A familiar classic

UAZ cars have been popular in Russia for decades. They have always been distinguished by high maneuverability, reliability and good control quality. The UAZ model range is constantly expanding, developing and improving. Everyone knows that cars are assembled from several thousand parts, and when the car is in use, it may be necessary to replace any, perhaps even the smallest part, which nevertheless plays a very large role in the life of the car.

There is an opinion that the clutch is one of the most vulnerable points in a UAZ car. The real cause of the problem is that the clutch of the UAZ 3303 and other cars of this series is adjusted incorrectly. Very often, the maintenance of the mechanism is not given enough attention and its importance is not realized. With proper and timely care of the diaphragm clutch installed on the car, it will work perfectly for a long period of time, at least five years exactly, and even with rather merciless operation.

Principle of operation

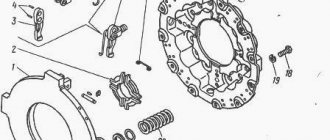

UAZ Patriot cars have the following type of clutch: single-disk with a centrally located diaphragm spring. By the type of friction it is dry, by the mode of activation it is constantly closed. Diaphragm clutch is also called petal clutch. This type is also used in other UAZ models: 3741 “loaf”, SUVs 469, 3151. Petal is also used for cars of other brands.

It consists of the following parts:

- pressure disk (basket),

- clutch disc (driven),

- release bearing,

- release bearing drive fork,

- drive system,

- off pedal.

The pressure plate is housed in a stamped steel housing, bolted to the engine flywheel. The driven disk is clamped by a spring, it is located between the flywheel and the pressure plate. During operation, the closed type bearing does not require lubrication.

clutch release drive on UAZ Patriot vehicles Its composition:

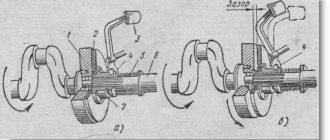

The purpose of the drive is to transmit force from the pedal to the fork. When the pedal is applied, a piston located in the master cylinder moves and forces fluid through a pipeline into the slave cylinder. A piston placed in the slave cylinder acts on the clutch release fork. Then the fork moves the bearing along the guide. The bearing, in turn, acts on the diaphragm spring, which stops pressing the pressure plate against the flywheel. The clutch switches off.

Paddle clutch has the following advantages:

- less weight of parts,

- smaller part size,

- long service life of parts before the next maintenance,

- improved functionality,

- easier maintenance.

Features of operation and operation of the UAZ clutch drive.

When the clutch pedal is abruptly released, a single knock is possible due to the choice of lateral clearances in the toothed connections of the gears, splined connections and in the gearbox synchronizers.

If, while driving, when you sharply press the gas pedal, the engine speed rises sharply, and then drops slightly and the car begins to accelerate, then the clutch requires repair or replacement. In order to reduce clutch wear and extend its service life, it is advisable to follow these simple recommendations:

— it is not recommended to constantly keep your foot on the clutch pedal, since it is depressed at least a little, the driven disk slips and wears out faster, in addition, although the release bearing is designed to operate in constant rotation mode, even with the pedal pressed slightly clutch, it is under load and therefore its service life is reduced

— for the same reason, it is not recommended to keep the clutch in the disengaged state for a long time, for example, before a traffic light; if you do not need to move away immediately, it is better to put the gearbox in neutral and release the clutch pedal.

Checking free play

Checking the free play of the working cylinder rod of a UAZ Patriot SUV is carried out as follows:

- This element has a tension spring installed on it, which must be removed. To do this, first disconnect the spring mount from the fork, and then from the cylinder.

- Next, you will need to use a ruler to measure the free play of the rod. To measure, the ruler must be positioned so that the measurement can be taken. After this, you need to press the fork all the way with your hand and put a mark on the ruler. Then release the fork and also make a mark. If the resulting distance (free play) exceeds the norm (1-3 mm), then adjustment is required.

How to upgrade?

To do this, we need a hose and a plastic bottle into which the airy liquid will drain. We will pump through the valve on the working cylinder. It is unscrewed with a 10mm wrench. We remove the protective cap from it, put on the hose and call a second assistant. He will press the clutch pedal. At this time, you need to monitor the draining liquid. It is necessary to press until it becomes homogeneous, that is, without bubbles. After this, check the clutch fluid level in the reservoir again. If it falls, add it to the maximum level. It is important not to mix liquids from different manufacturers. If you don’t know which brand was filled previously, make a complete replacement. It will be right. Moreover, the service life of the fluid for the clutch and brake system is no more than two years. Then it absorbs moisture and becomes ineffective.

So, we found out what a car clutch master cylinder is, how it works and how to replace it with your own hands.

Stroke adjustment

Need for adjustment

Adjustment of the pusher pitch in the clutch slave cylinder is carried out to ensure that the clutch performs its tasks correctly. If the adjustment is incorrect, two types of problems can occur.

Video of clutch adjustment UAZ Patriot

In the first case, incomplete pressing of the pressure plate against the driven one may occur. This happens when the free play of the rod is completely absent or it is less than normal. In this case, clutch slipping will occur, which will inevitably lead to wear of the components.

In another case, when the free play is greater than necessary, a phenomenon such as incomplete disengagement of the clutch will be observed. In this case, the driver of the SUV will experience problems with shifting gears, they will turn on poorly, or stop turning on completely. This entails increased wear on the synchronizer blocking rings.

At this point we should summarize and note that it is very important to monitor the serviceability of the clutch and add brake fluid to the reservoir on time.

A clutch malfunction on a UAZ Patriot SUV can have serious consequences.

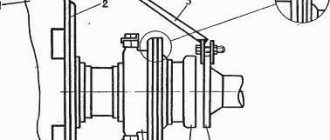

We recommend that you begin adjusting the cylinder rod pitch by cleaning the threads of the adjusting nuts. To do this, it is necessary to lubricate the threads and nuts with a special lubricant such as WD-40. After this, we proceed to the actual process:

One key secures the adjusting nut on this element, and the second one loosens the lock nut.

Using a hand vice or an “8” wrench, it is necessary to clamp the end of the pusher from turning it. When the rod is fixed, it is necessary to unscrew the locknut a few turns back.

After this, the free pitch is adjusted, bringing it to normal.

The locknut returns to its original position and fixes the stroke of the rod.

At the end of the work, it is necessary to check the presence of a free step. If it is within the normalized range, then everything was done correctly. This process is not labor-intensive and can be done with your own hands at no extra cost.

Sometimes it is necessary to adjust the UAZ clutch, which consists of changing the position of the clutch pedal. For this purpose, the main cylinder has an adjustment unit.

Adjusting the full travel of the UAZ clutch pedal.

The position of the clutch release pedal and its full travel is regulated by changing the length of the pusher of the clutch master cylinder. To do this, loosen the nut of the pusher adjustment unit, disconnect the pusher fork from the pedal and turn it in the desired direction to achieve the required result.

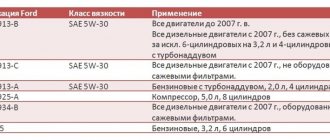

The full pedal travel for clutching with a diaphragm-type pressure spring must be within:

— For cars of the UAZ-3160 and UAZ-3162 family: 130-170 millimeters.

— For cars of the UAZ Patriot family until 2007: 130-170 millimeters.

— For cars of the UAZ Patriot family after 2007: 120-140 millimeters.

— For cars of the UAZ-3741, 3962, 3909, 2206, 3303 family of carriage layout: 180-220 millimeters.

And for UAZ vehicles with clutches with pressure springs and release levers -165-205 mm. More precisely, the amount of free play of the clutch pedal can be clarified in the operating manual for a specific vehicle.

Adjusting the free play of the clutch pedal UAZ.

The free travel of the clutch pedal with a diaphragm-type pressure spring in the range of 5-30 mm is ensured by the clutch design itself and is not adjustable. Adjusting the free travel of the clutch release pedal with pressure springs and pull-out levers, which can be installed on some UAZ vehicles with a UMZ-421 engine, is done by changing the length of the working cylinder pusher in the following order:

- disconnect the spring from the clutch release fork and loosen the lock nut, - by tightening or unscrewing the screwed part of the pusher, set the free play of the outer end of the clutch release fork within 2.5-3.6 mm, which will correspond to the free travel of the clutch release pedal within 35-55 mm.

Adjusting the clutch pedal contact sensor on a UAZ with ZMZ-409 Euro-3 and Euro-4 engines.

On UAZ vehicles with ZMZ-409 engines of Euro-3 and Euro-4 environmental class, a clutch pedal contact sensor (switch) 21.3720 is installed. Based on its signal, the electronic engine control unit determines whether the clutch is depressed or not.

When the clutch is depressed, the control unit briefly reduces the dose of injected fuel, thereby reducing the likelihood of jerks when changing gears. If there is no signal from the contact sensor, due to its malfunction or incorrect adjustment, jerking may occur when shifting gears.

The contact sensor (switch) of the clutch pedal is adjusted using two nuts so that a gap of 0.5 mm is provided between the buffer and the sensor rod. On UAZ cargo-passenger vehicles of carriage layout with ZMZ-4091 and ZMZ-40911 engines, the clutch pedal switch may not be installed.

Replacing the UAZ clutch master cylinder

If the car does not respond to pressing the pedal, and the fluid level is normal and there is no damage to the tubes, most likely the rod or piston itself is faulty.

As a result, it cannot generate the required pressure for the system to operate. In order to replace the clutch master cylinder, the UAZ needs to be placed on a flat surface and the fluid must be pumped out using a syringe. Next, disconnect the master cylinder from the pedal and seal all the holes from which fluid flows. This also applies to pipes. Make sure that dirt and moisture do not get inside. This liquid is very hygroscopic. Next, unscrew the nuts securing the cylinder and take it out. After installing the new element, add fluid and bleed the system.

Adjusting the UAZ Patriot clutch sensor (error 0704)

I got tired of error 07074 on the BC, over the weekend I missed misfires because of it, on a healthy engine this indicates bad fuel. In this case, it is confirmed that the Honda from the column