which serve as the basis.

- Suspended ones rest on the rail track from below.

- Gantry cranes have a special support structure.

Overhead cranes are most often used for:

- Carrying out loading and unloading operations in hard-to-reach places where there is no possibility to connect electric current.

- If it is necessary to carry out work in large workshops or warehouses with a huge volume of work.

- If it is necessary to carry out work in places with small free space.

- Work with bulk cargo by installing a special gripping device.

- Work with magnetically responsive loads where there is access to current.

Production of overhead cranes

This article is taken from a public source, is for informational purposes only and may contain inaccuracies!

Please go to the appropriate section of our website to familiarize yourself with the products we offer.

Overhead cranes of various designs, with various technical characteristics, are widely used in workshops of manufacturing and repair enterprises, as well as warehouses and the construction industry. These devices are equipped with various load-handling devices in accordance with their purpose, and they also use cargo trolleys to move loads.

Overhead cranes controlled from the floor , as a rule, are equipped with special pendant controls that allow you to control three movements: lifting the load, moving the trolley and the bridge. Such devices are easy to use, ergonomic and compact. They allow control from any location convenient for the operator. All pendant controls are required to be equipped with:

• A button to provide an urgent emergency stop;

• Reinforced supply cable;

• Locking with a key.

The devices have a degree of protection IP65 and are explosion-proof. They operate from a network with a maximum voltage of 250 V and a maximum current of 3 A. Also, the pendant controls can be equipped with an LCD display.

Overhead cranes controlled from the floor using a radio control system

Overhead cranes controlled from the floor using a radio control system are more expensive equipment, but despite this, they have advantages. Installing a radio remote control will allow you to:

• More accurately track the movement of goods and perform their positioning;

• Eliminate the bulky cabin from the design and provide freedom of movement to the operator;

• Remove the control cable, which often requires frequent repairs and replacements;

• Provide synchronous simultaneous control of a pair of cranes using one remote control;

• Promptly and accurately carry out work operations of the crane;

• Increase personnel safety;

• Significantly save labor resources;

• Improve working conditions for staff.

Radio control systems differ in modifications of remote controls, which can be push-button or with command devices. Both are compact, comfortable and ergonomic.

Receiving devices in the form of special cabinets are installed directly on the bridges of load-lifting cranes. The transmitter power, as a rule, ranges from 10 to 20 mW, which allows you to control the cranes from the floor at a distance of up to 200 m. The average continuous operation time of the devices is approximately 10 hours.

In addition to the article “ Overhead cranes controlled from the floor

»

Crane beam, device features

A beam crane is a device for loading and unloading operations . The equipment belongs to the pavement class. It is used and installed in warehouses, overpasses, workshops, and industrial premises. Very often, such a structure can be seen in sea and river ports, at construction sites of multi-storey residential and commercial projects.

Cathead

The overhead crane is a popular device and is often used in situations where:

- There is a shortage of free space.

- Narrow spans.

- The site is located in a location that is difficult to access for the use of other types of cranes.

Depending on the design, crane beams can be of two types: supporting and suspended. The first option is a beam that acts as a supporting structure, which is equipped with a moving hoist. The crane is also equipped with a control panel and various gripping devices.

The supporting crane beam is activated by connecting an electric current. The crane operator can control the device from the cab, or using a special control panel. The support crane beam is suitable for rooms with low intensity loading and unloading operations.

The suspended beam crane is designed as an overhead crane. It includes:

- Span type beam.

- Lifting device.

- Running carriage.

- Remote controller.

Control is carried out from a special push-button remote control. A similar device is used in large workshops with high productivity. Depending on the technical parameters, the crane beams differ in:

- Span height.

- The magnitude of the rise.

- Operating voltage supply force.

- Movement speed and responsiveness.

How to restore a bent crane beam?

PySy: A bit of a rush to the legal and regulatory system “Consultant+” - I found the Ministry of Labor Standard Instructions for Occupational Safety and Health for Slingers (TI R M-007-2000):

...This Instruction is intended for slingers of all types of cranes with a lifting capacity of up to 10 tons, controlled from the floor, which are not subject to registration with the state mining and technical supervision authorities, and when working with forklifts.

1.3. Persons at least 18 years of age who have undergone a preliminary medical examination, trained in a special program, certified by a qualification commission and received the appropriate certificate for the right to carry out work are appointed as slingers.

1.6. Admission to work for certified slingers with certificates is issued by order of the enterprise.

1.7. In accordance with the requirements of the current “Rules for the design and safe operation of load-lifting cranes”, repeated testing of the knowledge of slingers must be carried out by a qualified commission of the enterprise:

- periodically - at least once every 12 months;

- when these persons move from one enterprise to another;

- with a break in work in the specialty for more than 6 months;

- at the request of an engineering and technical worker for the supervision of lifting machines or inspectors of the State Mining and Technical Supervision.

The results of testing the knowledge of the slinger are documented in a protocol, the number of which is affixed to the certificate and confirmed by the seal of the enterprise.

…

And in accordance with the above Order of Rostechnadzor dated January 29, 2007. No. 37, it turns out that slingers generally need to be initially trained in a specialized training center.

It seems that the situation is similar with those responsible for these cranes up to 10t, controlled from the floor.

Only the certification period is 3 years.

I looked again - INTERINDUSTRY RULES ON LABOR SAFETY DURING LOADING, UNLOADING AND PLACEMENT OF CARGO (POT RM-007-98):

4.32. Permission to put into operation lifting machines that are not subject to registration with the state mining and technical supervision authorities is issued by an engineering and technical worker supervising the safe operation of lifting machines in the organization.

4.33. Lifting machines and removable load-handling devices must be subjected to a full technical inspection before they are put into operation.

Well, to the heap - Rostekhnadzor METHODOLOGICAL INSTRUCTIONS. COMPREHENSIVE INSPECTION OF CRANE RAILWAYS OF LOAD-LIFTING MACHINERY (RD-10-138-97):

2. Tolerances for deviations of building structures from the design position

2.2 Steel structures:

clause 7 Relative horizontal deflections of beams, no more than 1/500 (meaning their length)

And for those who are interested, there is “GOST 7890-93.

Single-beam suspended bridge cranes. Technical specifications" (adopted by the Interstate Council for Standardization, Metrology and Certification on 10/21/1993) Modified on 02/02/2011 11:13 by user Chernyshov

Differences between an overhead crane and a beam crane

An overhead crane and a beam crane are united by the fact that they belong to the category of bridge-type technical means. But there are also differences. Structurally, an overhead crane has a more complex structure; it can have two beam elements, while a beam crane has only a single beam system. Overhead cranes can have many more auxiliary devices, unlike a beam crane. In addition, the beam crane is considered a type of overhead crane; it is much weaker and is used in small workshops.

Repair and constructionComment

Crane control diagram

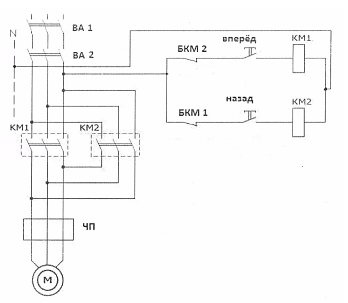

Electric hoists are used in closed production facilities, hangars and docks. The driving unit is mainly used three-phase asynchronous electric motors with a closed rotor, as well as DC motors with parallel and series connections.

The crane control diagram determines how power is supplied to electrical equipment, and also shows protective systems and fuses that automatically turn off the device when the circuit is overloaded.

The control scheme for the movement of a lifting mechanism depends on many factors: the type of engine, the maximum weight of the load being lifted, control using a radio remote control or via a flexible cable.

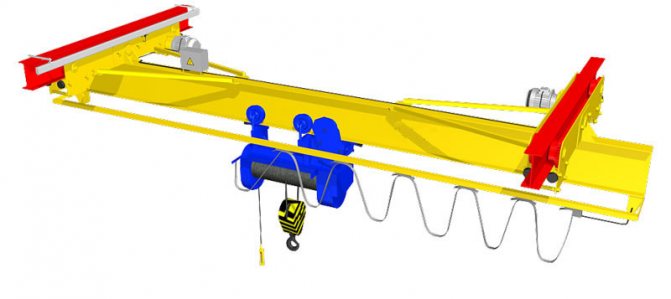

Fig.1. Hanging crane

Radio control allows the operator to move the undercarriage and load cable in any convenient position. The buttons on the remote control set the movement forward, backward, up, down.

The operating cycle of a suspended hoist includes:

- Grabbing/lowering a load.

- The main working stroke is lifting and transporting cargo.

- Idling – movement without load.

Working and idling speeds have three stages: acceleration, main speed and braking. End holders are installed at the edges of the supporting bridge structure, which limit the movement of the crane. This allows you to avoid impacts of the lifting structure on the edges of the columns when an incorrect command is given on the remote control.

Frequency converters are often built into the crane-beam control circuit from the floor. Thanks to these devices, the controllability and overall working life of the hoist are significantly increased.

Rice. 2. Electrical circuit for controlling a crane beam with a frequency regulator

Figure 1 shows the control diagram of a crane equipped with a frequency controller. This gives the suspended lifting system a number of advantages:

- Strong jerks disappear when starting to move and braking, and there is no swaying of the load. When commands are given from the floor, the regulator evenly distributes power across the mechanism components.

- Stopping the hoist at a given point is simplified.

- Smooth speed change.

In this circuit there are two power supply circuit breakers BA1-BA2. The push-button signal is supplied to the KM-1–KM-2 starters, which start the system. The frequency converter regulates the current supply to the undercarriage.

The general principles of constructing a control circuit are the same for all models of overhead crane beams. Differences may be in the number of batteries, type of command delivery, connection and installation of the device for lifting loads.