How to make a walk-behind tractor with your own hands

If you make a motorized cultivator with your own hands, a farmer can not only increase the efficiency of land cultivation, but also significantly reduce financial costs, saving on the purchase of a store-bought device. At the same time, to successfully complete the task, you will need suitable workpieces, tools, and materials.

Most often, various techniques that include an internal combustion engine are used as the basis for this type of device, although there are also electrical variations of the device. When learning how to make a walk-behind tractor with your own hands, it should be noted that the most popular options seem to be using:

- chainsaws;

- motorcycle;

- electric meat grinder.

You can make a walk-behind tractor yourself.

Each option has its own characteristics and nuances, and therefore deserves separate consideration. Products based on internal combustion engines represent the optimal balance of power and functionality, which is why they are in much greater demand from consumers than their electric counterparts.

Electric cultivators are characterized by lower power and a more complex manufacturing procedure, but in terms of their functionality they are completely identical to their gasoline counterparts.

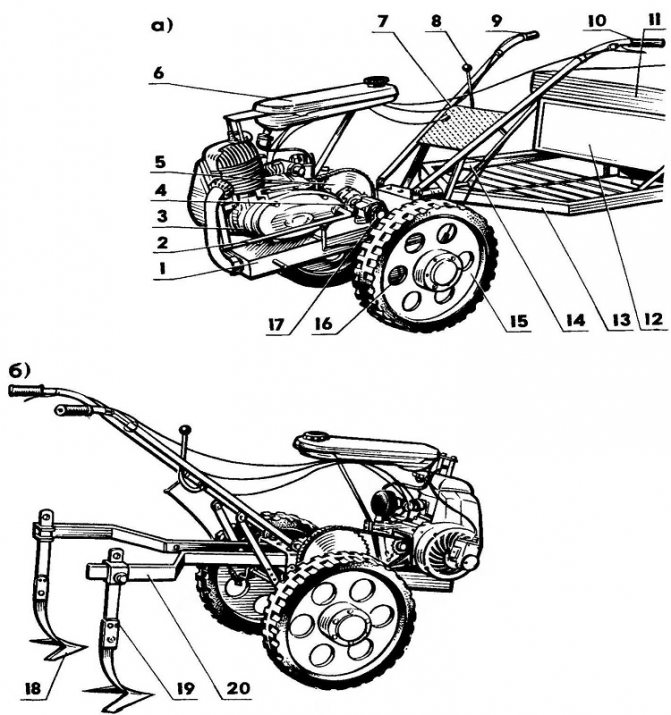

When figuring out how to make a cultivator with an internal combustion engine yourself, you must adhere to the following algorithm of actions:

- A frame with wheels is made, to which handles are attached.

- The engine and cooling equipment are installed. The need for additional cooling is due to the low speed of the unit.

- Install the gearbox and close the mechanisms for protection.

The assembly algorithm for the electrical analogue is almost identical, which makes it possible to easily manufacture the product according to the drawings. The frame of the device can be made from an unnecessary construction wheelbarrow or a steel pipe with a cross-section of at least 3.2 cm. In this case, you will need to attach wheels to it for free movement around the territory.

Recommendations from specialists for the manufacture of motor cultivators

The most popular base option for a homemade motor cultivator seems to be old motor vehicles. Such a conversion is considered the best opportunity to give outdated, faulty vehicles a new life, because motorcycle engines are ideal for this task.

In this case, preference should be given to two-stroke power units, although it is possible to use more advanced 4-stroke modifications.

Gasoline products seem to be the best option for a cultivator, since they are characterized by mobility and high power.

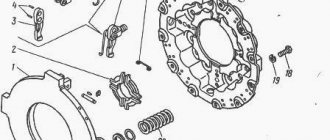

It is important to note that the transmission of the finished device directly depends on the components that are planned to be used for its manufacture, as well as the intended functionality of the equipment. Experts recommend giving preference to a gear modification of the transmission, since it is used everywhere and is easy to install.

When planning to figure out how to make a homemade motor cultivator, the master may give preference to other gearbox options, among which the following types of transmission deserve mention:

- combined, involving the presence of worm gears;

- chain-belt or toothed;

- hydraulic gearbox is a more advanced, but expensive design option compared to mechanical analogues.

If you plan to modernize an electrical appliance, it should be noted that any type of motor powered by electricity, designed for a voltage of 220 V, can be used for it.

Required materials and tools for assembly

In order to successfully assemble this kind of device, you must first acquire the necessary tools for assembly, as well as materials. In addition, you should first study the drawings of the selected device model, which will allow you to avoid errors during its assembly, as well as make the necessary adjustments to the design.

Walk-behind tractor drawings

The engine for the device should be a motor from a moped, motorcycle, scooter or chainsaw. If you plan to make an electric version of the cultivator, you should get a motor from a meat grinder or other powerful equipment. Regardless of the type of device, you will need to find a gearbox that will reduce the rotation speed to the required values.

For assembly, the master will need a standard set of tools. If the frame is supposed to be made from several components, it is strongly recommended to use a welding machine. This will ensure the strength of the connections, as well as the long service life of the home-made unit, even with intensive use.

Device drawings

As mentioned earlier, during the manufacturing process it is necessary to be guided by the drawings, which will avoid annoying mistakes. However, they are only an example of a cultivator design, since the design of a specific model can differ significantly and depends on the materials and equipment used.

Reviews

“The assembly took me three days (of course, in addition to it, I was doing other things). I didn’t make a drawing, everything was done by eye. I took the seat from the Ural, the wheels from the mini Riga. I ordered a gas handle and a shock absorber for the seat on Aliexpress, everything turned out very convenient. I use my new moped for rides and to quickly get from place to place. It’s a good thing – cheap and reliable.”

“I put three wheels on my homemade motorcycle, and installed the engine behind the seat. The design turned out to be stable and with excellent maneuverability, including off-road and snow. I equipped it with wheels with tractor treads, thus solving the issue of fast movement on the ground.”

Snowmobiles from a walk-behind tractor on wheels

Let's look at how snowmobiles are made from a walk-behind tractor on wheels. The wheels for a homemade snowmobile should be chosen to be powerful, as this ensures its own safety and easy control. Cameras from the Urals or KamAZ can be used.

There are several ways to create wheels yourself, which involve a metal base with a camera built inside. The main condition when creating an all-terrain vehicle on wheels is to be equipped with 3 or 4 wheels.

When installing wheels for this snowmobile, low-pressure tires or tubes from large cars are selected. They are put on standard discs and secured with chains. The walk-behind tractor engine consumes little fuel, so the high autonomy of a self-produced snowmobile will allow you to travel long distances.

The advantage of a tracked snowmobile. In winter, crawler-mounted walk-behind tractors are much preferable. A large coverage area contributes to proper load distribution and pressure on the ground. The track attachment will never get stuck in snow or other unstable surfaces, which cannot be said about the wheels.

Let's find out how much homemade snowmobiles made from a walk-behind tractor cost. If you compare a finished snowmobile with a homemade one, the price difference will be significant. A homemade one will cost 5 times less. And if you have some parts in stock, then even less. As for the reliability of the machine, when making it yourself, the master approaches the selection of parts thoroughly, selecting the most reliable parts. The result is a powerful, go-anywhere design.

Mini tractor and all-terrain vehicle made from a walk-behind tractor

Almost all homemade products from a walk-behind tractor are made to increase comfort at work. Indeed, why waste energy driving a heavy unit “by the horns” when you can ride it, turning it into a maneuverable mini tractor?

However, one important note needs to be made here. By sitting astride a walk-behind tractor, you will increase its center of gravity. This will increase the risk of rollover during sharp turns. To increase stability, you need to make the second driven axle quite wide (1-1.2 m).

It is very desirable to expand the narrow wheelbase of the walk-behind tractor itself. Today, you don’t need to look for an experienced turner for such alterations. There are ready-made bushings (extensions) available for sale that are placed on the drive shaft to increase the distance between the wheels of the walk-behind tractor.

If a light or medium walk-behind tractor does not have a differential, then you can increase its maneuverability and at the same time increase the wheelbase by installing locking rotary extensions that perform these functions.

Anyone who is not confident in working with iron and does not have much experience in designing machines can make a mini tractor from a walk-behind tractor by purchasing a ready-made kit.

It includes:

- frame with engine mounts;

- footrests with pedals;

- seat;

- axle shaft lock release levers;

- steering with rods;

- front beam with brake discs and wheel hubs;

- rear linkage with manual lifting mechanism;

- wings.

The price of such a kit is in the range of 20-22 thousand rubles. There are no special problems when converting a walk-behind tractor into a mini tractor if the listed assembly units are available.

As a result, you will get a homemade tractor on which you can comfortably cultivate the area and carry loads by attaching a trolley. An important advantage of the finished technical kit is its design - precisely calculated and tested in operation. When independently adapting a walk-behind tractor to a homemade tractor base, most of the components will have to be manufactured and docked independently. This process often requires rework and fine-tuning.

Anyone who made a mini tractor with their own hands can assemble an all-terrain vehicle from a walk-behind tractor without any problems . To do this, just change the standard wheels to wider ones and install off-road tires on them.

It is best if the base for such a mini-all-terrain vehicle is a walk-behind tractor with a water-cooled rather than air-cooled engine. It is more resistant to prolonged loads and overheats less.

Motorcycle dog and caracat

Anyone who has had the chance to ride an imported motorized towing vehicle will probably see in its design a lot of similarities with a conventional walk-behind tractor. Almost the same front traction unit with the engine, a similar method of transmitting torque, similar controls on the steering wheel. The only thing missing is rubber tracks, with the help of which the motorized dog will pull the sled and rider across the snowy field.

When realizing their dream of a motorized towing vehicle, avid fishermen and hunters can go in two ways: buy a ready-made snowmobile attachment or make it yourself.

Today, tracked attachments for almost all types of walk-behind tractors (Neva, Salyut, Agat, Favorit, Cascade, Forza, etc.) are produced on an industrial scale. The price of this unit is quite high (about 30 thousand rubles).

Therefore, anyone who is trying to save money and at the same time is well acquainted with the caterpillar undercarriage structure can make it and ski sleds themselves. To do this, you need to weld a strong frame on which the engine and steering wheel, chassis and driven sprockets, as well as two intermediate shafts with rubber rollers will be placed.

Speaking about what can be made from a walk-behind tractor, it is worth mentioning such an interesting homemade product as a karakat. The strength of this car is in its huge wheels, which are ordinary inner tubes, tightened with strong belts.

Sometimes truck tires are used to make ultra-low pressure tires. They are lightened by carefully cutting out part of the surface with an electric jigsaw, leaving only part of the bead and lug tread pattern.

Homemade rims are installed on the karakat from a walk-behind tractor, modifying and expanding standard car rims. You can also put a very original wheel on a lightweight walk-behind tractor. To do this, two aluminum basins are welded along the contour, the bottom is cut out to fit the size of the hub, and they are equipped with stiffening ribs and side stops for fixing the camera.

Despite its external clumsiness, the carakat based on a walk-behind tractor is surprisingly passable and stable. It not only easily overcomes swampy lowlands, but is also capable of carrying quite a significant load (up to 100 kg).

Anyone who plans to assemble an ATV using a walk-behind tractor as a base must be prepared for the fact that he will not reach super-high speed on it. But in terms of maneuverability and maneuverability, such a device is in no way inferior to a more expensive one.

The seating position in a home-made SUV remains traditional “motoblock”, and not motorcycle-like as in a “quad”. There is no need to make rims for this ATV yourself. You can use standard ones from any passenger car, designed to install wide-profile “mud” tires.

DIY sled on skis for a snowmobile

When a snowmobile is supposed to transport cargo or adults, the sled is made durable and can withstand heavy loads. For cross-country ability they are placed on skis. Good runners will be made from a thick-walled plastic pipe. You will need only 7 m of it. The pipe diameter is 230 mm, the wall thickness is 25 mm. A piece 3 m long is cut off for the skis. The pipe is unraveled lengthwise with a jigsaw or grinder. It turns out two stripes.

From a sawn piece of pipe 3 m long, two runners for skis are obtained

The remaining 4 m of pipes are cut into pieces 1 m long. These will be the jumpers between the runners. Part of the body of each pipe needs to be cut out, and rings left on the sides. They will act as shock absorbers.

The runners are connected by jumpers cut from a similar pipe

The runners are given the curved shape of skis. To do this, the edges of the pipe are heated over a fire and bent to the desired angle. The jumpers are fastened to the runners with furniture bolts, and they are placed with the cutout downwards so that while the sleigh is moving they do not cling to obstacles.

How to make a caterpillar attachment for a walk-behind tractor

When assembling a snowmobile with your own hands, special emphasis is placed on the caterpillar track. Let's look at the features of assembling a homemade product: how to make a caterpillar attachment to a walk-behind tractor with your own hands.

Some craftsmen install parts from a walk-behind tractor or make them with their own hands, and those who cannot manufacture them purchase a universal factory caterpillar drive. A homemade caterpillar can be made from:

- bushing roller chain and conveyor belt;

- tires;

- belts